A method and system for automatically disassembling power battery packs of scrapped and recycled new energy vehicles

A technology for power battery packs and new energy vehicles, which is applied in the field of automatic disassembly methods and systems for power battery packs for scrap recycling of new energy vehicles, can solve problems such as low efficiency and insecurity, and achieves improved accuracy, reduced safety issues, and reduced difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

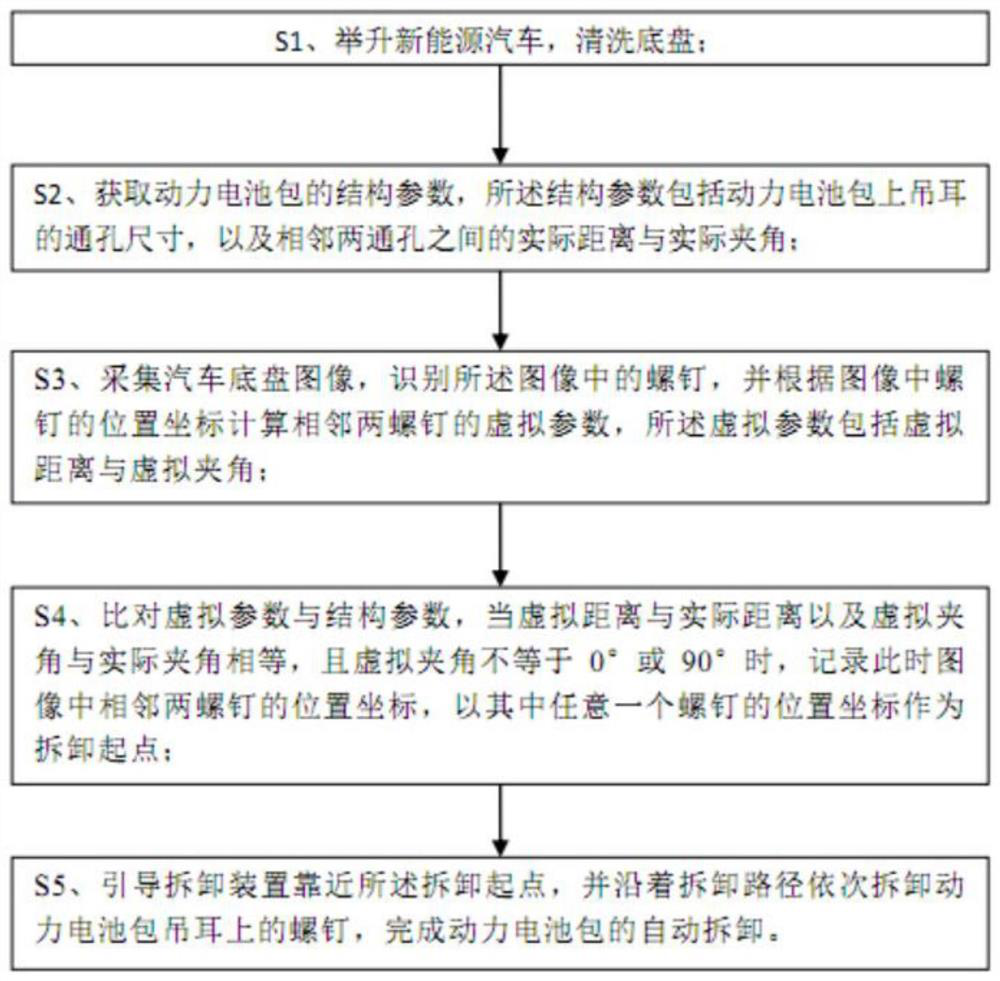

[0055] This embodiment provides a method for automatically disassembling the scrapped and recycled power battery pack of a new energy vehicle, such as figure 1 As shown, the method includes:

[0056] S1. Lift the new energy vehicle and clean the chassis.

[0057] When the power battery pack reaches the scrapping standard or the new energy vehicle reaches the scrapping standard, the power battery pack needs to be disassembled. During the use of new energy vehicles, the chassis of the car will be covered with dust, water, etc. Therefore, it is necessary to clean the chassis of the car when it is automatically disassembled. Manual disassembly does not require high chassis cleanliness, and generally does not require chassis cleaning.

[0058] In this embodiment, firstly, the car is lifted to the top of the cleaning equipment. Then, wash the chassis of the car through a high-pressure water gun, and the pressure of the high-pressure water gun is 10Mpa-25Mpa. Finally, the car cha...

Embodiment 2

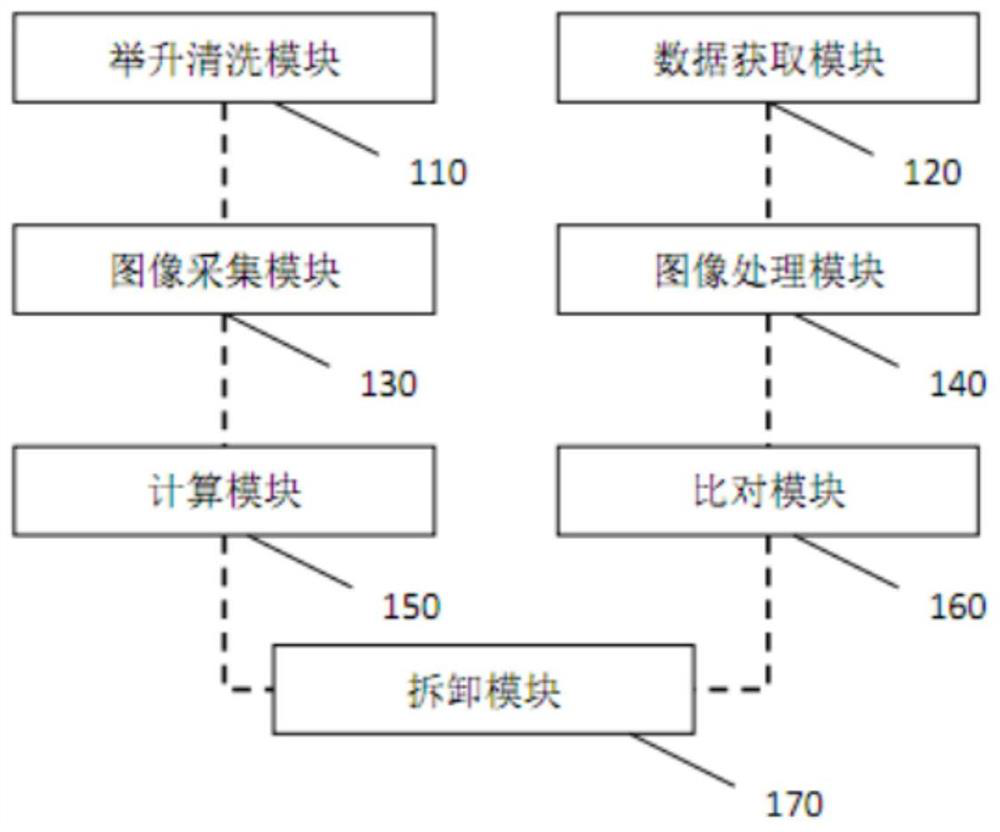

[0101] Such as image 3 As shown, this embodiment provides an automatic disassembly system for scrapping and recycling power battery packs of new energy vehicles, including:

[0102] Lifting and cleaning module 110, used for lifting new energy vehicles and cleaning the chassis;

[0103] The data acquisition module 120 is used to read the structural parameters of the power battery pack stored in the two-dimensional code of the chassis;

[0104] The image acquisition module 130 is used to acquire the image of the automobile chassis, and sends the acquired image to the image processing module;

[0105] The image processing module 140 is used to process the image of the automobile chassis, and recognize the screws in the image;

[0106] A calculation module 150, configured to calculate a virtual distance and a virtual included angle according to the screw information identified by the image processing module;

[0107] Comparison module 160, used to compare virtual parameters an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com