Patents

Literature

75results about How to "Avoid stress shocks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

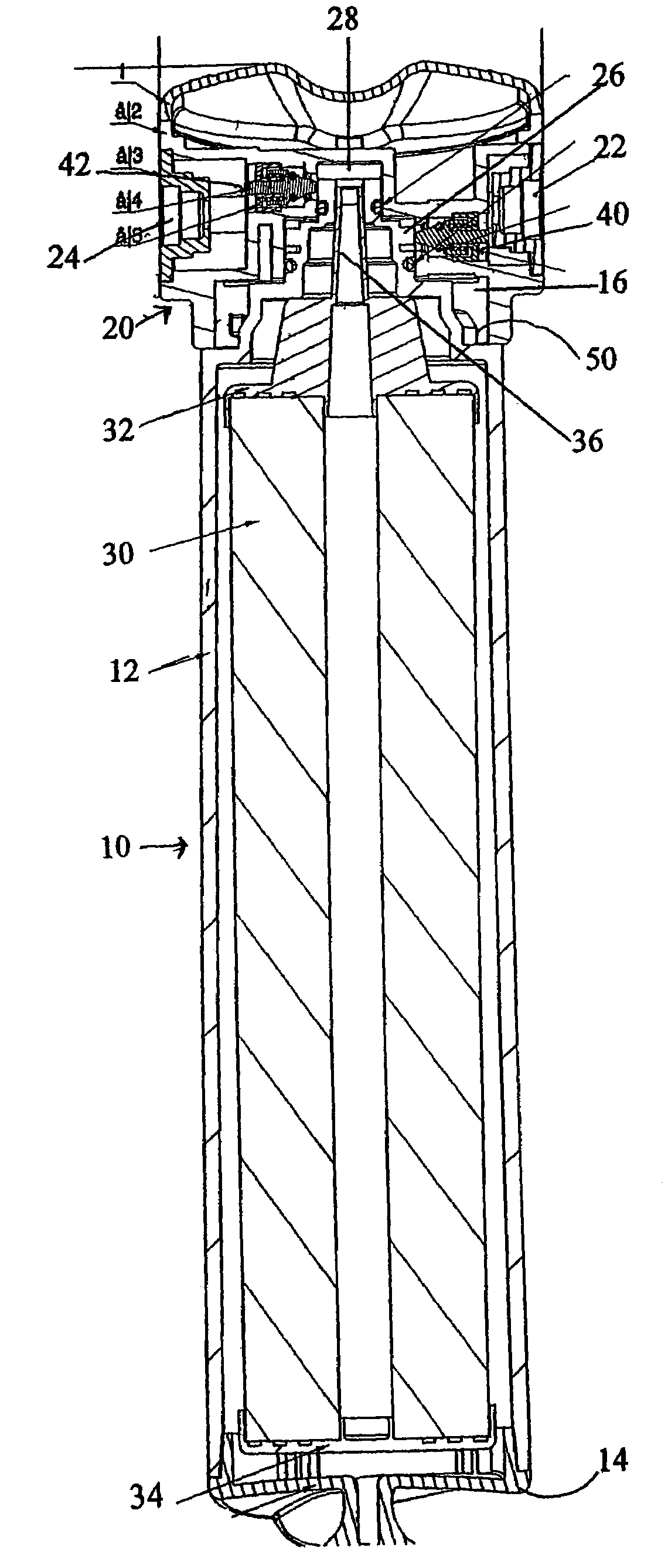

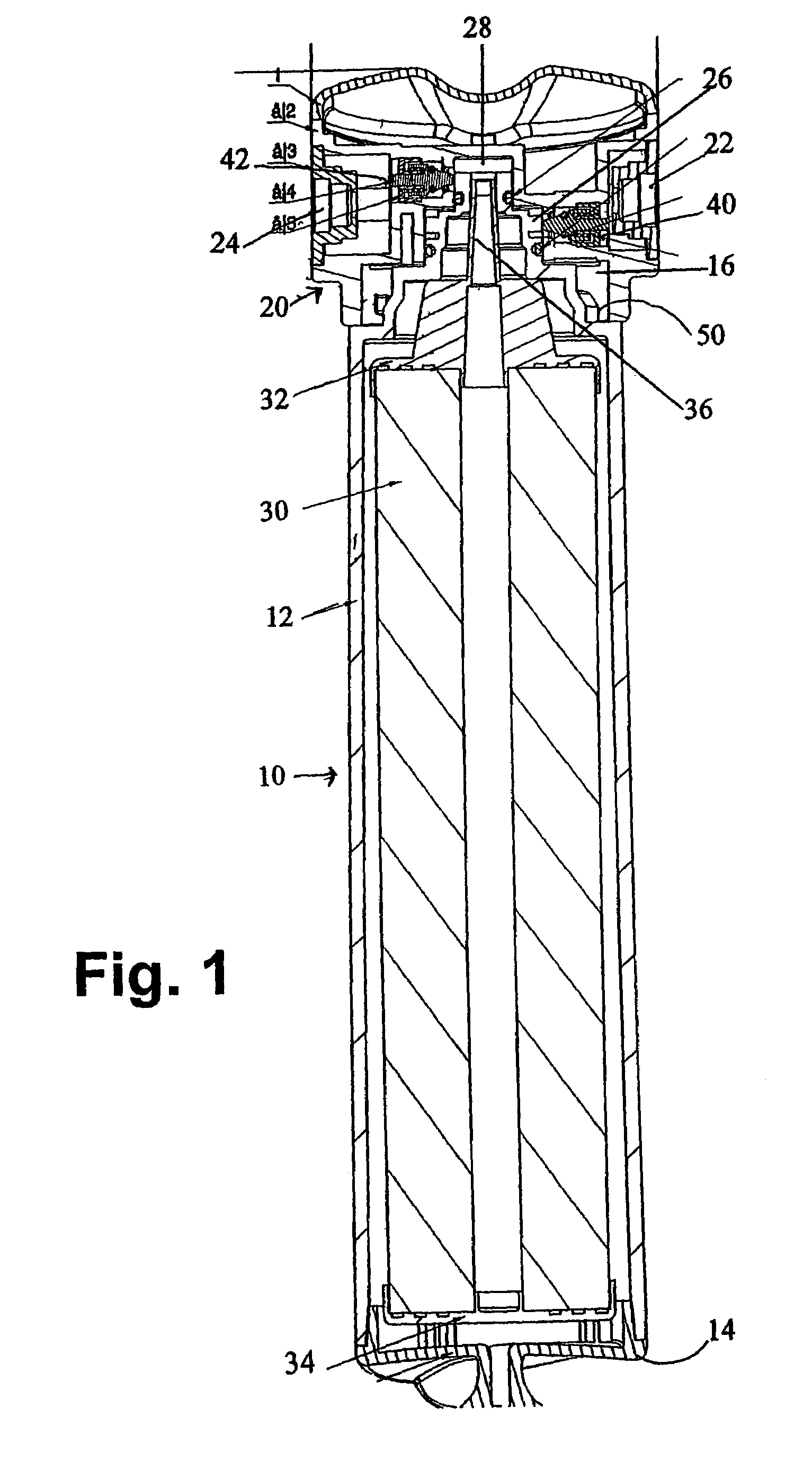

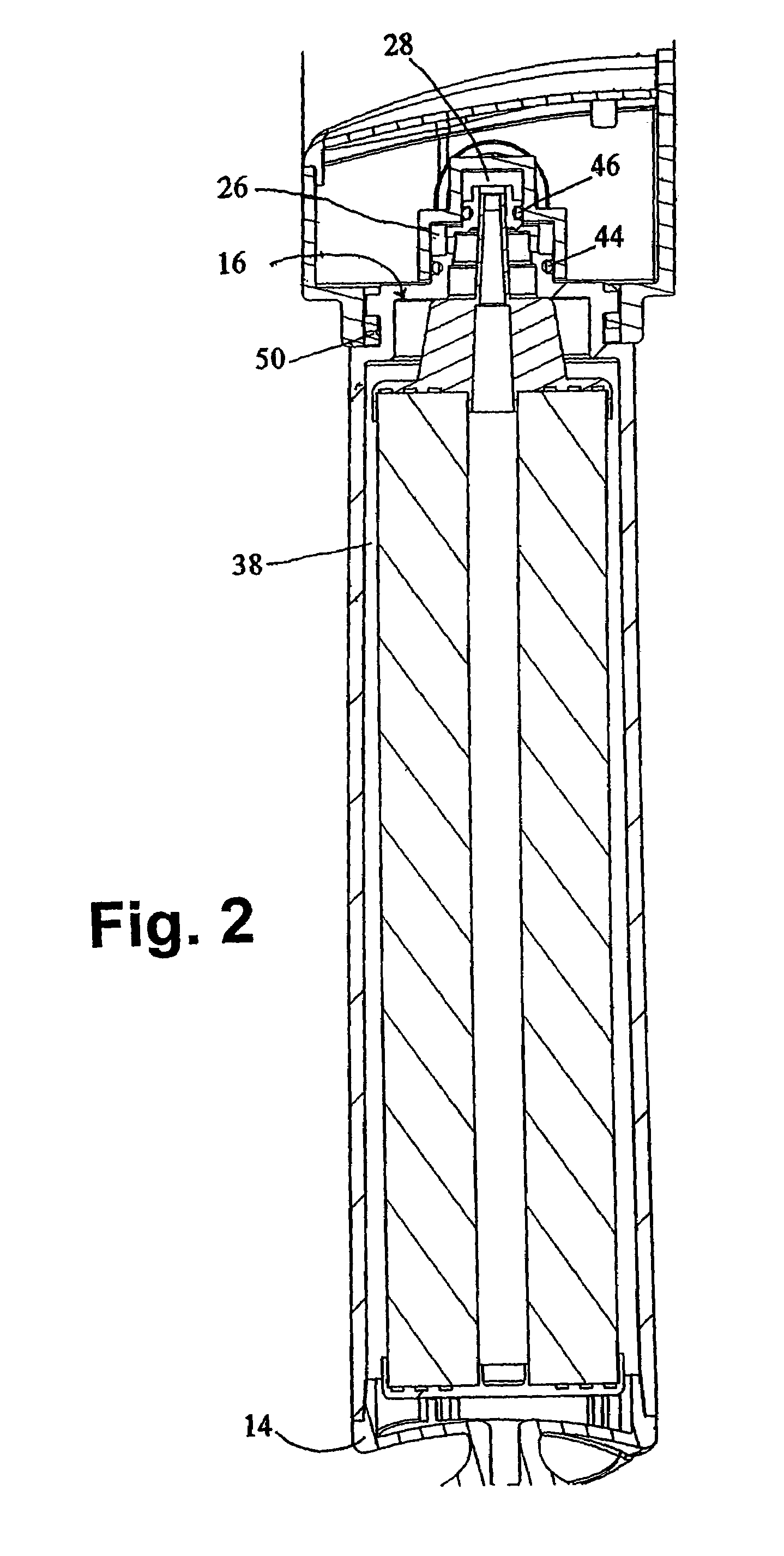

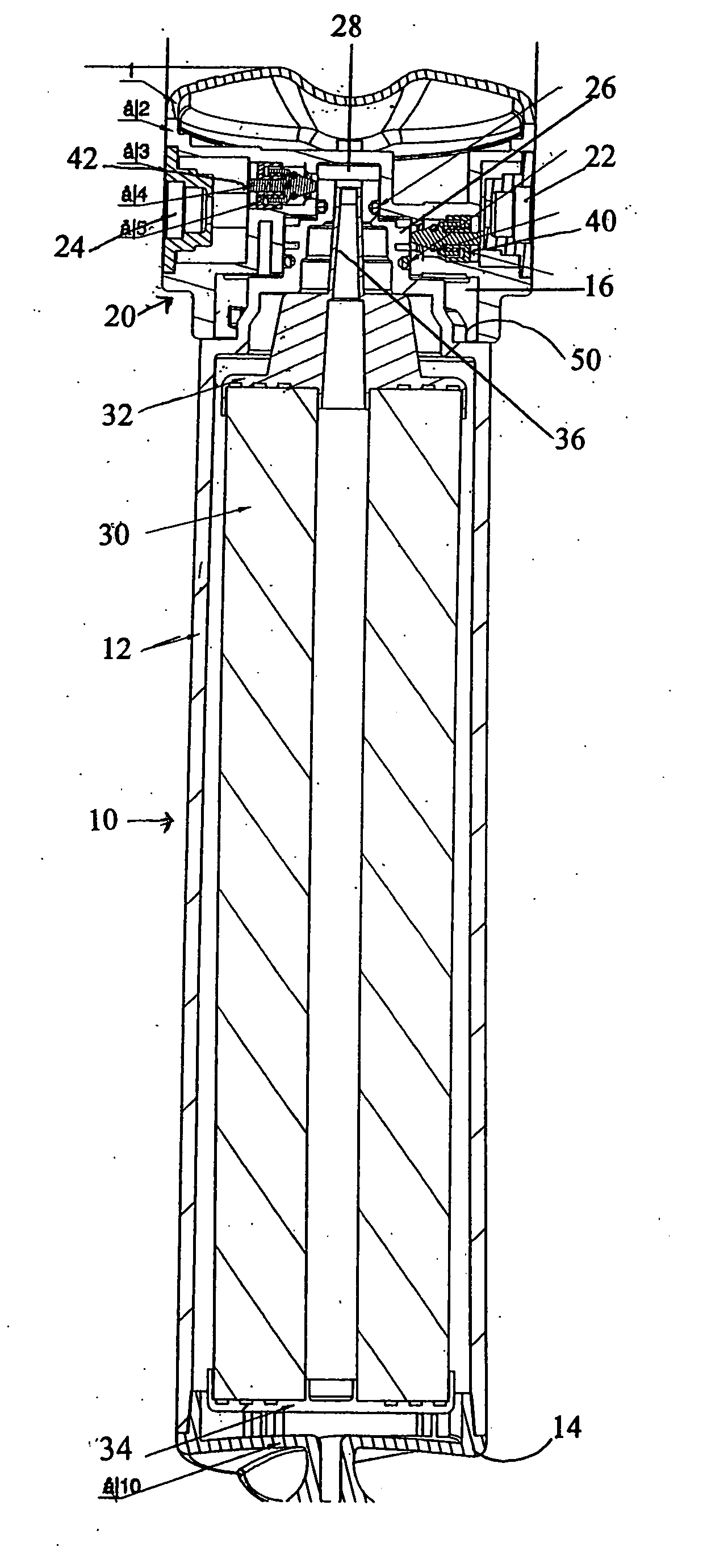

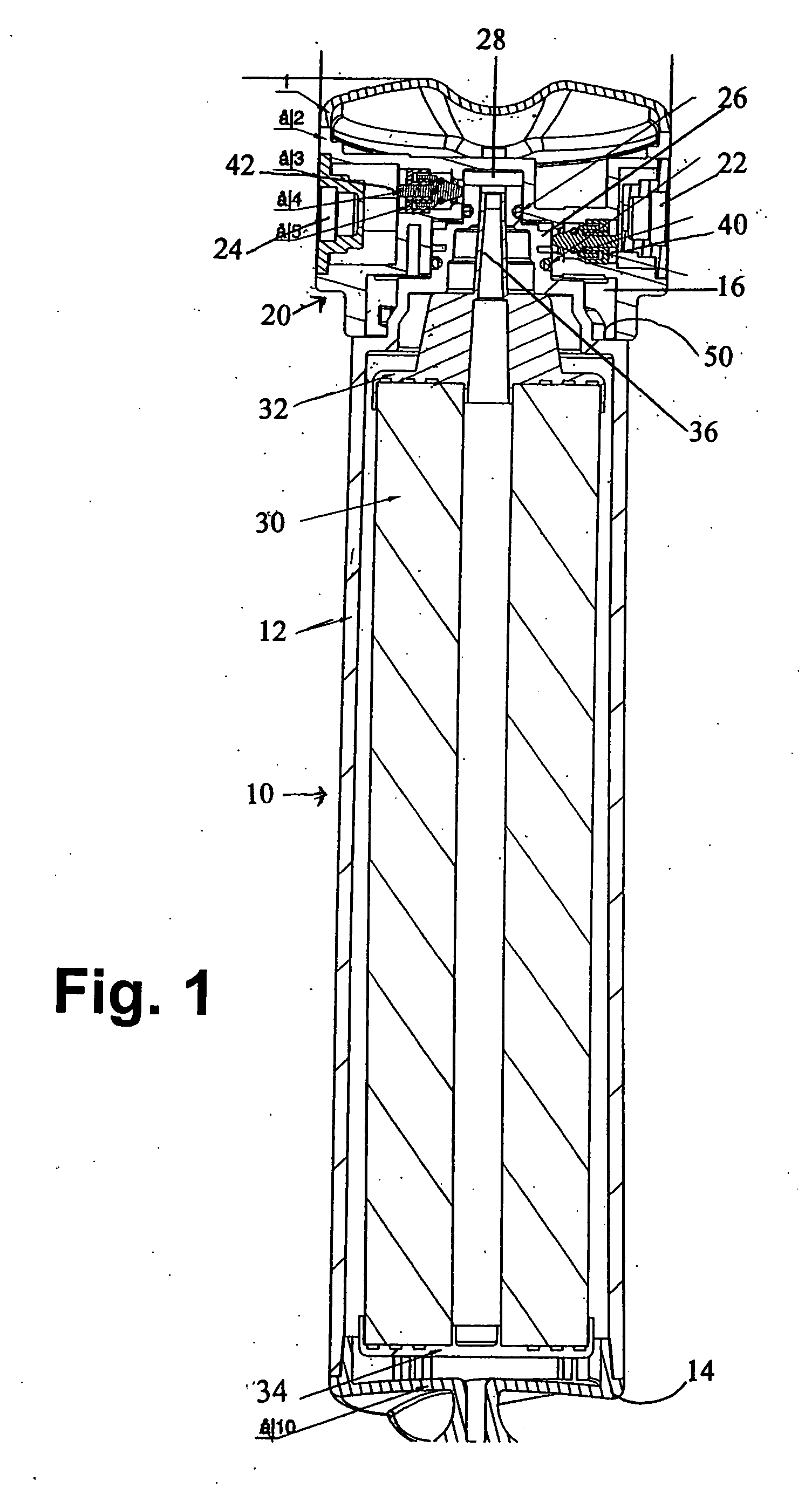

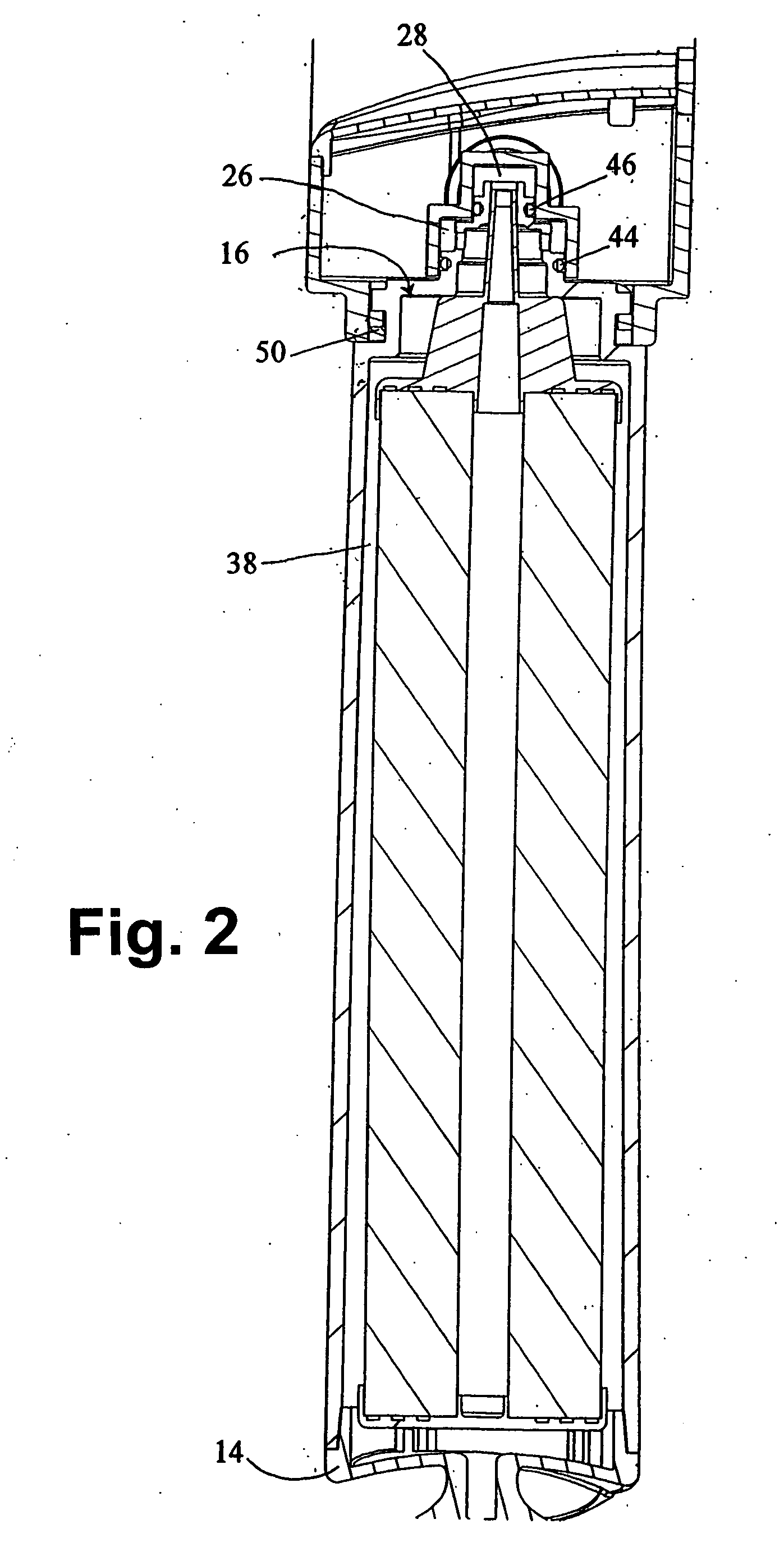

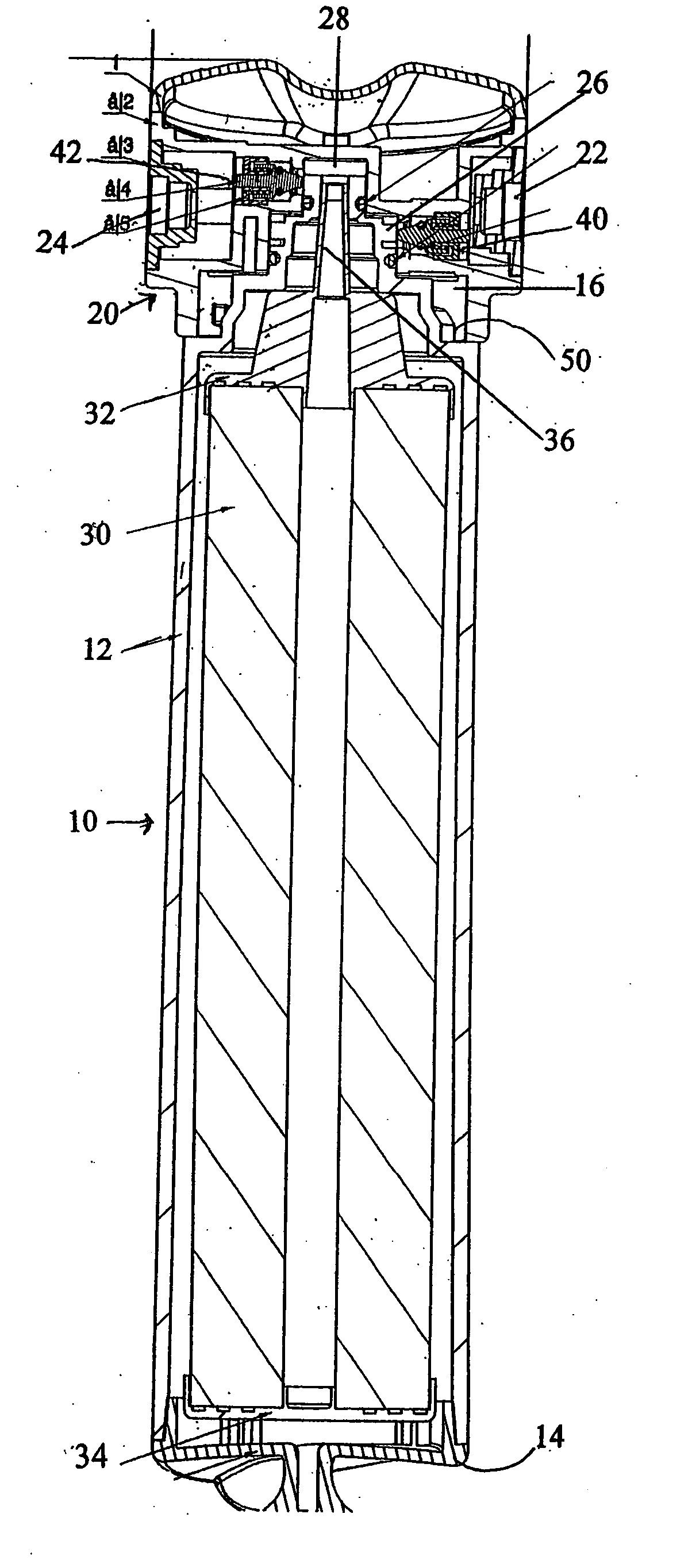

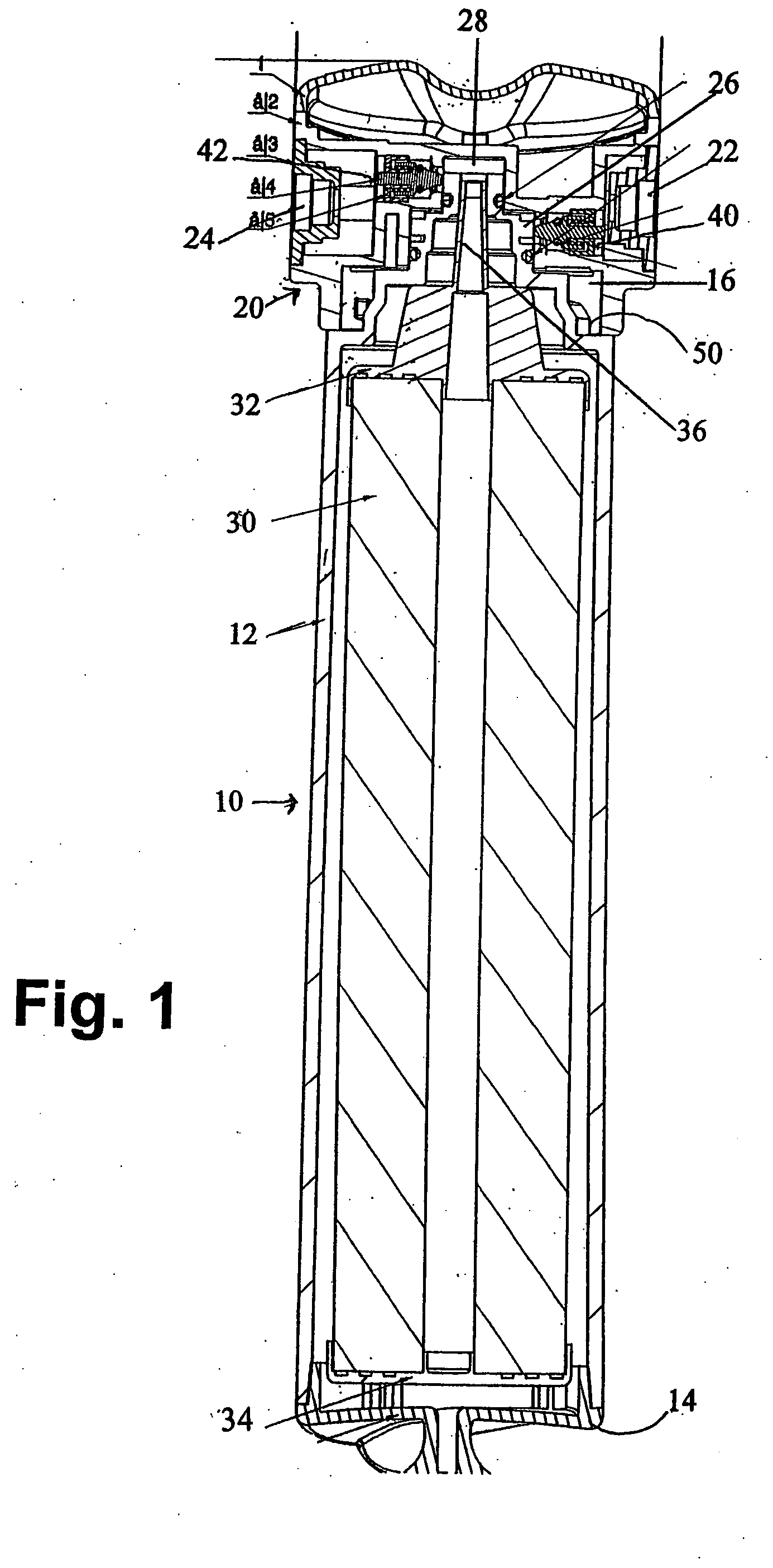

Fluid filter apparatus and method

ActiveUS6977039B2Easy to installAvoid stress shocksSedimentation separationMultistage water/sewage treatmentFilter systemEngineering

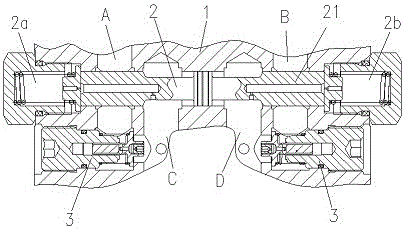

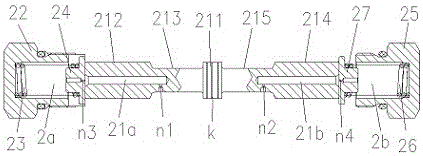

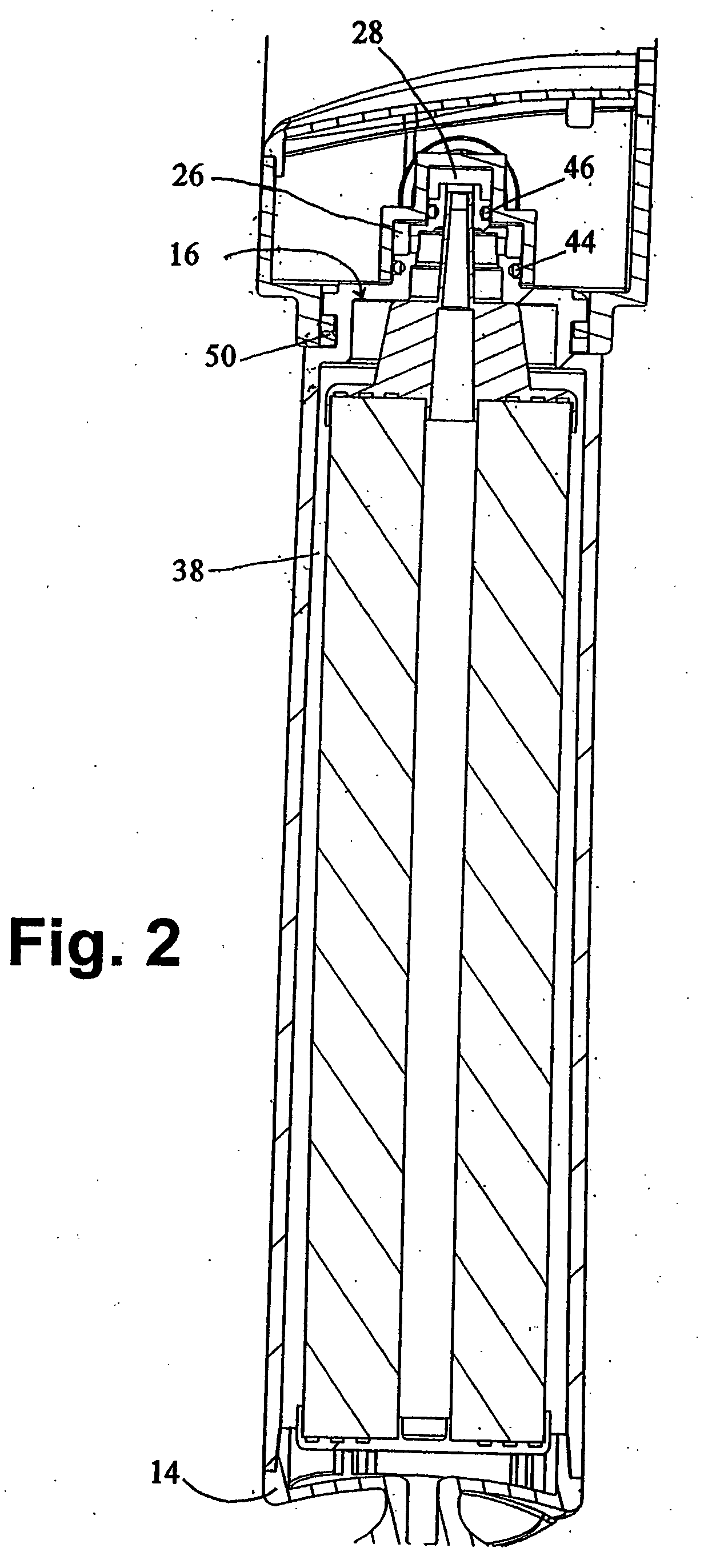

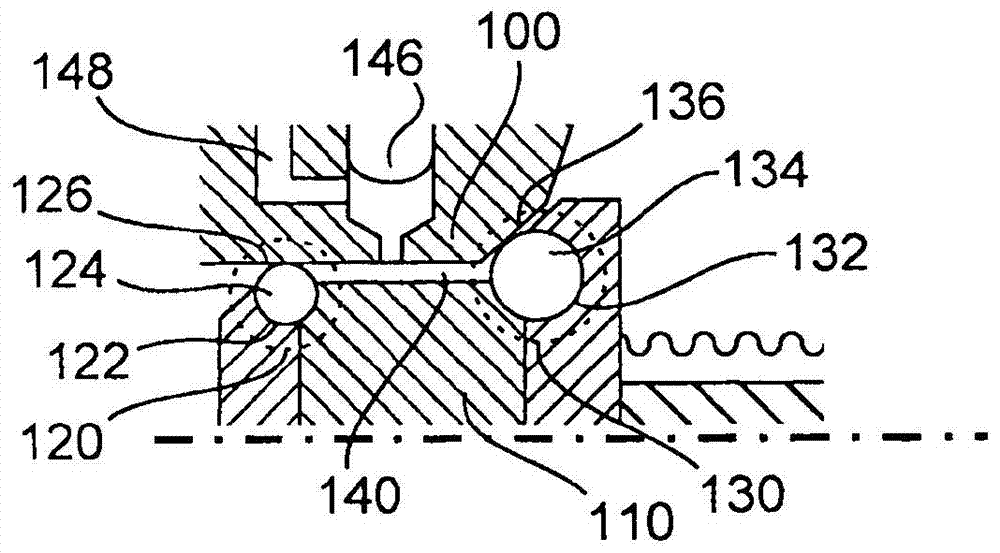

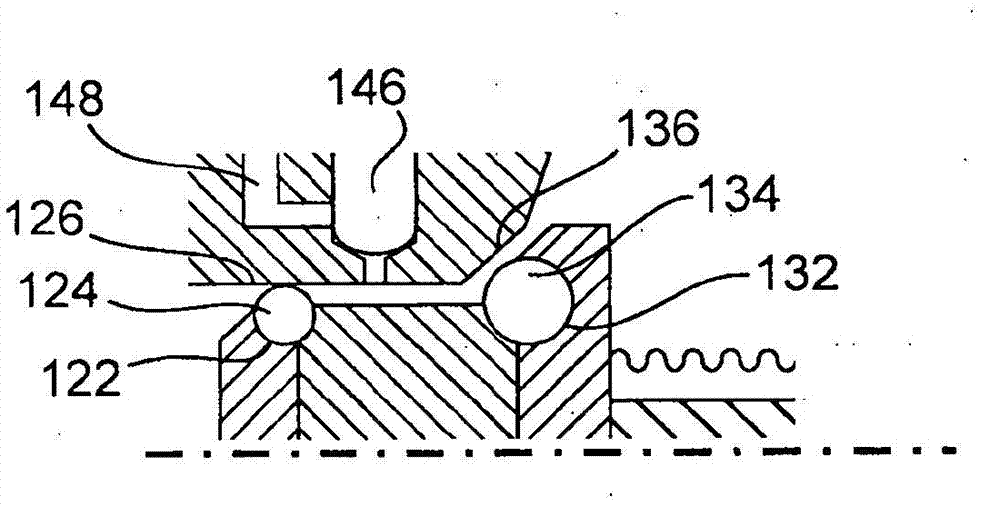

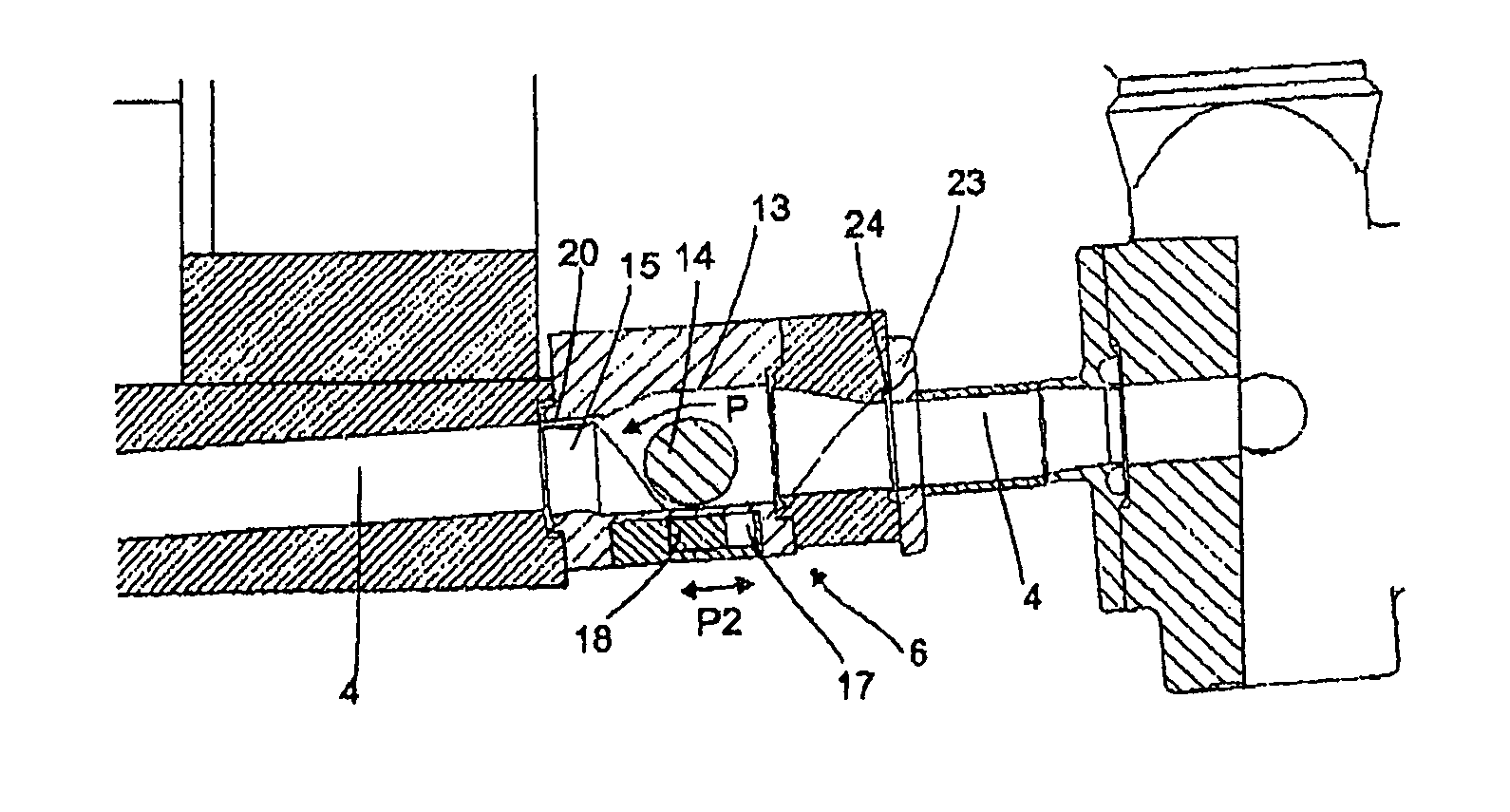

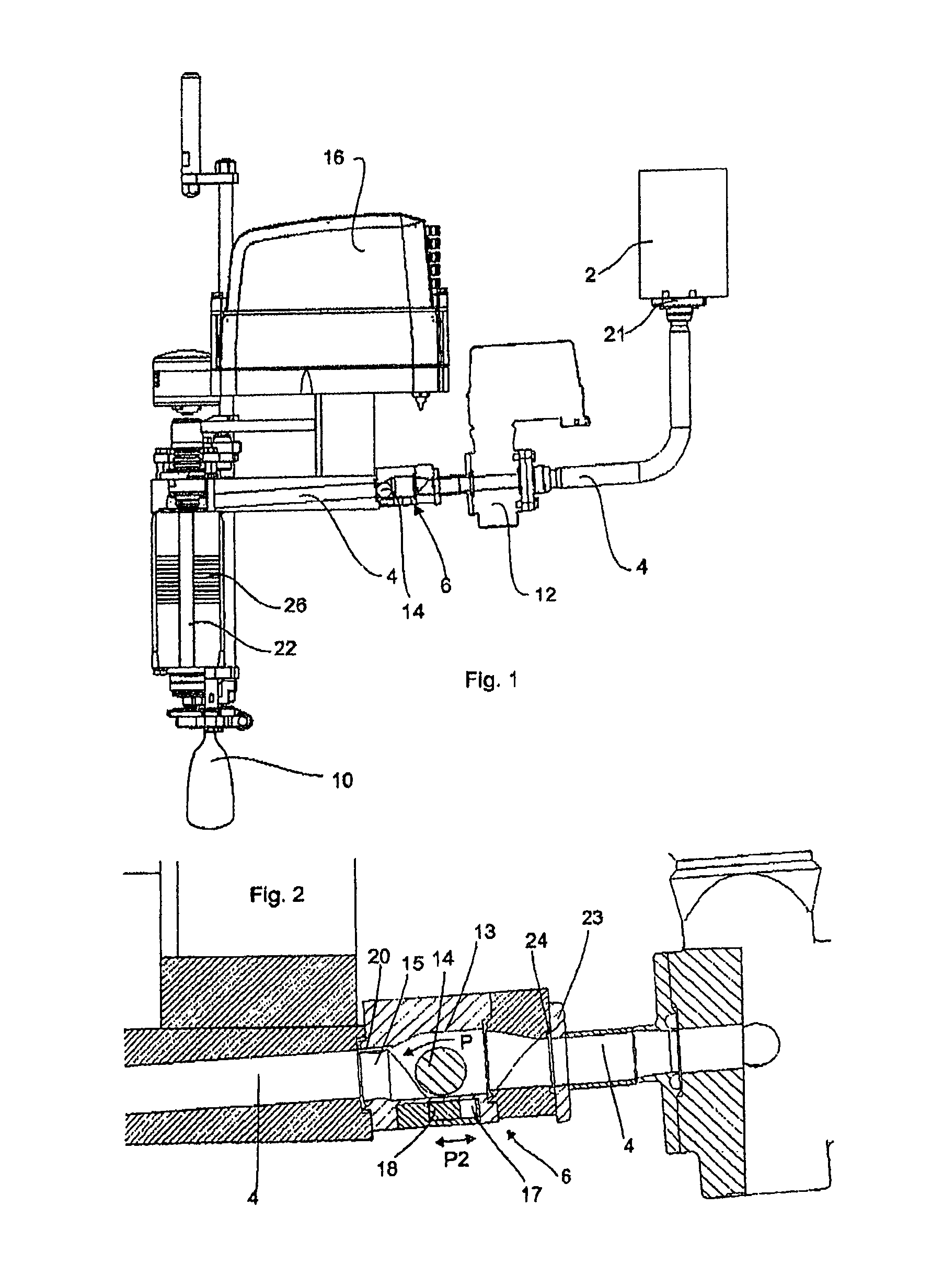

A fluid filter system has a manifold having a fluid inlet with an inlet stop and a fluid outlet with an outlet stop and a cartridge seat. A cartridge is separable from the manifold and adapted to mount and dismount in the manifold. The cartridge has a filter housing containing a filter for filtering fluid, and an integral closure member having a first level and a second level. A radial inlet port is on a face of the first level of the closure member and an axial outlet port is on top of the second level of the closure member. A first boss on the closure member opens the inlet stop when the cartridge is mounted in the manifold. A second boss on the closure member is disposed to open the outlet stop when the cartridge is mounted in the manifold. The bosses engage the stops sequentially.

Owner:NATURAL CHOICE CORP

Fluid filter mounting apparatus and method

InactiveUS20050218059A1Simple twisting motionEasy to installCartridge filtersFluid intakeFluid output

A fluid filter mounting apparatus includes a mounting bracket having a fluid intake and a fluid output, a first manifold and second manifold within the mounting bracket, each of the first manifold and the manifold having a fluid inlet and a fluid outlet. The fluid intake of the mounting bracket is in fluid communication with the fluid inlet of the first manifold. The fluid outlet of the first manifold is in fluid