Hydraulic clamp for electro-hydraulic servo fatigue testing machine

A technology of fatigue testing machine and hydraulic fixture, which is applied in the direction of applying repeated force/pulsation force to test the strength of materials, measuring devices, instruments, etc., which can solve problems such as damage and deformation of samples, so as to ensure accuracy and reduce the probability of fracture , Improve the efficiency of fatigue test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further understand the present invention, the present invention is described below in conjunction with examples, but the examples are only to further illustrate the features and advantages of the present invention, rather than limiting the claims of the present invention.

[0033] In order to solve the inconvenience of manual operation caused by manual repeated locking of mechanical fixtures used in traditional high-temperature tests, and to reduce the test cost of material research and development, the present invention designs a set of Electro-hydraulic servo Hydraulic grips for fatigue testing machines.

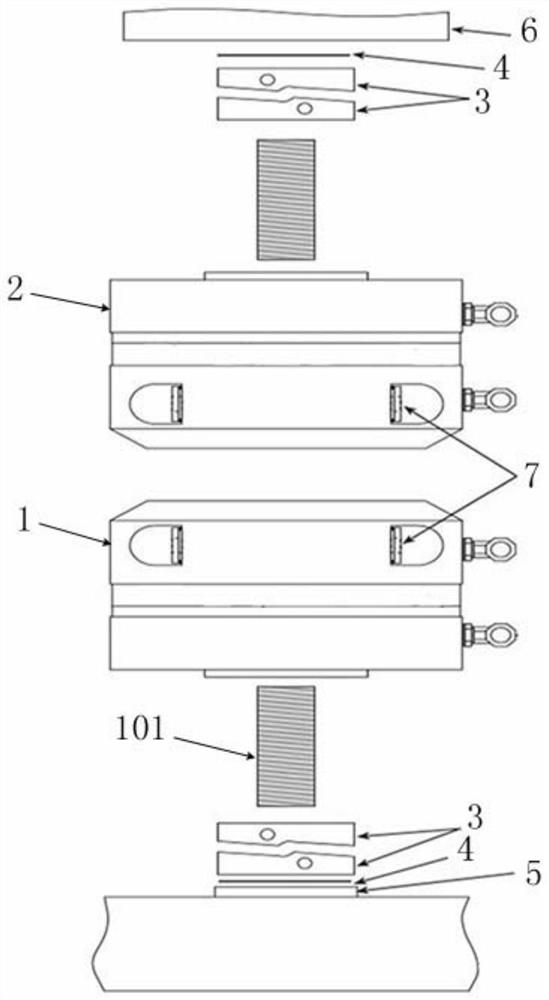

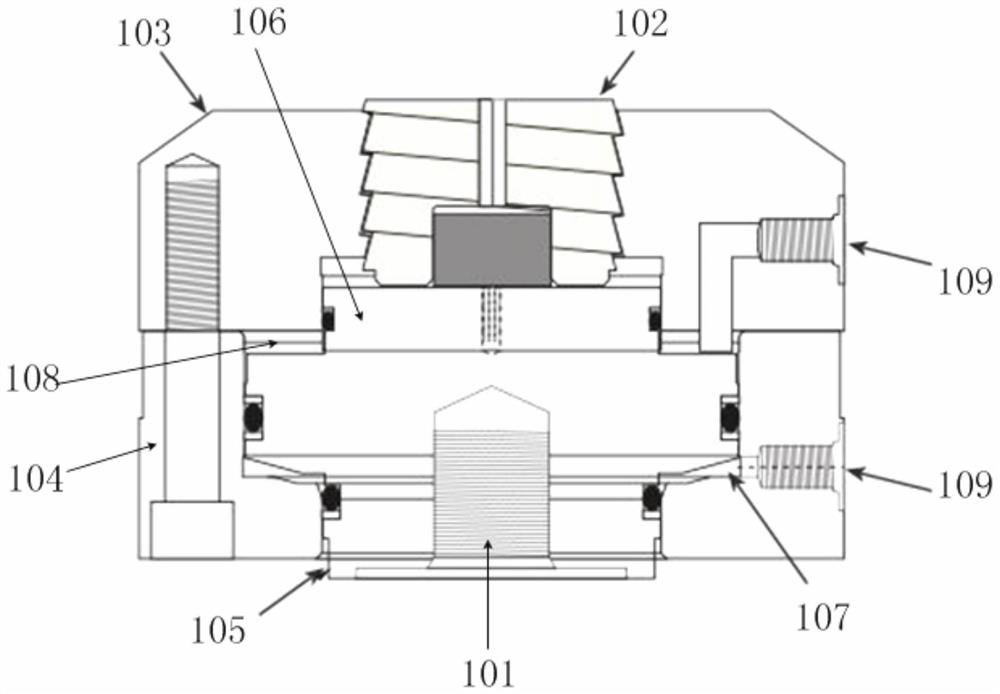

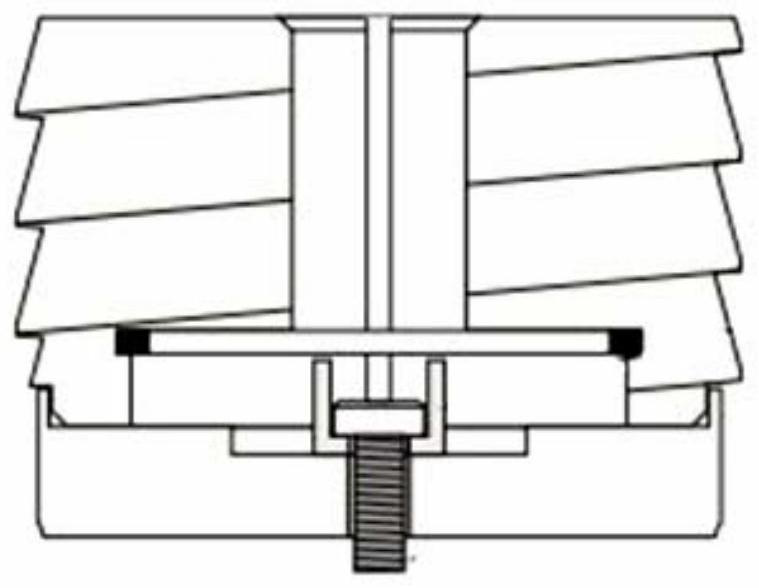

[0034] Such as Figure 1-4 As shown, the hydraulic clamp includes an upper clamp 2 and a lower clamp 1 with the same structure. Both the upper clamp and the lower clamp include a locking thread 101, a clamp outer cover and an annular clamp block 102, wherein: the clamp outer cover is formed by the clamp shell 103 and the end cover 104 are sealed and fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com