A printed circuit board drilling device

A technology for printed circuit boards and drilling devices, applied in metal processing and other directions, can solve problems such as unsatisfactory adaptability and flexibility, reduce the number of repositioning and support, reduce intermediate transfer links, and improve support effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Order that the invention object, technical solutions, and advantages of the embodiments more clearly, the following embodiments of the present invention will be described in detail in conjunction with the accompanying drawings, the described embodiments of the present invention, part of the embodiments of the present invention rather than all embodiments .

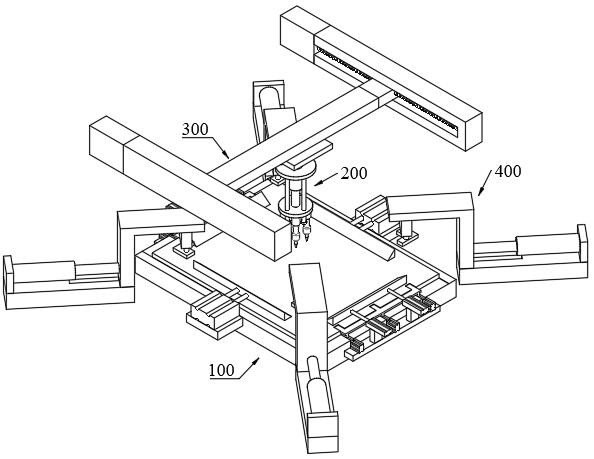

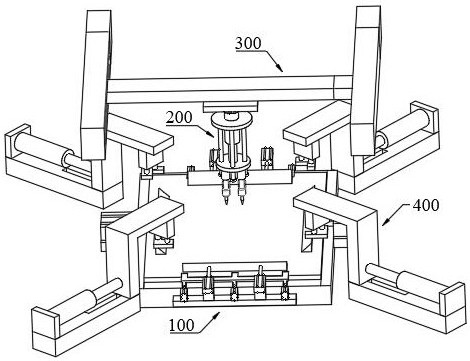

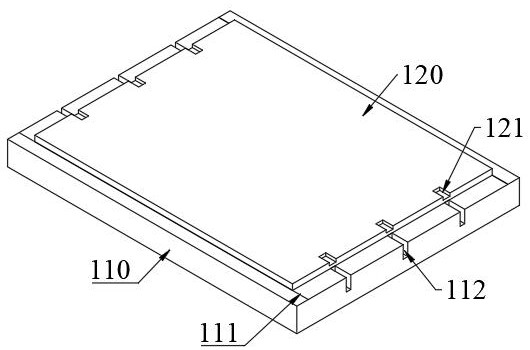

[0042] The embodiment provides a printed circuit board drilling apparatus of the present application, such as figure 1As shown, including: support assembly 100, drilling module 200, stroke assembly 300, compression assembly 400. One end of the printed circuit board drilling device is taken to the delivery device for receiving the printed wiring board to the support assembly 100 from the front one. Specifically, the delivery device prior art generally uses track and roller delivery, and the end of the conveying device is set to be higher than the support assembly 100, and passed through a tilted transition plate between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com