Semi-physical real-time simulation system for electro-hydrostatic actuator

A semi-physical simulation, electro-hydrostatic technology, applied in the field of servo actuators, can solve the problems of cumbersome development and testing process, long design cycle of electro-hydrostatic actuators, accurate modeling and simulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

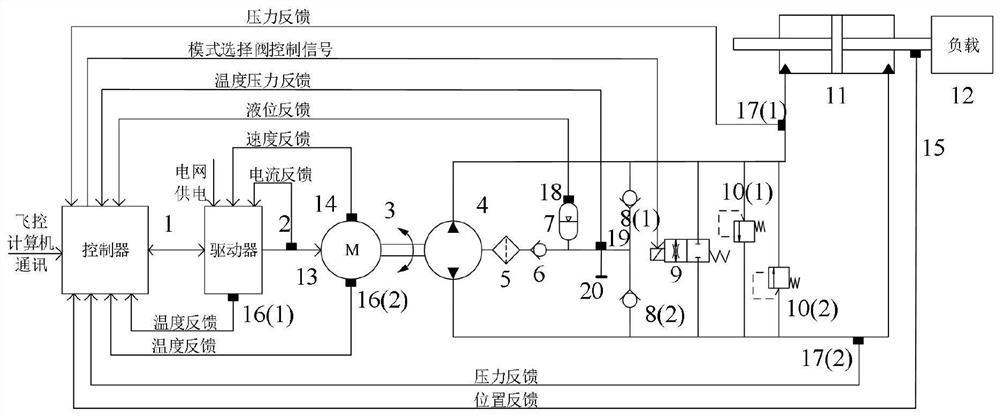

[0078] The semi-physical real-time simulation system of the electric hydrostatic actuator provided by the embodiment of the present invention is used for the RCP verification of the electric hydrostatic actuator, and the hardware parts involved refer to Figure 4 As shown, it includes: a host computer 100, a real-time target computer 200, a driver 2 and an electric hydrostatic actuator body 300;

[0079] The upper computer 100 communicates with the real-time target machine 200; the real-time target machine 200 is respectively connected to the driver 2 and the electrohydrostatic actuator body 300; the driver 2 is connected to the electrohydrostatic actuator body 300; The device body 300 includes components such as a servo motor, a hydraulic pump, a hydraulic valve, an actuator, a sensor, and an oil tank.

