Material strain-hardness relation detection method

A detection method and hardness testing technology, applied in the direction of testing material hardness, analyzing materials, measuring devices, etc., can solve problems such as insufficient accuracy, and achieve the effect of accurate strain-hardness relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

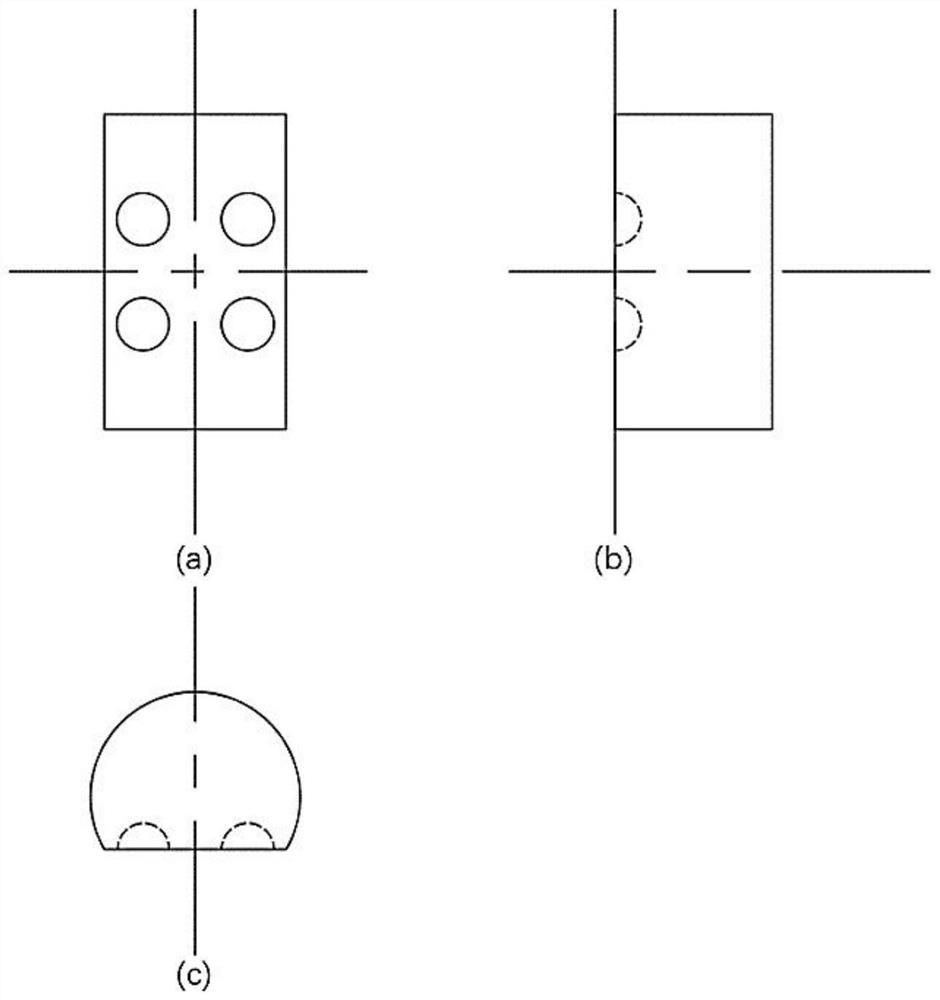

[0024] Such as figure 1 Shown in (a)~(c), it is a kind of sample to be tested that this embodiment relates to, and the measuring method of its strain-hardness relation specifically comprises:

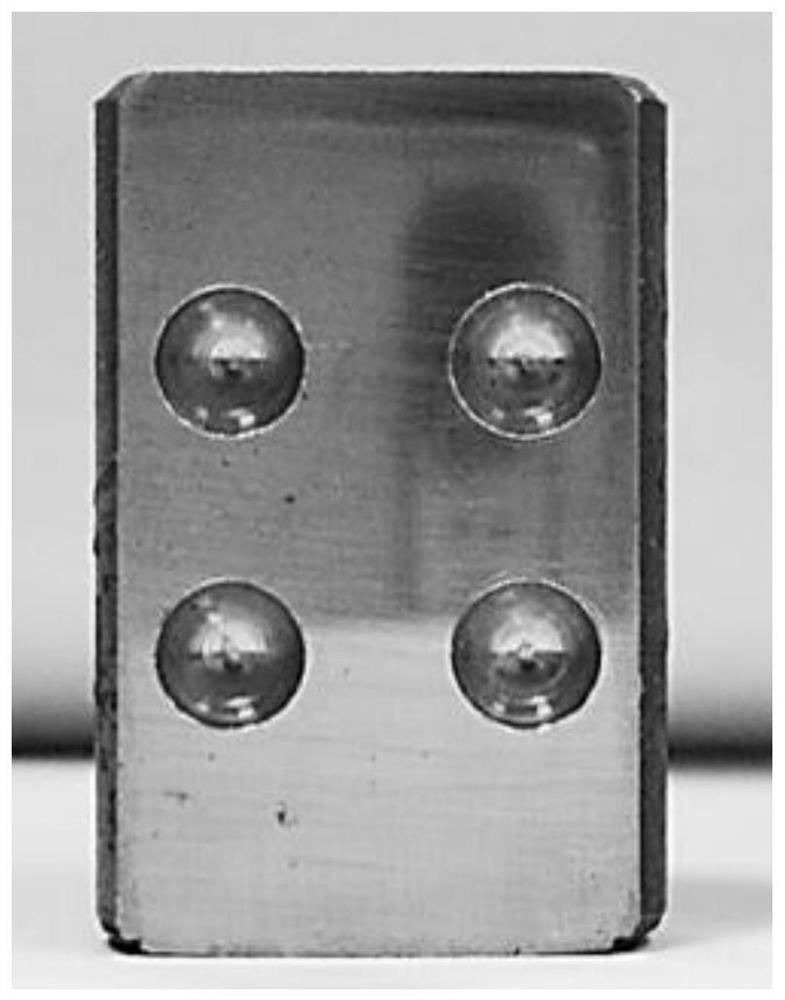

[0025] The first step is to prepare the sample to be tested: use 20MnMoB as the material to prepare an incomplete cylinder with a diameter of 20mm and a height of 30mm. The central axis is 5 mm; four hemispherical pits are further arranged on the plane, and the four pits are symmetrically distributed around the center of the plane; the diameter of the hemispherical pits is 5 mm, and the length and width distances between the hemispherical pits are both 10 mm.

[0026] The second step, surface spraying treatment: spray paint on the side plane of the sample with spherical pits obtained in the first step, spray white paint first, and then spray black paint after the white paint is dry, to ensure the plane outside the spherical pits Uniform spraying to ensure complete and accurate capture ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com