communication with the fluid inlet in the second manifold and the fluid outlet of the second manifold is in of fluid communication with the fluid output of the mounting bracket. A first mounting throughhole and a second mounting throughhole in the bracket are each dimensioned to align a first cartridge housing and a second cartridge housing with each of the first and second manifolds. Each of the throughholes are also dimensioned to secure a first portion of the filter cartridge housing when a closure member of the filter cartridge housing is seated in the manifold.

Owner:KNOLL GEORGE

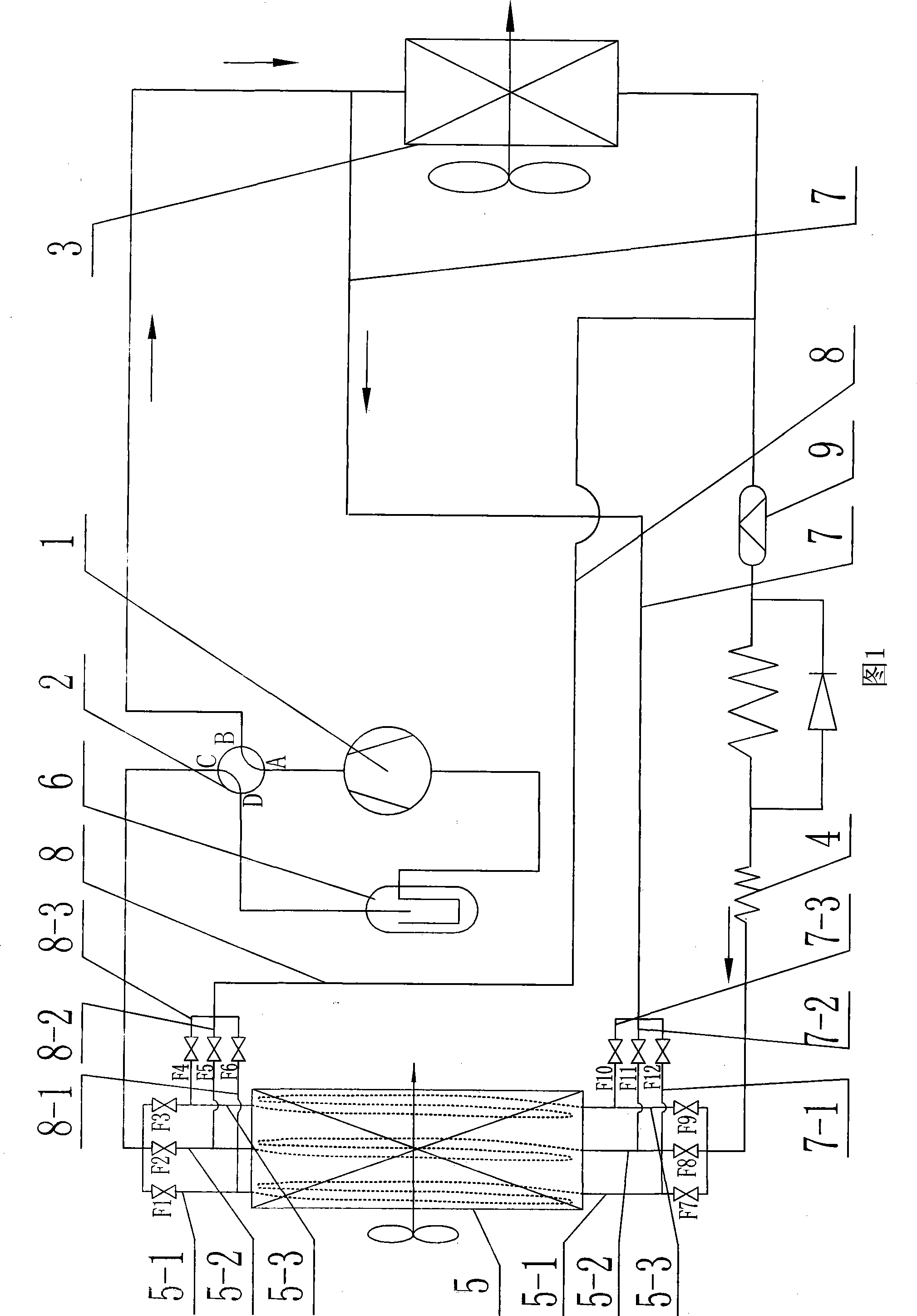

Air source heat pump system capable of intermittently supplying heat under defrosting operating condition

InactiveCN101435639AReduces drastic changes in inspiratory pressureRealize uninterrupted heatingHeat pumpsCorrosion preventionVapor–liquid separatorEngineering

The invention discloses an air source heat pump system which can unintermittently supply heat under the working condition of defrosting and relates to an air source heat pump system. The system solves the problems that the prior defrosting mode has drastic change of air suction pressure, stops heat supply and blows cold wind indoors in the defrosting process. The outlet end of a compressor is communicated with a first port of a four-way reversing valve; a second port of the four-way reversing valve is communicated with the inlet end of an indoor machine; the outlet end of the indoor machine is respectively communicated with one end of a first bypass shunt circuit, one end of a second bypass shunt circuit and one end of a third bypass shunt circuit through a throttling mechanism; the other end of the first bypass shunt circuit, the other end of the second bypass shunt circuit and the other end of the third bypass shunt circuit are communicated with a third port of the four-way reversing valve; a fourth port is communicated with the inlet end of a gas-liquid separator; and the outlet end of the gas-liquid separator is communicated with the inlet end of the compressor. The system realizes unintermittent heat supply in the defrosting process, simultaneously reduces drastic change of air suction pressure of the compressor and is more stable in the conversion process of heat supply and defrosting.

