Paper rolling device of cylinder roll paper

A drum-type, roll-to-roll technology, which is applied in the directions of winding strips, transportation and packaging, and thin material processing, etc., and can solve problems such as early operation time, ineffective paper tape, and shifting travel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

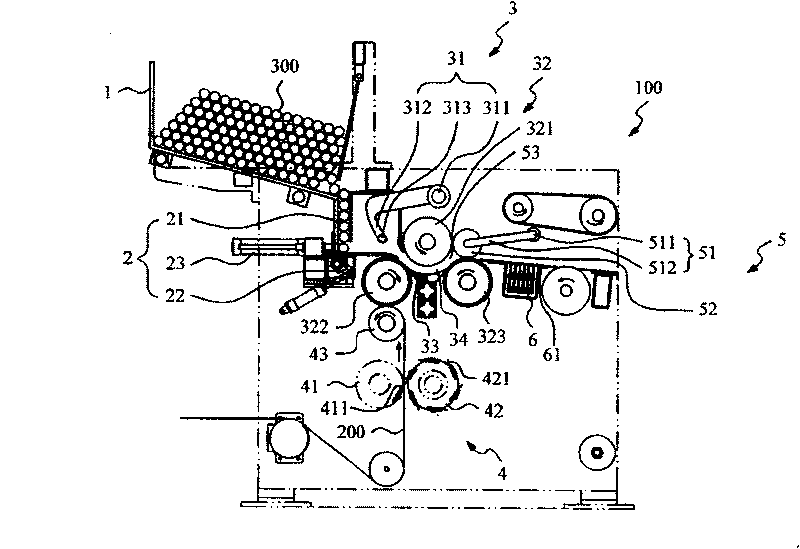

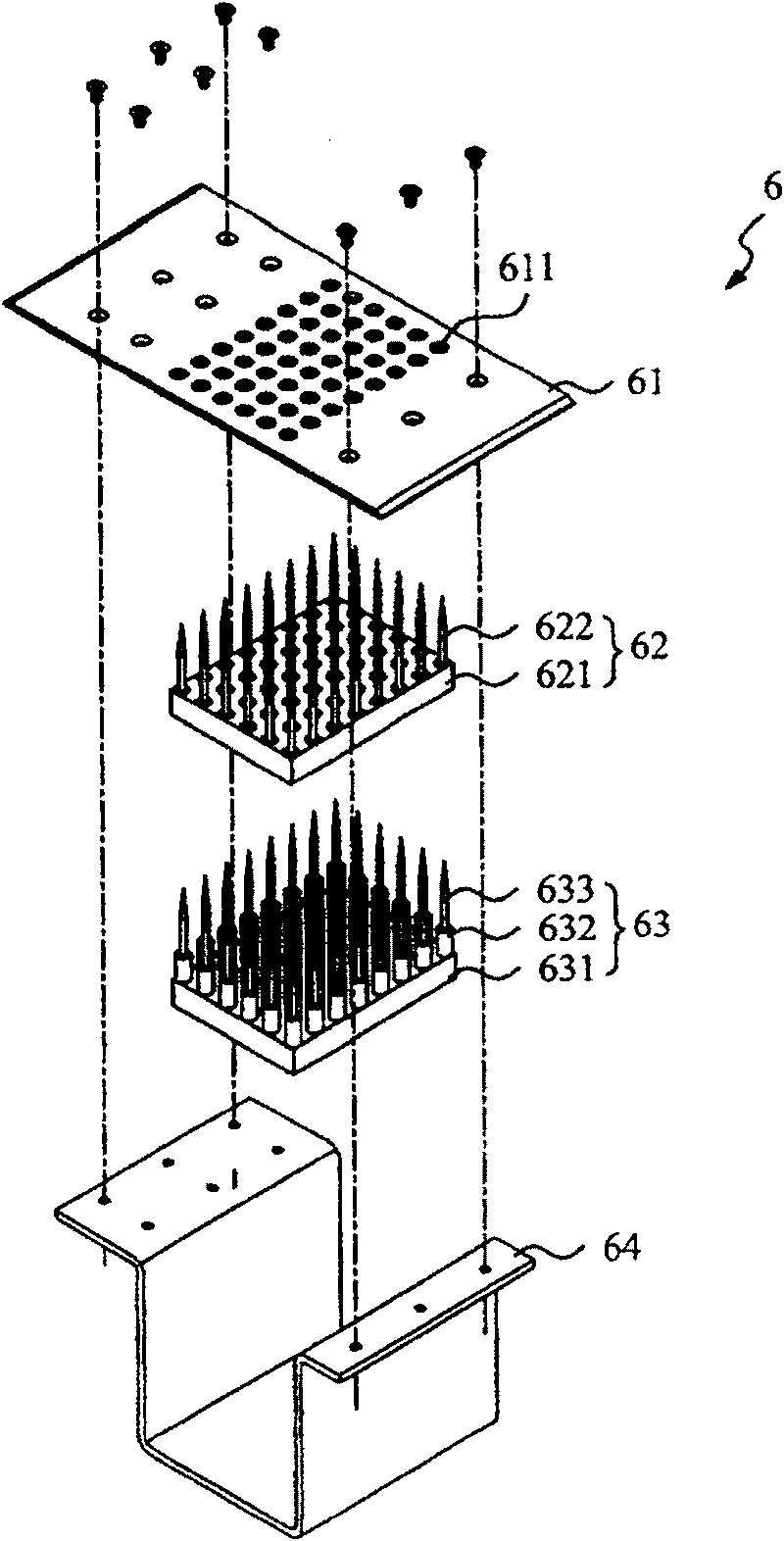

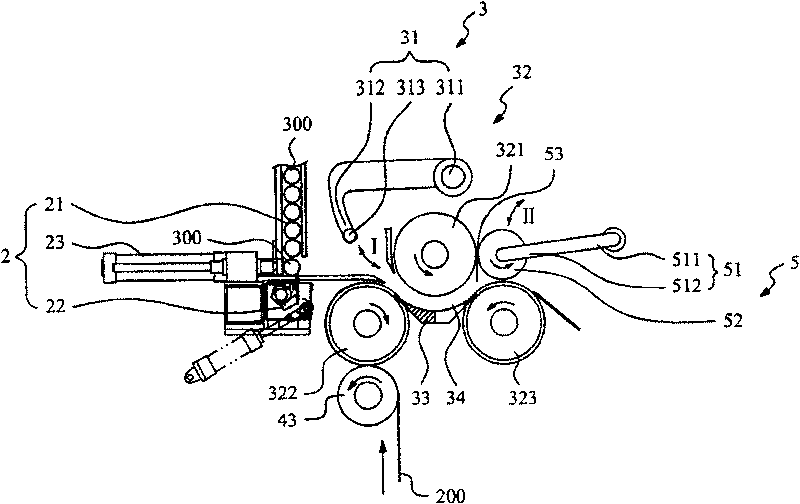

[0025] see figure 1 , which is a schematic diagram showing an embodiment of the present invention. As shown in the figure, a paper rolling device 100 is used for rolling a long strip of paper material 200 . The paper rolling device 100 includes a core tube supply tank 1, a core tube feeding guide unit 2, a roll transfer unit 3, a paper material belt feeding wheel set 4, a clamping swing arm roller set 5 and One glue supply mechanism6.

[0026] The cartridge supply tank 1 contains a plurality of cartridges 300, the cartridge feed guide unit 2 is adjacent to the cartridge supply tank 1, and includes a feed guide channel 21, a glue supply mechanism 22 and a Cartridge pushing mechanism 23. Wherein, the head glue supply mechanism 22 is provided with adhesive head glue. The feeding guideway 21 is adjacent to the core tube supply tank 1 and the head glue supply mechanism 22, so as to guide the core tube 300 out of the core tube supply tank 1 and attach the head glue. The core tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com