Display panel

A display panel and substrate technology, applied in identification devices, instruments, etc., can solve the problems of display panel cost increase, small line width design accuracy doubts, circuit overheating, etc., to reduce production costs and circuit overheating risks, and reduce line width accuracy Requirements, the effect of reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

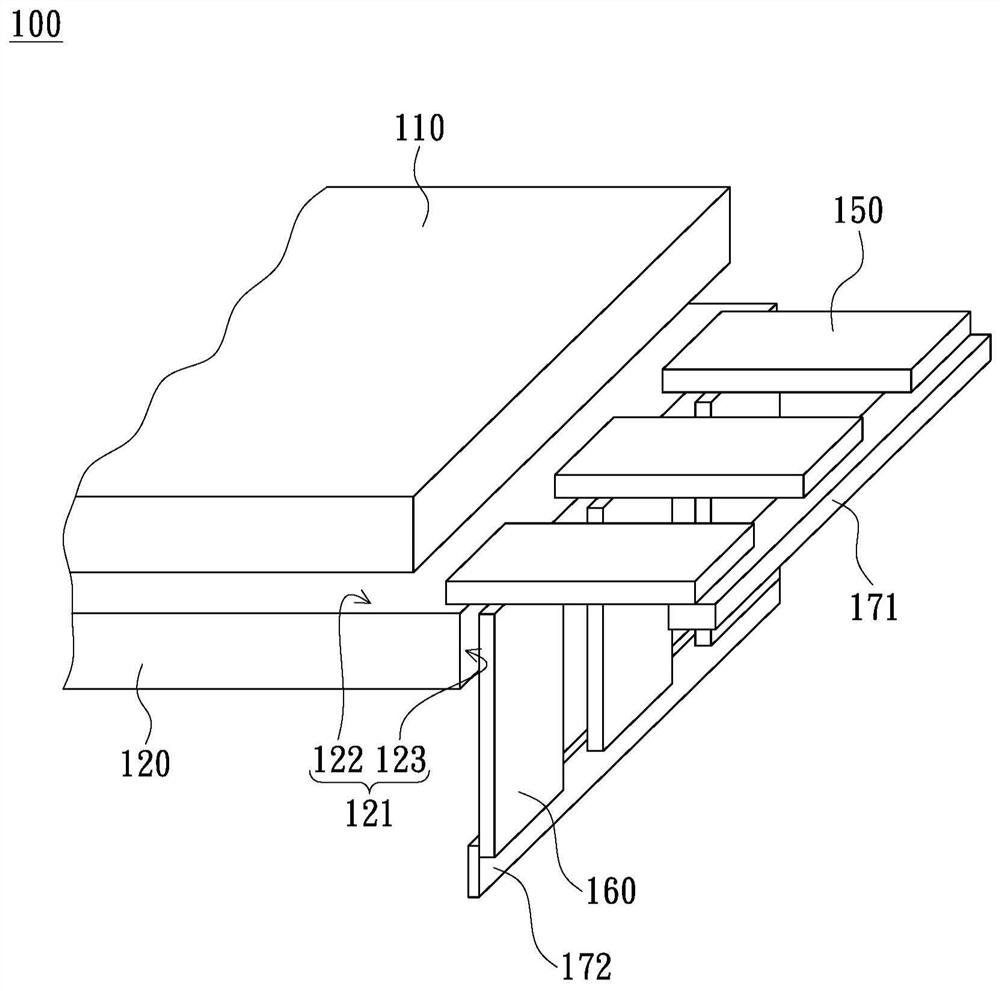

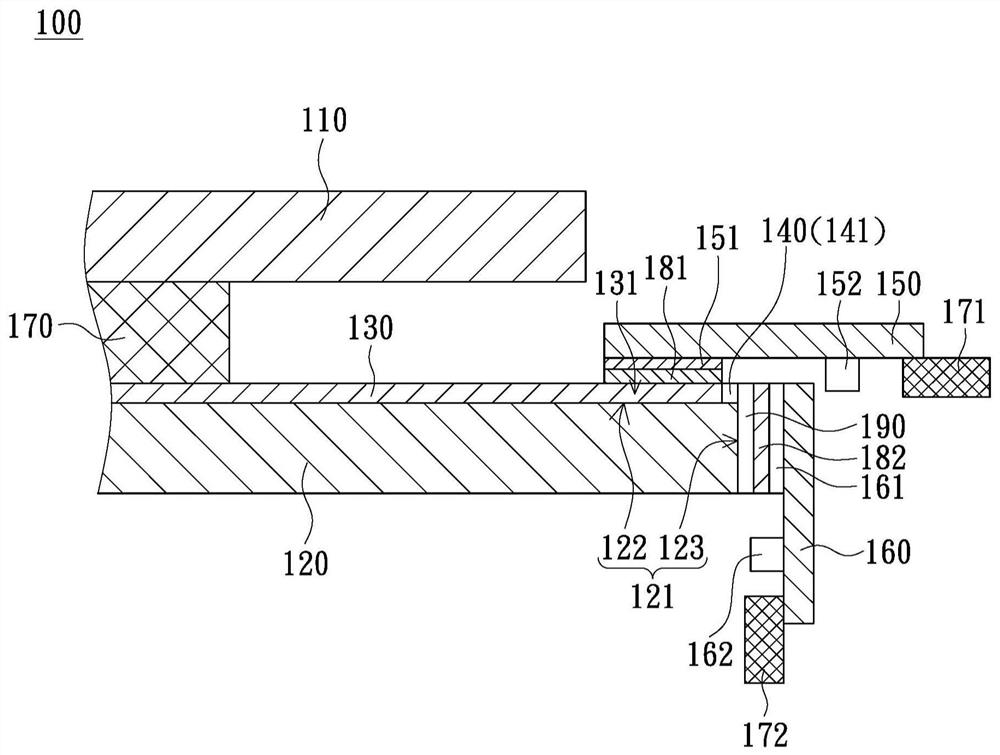

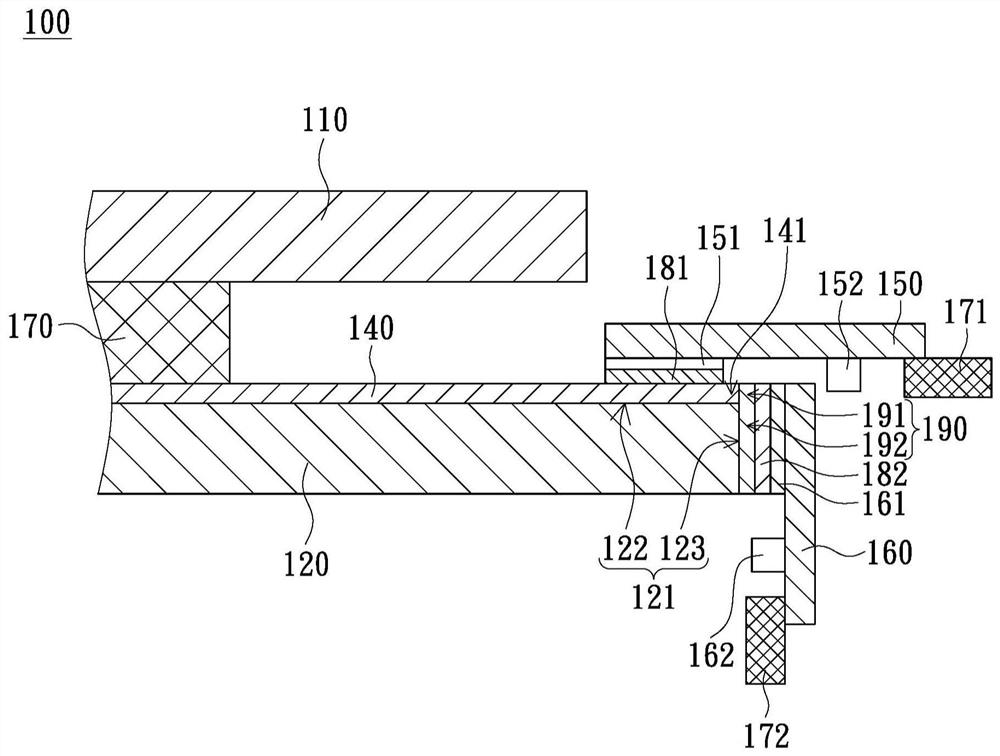

[0052] figure 1 It is a partial perspective view of a display panel according to an embodiment of the present invention. figure 2 for figure 1 A schematic cross-sectional view of the display panel shown. image 3 for figure 1 Another schematic cross-sectional view of the display panel shown. Figure 4 for figure 1 A schematic right-side view of the display panel shown. Figure 5 for figure 1 A schematic top view of the display panel shown. For easy understanding, the Figure 4 Omit the first circuit board 150, the third bonding end 151, the first driver chip 152, the second circuit board 160, the second driver chip 162, the first external circuit board 171, the second external circuit board 172 and the upper conductive bonding layer 181 , and at Figure 5 Omit the first circuit board 150, the third bonding end 151, the first driving chip 152, the second circuit board 160, the fourth bonding end 161, the second driving chip 162, the first external circuit board 171, a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap