A ceramsite board processing table

A technology of processing table and ceramsite board, applied in stone processing equipment, metal processing equipment, work accessories, etc., can solve the problems of large waste, environmental damage, water resource waste, etc., to reduce waste, avoid environmental damage, and process The effect of environmental improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

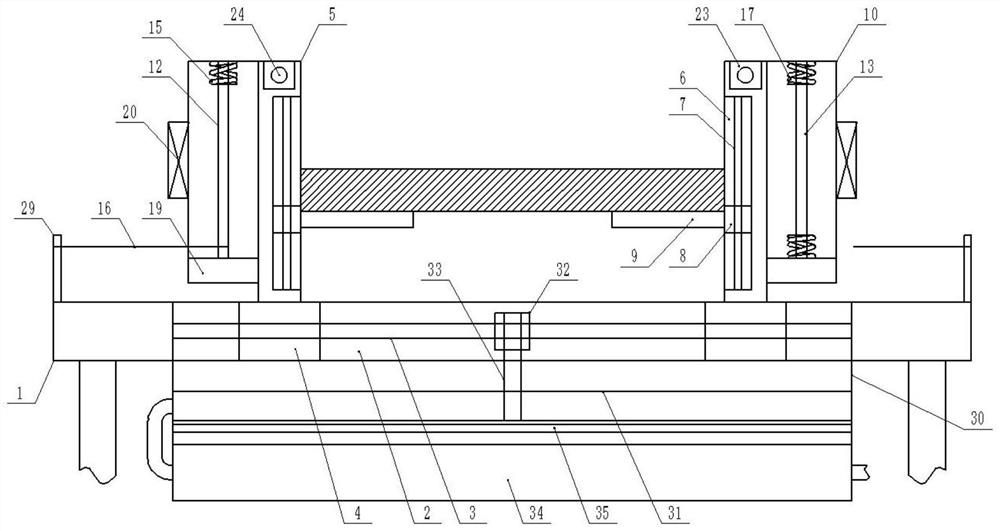

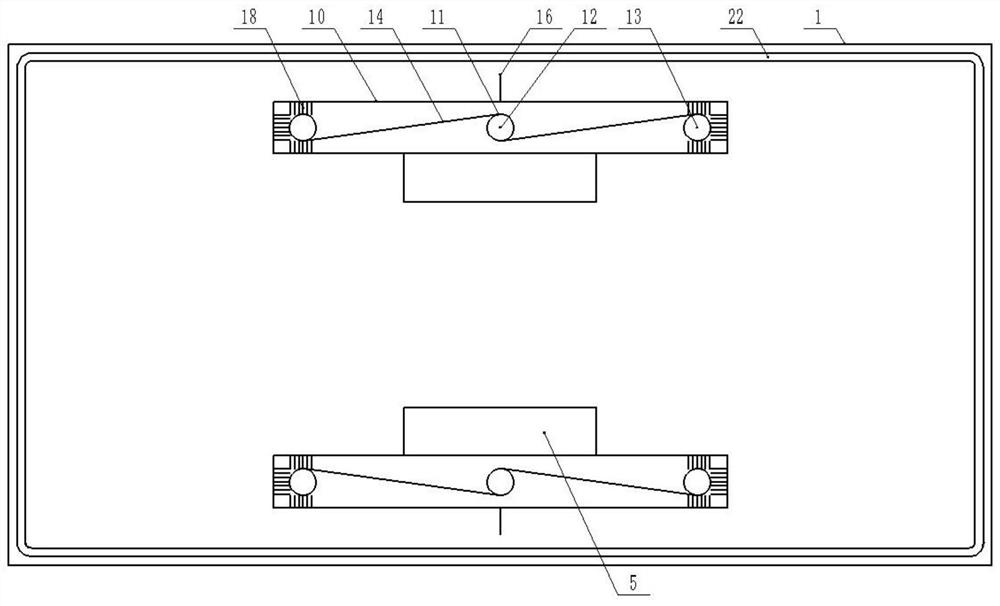

[0013] Embodiment 1: see figure 1 , figure 2 , image 3 Now, a ceramsite board processing platform provided by the present invention will be described, including a platform 1 and a support leg fixed vertically and evenly at the lower end of the platform 1, and the middle side of the upper end of the platform 1 and along its width direction. Rectangular opening 2, the first threaded mandrel 3 is arranged inside the rectangular opening 2, the inner ends of both sides of the length direction of the rectangular opening 2 are provided with rectangular sliding seats 4, and the upper ends of the rectangular sliding seats 4 are all vertical Fixedly provided with clamping and stabilizing seat 5, said clamping and stabilizing seat 5 is all vertically provided with the first strip-shaped groove 6 along the middle side of the corresponding end in the width direction of said platen 1, and said first strip-shaped groove 6 are provided with a second screw rod 7 and a first strip slide 8, ...

Embodiment 2

[0014] Example 2: see figure 1 , figure 2 , image 3Now, a ceramsite plate processing table provided by the present invention will be described. The rectangular opening 2 is an opening in the vertical direction. The seat 4 is set, and the inner end wall of the movable penetration of the rectangular sliding seat 4 is provided with a first screw drive assembly between the outside of the first screw mandrel 3, and the outer end of one side of the first screw mandrel 3 in the length direction The first screw mandrel manual frame is set, the second screw mandrel 7 vertically moves through the first strip-shaped sliding seat 8, and the first strip-shaped sliding seat 8 moves through the inner end wall of the place and the first strip-shaped sliding seat 8 A second screw drive assembly is arranged between the outsides of the two screw mandrels 7. The outer end of one side of the second screw mandrel 7 in the length direction is covered with a second screw mandrel manual frame. Th...

Embodiment 3

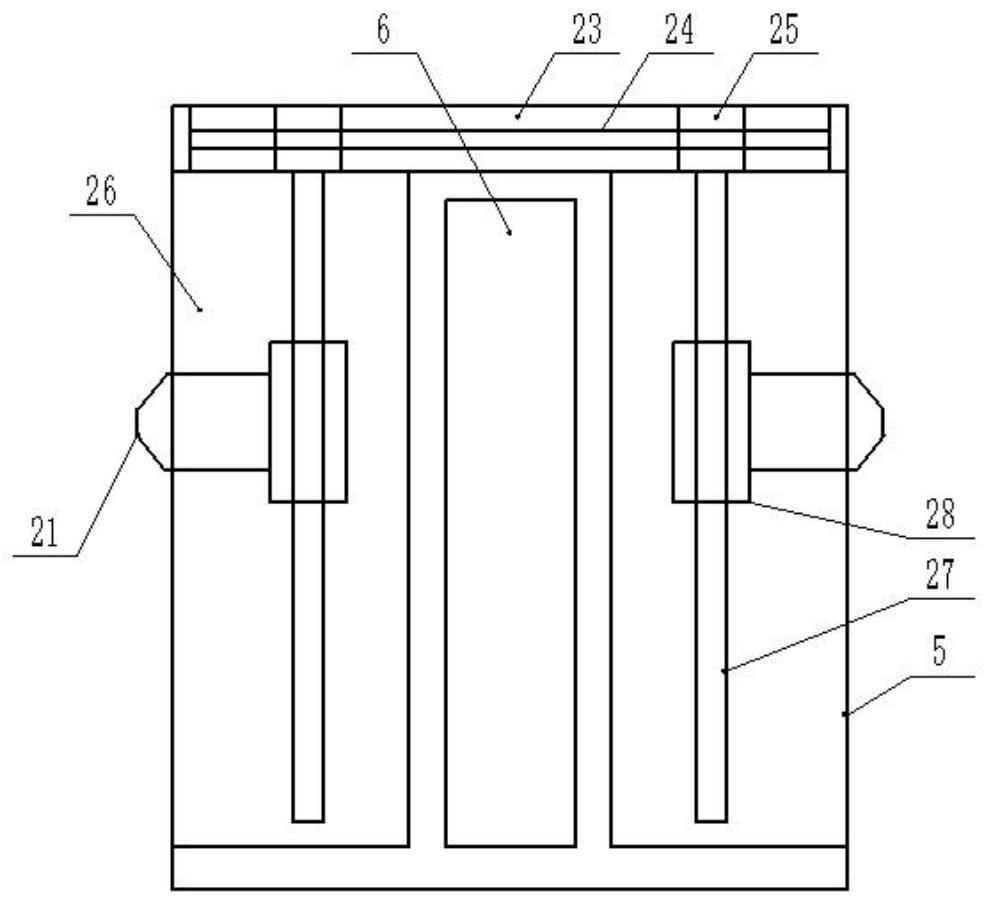

[0015] Embodiment 3: see figure 1 , figure 2 Now, a kind of ceramsite plate processing platform provided by the present invention will be described, one end of the first torsion spring 15 is fixedly connected with the inner end wall of the dust removal housing 10, and the other end is connected with the first rotating shaft 12 The outer end wall is fixedly connected, one end of the second torsion spring 17 is fixedly connected to the inner end wall of the dust removal housing 10, and the other end is fixedly connected to the outer end wall of the second rotating shaft 13, the filter The belt 14 is evenly and densely provided with filter mesh holes, and the filter belt 14 is wound on the first rotating shaft 12, and one end of its length direction is connected with the second rotating shaft 13 located on one side, and the other end is connected with the second rotating shaft 13 located on the other side. The second rotating shaft 13 on the side is connected, and the inner end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com