Owner:HARBIN INST OF TECH

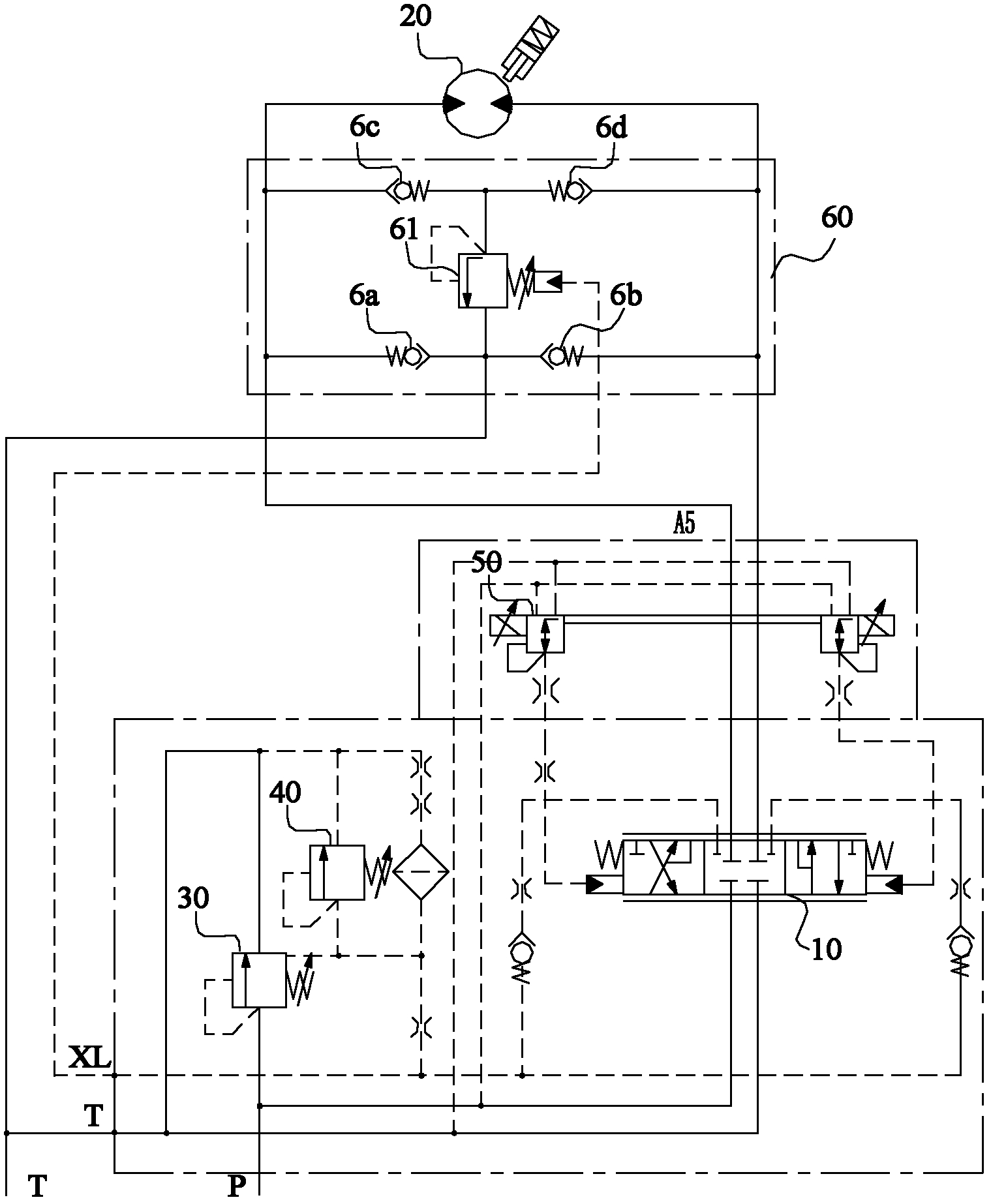

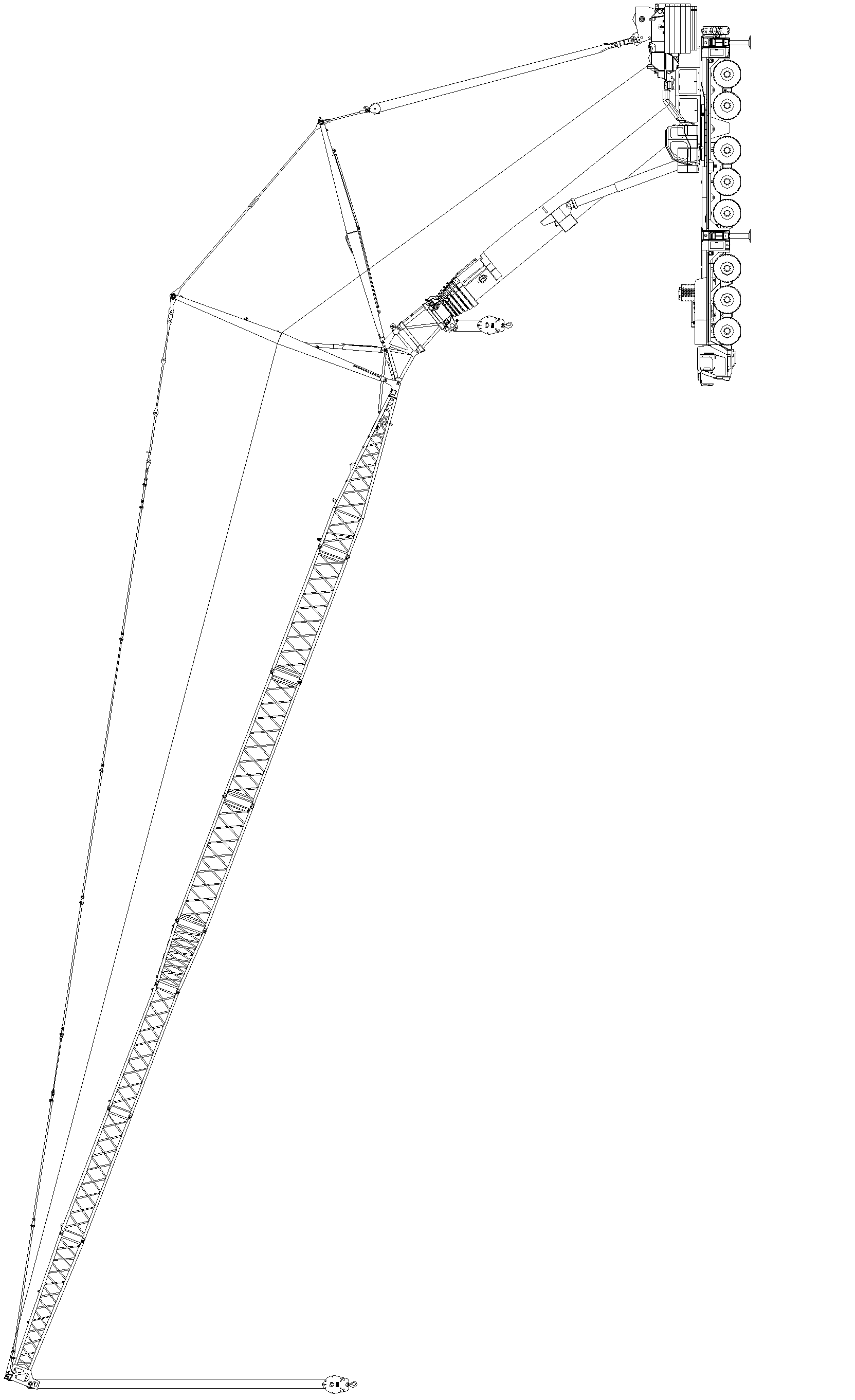

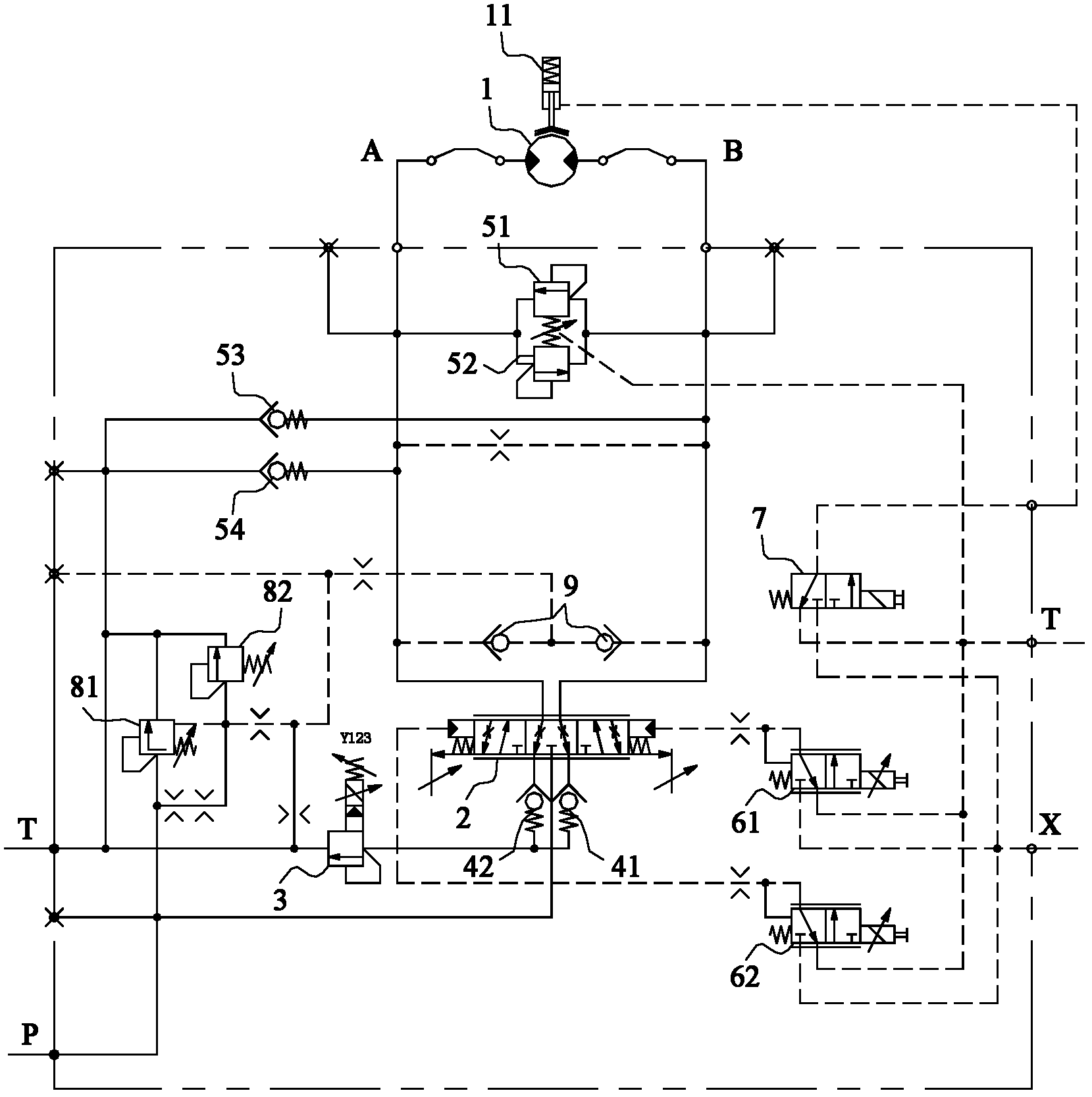

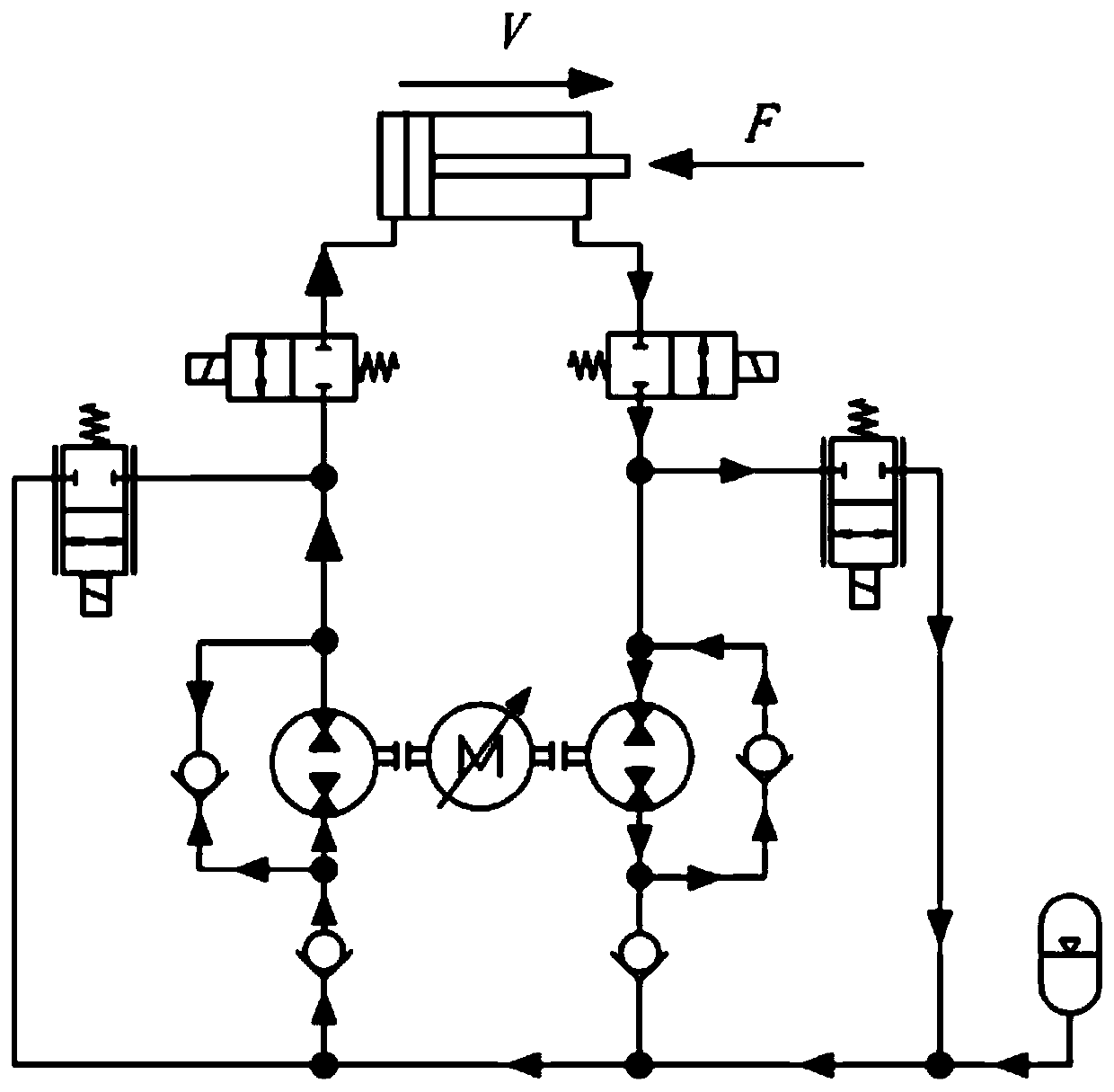

Superstructure rotary hydraulic control system and crane with same

ActiveCN102515025AImprove stabilityIncrease stiffnessLoad-engaging elementsCranesSystem pressureEngineering

The invention discloses a superstructure rotary hydraulic control system, which comprises a first direction control valve and a variable backpressure element, wherein the direction control valve is arranged between a rotating motor and system pressure and system oil return oil circuits, the variable backpressure element is arranged between an oil return port of the first direction control valve and the system oil return oil circuit, and the first direction control valve is in one-way communication with the variable backpressure element. Compared with the prior art, the superstructure rotary hydraulic control system has the advantages that when the moment of resistance is higher in rate of change under the operating conditions of rotation starting and stopping, oil return pressure of the variable backpressure element can be increased by adjusting the variable backpressure element, and accordingly system rigidity can be improved to overcome pressure impact under the operating conditions of starting and stopping, and improvement of rotating performance and overall stability is guaranteed reliably. Meanwhile, since the system oil return oil circuit is provided with a fixed backpressure constantly, system rigidity is improved correspondingly, and high impact resistance can be achieved in the whole superstructure rotation process. The invention further provides a crane with the superstructure rotating hydraulic control system.

Owner:XUZHOU HEAVY MASCH CO LTD

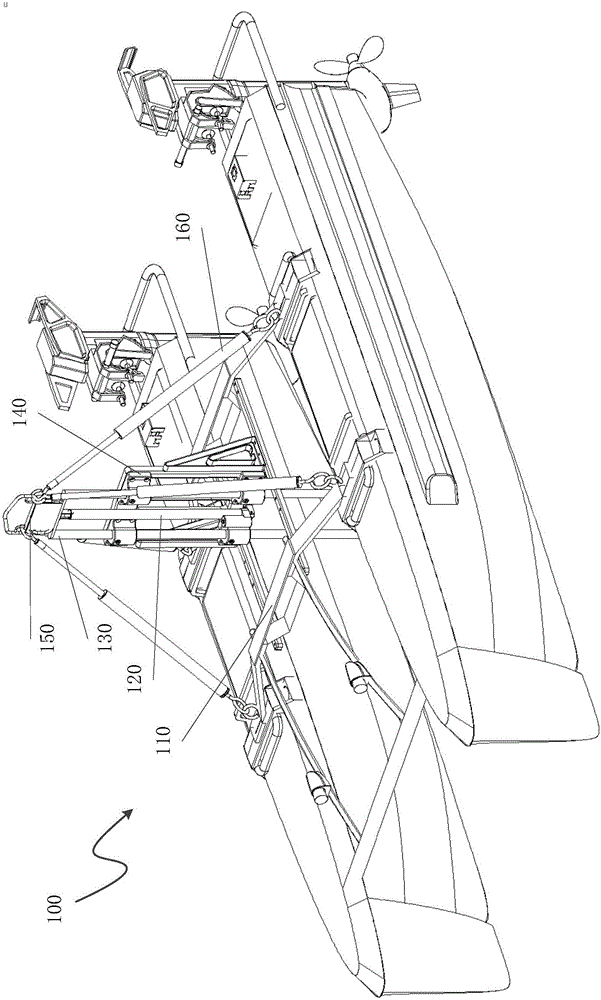

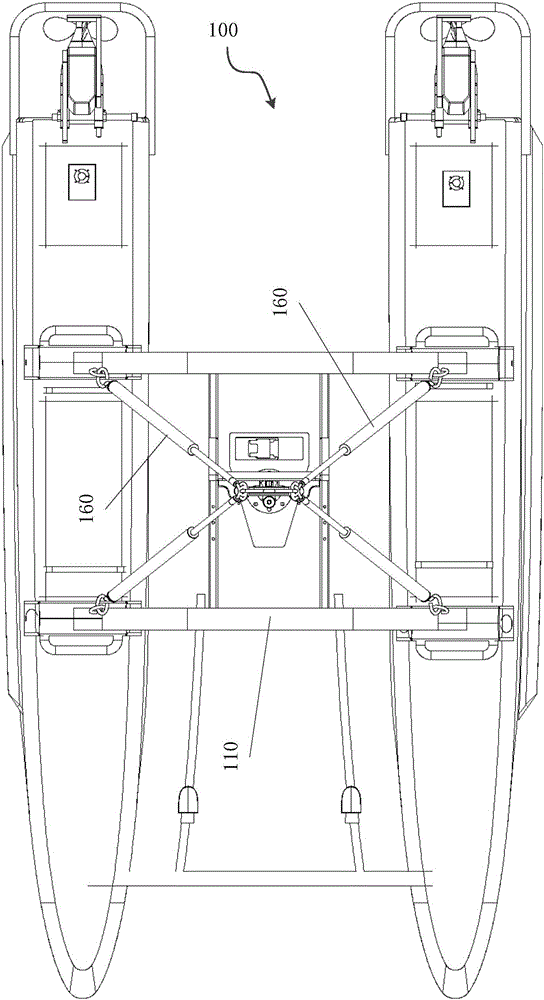

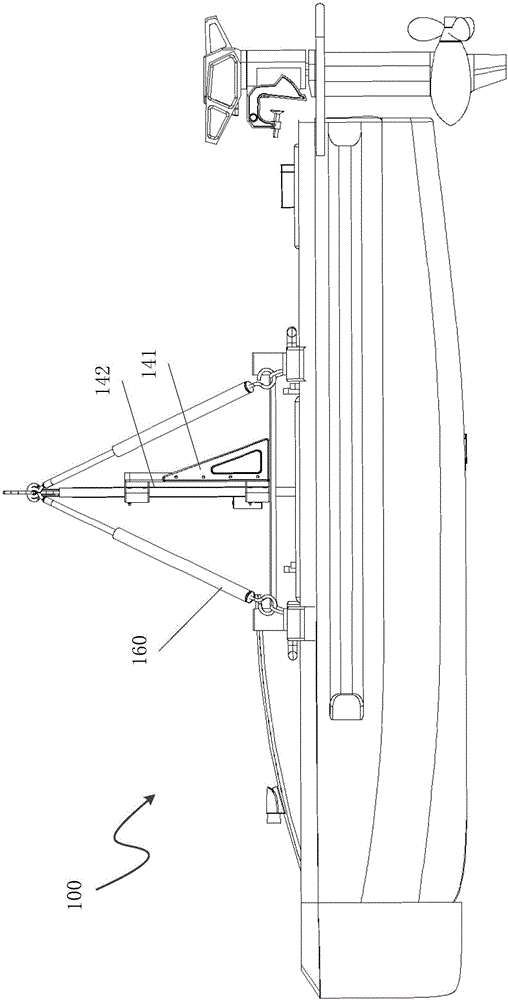

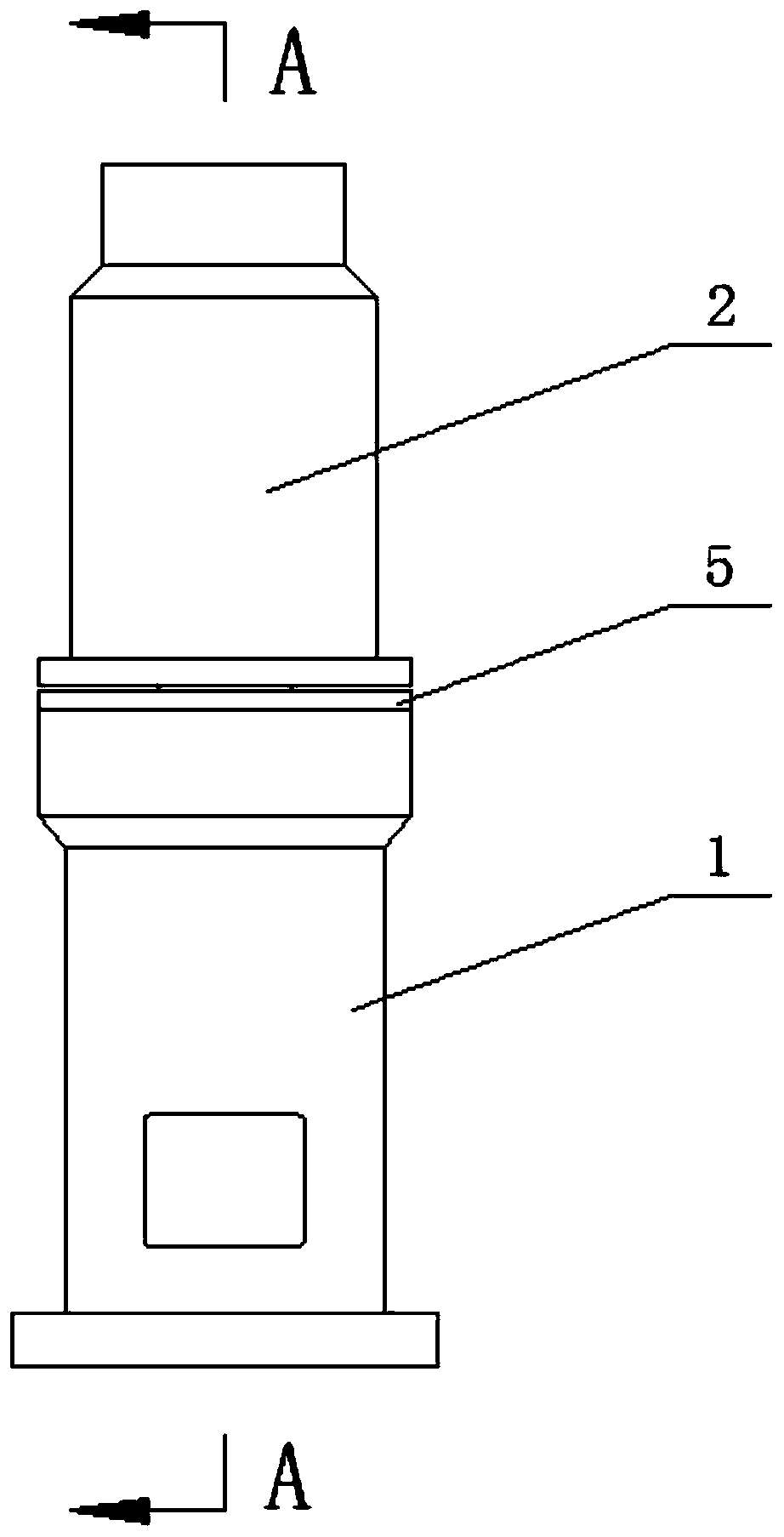

Support structure and ship

Owner:SHENZHEN YUNZHOU INNOVATION TECH COMPANY

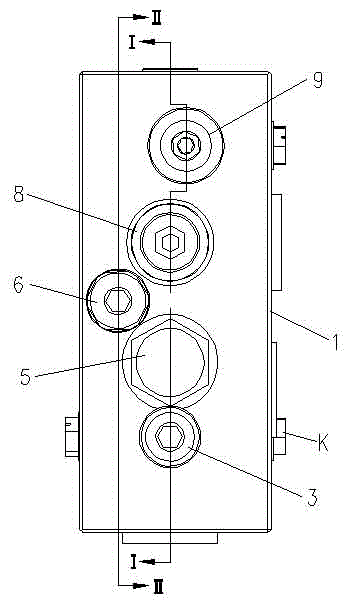

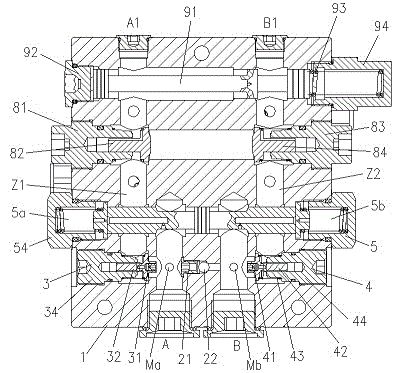

A compact type fully hydraulic walking pile-up valve

ActiveCN104912866ASmooth switchingEliminate pressure vibration problemsFluid-pressure actuator safetyServomotor componentsPath switchingEngineering

