A Two-way Rotating Involute Tooth Profile Internal Gear Pump

A technology of internal meshing gear pumps and involute teeth, which is applied in the direction of rotary piston pumps, rotary piston/swing piston pump components, rotary piston machinery, etc. Friction and wear, lubricating oil film instability and other problems, to achieve the effect of reducing wear, prolonging service life, improving stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

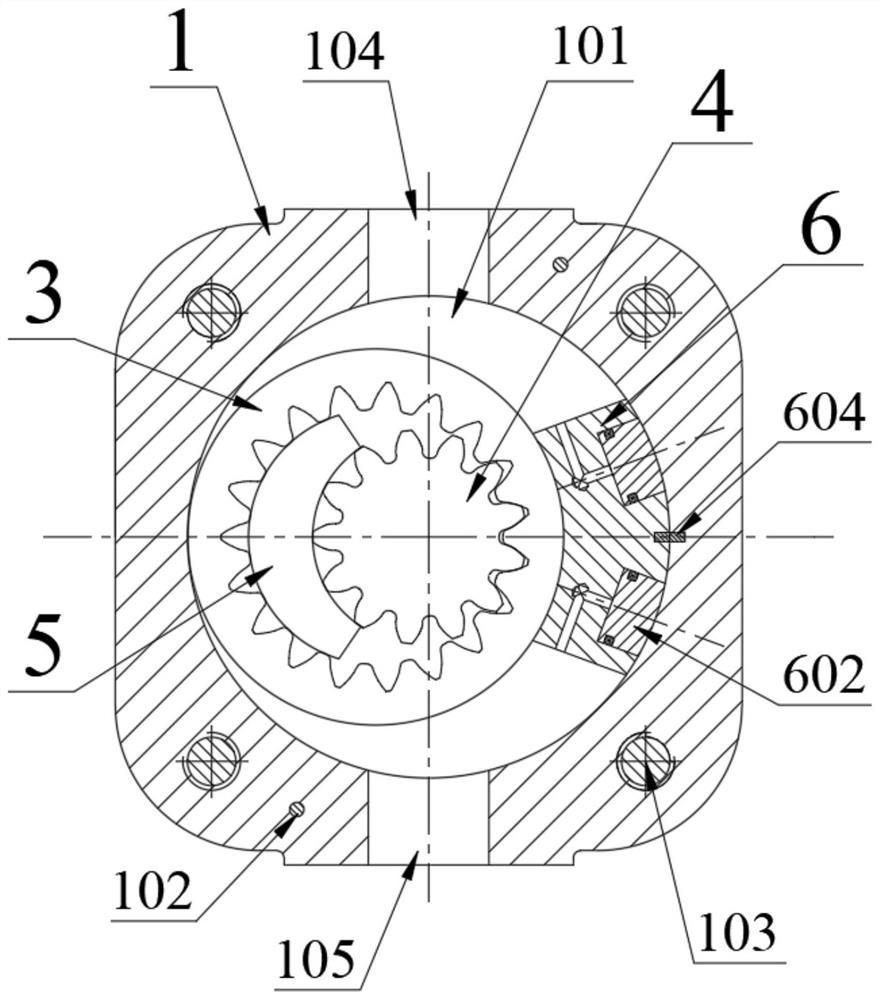

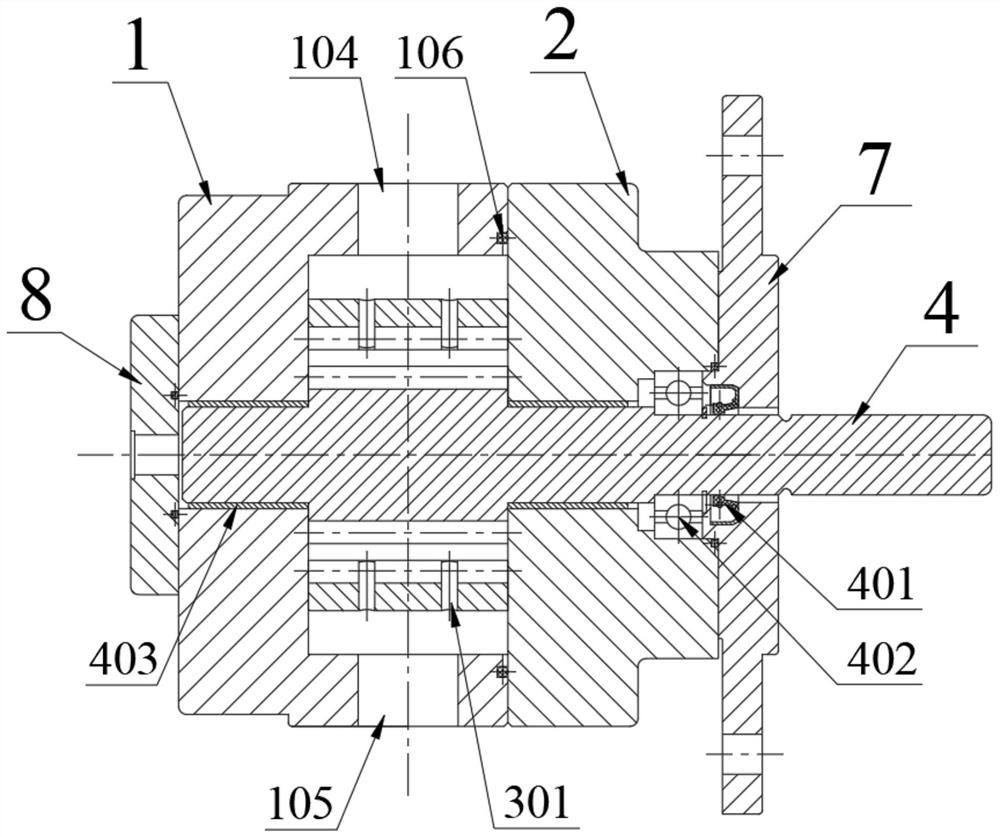

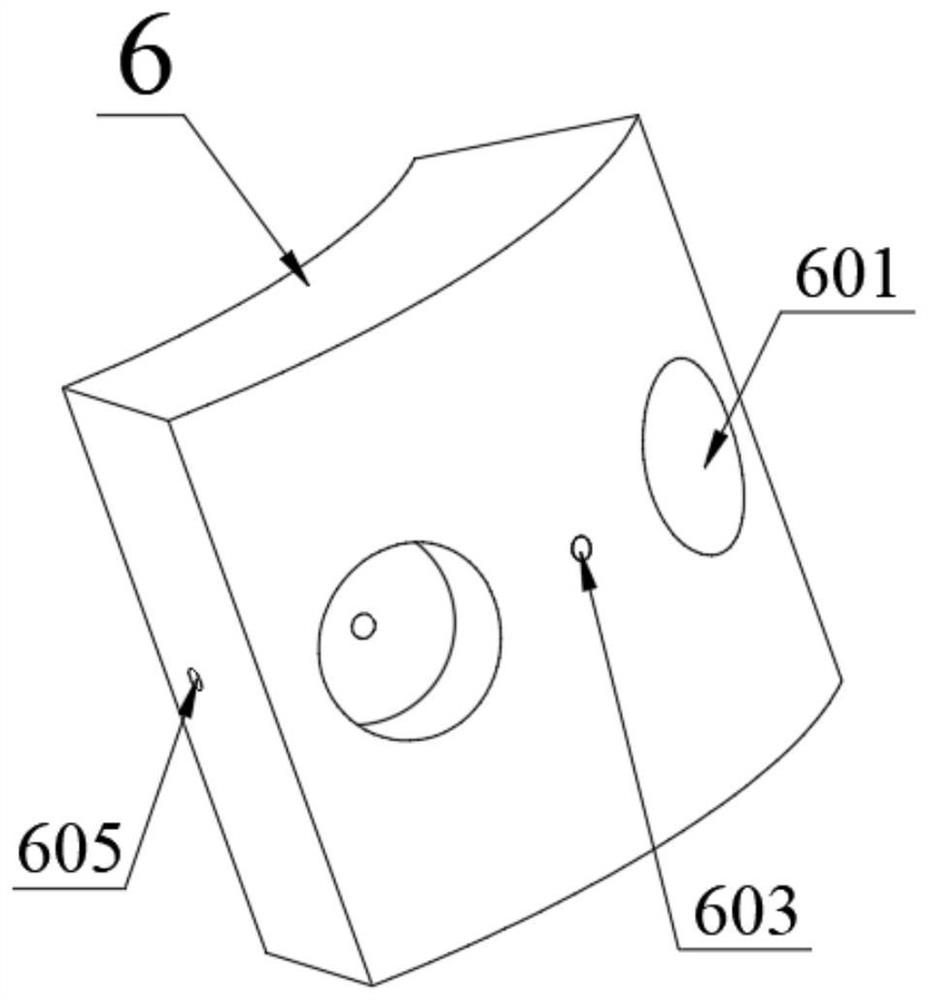

[0037] see Figures 1 to 3 , the bidirectionally rotatable involute tooth profile internal meshing gear pump in the preferred embodiment of the present invention includes a lower pump body 1 and an upper pump body 2, and the lower pump body 1 is provided with a seat hole 101, so that after the upper and lower pump bodies are matched, A closed cavity structure is formed between the two. The upper and lower pump bodies are connected and fixed by a number of fastening screws 103, and a number of positioning pins, namely the first positioning pins 102, are correspondingly arranged between the upper and lower pump bodies, and the opposite end faces of the upper and lower pump bodies are provided with corresponding first positioning pins 102. The pin hole is used for corresponding accommodation of the first positioning pin 102 .

[0038] Specifically, the lower pump body 1 in the preferred embodiment is as follows figure 1 As shown in the figure, a seat hole 101 with a certain dep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com