Zoom security monitoring camera lens

A security monitoring and lens technology, applied in the field of lenses, can solve the problems of imaging clarity and uniformity, limited to 1080P, difficult to apply multiple object distances and different field of view frames at the same time, to achieve high image color reproduction, The imaging picture is clear and uniform, and the effect of improving the imaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

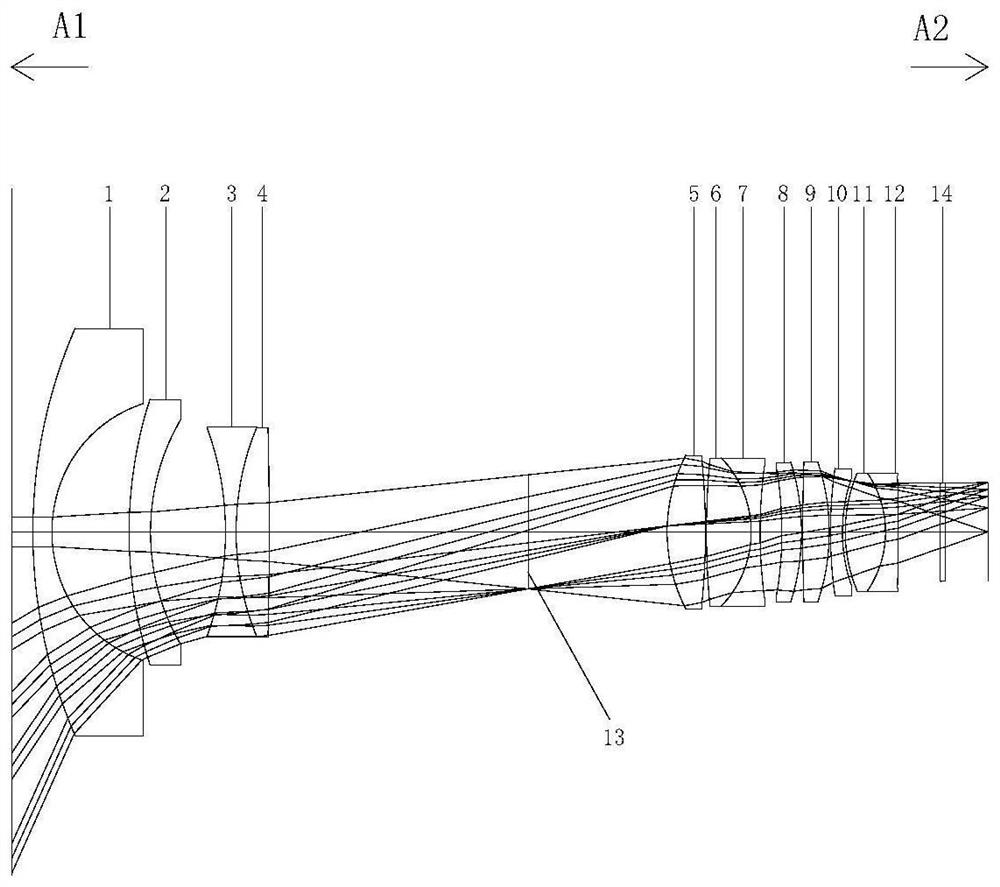

[0130] refer to figure 1 As shown, the present embodiment discloses a zoom security monitoring lens, and the first lens 1 to the 12th lens 12 is sequentially included in one optical axis from the object side A1 to the image side A2; the first lens 1 to 12 The lens 12 each includes a side surface and a web side surface that pass through the object side A1 and causes the imaging light passing toward the image side A2 and enables the imaging light to pass.

[0131] The first lens 1 has a negative refractive rate, and the side surface of the first lens 1 is a convex surface, and the side surface is a concave surface; the second lens 2 has a negative refractive rate, the second lens 2 side surface For the convex surface, the side surface is a concave surface; the third lens 3 has a negative refractive rate, and the side surface of the third lens 3 is a concave surface, and the side surface is a concave surface; the fourth lens 4 has a positive refractive rate, The side surface of the f...

Embodiment 2

[0147] Cooperate Figure 15 to 28 As shown, the present embodiment is substantially the same as the face unevenness and refractivity of the respective lenses of the embodiment, and the optical parameters such as the curvature of each lens surface, the lens thickness are different.

[0148] The detailed optical data of the shortest focal length (short focal) of the present embodiment is shown in Table 2-1.

[0149] Table 2-1 Detailed optical data at the shortest focal length of the first example

[0150] surface Cleaner size (diameter) Curvature radius thickness Material Refractive index Dispersion coefficient focal length 0 Infinity Infinity 1 First lens 36.43 45.69 1.77 H-LAF62 1.719999 43.6912 -24.12 2 23.50 12.42 7.08 3 Second lens 24.00 34.41 2.01 H-ZPK2A 1.603001 65.4596 -73.79 4 20.50 19.00 7.22 5 Third lens 19.17 -26.55 1.00 H-ZBAF3 1.656914 51.1566 -18.96 6 Fourth ...

Embodiment 3

[0160] Cooperate Figure 29 to 42 As shown, the present embodiment is substantially the same as the face unevenness and refractivity of the respective lenses of the embodiment, and the optical parameters such as the curvature of each lens surface, the lens thickness are different.

[0161] The detailed optical data at the shortest focal length (short focal) of the present embodiment is shown in Table 3-1.

[0162] Table 3-1 Detailed Optical Data when the 3-short focal length

[0163]

[0164]

[0165] The detailed optical data of the longest focal length (telephoto) of the specific embodiment is shown in Table 3-2.

[0166] Table 3-2 Detailed optical data at the three longest focal length

[0167]

[0168]

[0169] The fifth lens 5 aspherical parameter detailed data should be refer to the table below:

[0170] Sequence number K A4 A6 A8 A10 A12 A14 9 -0.96 4.190E-05 2.730E-07 2.043E-08 -4.970E-10 2.024E-12 1.292E-13 10 -3.92 3.994E-05 6.071...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com