Rock Tunneling Machine Bidirectional Rotary Cutterhead and Bidirectional Rotary Tunneling Method

A two-way rotating, roadheader technology, used in earth-moving drilling, mining equipment, tunnels, etc., can solve problems such as large wear of the main drive gear pair, fatigue wear of the hob bearing and main drive bearing, affecting the service life, etc. The effect of improving and reducing the difficulty and danger of construction and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

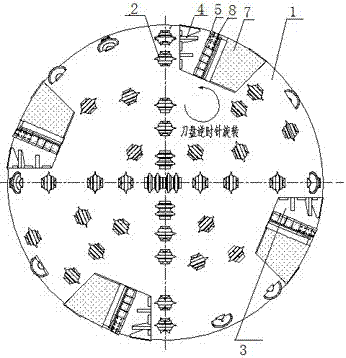

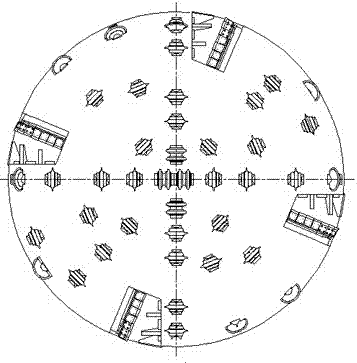

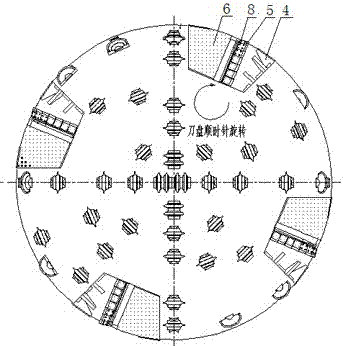

[0020] As shown in Figure 2, the present invention provides a bidirectional rotary cutter head for a rock boring machine, including: cutter head body 1, hob 2, slag outlet 3, grid 4, bucket 5, clockwise rotating blind plate 6. Rotate the blind plate 7 counterclockwise and high-strength connecting bolts 8. It is characterized in that: the working surface of the cutter head body 1 forms a convex surface with a radian in the working direction, and multiple water spray devices are arranged on the cutter head body. There is an ultrasonic vibrator on the top, and a hob wear detection device on the hob. Four pairs of slag outlets 3 are evenly arranged on the cutter head body 1, which are respectively arranged on the counterclockwise and clockwise sides of the bucket. The bucket and counterclockwise rotation bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com