High mountain windproof porcelain insulator

A technology of porcelain insulators and insulators, which is applied in the field of alpine windproof porcelain insulators, can solve the problems of performance degradation, achieve good protection, avoid pressure shocks, and avoid excessive instantaneous shocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

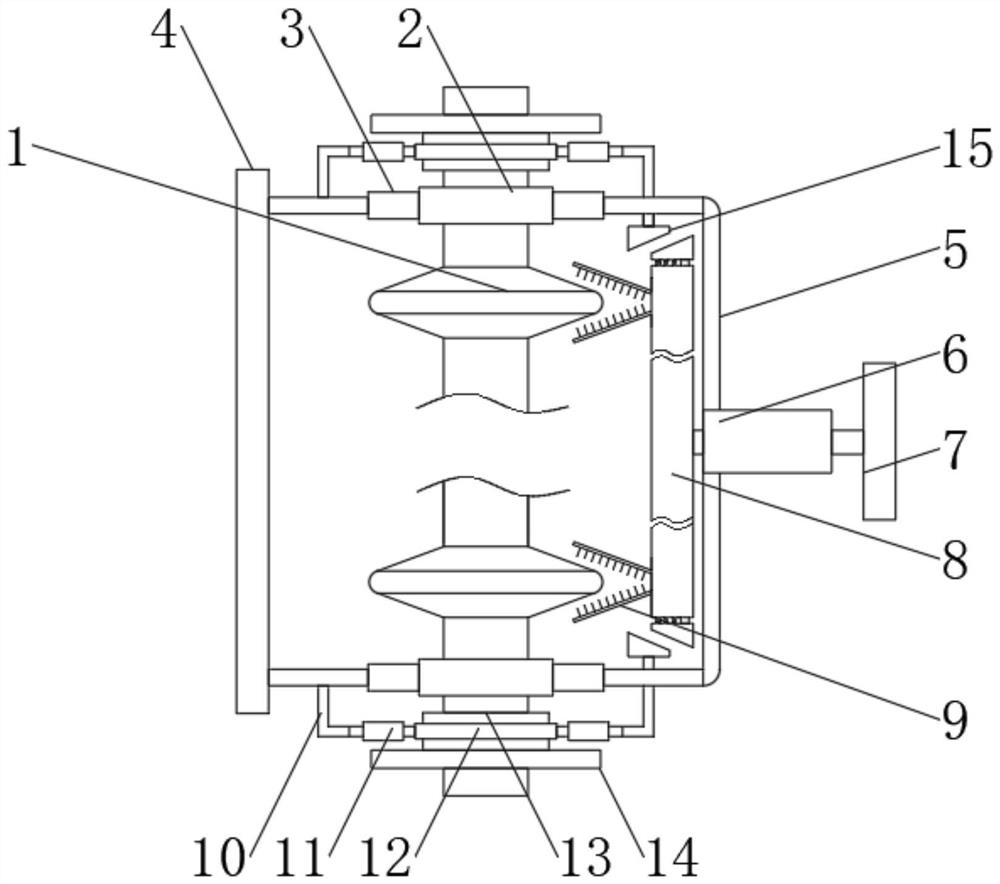

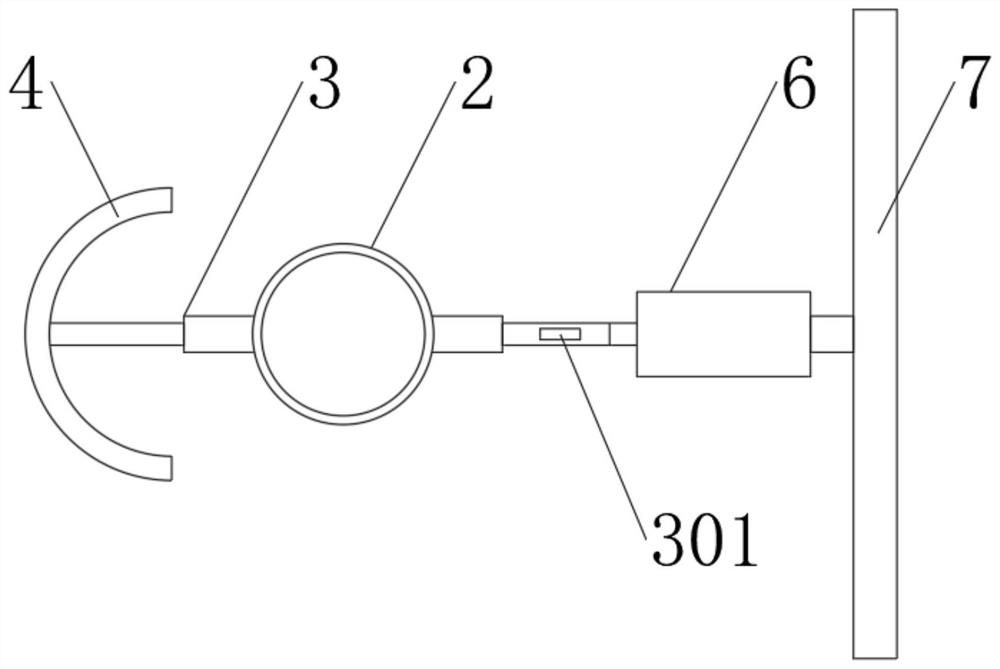

Embodiment 1

[0030] Embodiment one, by Figure 1-7 Given, the present invention includes an insulator body 1, on which a bearing 2 is mounted symmetrically for rotation, and a telescopic rod 3 is mounted symmetrically on the bearing 2, wherein a windshield 4 is installed at one end of one telescopic rod 3, and the other telescopic rod 3 One end of the driver 6 is equipped with a vertically arranged connecting rod 5, and the connecting rod 5 is symmetrically installed on the driver 6. One end of the driver 6 is equipped with a wing plate 7, and the other end of the driver 6 is installed with a locator 8, and the locator 8 is symmetrically installed. The brush holder 9, the telescopic end of the telescopic rod 3 is equipped with an L-shaped rod 10, and one end of the L-shaped rod 10 is equipped with a connector 11, and one end of the connector 11 is installed on the ring body 12, and the ring body 12 is rotated and installed on the insulator. On the cylinder 13 outside the body 1, the cylind...

Embodiment 2

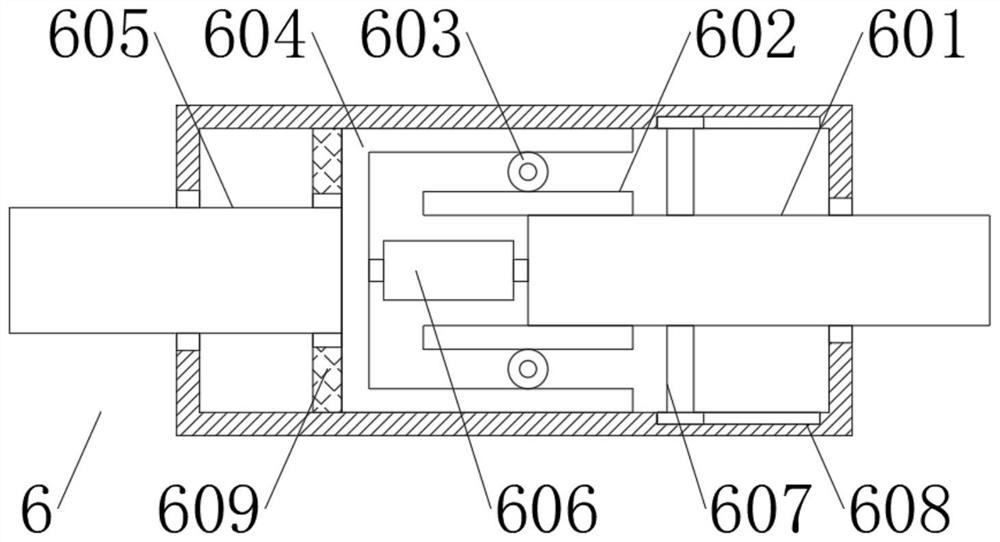

[0033]Embodiment 2, on the basis of Embodiment 1, U-shaped frames 6061 are installed symmetrically inside the buffer assembly 606, and the U-shaped frames 6061 are arranged alternately, and elastic mechanisms 6062 are installed in the spaces formed between the U-shaped frames 6061 , a good cushioning effect can be achieved through multiple elastic mechanisms 6062, thereby avoiding the contact between the rear rod body 601 and the U-shaped frame 6061, thereby improving the cushioning performance of the buffer assembly 606 and ensuring its performance. The U-shaped frame 6061 The outer wall is equipped with a connecting frame 6063, and the elastic mechanism 6062 includes symmetrically arranged slide rails 6064. X-shaped rods 6065 are installed between the slide rails 6064, and buffer springs 6066 are installed between adjacent rod bodies in the X-shaped rods 6065. The corners of the bar 6065 are all rotatably mounted with bearings 6067, and the bearings 6067 are slidably installe...

Embodiment 3

[0034] Embodiment 3, on the basis of Embodiment 1, an L-shaped rod 10 is installed on the telescopic end of the telescopic rod 3, and a connector 11 is installed on one end of the L-shaped rod 10, and one end of the connector 11 is installed on the ring body 12, and the ring The body 12 is rotatably mounted on the cylinder body 13 located outside the insulator body 1, and the cylinder body 13 is installed on the mounting bracket 14, and the wind force received by the windshield 4 can be transmitted to the cylinder body 13 through the connector 11, thereby avoiding its impact on the The insulator body 1 is impacted, thereby playing a good protective role for the insulator body 1, and the L-shaped rod 10 and the connector 11 are symmetrically arranged, and the inside of the connector 11 is symmetrically installed with a short rod 1101, and one end of the two short rods 1101 Sliders 1102 are installed, and telescopic springs 1103 are installed between the middle of the two short r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com