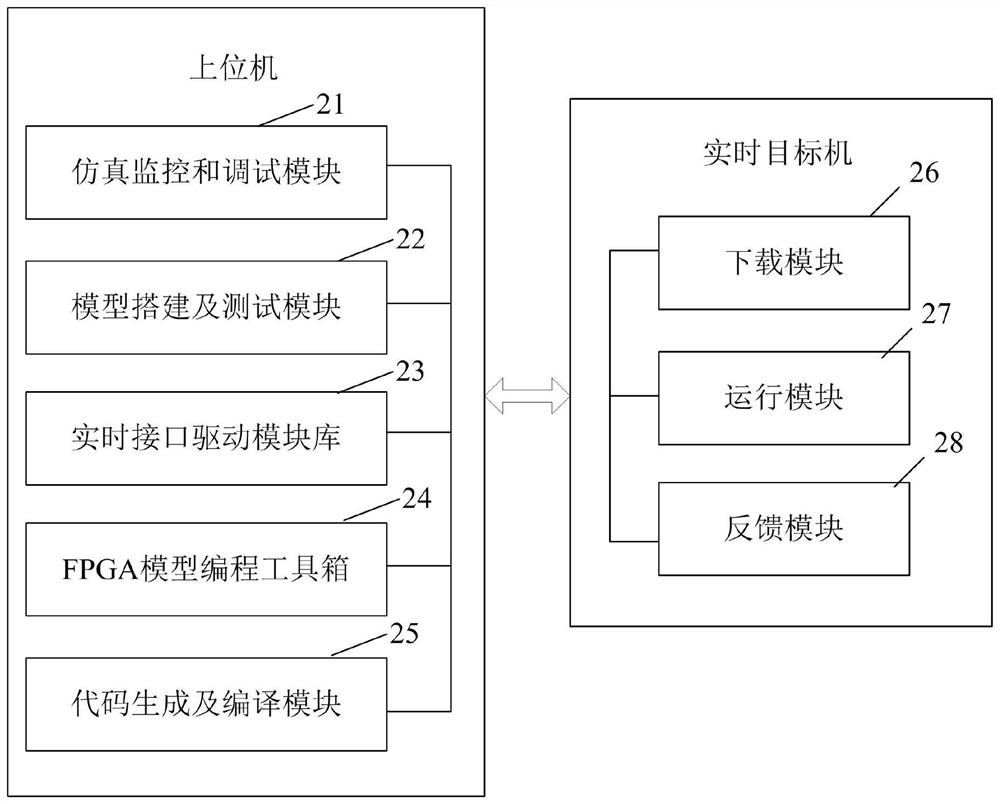

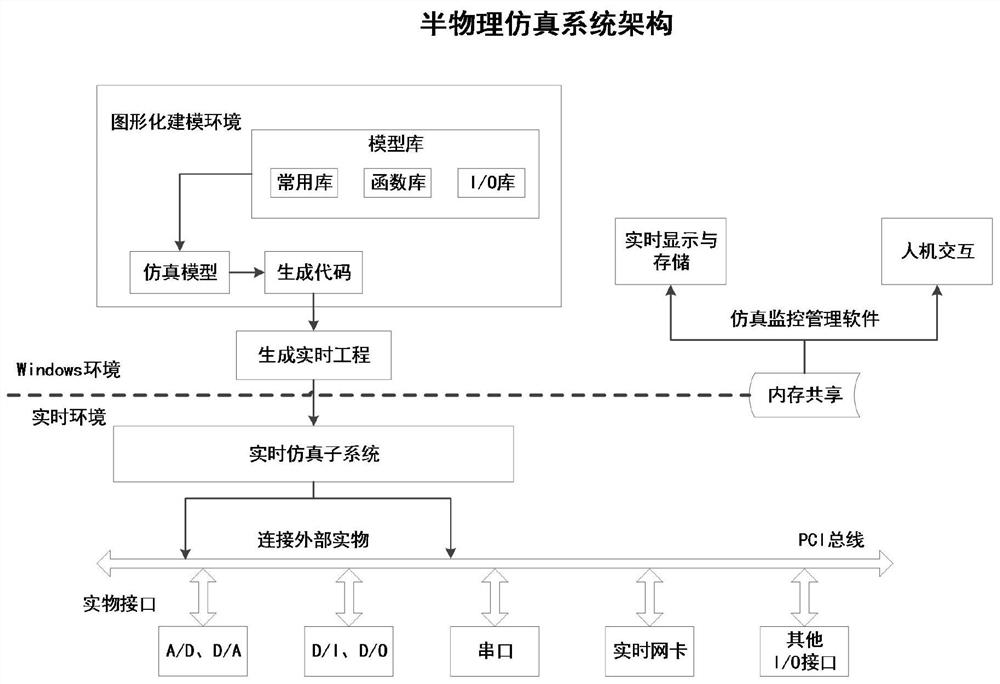

[0080] The upper computer realizes the control algorithm through the establishment of a graphical modeling interface, which can be downloaded by the real-time target computer...

Embodiment 2

[0104] The electrohydrostatic actuator semi-physical real-time simulation system provided by the embodiment of the present invention is used for the HIL verification test, and the hardware parts involved refer to Figure 7 As shown, it includes: an interconnected upper computer 100, a real-time target computer 200 and a controller 1;

[0105] The upper computer 100 communicates with the real-time target computer 200. Here, the upper computer 100 is used to build a model for simulating the electrohydrostatic actuator body, driver and load conditions. The real-time target machine 200 is used to run and download the model for simulating the electrohydrostatic actuator body, driver and load conditions, and realize real-time interaction with the controller 1 . Among them, the simulated electrohydrostatic actuator body also includes components such as servo motors, hydraulic pumps, hydraulic valves, actuators, sensors, and fuel tanks.

[0106] refer to Figure 5 As shown, the real...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap