Spray paint fixture dismantling machine and its dismantling method

A technology of jigs and manipulators, applied in the direction of injection devices, etc., can solve problems such as low efficiency, high labor costs, product damage, etc., and achieve the effect of low process cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that all the drawings of the present invention are in simplified form and use inaccurate scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

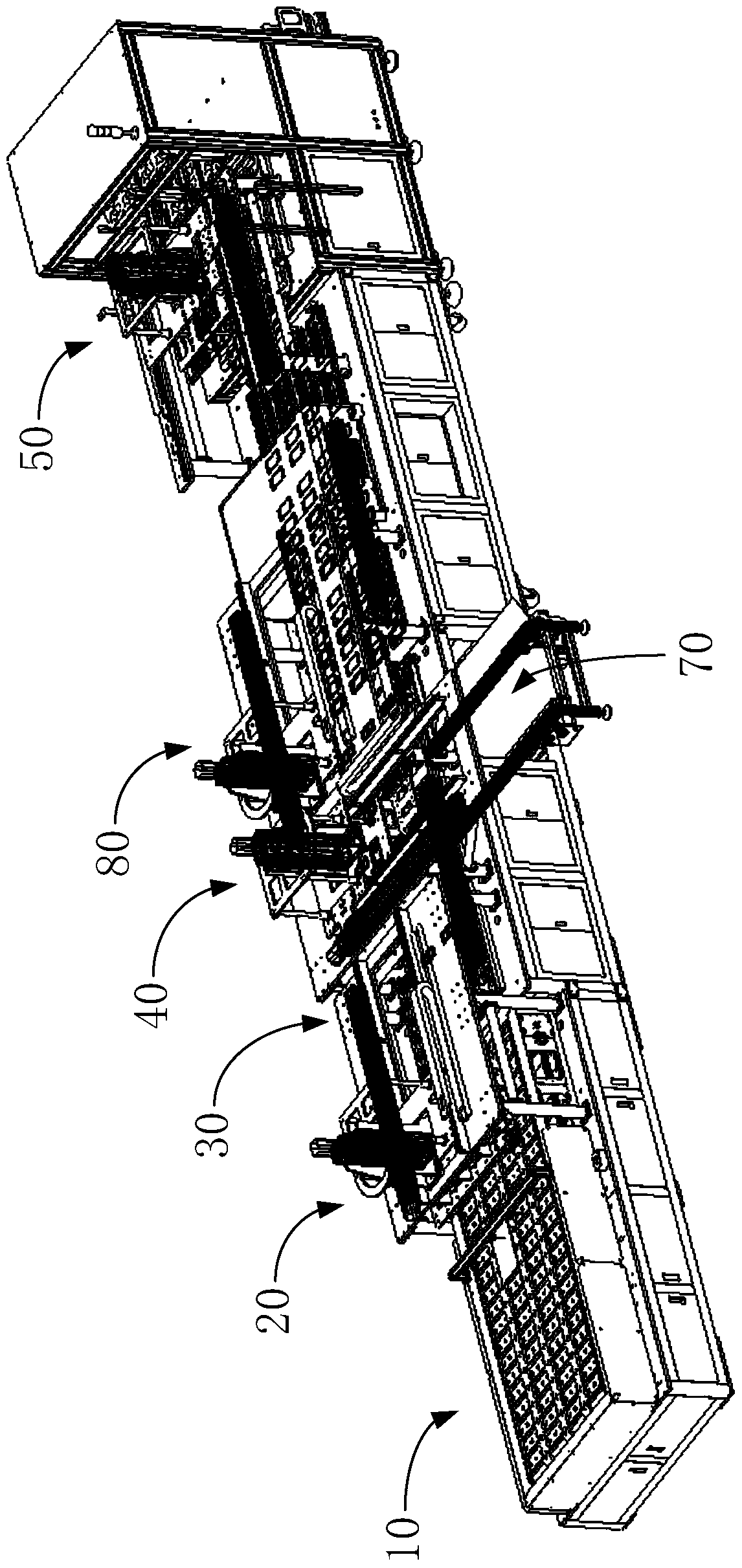

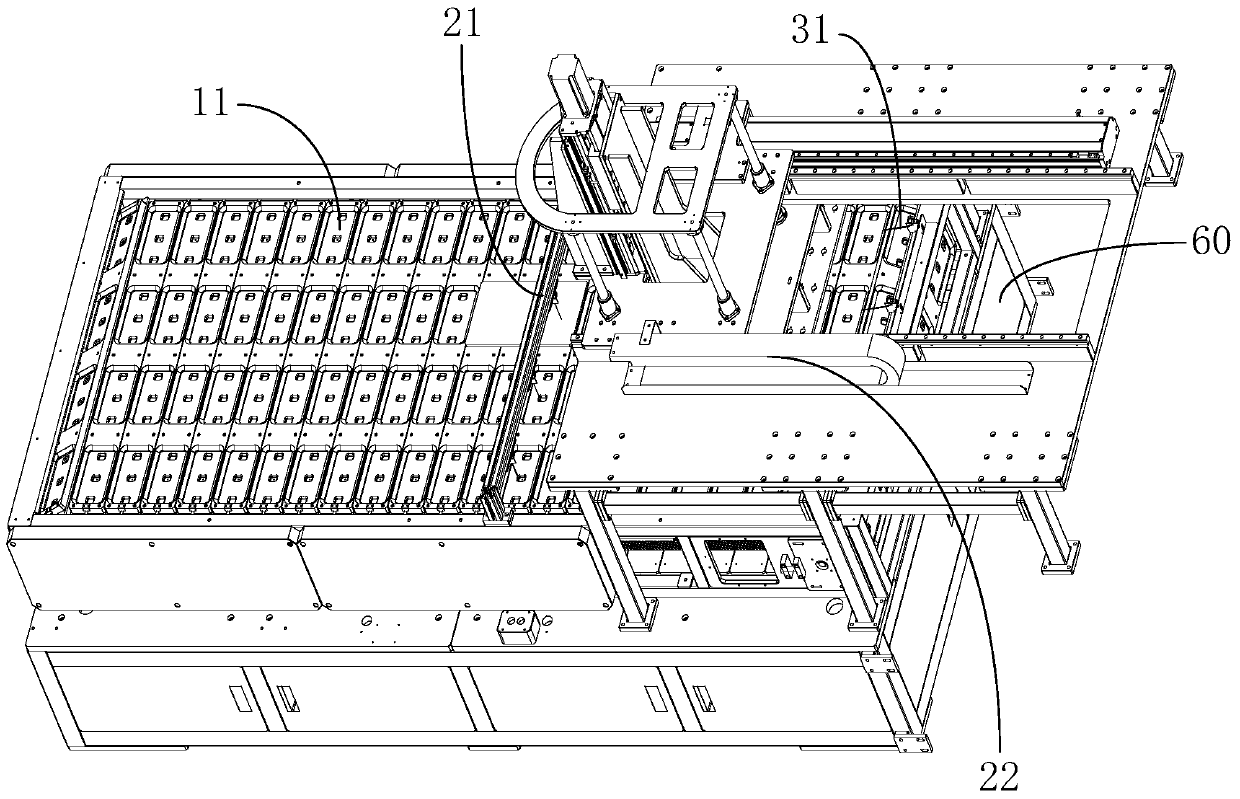

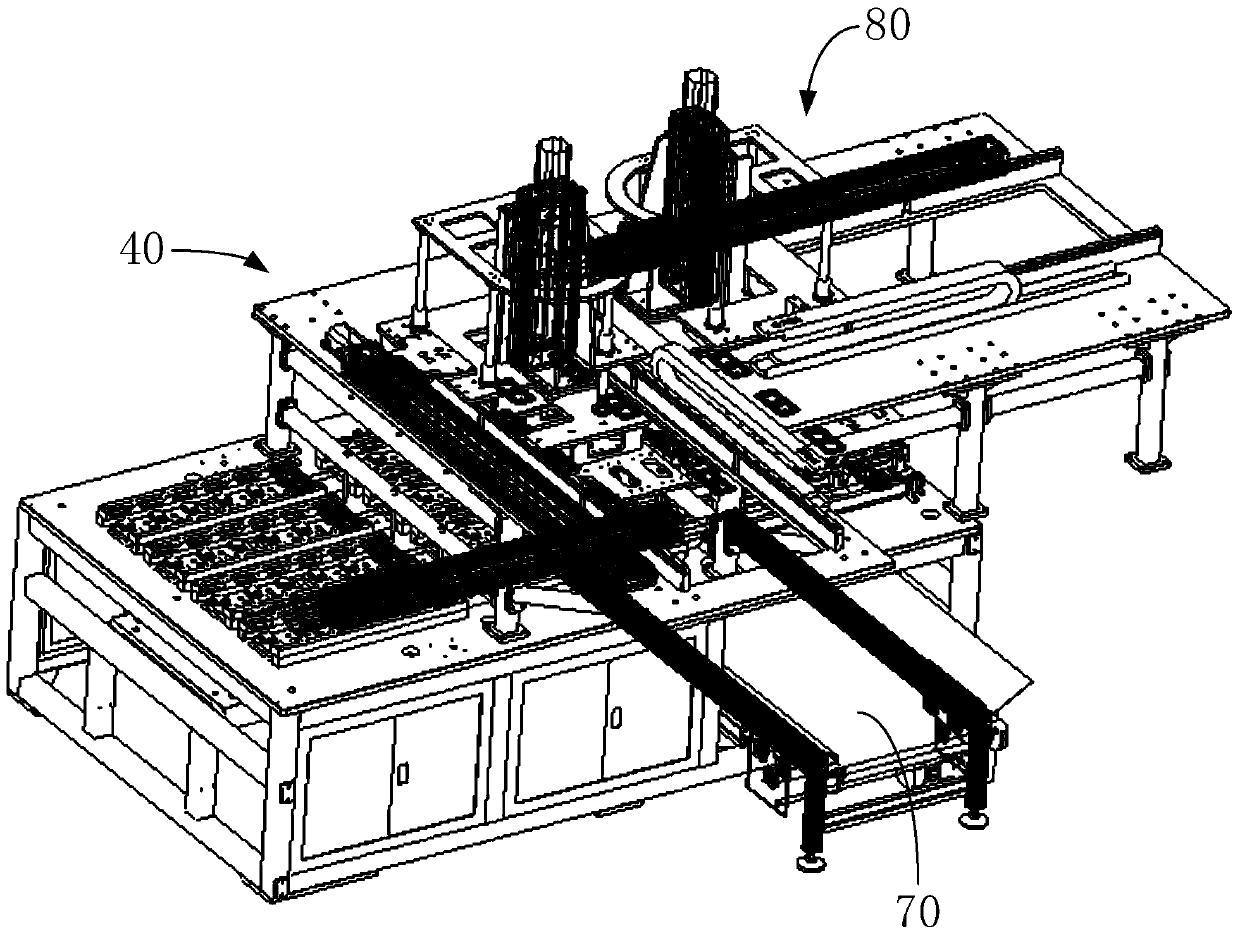

[0026] The paint spraying fixture dismantling machine provided by the invention, as figure 1 As shown, it includes a feeding mechanism 10, a grabbing mechanism 20, a dismantling mechanism 30, a product extracting mechanism 40, and a product unloading mechanism 50 in sequence, wherein the grabbing mechanism 20 is connected between the feeding mechanism 10 and the dismantling mechanism. 30, the dismantling mechanism 30 separates the upper cover from the product; the product and the lower cover are transfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com