Cooling channel for winding overhang of stator, and stator comprising cooling channel of this type

A technology for cooling channels and winding ends, applied in the field of stators, can solve the problems of increasing the cost of cooling caps and design difficulties, and achieve the effect of improving sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

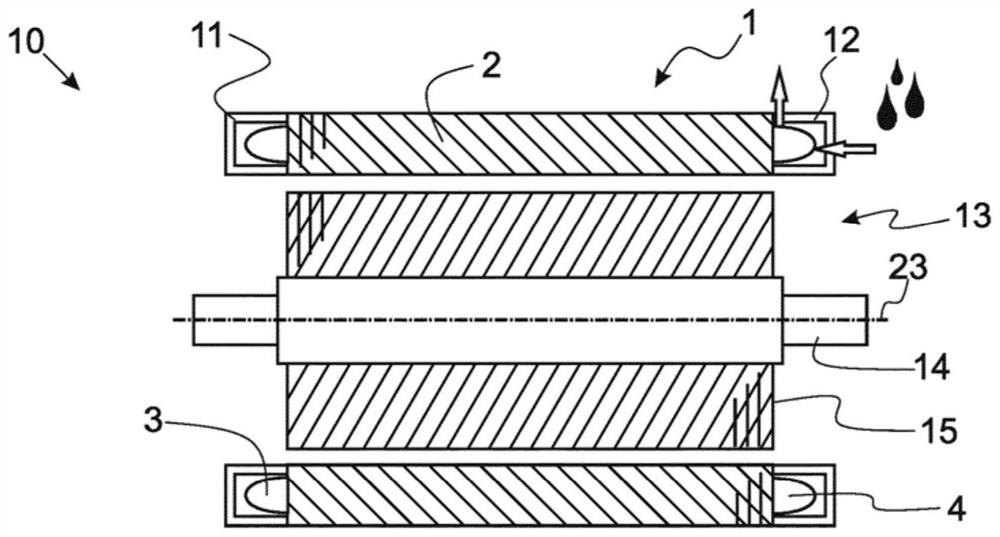

[0043] figure 1 A cross-sectional view of an electric machine 10 is shown, comprising a stator 1 and a rotor 13 arranged inside the stator. The stator 1 , in particular the laminated stator core 2 , is hollow cylindrical and has annular cooling channels 11 and 12 at both ends. The cooling channels 11 , 12 communicate with a fluid reservoir (not shown) for cooling by means of a fluid the winding ends 3; 4 formed or arranged in the cooling channels (see arrows, one in and one out). The rotor 13 is formed by a rotor shaft 14 and a rotor laminated core 15 , wherein the rotor can have, for example, permanent magnets, short-circuit rings or field windings, depending on the implementation. The electric machine 10 (and thus the stator 1 and the rotor 13 ) are designed rotationally symmetrically about an axis of rotation 23 .

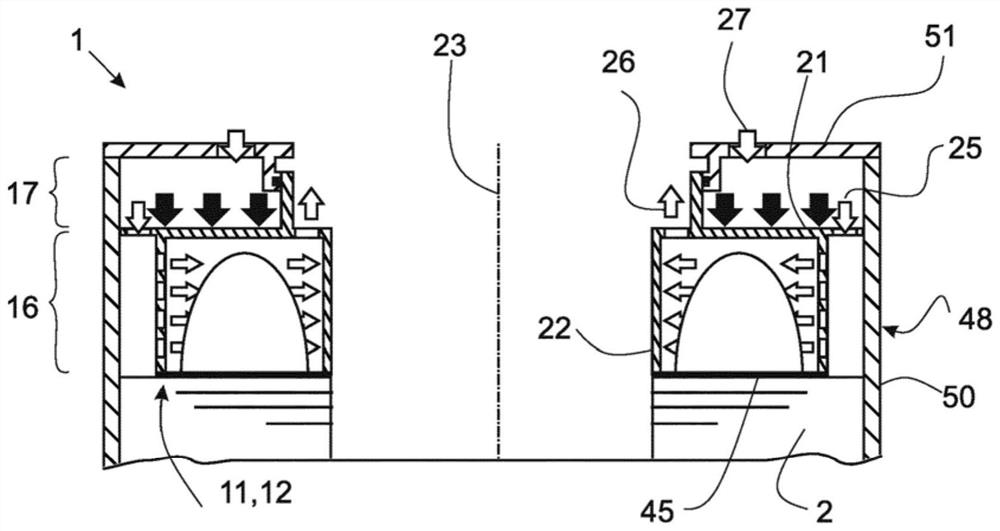

[0044] figure 2 A greatly simplified cross-sectional view is shown through a cooling channel 11 or 12 according to a preferred embodiment, which is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com