The invention provides a compact type fully hydraulic walking pile-up valve comprising a valve body. The valve body is internally provided with a high pressure selector valve formed by combining a threaded check valve base, a steel ball and a valve hole in the valve body. A first one-way throttle valve is arranged in the valve body and on the left side of the high pressure selector valve and a second one-way throttle valve is arranged in the valve body and on the right side of the high pressure selector valve. A balance valve is installed in a balance valve cavity of the valve body. A two-stage buffer overload valve comprising a first buffer overload valve and a second buffer overload valve is arranged on a main oil way in the valve body. A large-opening diameter oil supplementing valve formed by combining two sets of planar large-drift diameter check valves is installed in a valve cavity in the valve body and above the balance valve. An oil path switching valve is installed in the uppermost switching valve cavity of the valve body. The compact type fully hydraulic walking pile-up valve can effectively solve the problems such as great hydraulic shock, air suction of oil liquid and high noise in a braking process of fully hydraulic wheel excavators and loaders, has the advantages of compact structure, small size and high integration degree and is especially suitable for moving apparatuses.

Owner:浙江宏盛精密机械有限公司

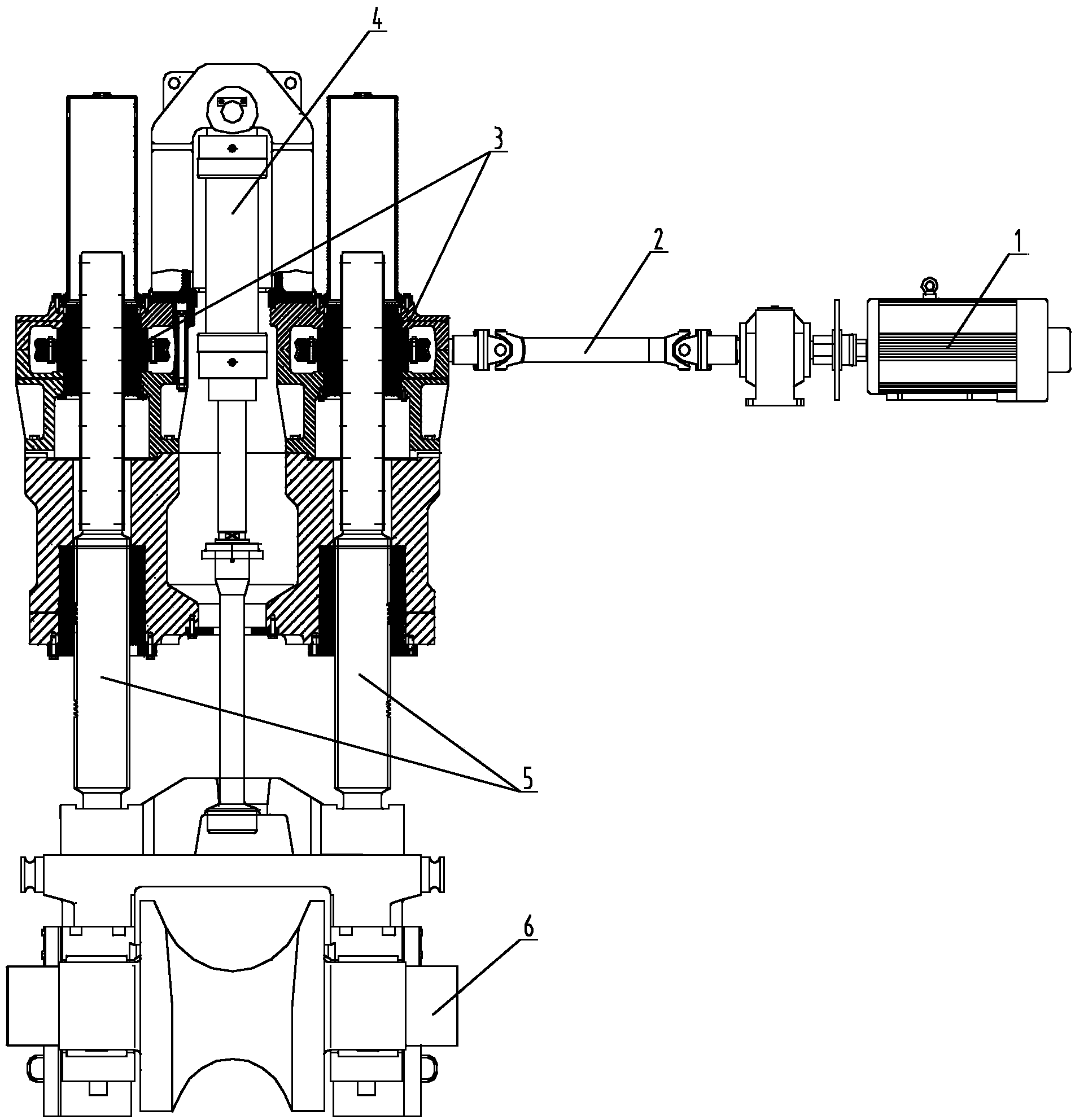

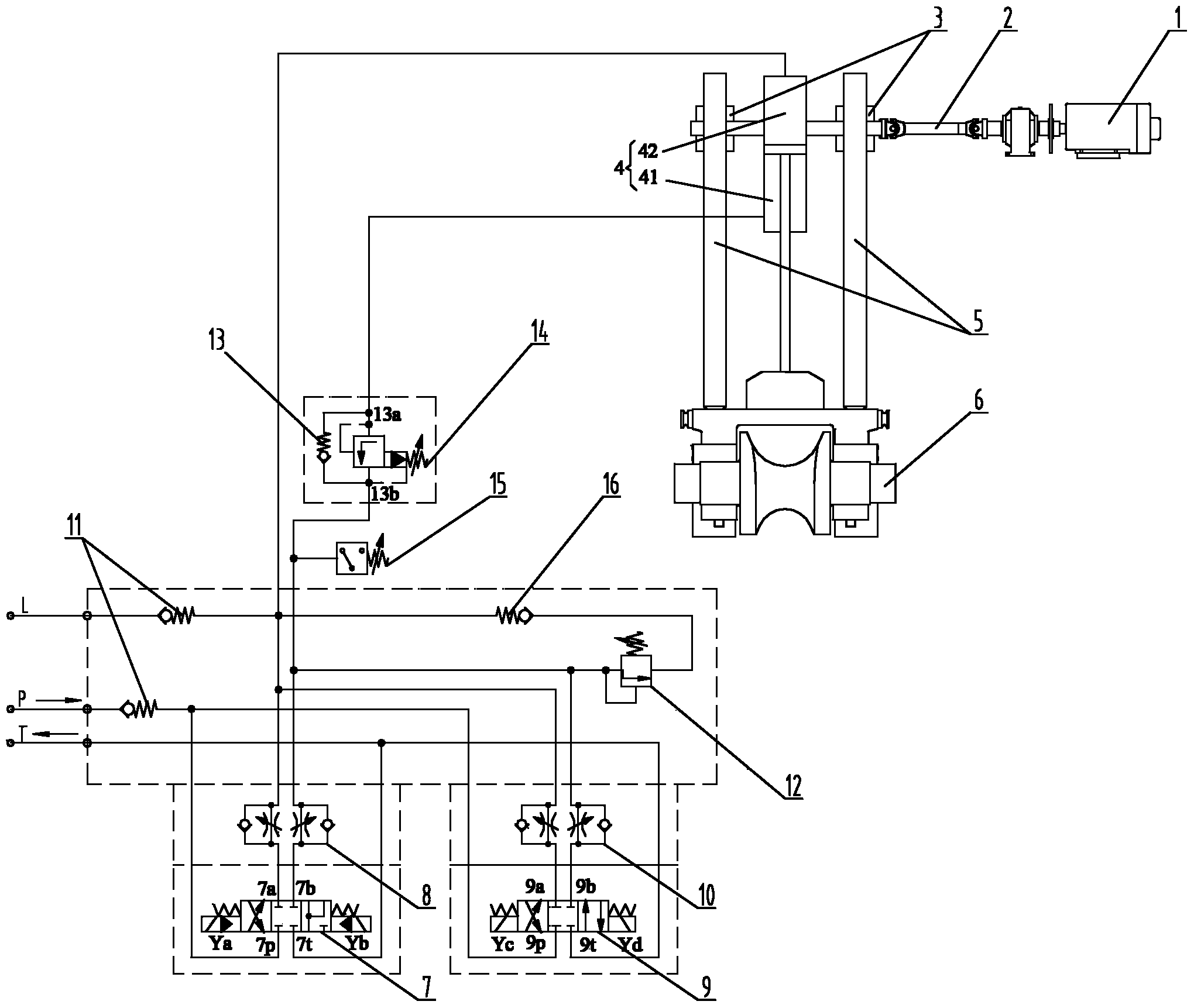

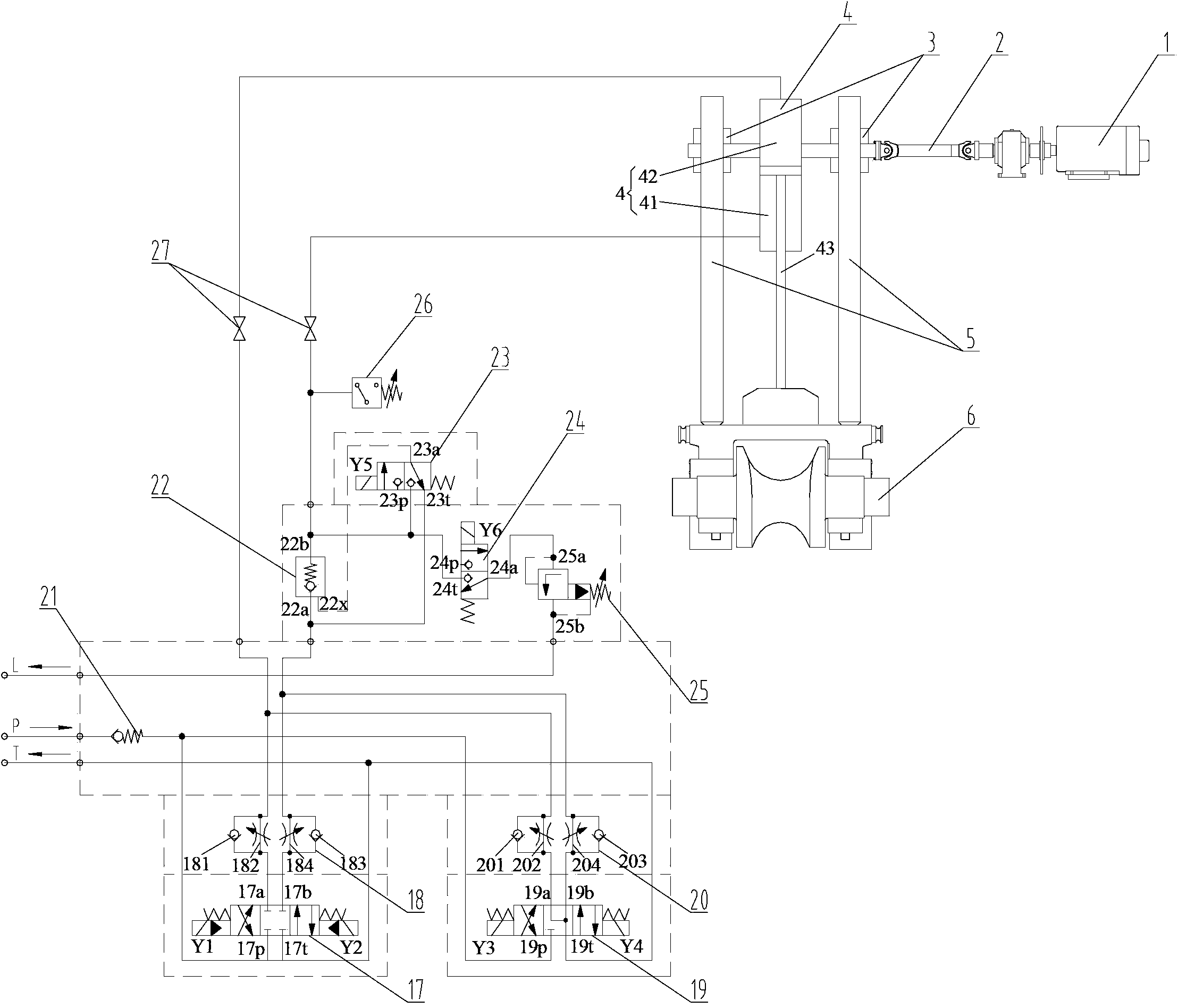

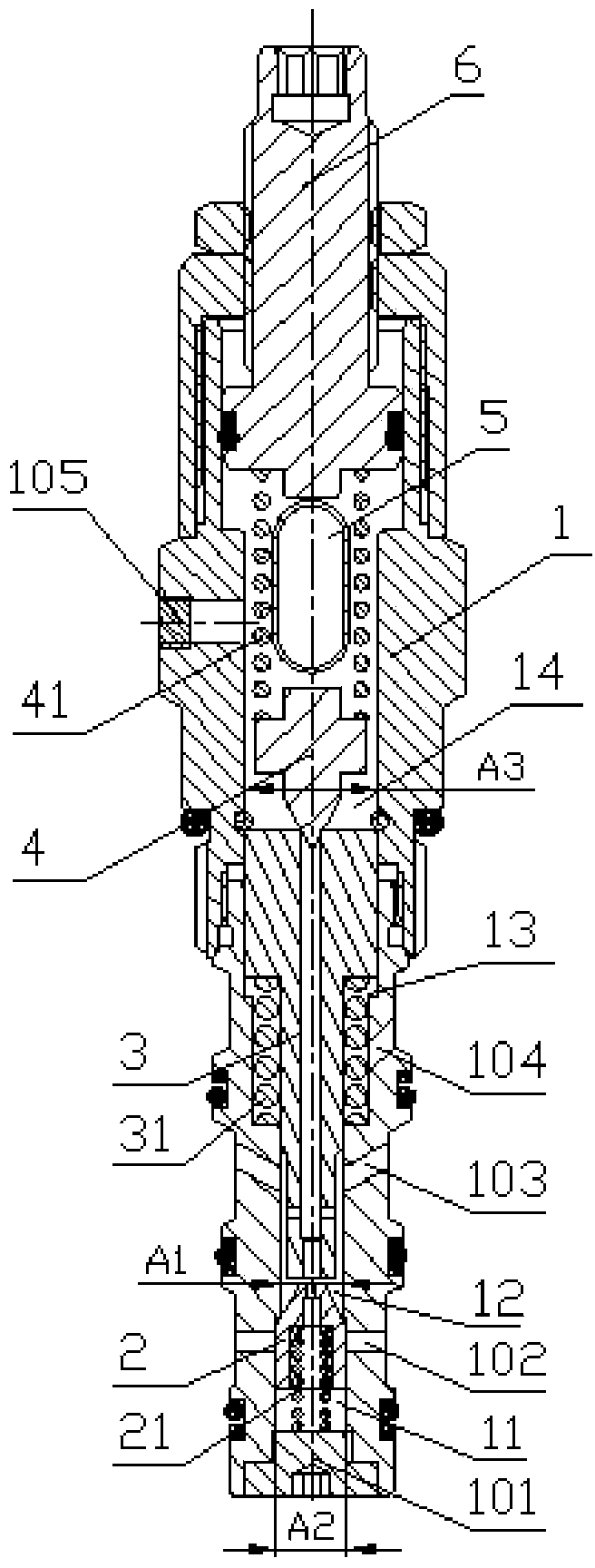

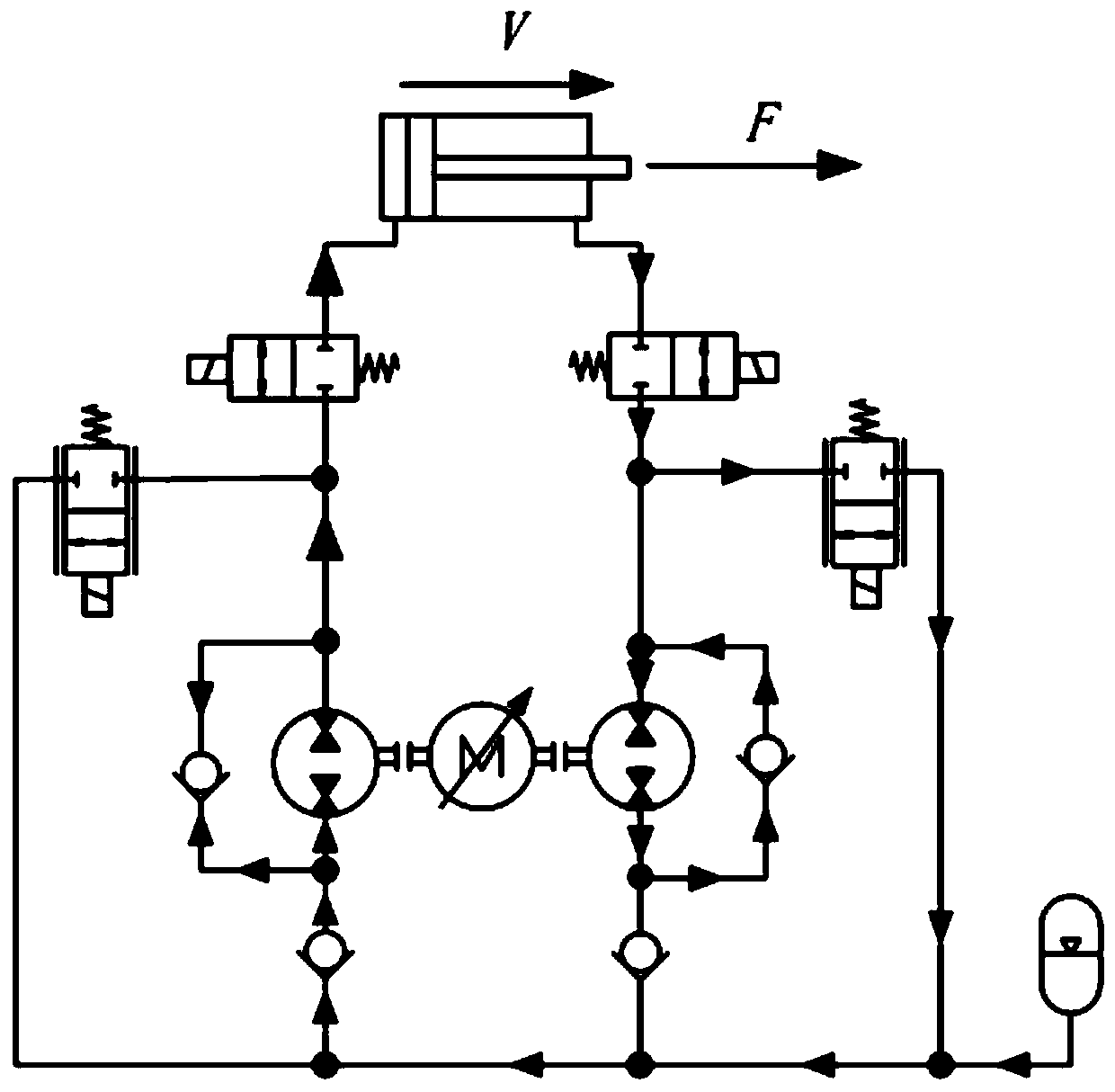

Hydraulic control system for upper roll balancing device of rotary forging mill

ActiveCN103447317ASmooth releaseOvercoming intermittent pausesRoll mill control devicesMetal rolling arrangementsControl systemElectro hydraulic

The invention provides an upper roll balancing device and a hydraulic control system. The hydraulic control system comprises a system oil inlet, a system oil return port, a system oil drainage port, an upper roll balancing cylinder, a first electro-hydraulic directional valve, a second electro-hydraulic directional valve, a first one-way throttle valve, a second one-way throttle valve, a hydraulic control one-way valve, a first electromagnetic ball valve, a second electromagnetic ball valve and an overflow valve, wherein the first electro-hydraulic directional valve can be positioned at a left position, a middle position and a right position to control oil in the hydraulic control system to flow into a rod-including cavity and a rodless cavity of the upper roll balancing cylinder or be isolated from the rod-including cavity and the rodless cavity; the second electro-hydraulic directional valve can be positioned at a left position, a middle position and a right position to control oil in the hydraulic control system to flow into the rod-including cavity and the rodless cavity of the upper roll balancing cylinder or be communicated with the rod-including cavity and the rodless cavity; the hydraulic control one-way valve is communicated to the rod-including cavity through a pipeline; the first electromagnetic ball valve is connected in parallel to the hydraulic control one-way valve, and can be used for controlling the hydraulic control one-way valve to be opened; the second electromagnetic ball valve is communicated to the rod-including cavity through a pipeline, and is connected with the overflow valve; and the overflow valve is connected to the system oil drainage port.

Owner:TAIYUAN HEAVY IND

Pressure safety valve

ActiveCN104358902AReduce riskAvoid stress shocksEqualizing valvesSafety valvesEngineeringSafety valve

The invention discloses a pressure safety valve. The safety valve comprises a valve body, wherein a first chamber is formed by a first one-way valve core and the front part of an inner hole of the valve body in a surrounding manner, a second chamber is formed by the first one-way valve core, the front end of a push rod and the inner hole of the valve body in a surrounding manner, third chambers are formed by the middle part of the push rod and the inner hole of the valve body in a surrounding manner, and a fourth chamber is formed by the back end of the push rod and the back part of the inner hole of the valve body in a surrounding manner; second oil holes are formed in the valve body and in positions corresponding to the first one-way valve core, third oil holes are formed in the valve body and in positions corresponding to the front part of the push rod, fourth oil holes are formed in the valve body and in positions corresponding to the third chambers, and a fifth oil hole is formed in the valve body and in a position corresponding to the fourth chamber; the second oil holes and the fourth oil holes are connected with an oil tank, the third oil holes are connected to a hydraulic system in parallel, and the fifth oil hole is an oil outlet; pressure maintenance structures which are used for maintaining the balanced pressure of the push rod are arranged in the third chambers and the fourth chamber. The safety valve disclosed by the invention can prevent pressure impact, prevent equipment from being damaged and improve the security of the equipment.

