Connecting component between container bodies

A technology for connecting components and containers, applied in the directions of packaging, transportation, packaging, containers, etc., can solve the problems of inability to adjust the connection position and connection, and achieve the effect of convenient corresponding connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

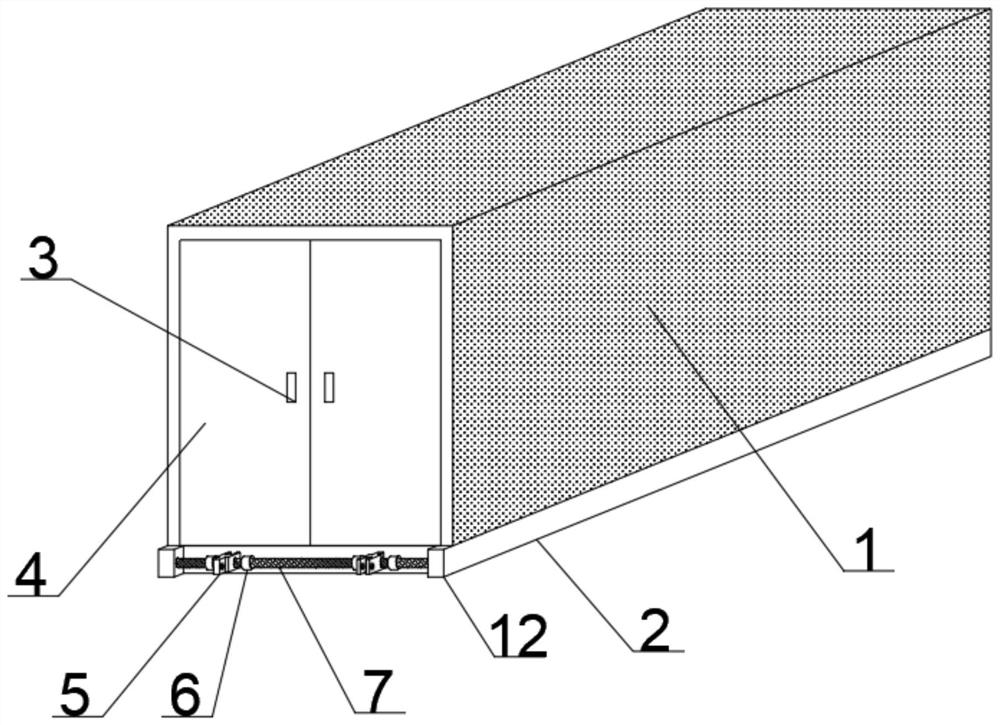

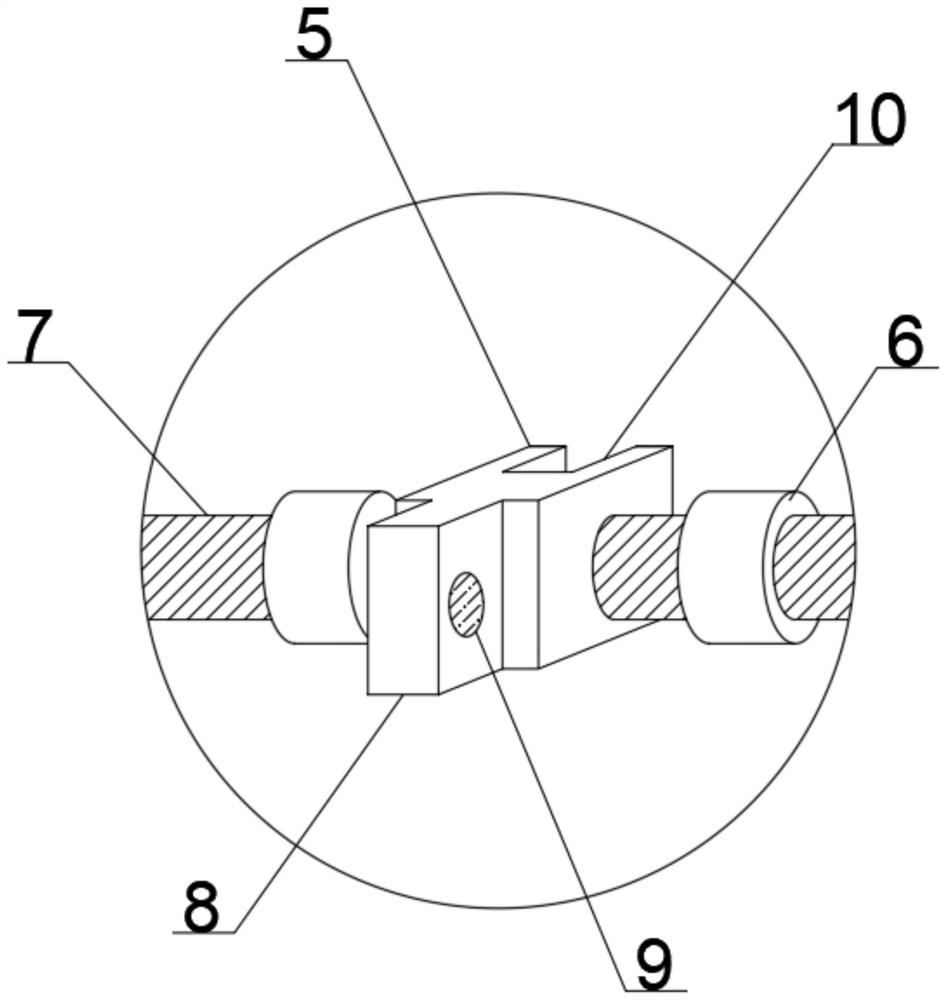

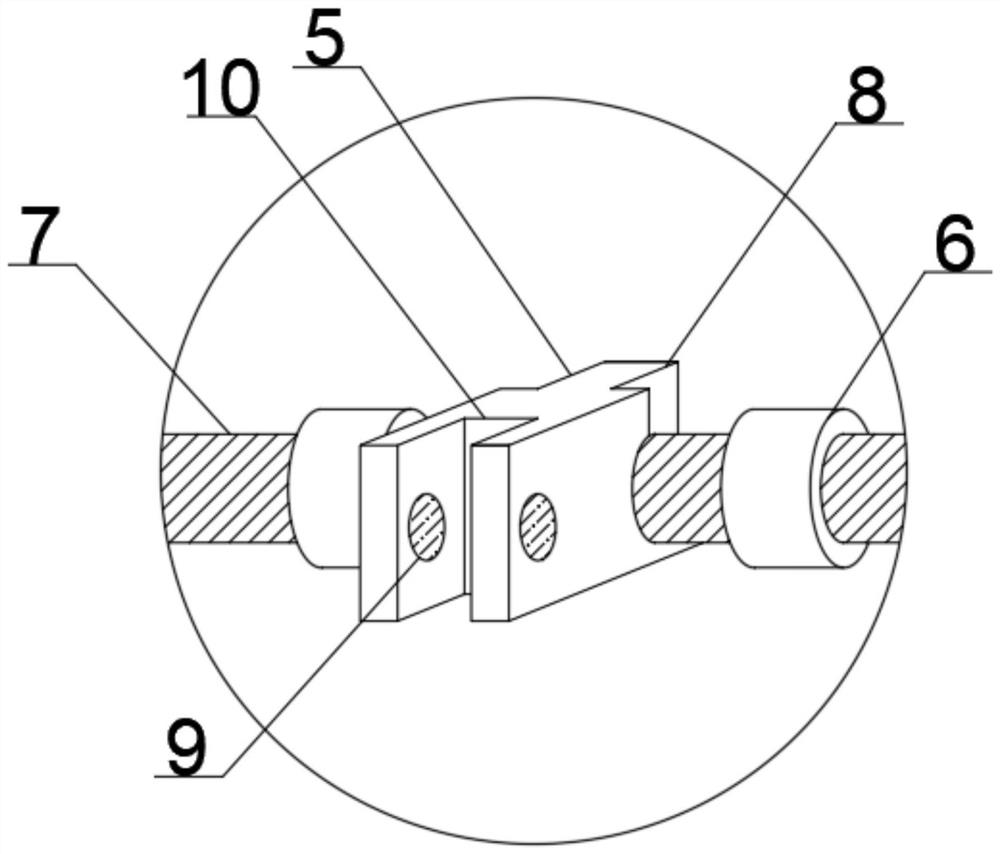

[0026] see figure 1 , figure 2 , image 3 , Figure 4 , the present invention provides a technical solution: a connecting member between container boxes, including a container main body 1, a base 2 is provided at the lower side of the container main body 1, and a box door is provided at the left side of the container main body 1 4. A door handle 3 is provided at the outer side of the box door 4, a fixed block 12 is provided at the left side of the base 2, a threaded rod 7 is provided at the middle of the fixed block 12, and a nut 6 is provided on the threaded rod 7, The right side of the nut 6 is provided with a connecting piece 5, the connecting piece 5 includes a convex body 8, a round hole 9, and a concave body 10, the rear side of the convex body 8 is provided with a concave body 10, and the inner middle position of the concave body 10 A round hole 9 is arranged at the position, and a connecting rod 11 is arranged at the inner side of the round hole 9 .

Embodiment 2

[0028] see figure 1 , figure 2 , image 3 , the present invention provides a technical solution: a connecting member between container boxes, two connecting parts 5 are provided in total, and the two connecting parts 5 are respectively arranged at the outer positions of the threaded rods 7, and the two container bodies 1 can be connected via connecting piece 5.

Embodiment 3

[0030] see figure 1 , figure 2 , image 3 , the present invention provides a technical solution: a connecting member between container boxes, the connecting piece 5 is connected to the threaded rod 7 through a threaded connection, and the connecting piece 5 can move and rotate on the threaded rod 7 through the rotating thread , the position of the connecting piece 5 on the threaded rod 7 can be moved to dock container bodies 1 of different sizes. There are four nuts 6 in total, and the four nuts 6 are respectively arranged at the outer positions of the threaded rod 7. The nuts 6 pass through the threads The connection method is connected with the threaded rod 7. There are three round holes 9 in total, and the three round holes 9 are respectively set at the inner side of the connecting piece 5. The connecting rod 11 penetrates through the connecting piece 5 through the round holes 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com