Tractor tire pressure multi-state control system

A control system and tractor technology, which is applied to tire measurement, tire parts, vehicle parts, etc., can solve the problems of inconvenient operation and no tire pressure adjustment, and achieve the effects of simple and convenient operation, reduced fuel consumption, and improved operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

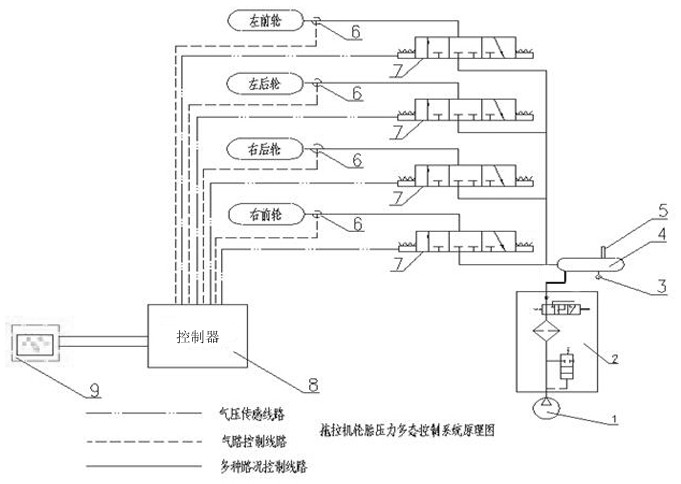

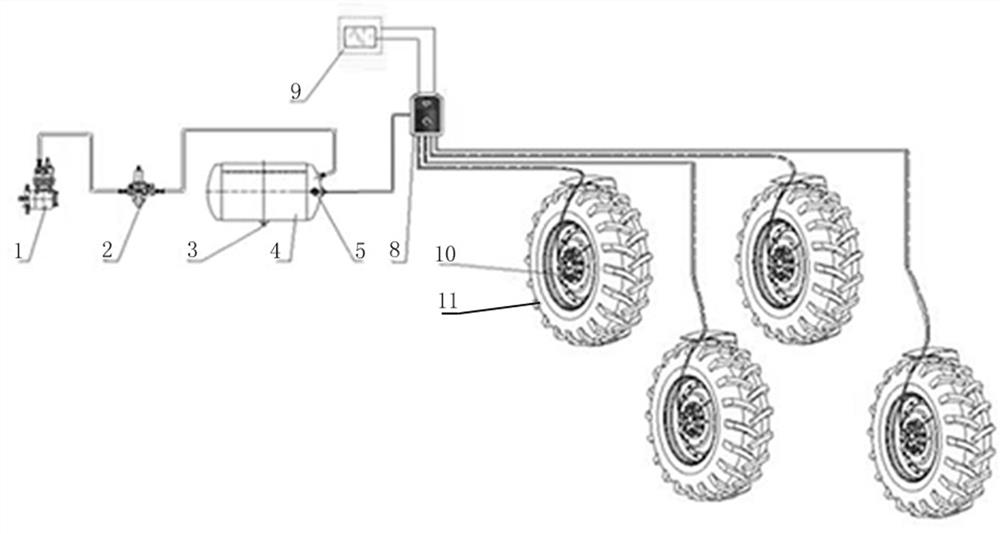

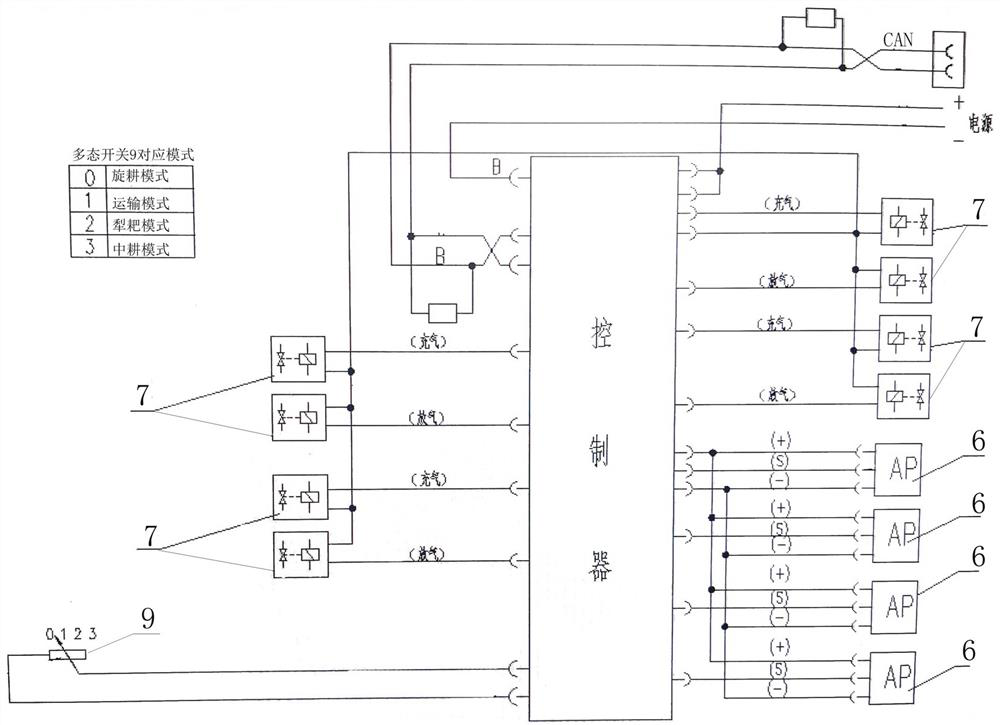

[0029] A tractor tire tire pressure multi-state control system, including a controller 8, a pressure sensor 6 and a tire inflation and deflation actuator; the controller 8 is preset with a variety of tire pressure standard values corresponding to different operation forms, and the pressure sensor 6 is used to detect the tire pressure and transmit the tire pressure value to the controller 8, and the controller 8 is used to compare the tire pressure value transmitted by the pressure sensor with the standard value of the tire pressure in the controller 8 corresponding to the working mode. Compare, and according to the result of the comparison, send a command to the tire inflation and deflation actuator to inflate or deflate the tire 11 or keep it still, so as to realize the intelligent control of the tire pressure. Connected with the controller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com