Owner:浙江三尚智迪科技有限公司

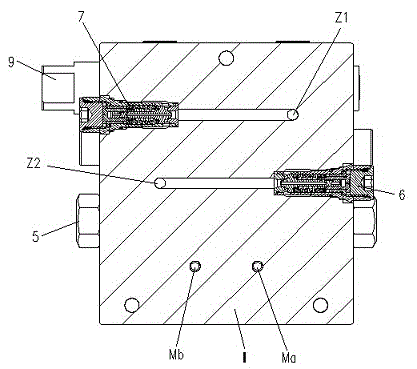

Damping balance valve

InactiveCN105041751AImprove smoothness of movementAvoid stress shocksServomotor componentsEngineeringThrottle

The invention discloses a damping balance valve. The damping balance valve comprises a valve body with a balance valve core group, wherein the balance valve core group is provided with a damper; an one-way throttle valve combination which has a buffering function so as to improve the action smoothness of the balance valve core group and is provided with a dismountable damper is mounted in the valve body; the one-way throttle valve combination with the dismountable damper consists of two one-way throttle valves with dismountable dampers, which are mounted in the valve body in a symmetrical manner; in the valve body, a hole is drilled downwards in the upper end of a left end surface relatively close to the valve body, so that a channel A used as a main working oil channel extending downwards is formed; a hole is drilled downwards in the upper end of a right end surface relatively close to the valve body, so that a channel B used as a main working oil channel extending downwards is formed; a channel C which extends upwards and is used as a main control oil channel, and a channel D which extends upwards and is used as a main control oil channel are symmetrically formed in a punching manner in the left side and the right side of the center line in the valve body; a balance valve cavity penetrating through the channel A, the channel C, the channel D and the channel B sequentially is horizontally formed in the left end surface of the valve body. The damping balance valve is simple in structure and high-efficient in performance, and can effectively weaken the pressure peak generated by hydraulic pressure fluctuation, so that the whole system can stably run.

Owner:宁波江东晟利工业产品设计有限公司

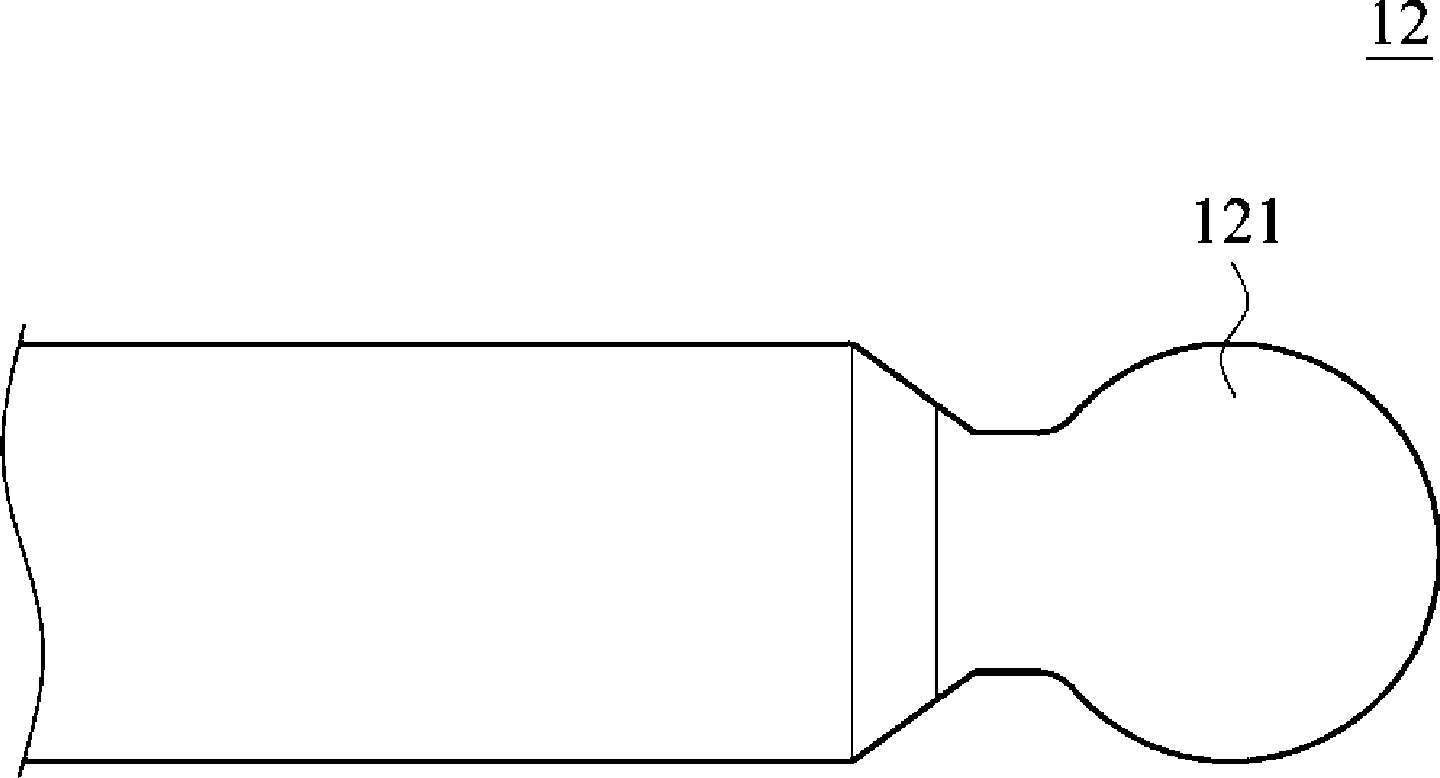

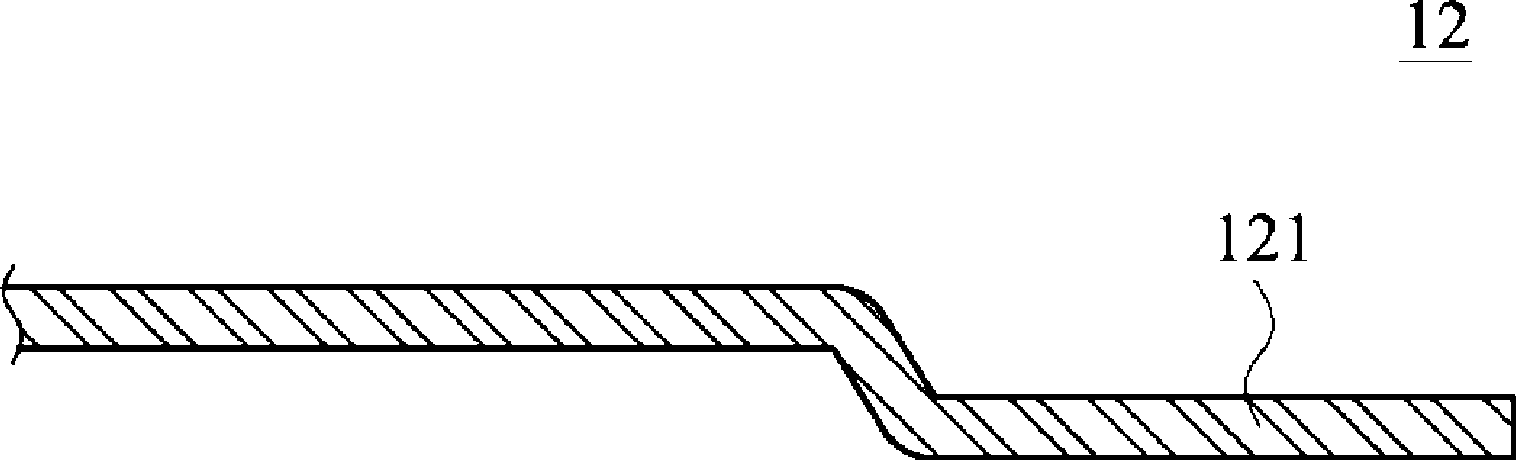

Lead frame structure and surface sticking semiconductor packaging structure formed by same

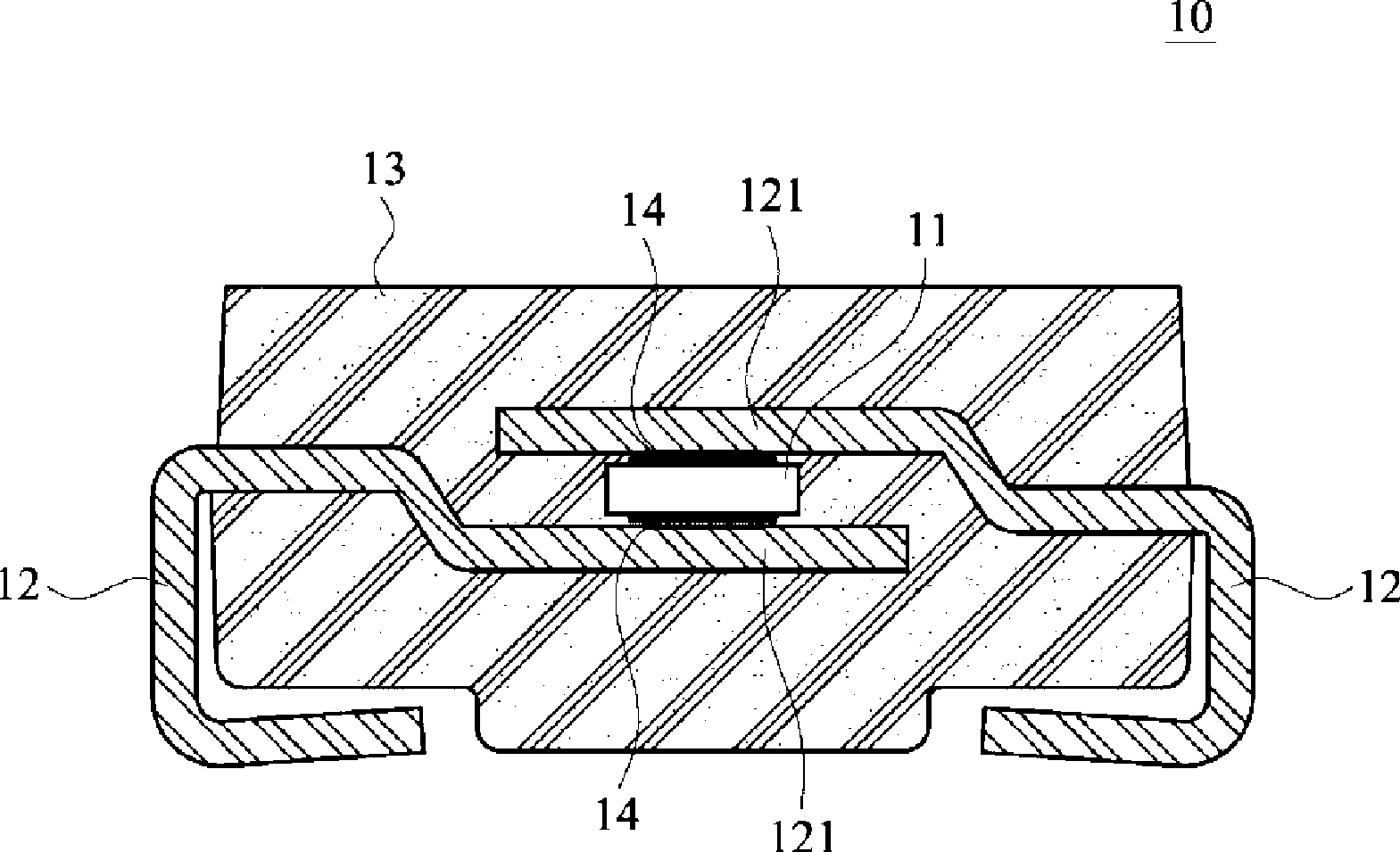

InactiveCN101521188AImprove reliabilityAvoid stress shocksSemiconductor/solid-state device detailsSolid-state devicesNeck partsSemiconductor package

The invention discloses a lead frame structure and a surface sticking semiconductor packaging structure formed by the same. The lead frame comprises a first pin part, a bending part and a second pin part, wherein the bending part is formed by extending a first end part of the first pin part; the second pin part is a square plate body formed by extending a neck part of the bending part, and a square convex part is formed on the square plate body so that a chip can be welded and fixed between the square convex parts of two lead frames. The surface sticking semiconductor packaging structure comprises a chip, lead frames and a packaging body, wherein the packaging body is coated on the chip as well as the second pin part, the bending part and the first end part of the each of two lead frames so as to finish the packaging of the surface sticking semiconductor, improve the reliability of the surface sticking semiconductor and enhance the bearing power of the surface sticking semiconductor.

Owner:昆山东日半导体有限公司

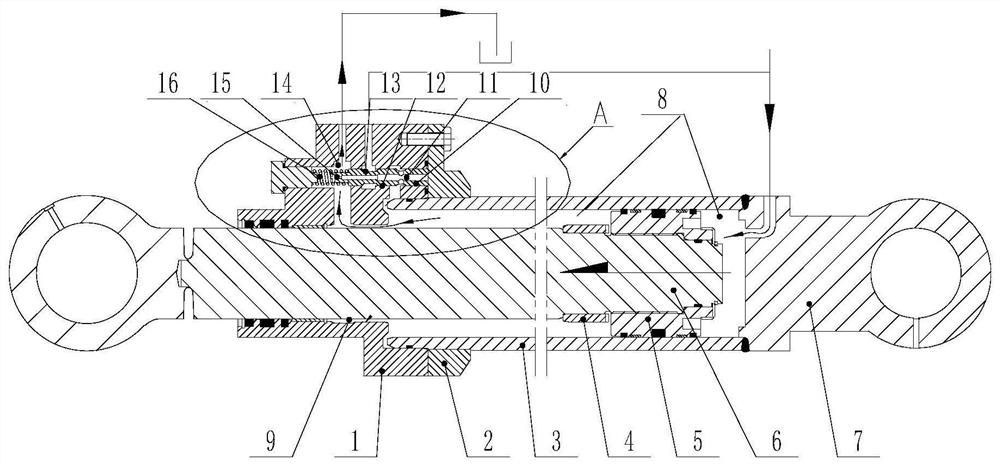

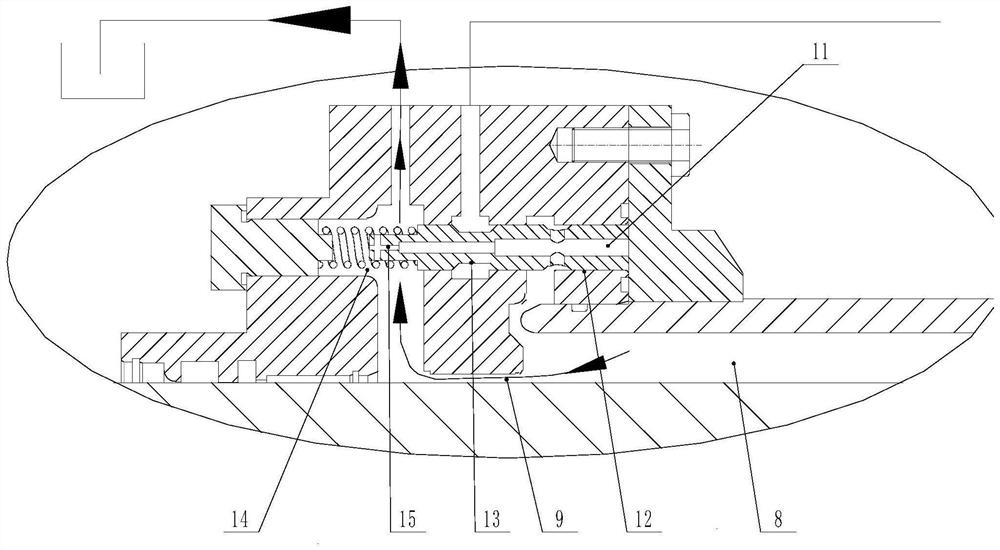

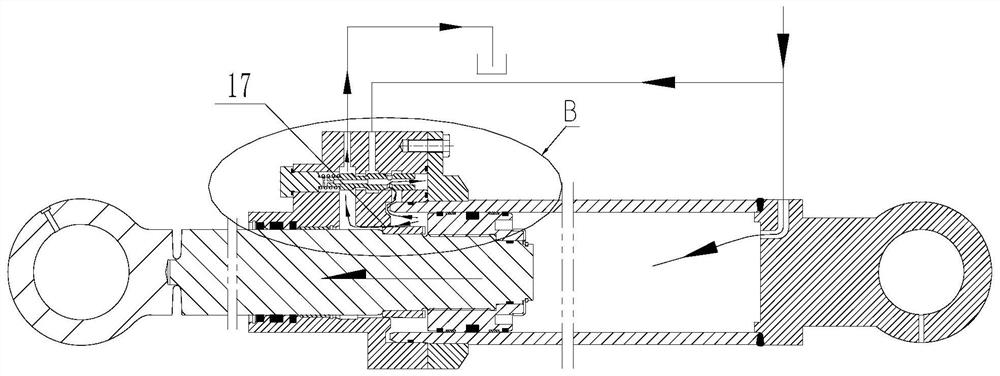

Unloading valve, combination valve comprising unloading valve and combination valve type buffer oil cylinder

InactiveCN112196861ASave powerAvoid power consumption and system heatingEqualizing valvesSafety valvesHydraulic ramCylinder block

The invention relates to the field of hydraulic oil cylinders, in particular to an unloading valve, a combination valve comprising the unloading valve and a combination valve type buffer oil cylinder.The unloading valve comprises a valve body, a valve element and a return spring. The valve element is further provided with a damping hole and an unloading groove. The combination valve comprises theunloading valve and a throttling valve. The throttling valve comprises a buffer plug and a buffer cavity. A piston rod assembly of the combination valve type buffer oil cylinder is installed in a cylinder body. The cylinder body comprises a cylinder head flange, a cylinder bottom and a cylinder barrel. The piston rod assembly comprises a guide sleeve, a piston and a piston rod. The combination valve is arranged on the guide sleeve and / or the cylinder bottom. According to the unloading valve, the combination valve comprising the unloading valve and the combination valve type buffer oil cylinder disclosed by the technical scheme, the unloading function of an oil inlet cavity is added, the buffer effect is outstanding, and the buffer pressure is reduced; and meanwhile, a system is in an unloading state in a buffer stage, energy losses and the heating of the system are reduced, pressure impact caused by buffer on the system is avoided, the reliability of the system is improved, and the difficulty of performance matching and installing and debugging of an original buffer valve is lowered.

Owner:QINGDAO ACME INNOVATION TECH CO LTD

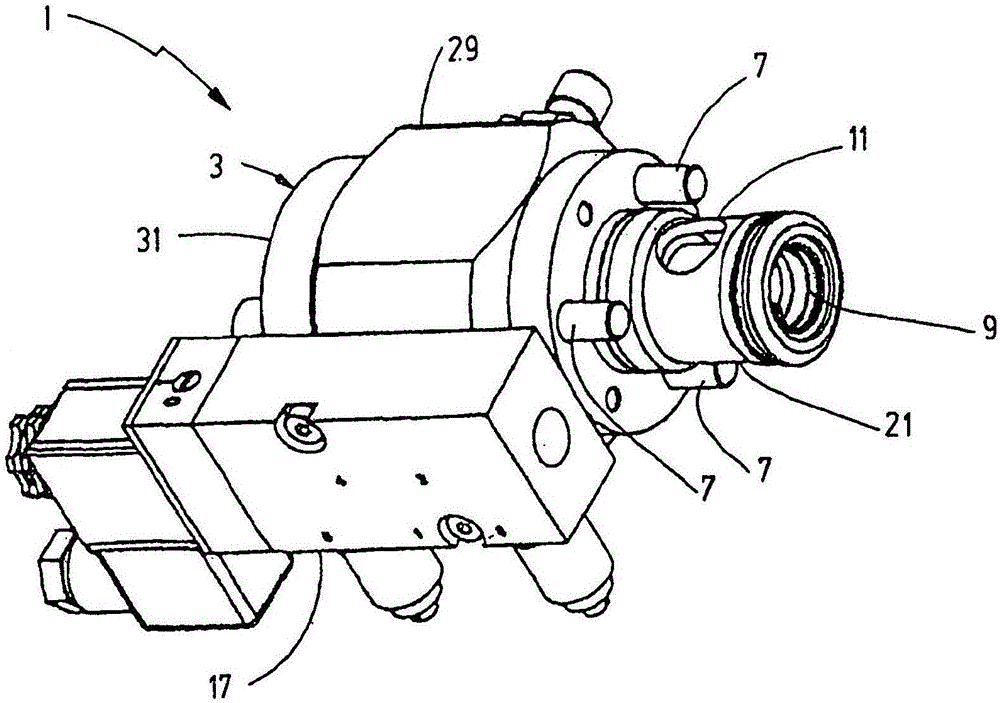

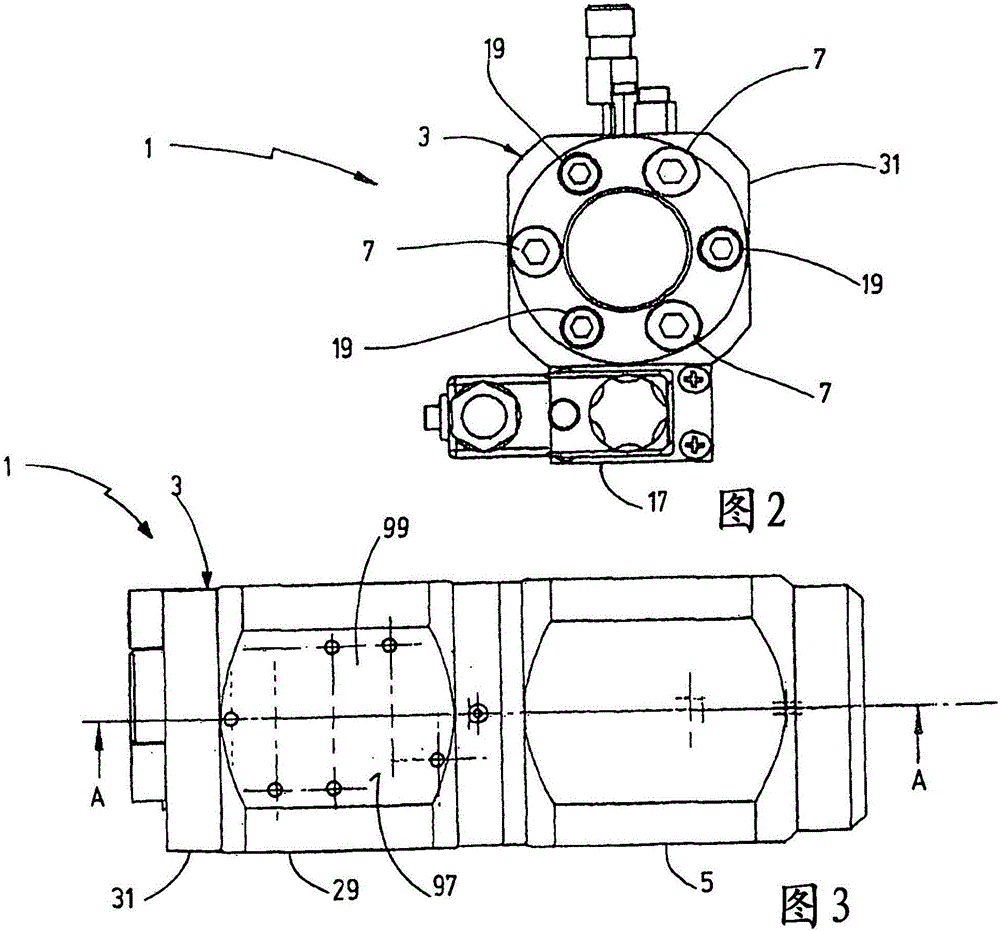

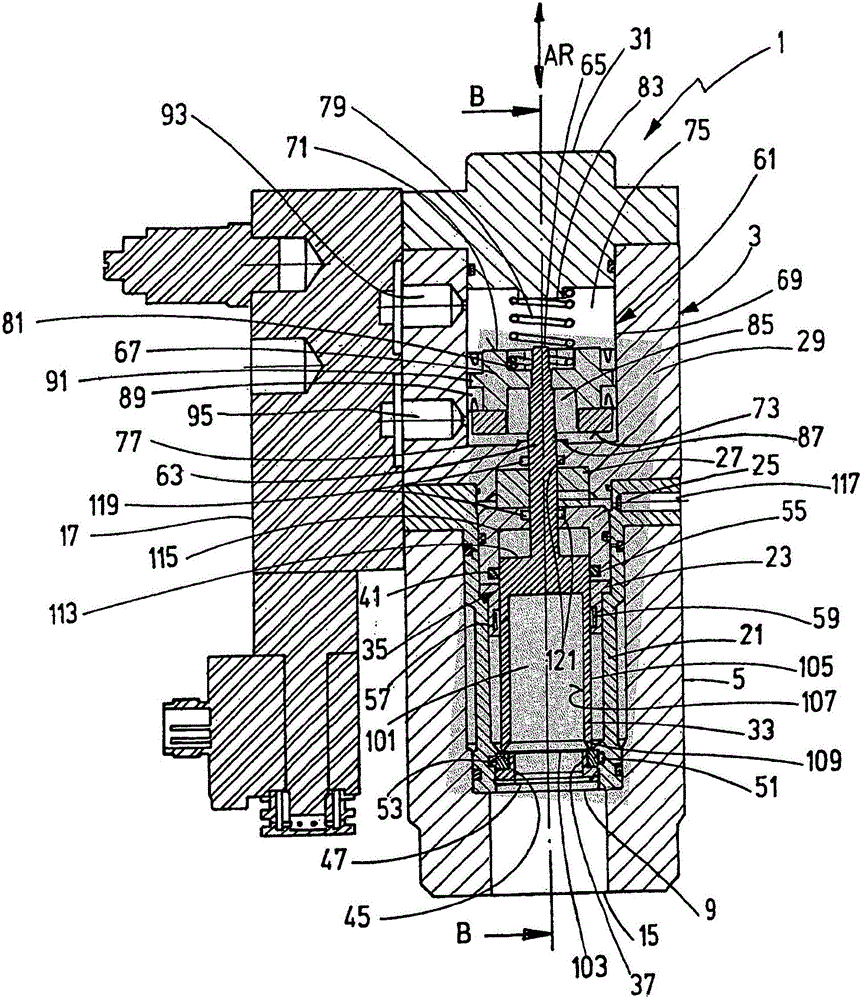

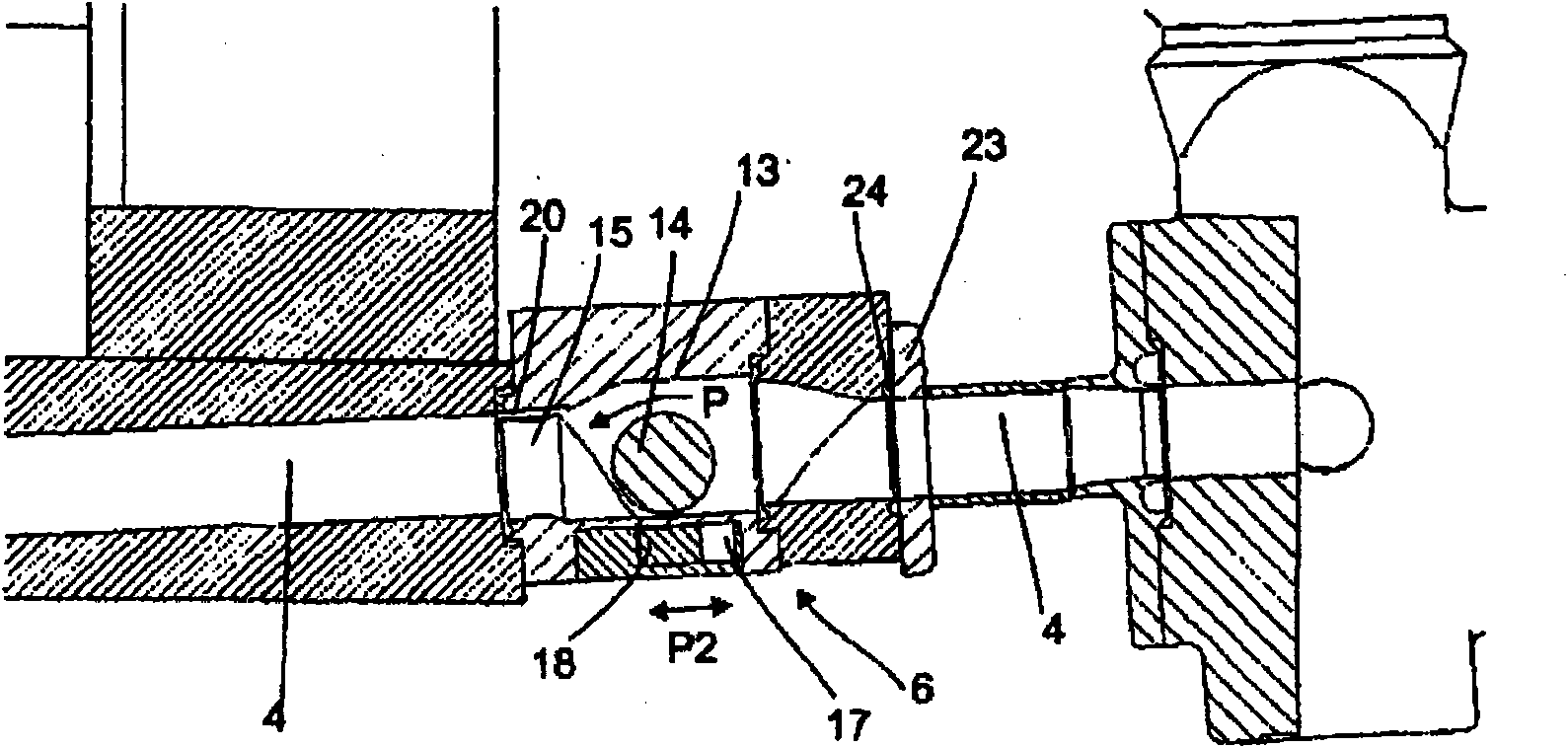

Valve device for controlling media flows of any type

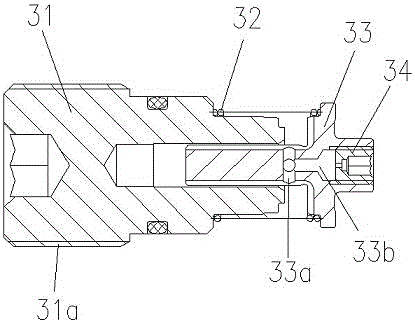

ActiveCN106461114AQuick conversionImprove functional safetyOperating means/releasing devices for valvesSlide valveEngineeringEqualization

The invention relates to a valve device (1) for controlling media flows of any type by means of at least one valve control piston (33), which is guided in a longitudinally movable manner in a valve housing (3) and which controls a media connection between at least two media connection points (9, 11) in the valve housing (3), of which at least one media connection point is a pressure supply inlet (P) and at least one other media connection point is a load outlet (A), wherein the valve control piston (33) is guided in the valve housing (3) with pressure equalization by means of at least one equalizing apparatus (35) at least with respect to the media pressure at the respective pressure supply inlet (P).

Owner:RSG ELECTRONICS

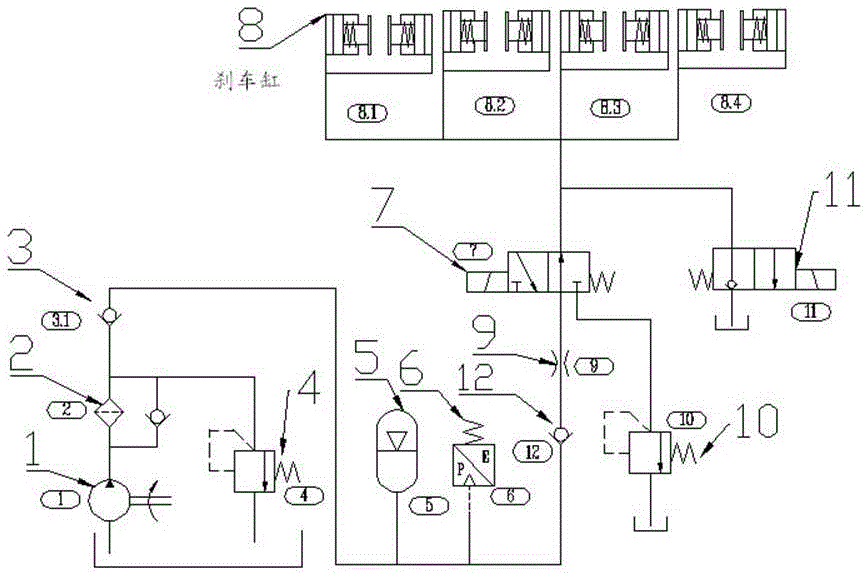

Hydraulic brake system of marine winch

InactiveCN104477808AAvoid stress shocksAvoid jitterServomotorsHoisting equipmentsFuel tankEngineering

The invention relates to a hydraulic brake system of a marine winch. The hydraulic brake system comprises an oil pump (1), a filter (2), a one-way valve I (3), a one-way valve II (12), a throttling valve (9), a reversing valve I (7), a reversing valve II (11), an overflow valve I (4), an overflow valve II (10), an energy accumulator (5), a pressure switch (6) and an oil cylinder group (8). After passing the oil pump (1) and the filter (2), one part of oil returns to an oil tank through the overflow valve I (4), and the other part of the oil passes the one-way valve I (3), the energy accumulator (5), the pressure switch (6) and the throttling valve (9). A certain volume of pressure oil stores in the energy accumulator (5). The pressure switch (6) controls the pump to stop and start according to the pressure of the energy accumulator. The throttling valve (9) adjusts the pressure and flow fluctuation to guarantee that a brake works stably. The oil cylinder group (8), the reversing valve I (7) and the reversing valve II (11) form a semi-pressure brake loop which is used for preventing second sliding down and jittering during starting and stopping. The oil cylinder group (8) and the reversing valve II (11) form a pressure relief loop. When the winch works, the brake system is turned on. Actual application indicates that the hydraulic brake system is low in work energy consumption, high in work efficiency, and stable in winch ascending, descending and braking.

Owner:TIANJIN JINNUODING HYDRAULIC TECH

Fluid filter apparatus and method

ActiveUS20050218060A1Simple actionEasy to installSedimentation separationMultistage water/sewage treatmentFilter systemIntegrally closed

A fluid filter system has a manifold having a fluid inlet with an inlet stop and a fluid outlet with an outlet stop and a cartridge seat. A cartridge is separable from the manifold and adapted to mount and dismount in the manifold. The cartridge has a filter housing containing a filter for filtering fluid, and an integral closure member having a first level and a second level. A radial inlet port is on a face of the first level of the closure member and an axial outlet port is on top of the second level of the closure member. A first boss on the closure member opens the inlet stop when the cartridge is mounted in the manifold. A second boss on the closure member is disposed to open the outlet stop when the cartridge is mounted in the manifold. The bosses engage the stops sequentially.

Owner:NATURAL CHOICE CORP

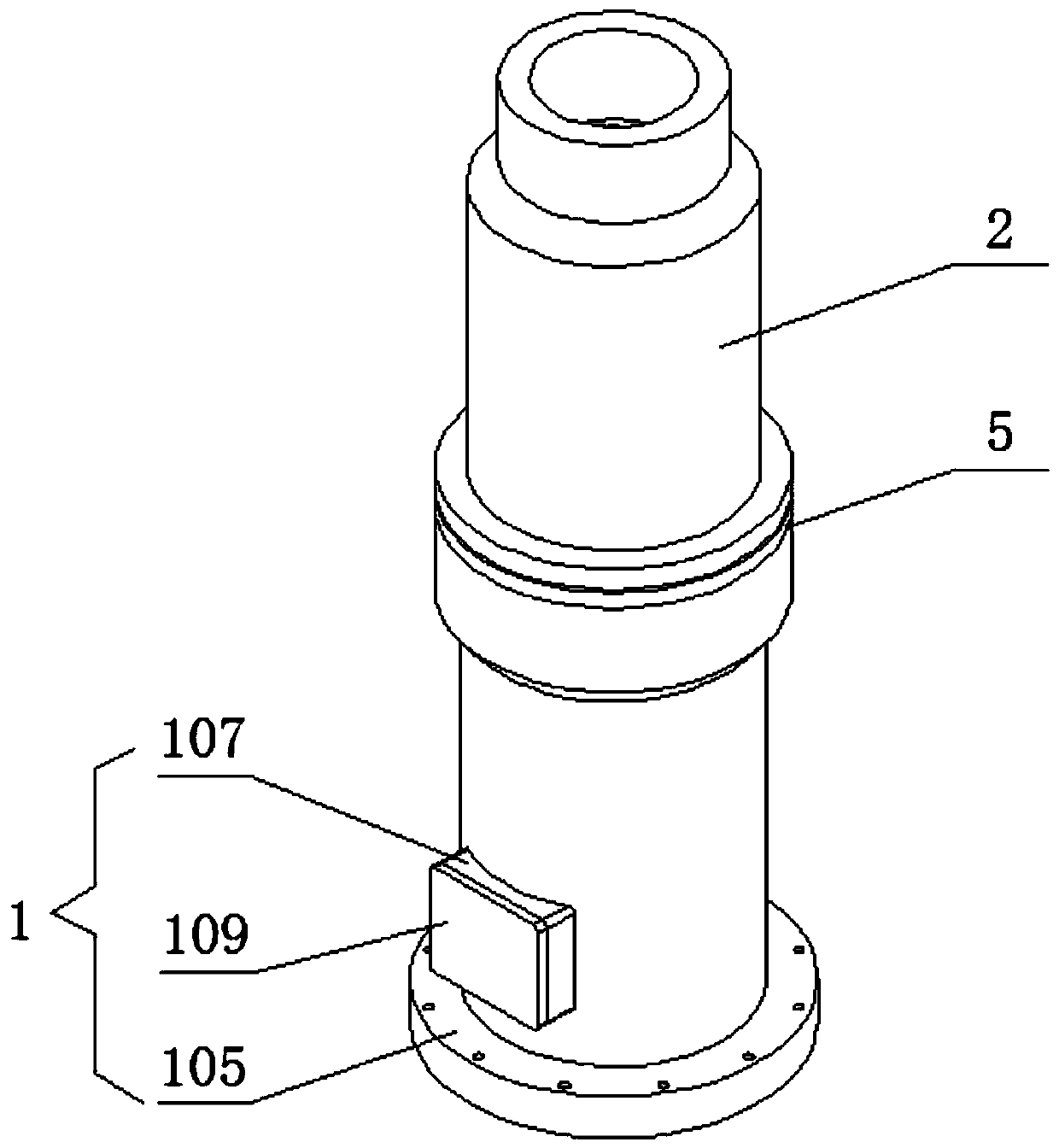

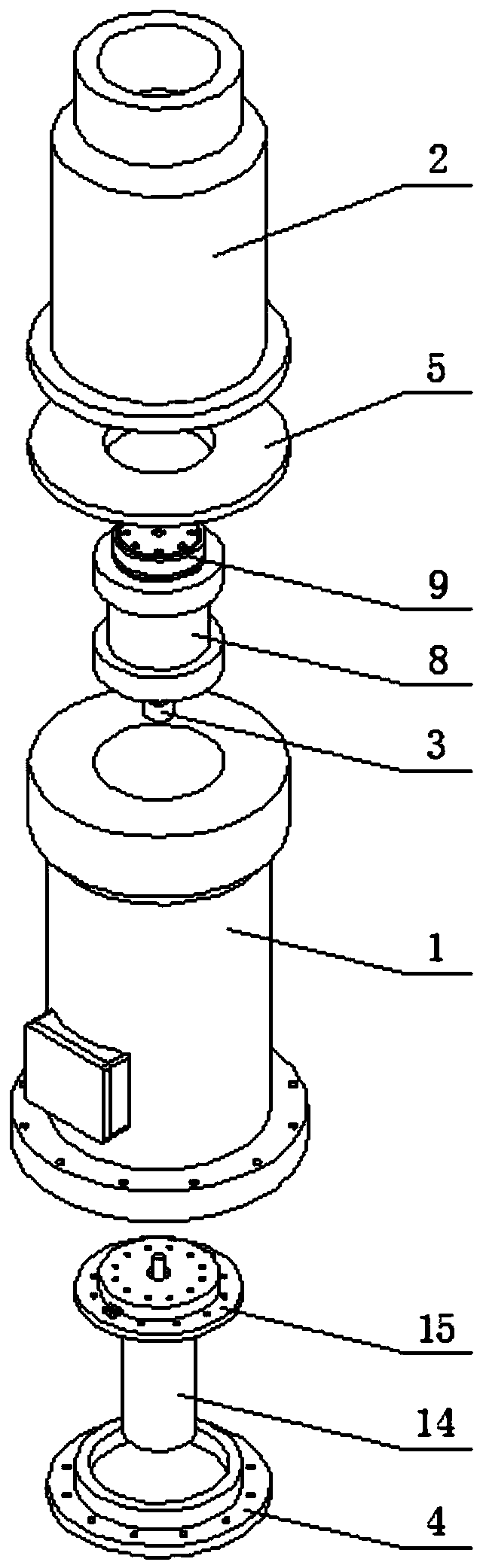

Efficient solar large assembly vertical stacker crane equipment

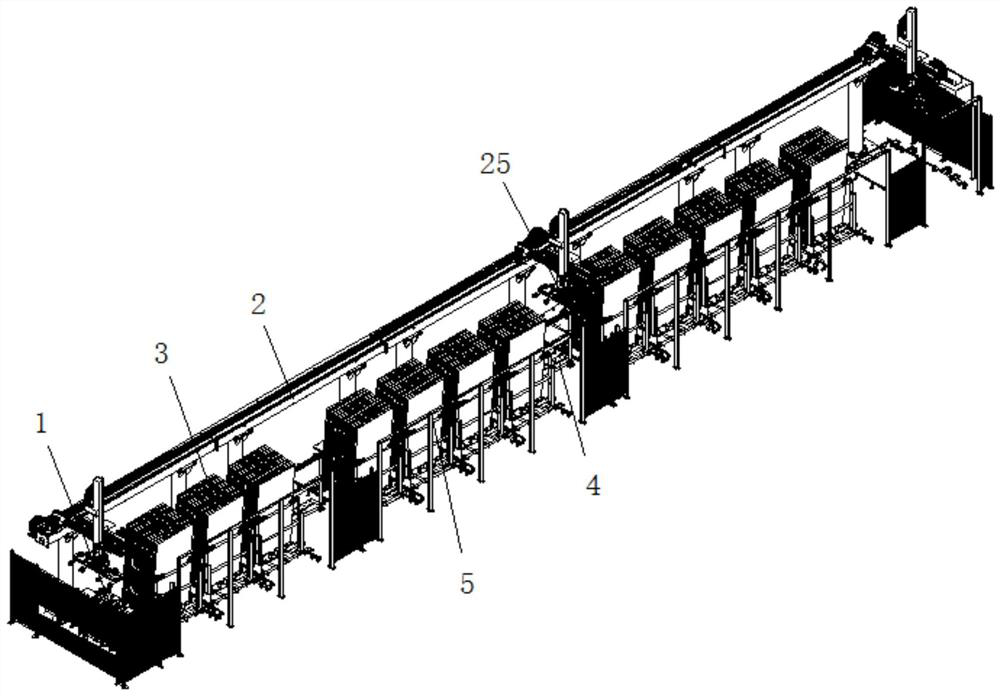

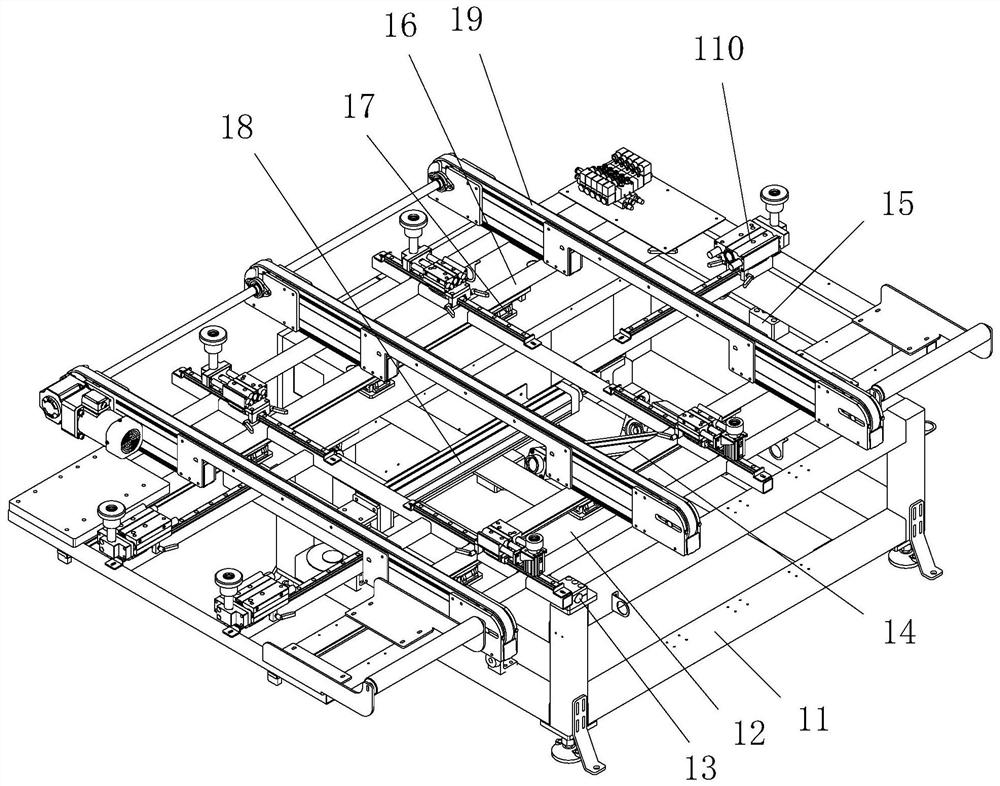

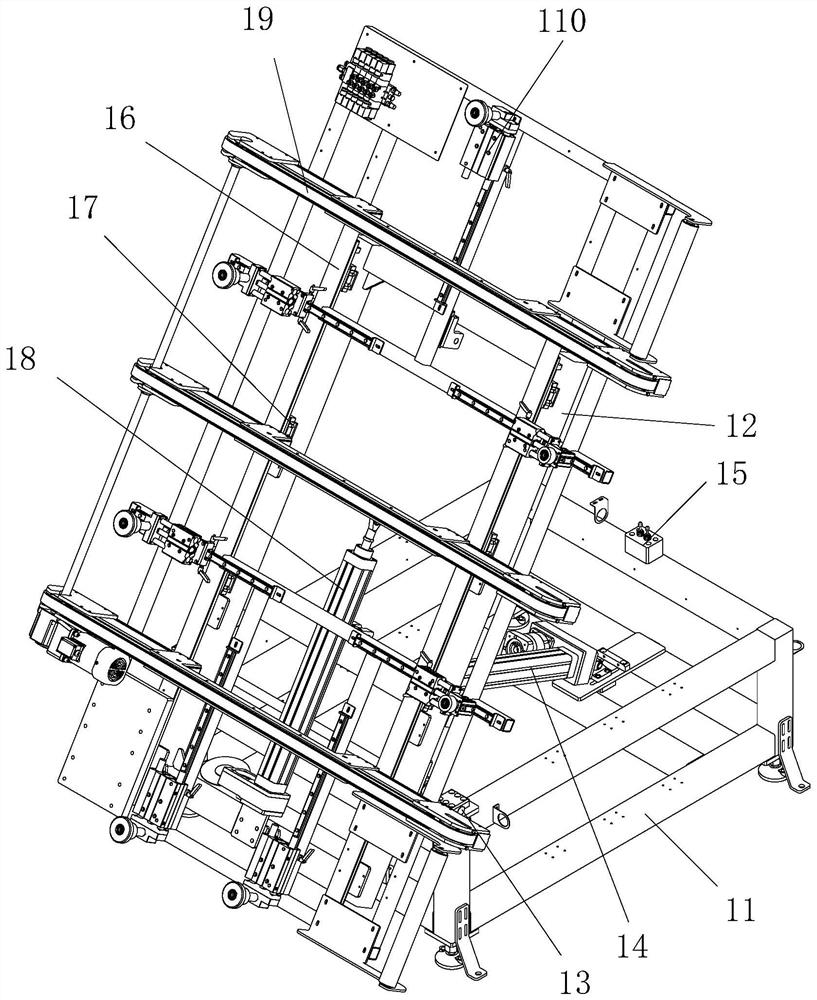

PendingCN113716357ACompact structureGuaranteed uptimeStacking articlesDe-stacking articlesButt jointPalletizer

The invention discloses efficient solar large assembly vertical stacker crane equipment which comprises a turnover conveying line, a displacement gripper mechanism, short-edge vertical trolley mechanisms, assembly temporary-storage frames and a protective net. The right side of the turnover conveying line is provided with the displacement gripper mechanism in a butt joint mode; the displacement gripper mechanism is provided with three stations used for being responsible for displacement grippers of gripping operation of different strokes; a row of short-edge vertical trolley mechanisms are arranged on the front side of the displacement gripper mechanism in a butt joint mode; the number of the short-edge vertical trolley mechanisms is three, four or five; the assembly temporary-storage frames are arranged in each set at intervals; and the protective net is arranged on the front side walls of the short-edge vertical trolley mechanisms. By means of the mode, through the advanced horizontal turnover and standing technology and the corresponding displacement grippers, short-edge vertical turnover is carried out, and short edges are placed in short-edge vertical trolley stacking positions, so that the purpose of rapid and accurate stacking is achieved.

Owner:苏州晟成智能装备有限公司

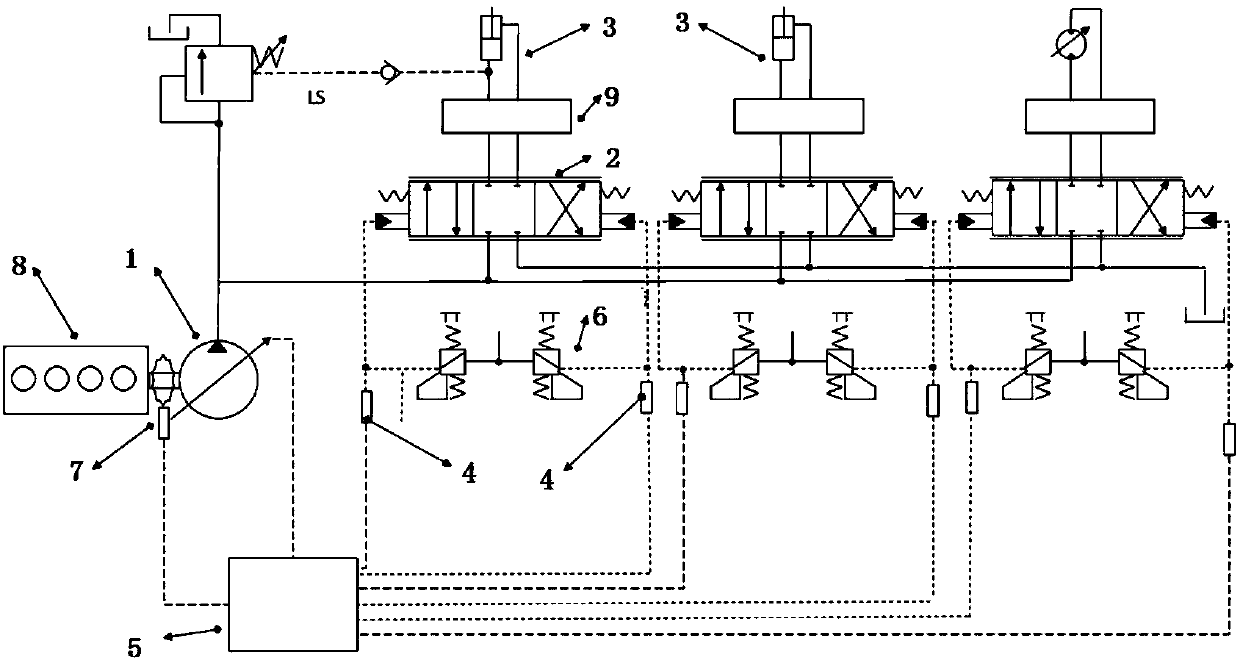

Hydraulic system for engineering machinery and engineering machinery

ActiveCN107701530AReduce energy loss and pressure fluctuationsThe system responds quicklyServomotorsServometer circuitsPressure sensorControl engineering

The invention provides a hydraulic system for engineering machinery and the engineering machinery provided with the hydraulic system. The hydraulic system comprises a main pump for providing hydraulicoil to the hydraulic system in a positive flow control manner, multiple actuation mechanisms, a main valve set comprising multiple main valve elements and multiple pressure compensators, multiple operation parts for respectively inputting pilot pressure to the corresponding main valve elements, an electric control unit for storing flow characteristic curves corresponding to the multiple main valve elements, and multiple pressure sensors. The multiple pressure sensors are connected with the electric control unit for detecting the pilot pressure input by the corresponding operation parts and inputting pilot pressure signals to the electric control unit; the electric control unit calculates flows needed by all the corresponding main valve elements according to the pilot pressure values detected by the multiple pressure sensors based on the self-stored corresponding flow characteristic curves, and a total flow needed by the hydraulic system is calculated; and the main pump outputs corresponding displacement based on the total flow through the positive flow control mode.

Owner:WEICHAI POWER CO LTD +1

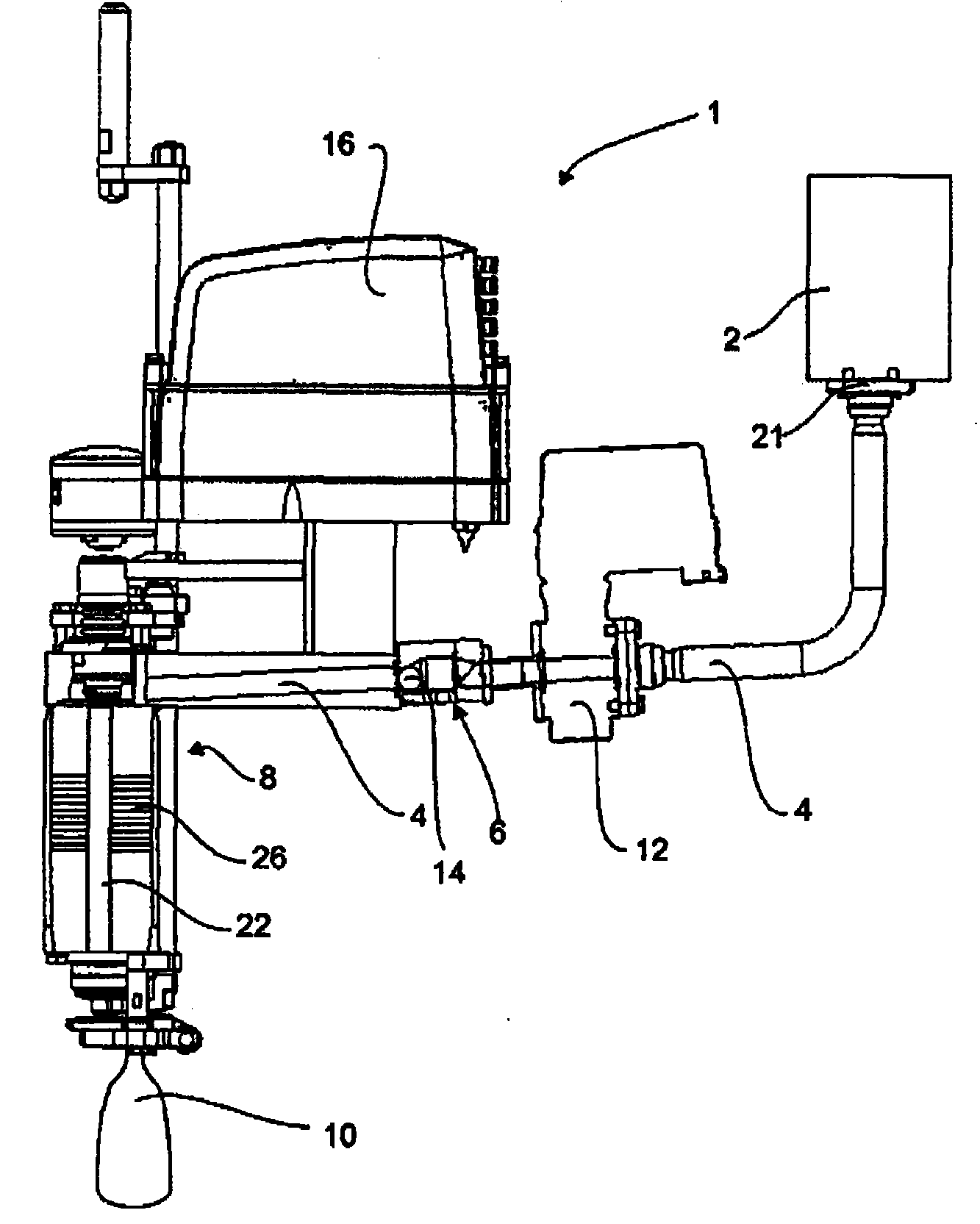

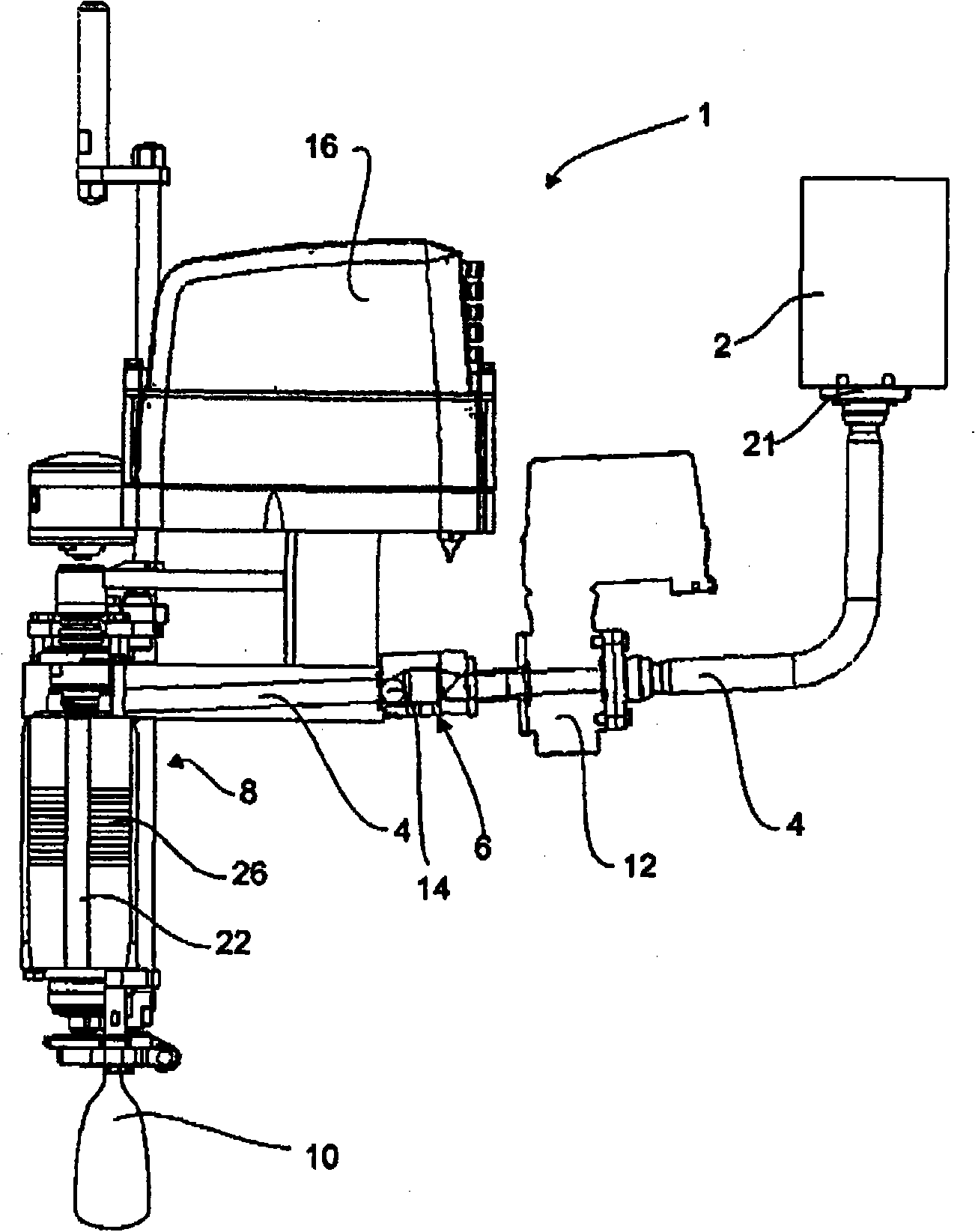

Device for bottling beverages

ActiveCN101815670AAuto switchAvoid stress shocksOperating means/releasing devices for valvesSafety device in filling machineryEngineeringClosed state

The invention relates to a device (1) for filling containers, comprising a storage container (2) in which a fluid to be bottled in the containers can be accommodated, comprising a filling device (8) filling the fluid into the containers (10), and comprising a transport line (4) by means of which the fluid is transported form the storage container (2) to the filling device (8). According to the invention, a valve device (6) is disposed in the transport line (4) between the storage container (2) and the filling device (8), said valve device changing automatically between an open and a closed state depending on a flow velocity of the fluid within the transport line (4).

Owner:KRONES AG

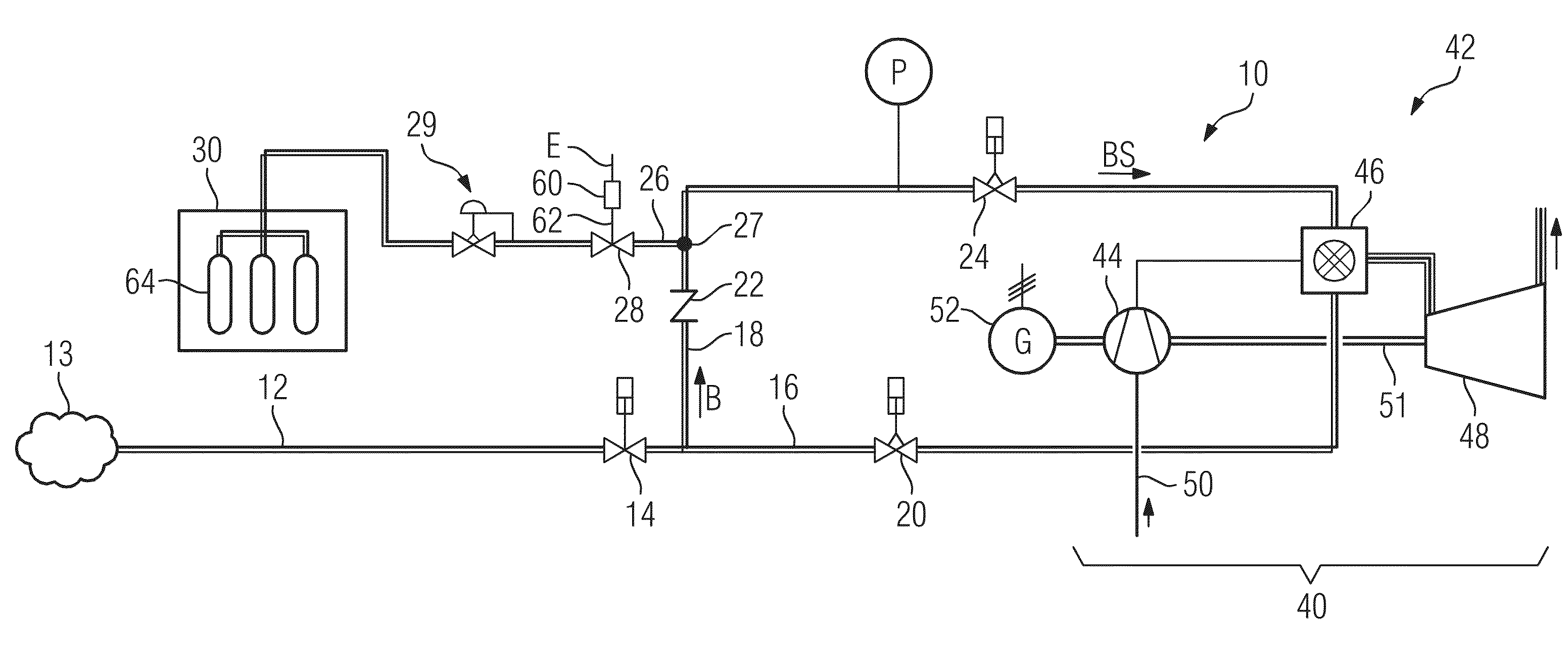

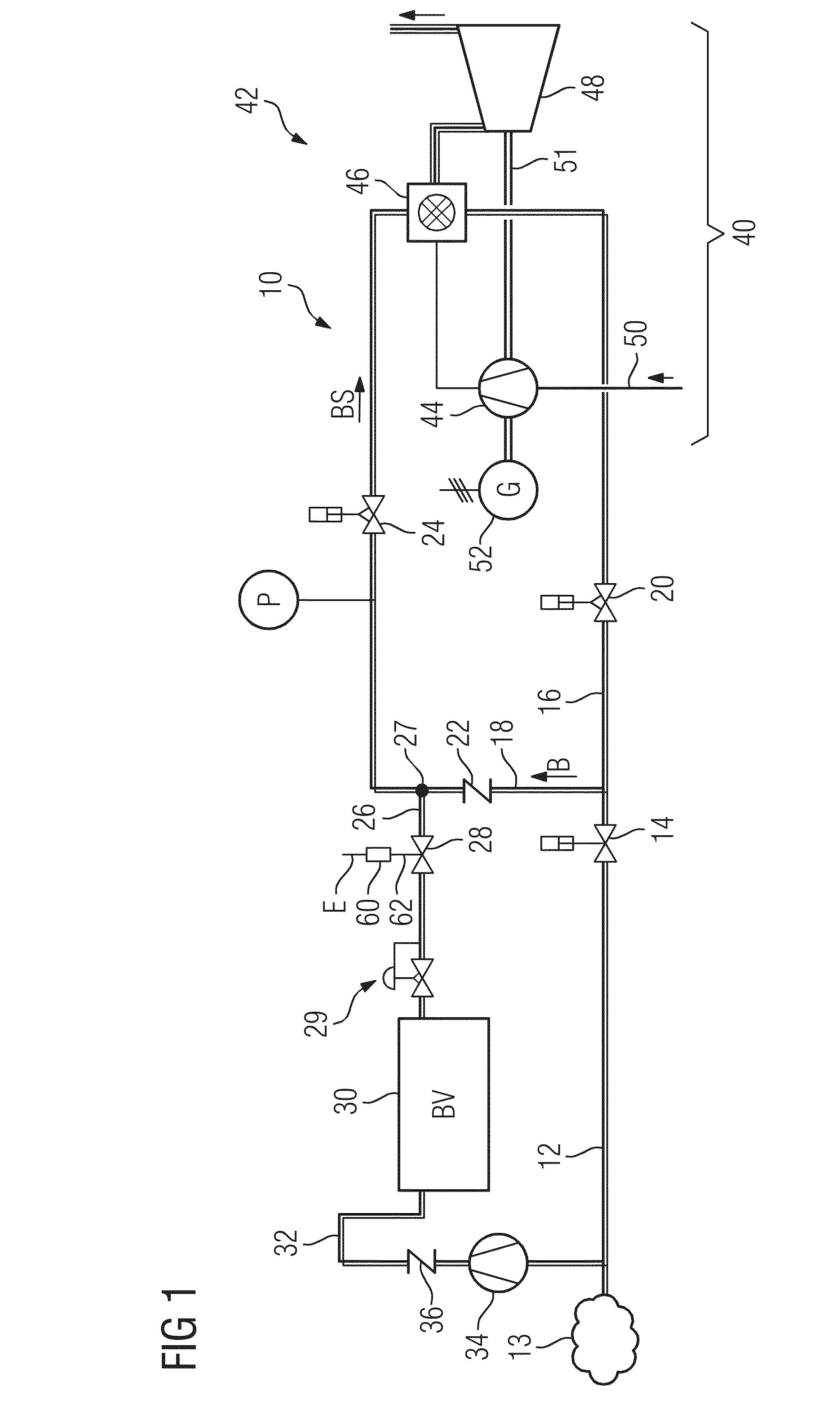

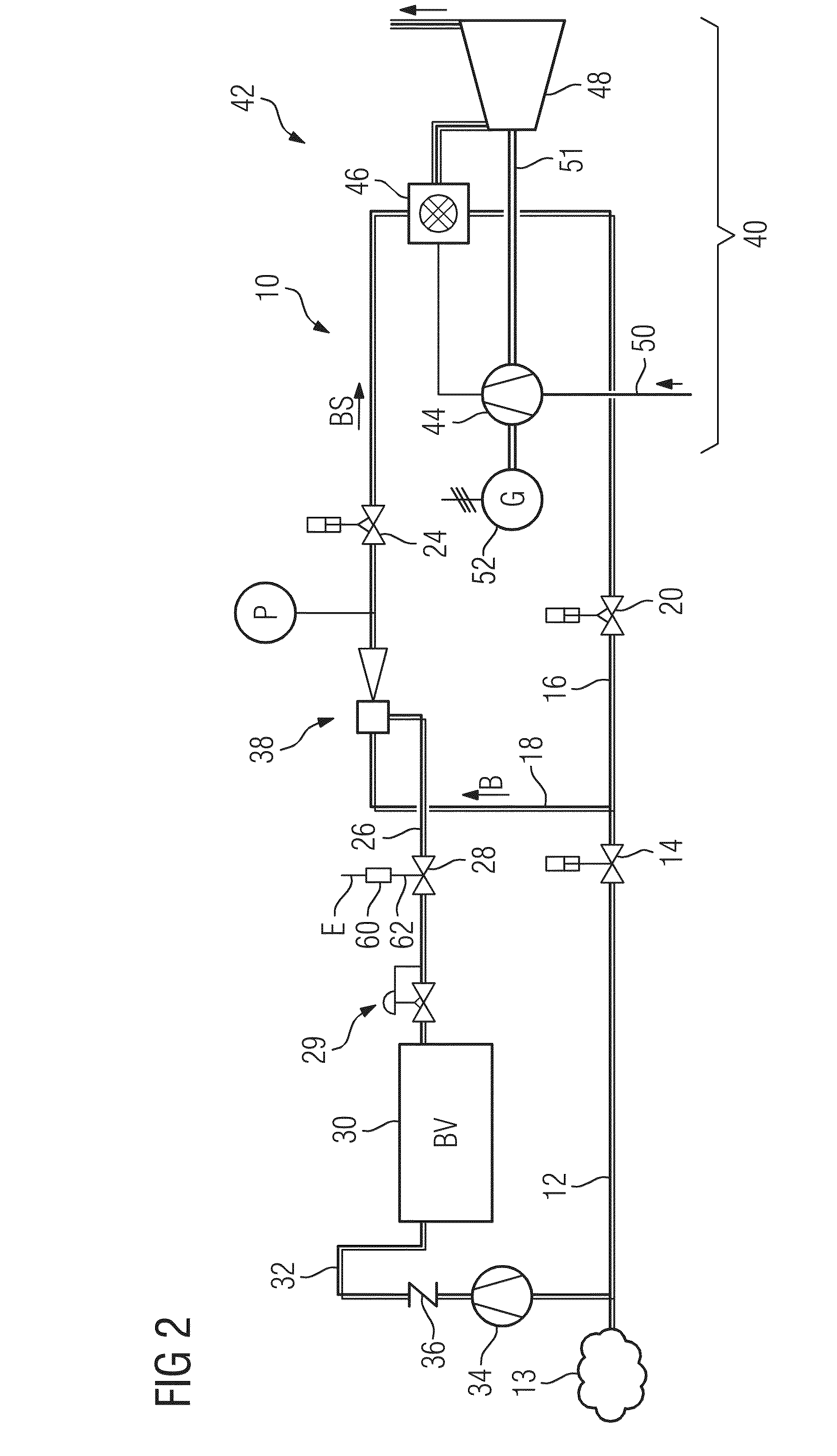

Method for operating a fixed gas turbine, device for regulating the operation of a gas turbine and power plant

InactiveUS20130247578A1Reduce demandIncrease fuel pressureTurbine/propulsion engine ignitionTurbine/propulsion engine startersPower stationCombustion chamber

A method of operating a gas turbine, a device for regulating the starting and / or the operation of a gas turbine and a power plant are provided. The method includes continuously extracting fuel from a fuel network, and combusting, in at least one combustion chamber of a gas turbine, the fuel by adding combustion air. For an increase of a fuel stream supplied to the at least one combustion chamber, a fuel volume is extracted from a fuel store and supplied to the fuel still to be supplied to the at least one combustion chamber.

Owner:SIEMENS AG

Valve apparatus, arrangement with valve apparatus and method for operating arrangement

Owner:GEA ASEPTOMAG

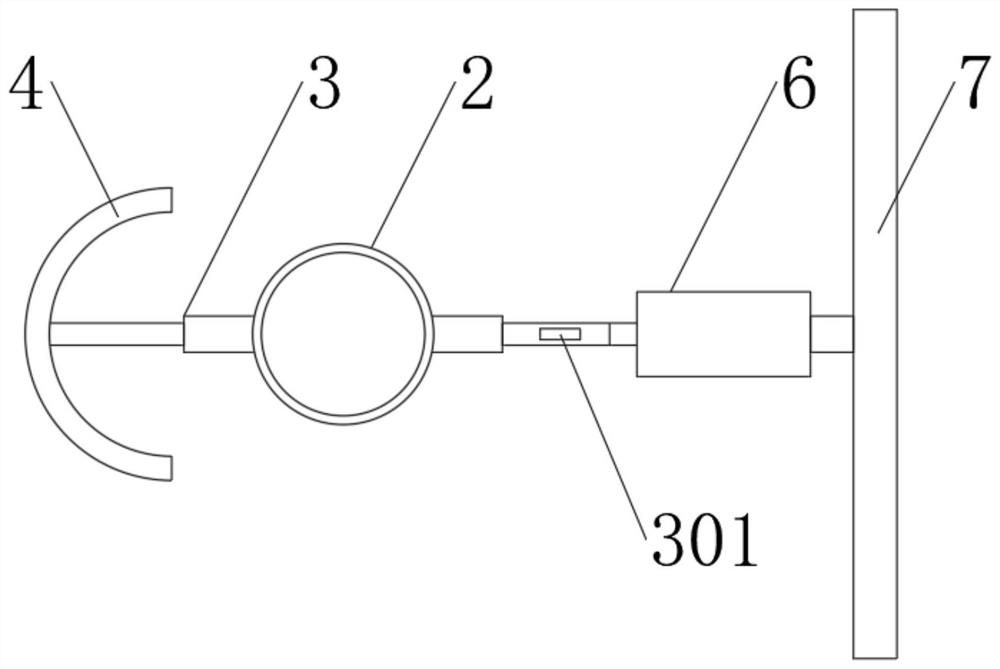

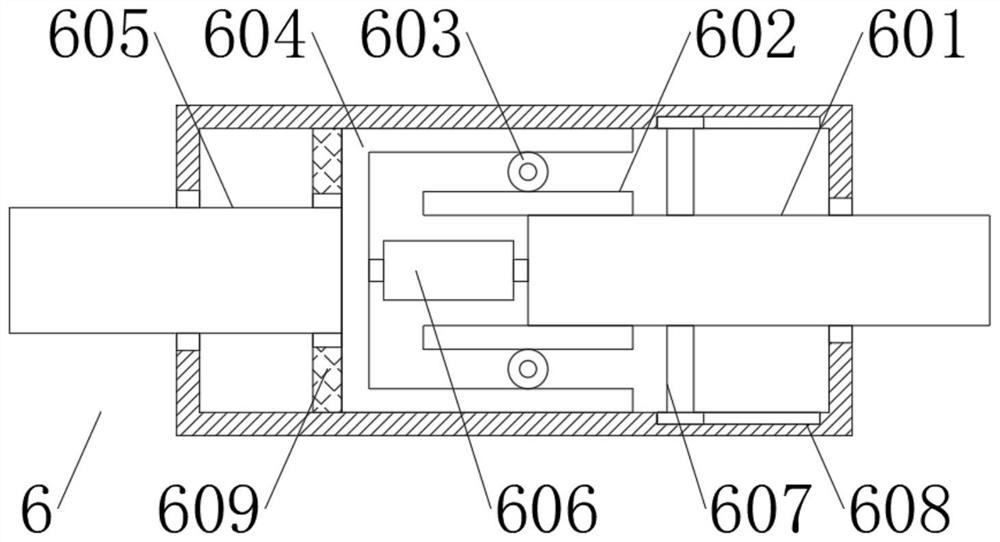

Rotary connecting device of robot end executing mechanism

ActiveCN111216156AExtended service lifeReduce stress concentrationGripping headsCouplingElectric machinery

The invention discloses a rotary connecting device of a robot end executing mechanism, and relates to the technical field of robots. The rotary connecting device comprises a rotary connecting arm anda fixed connecting arm, wherein a positioning ring is arranged in the middle of the rotary connecting arm, and a rotary cavity is arranged at the front end of the positioning ring; a driving cavity isarranged at the rear end of the positioning ring; a cavity, positioned at the front end face of the positioning ring, of the rotary cavity is sleeved with a rotary assembly; and a cavity, positionedat the rear end face of the positioning ring, of the driving cavity is fixedly sleeved with a driving assembly. According to the rotary connecting device, the matching surface of a rotary seat and therotary connecting arm is a soft contact surface, so that the stress concentration effect on the surface of the rotary seat is reduced, the service life of the rotary seat and the rotary connecting arm is prolonged, and the loss of the whole rotary assembly is reduced; and a main shaft of a driving motor is connected with the shaft end of a rotary shaft assembly through a coupler, so that the stress impact of direct plug-in connection of the driving motor and the rotary shaft assembly is avoided, and the service life of the whole rotary connecting device is prolonged.

Owner:CHANGZHOU INST OF MECHATRONIC TECH +1

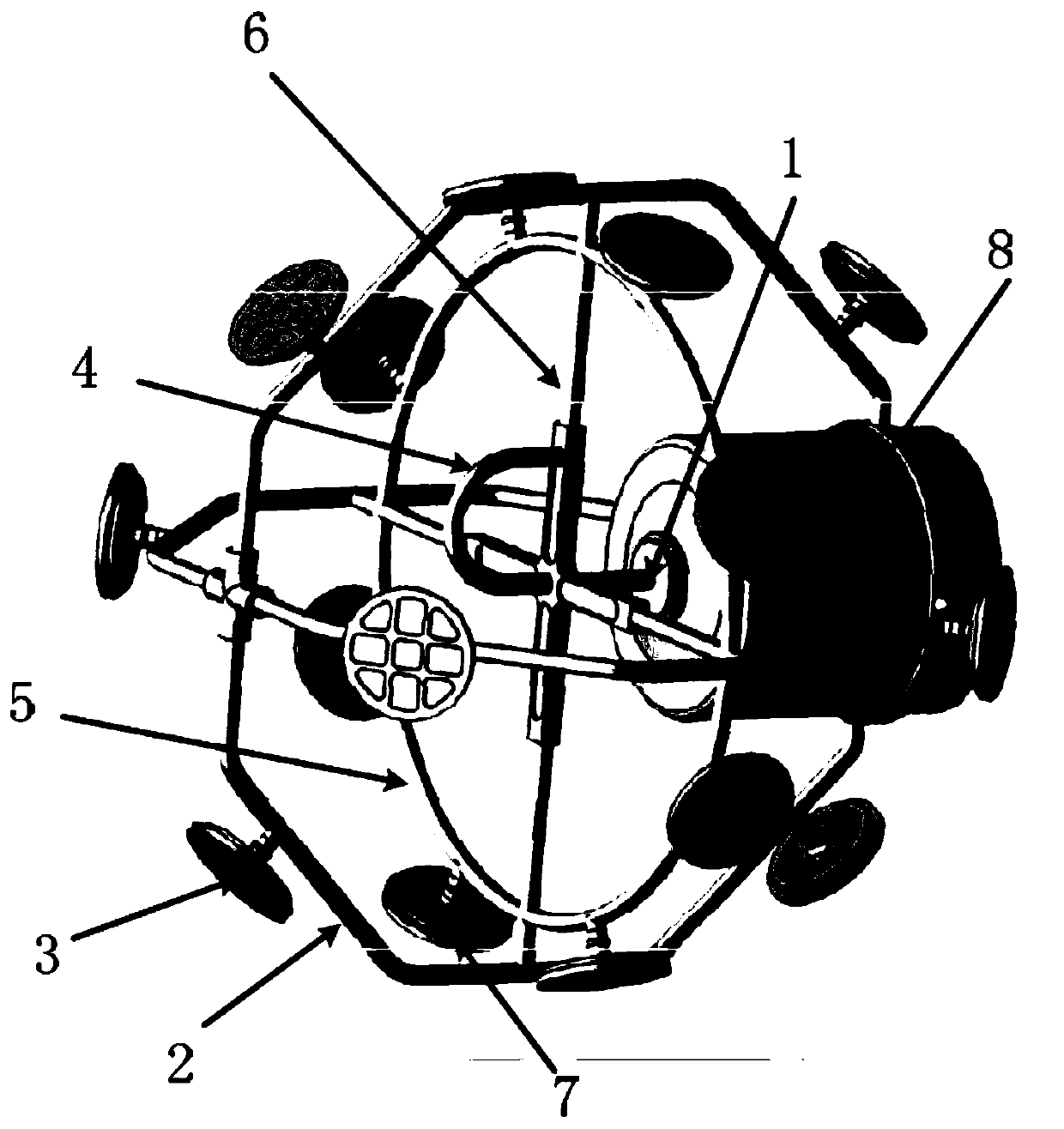

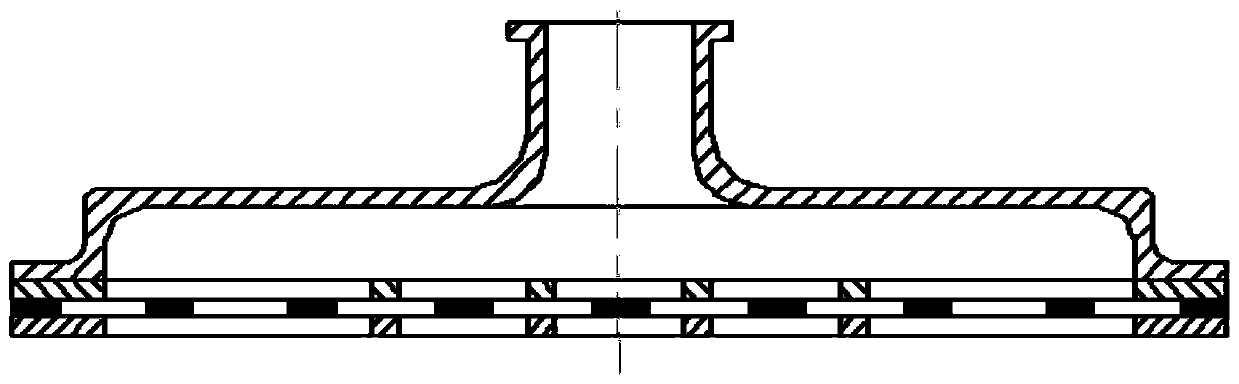

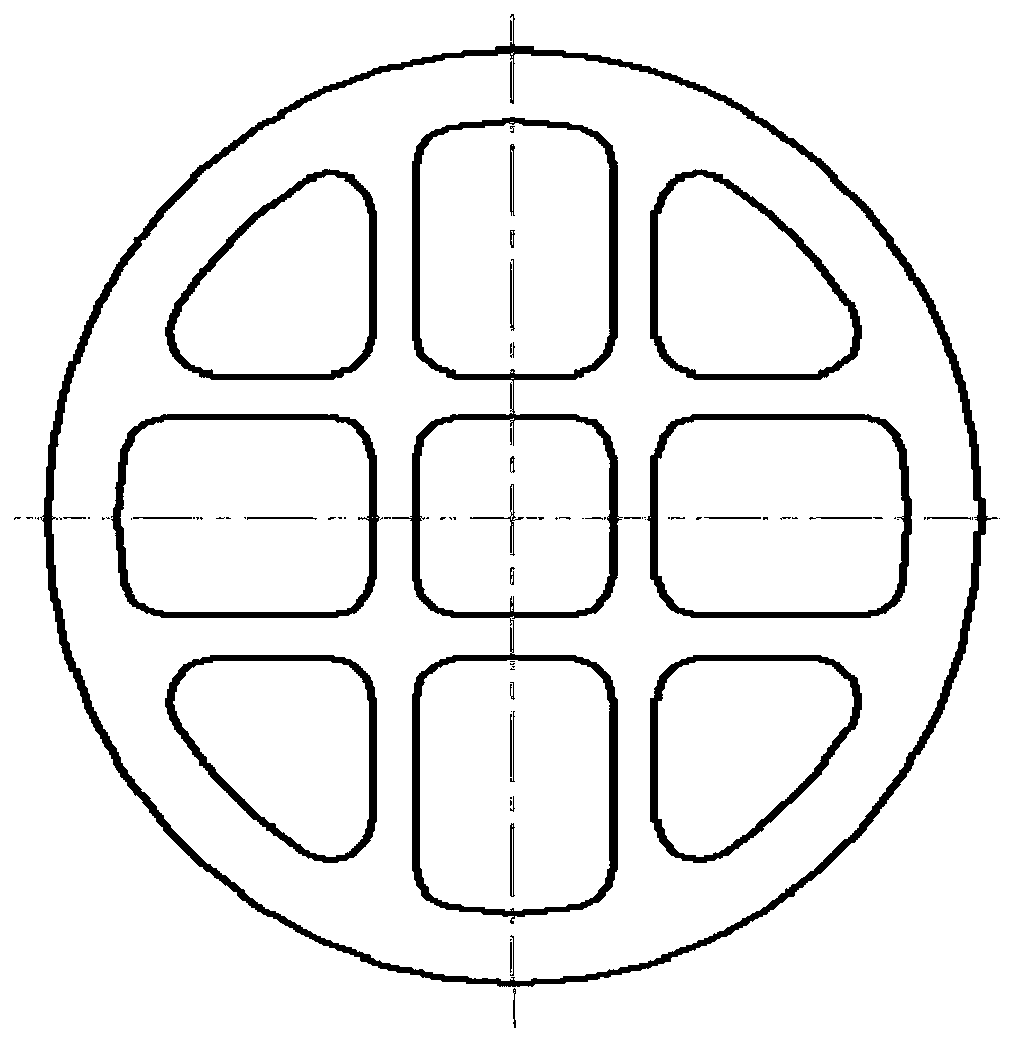

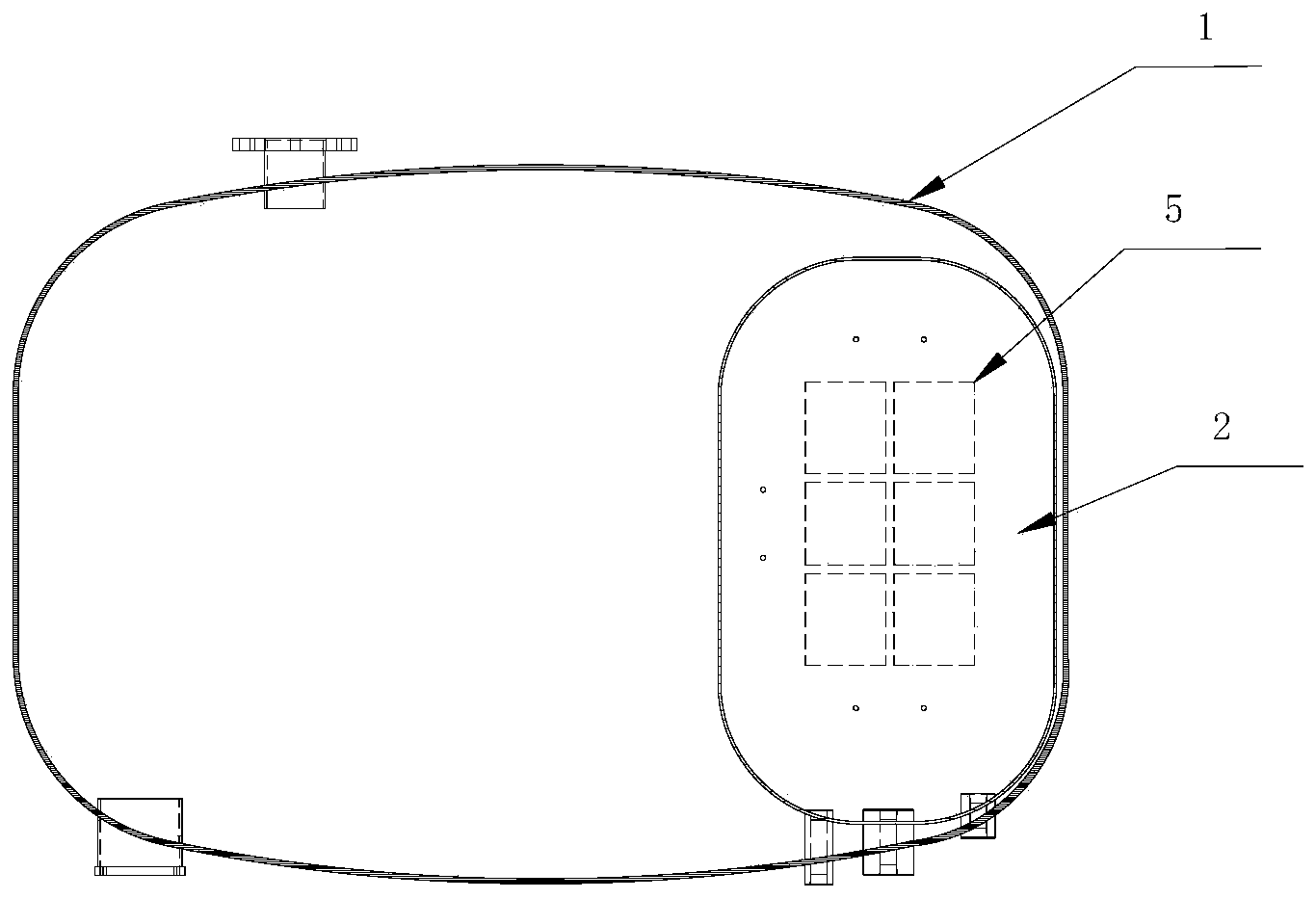

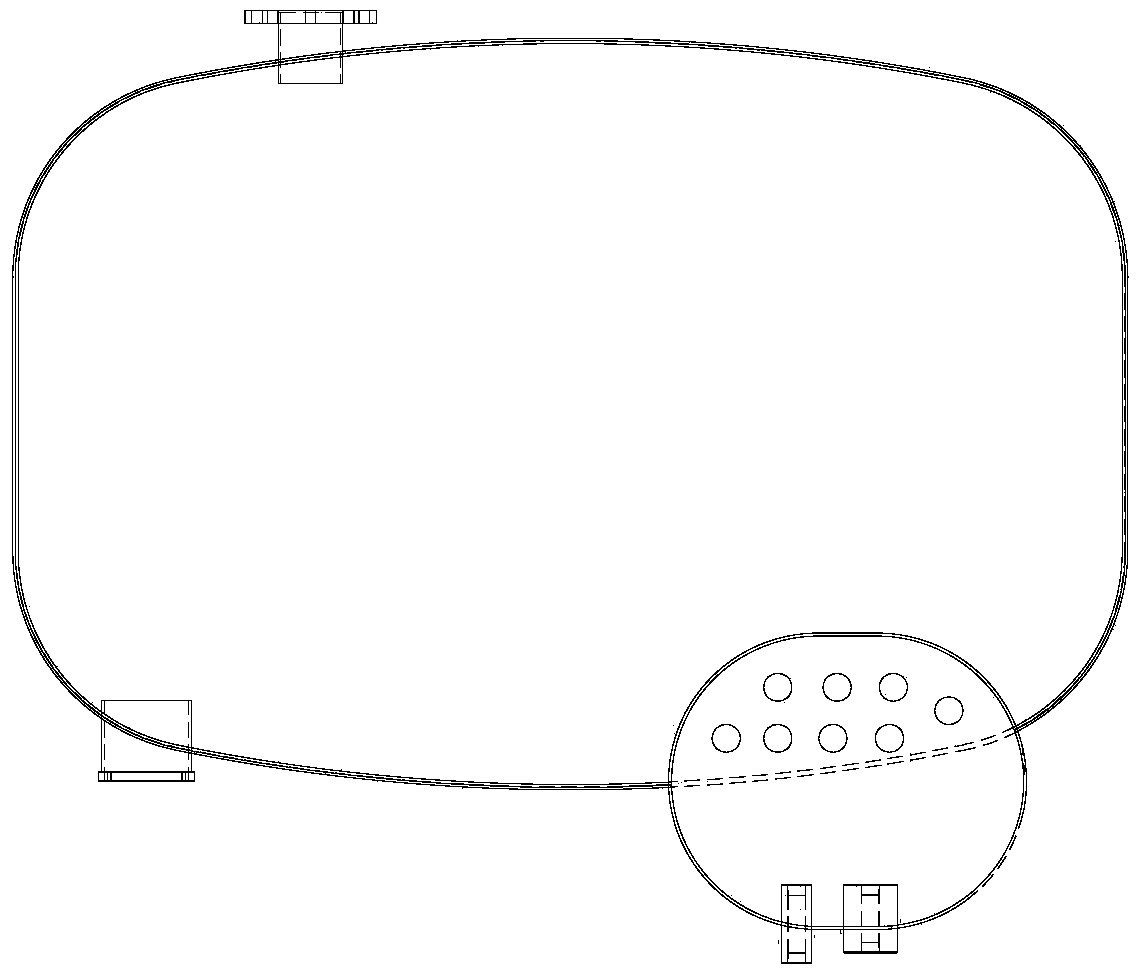

Efficient full-management device for surface tension storage tank propulsive agent

The invention discloses an efficient full-management device for a surface tension storage tank propulsive agent, belongs to the technical field of space propulsion and particularly relates to a management device used for a satellite propulsion system propulsive agent. Four axial pipelines are arranged and are evenly distributed in the circumferential direction, and two axial hydraulic accumulatorsare installed on each axial pipeline; and the four axial pipelines are redundancy backup mutually, and it can be ensured that the propulsive agent is conveyed into the management device stably underthe micro-gravity environment as long as lone channel is connected with liquid. By means of the efficient full-management device, a ring-shaped channel and the axial channels are installed and fixed to a crossed-shaped supporting frame, the ring-shaped pipeline is of a circular ring pipe-shaped structure, the ring-shaped pipeline communicates with the axial channels through the crossed-shaped supporting frame, meanwhile, the crossed-shaped supporting frame can fix the axial channels and the ring-shaped pipeline, and rigidity of the whole management device is improved.

Owner:BEIJING INST OF CONTROL ENG

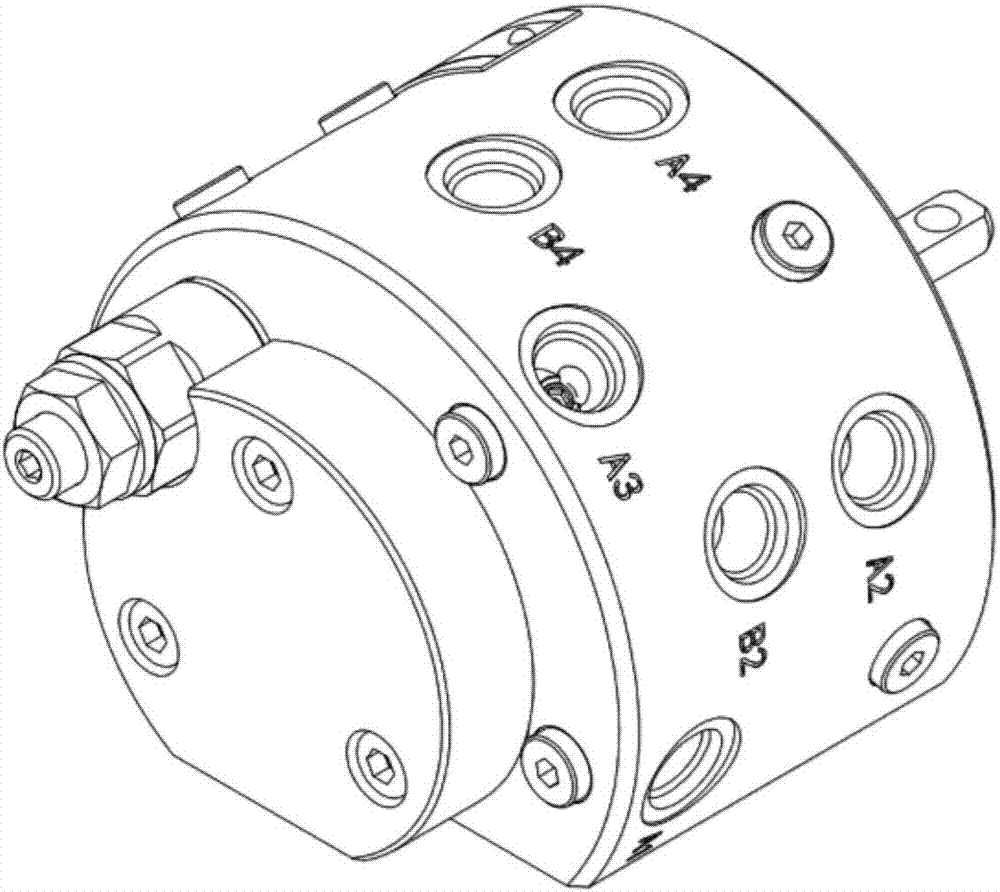

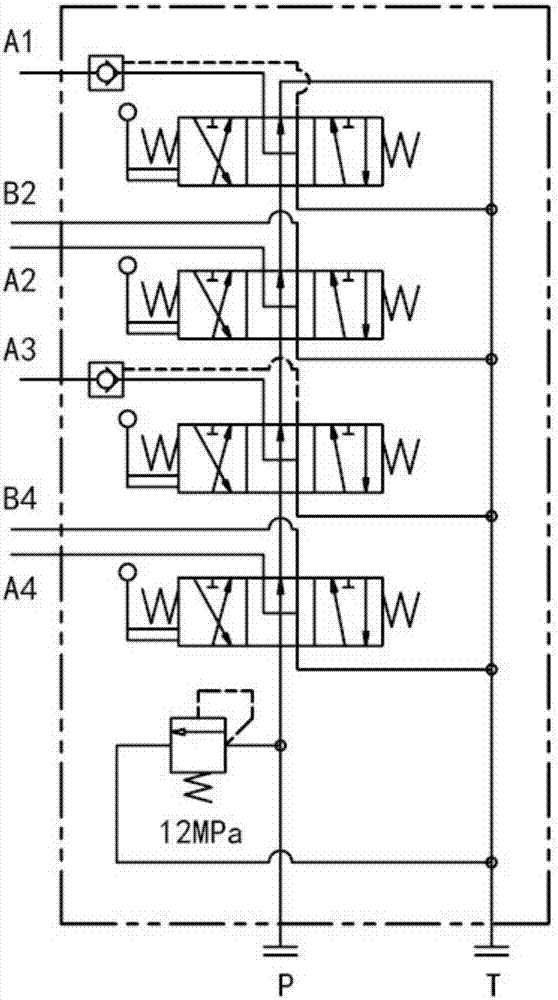

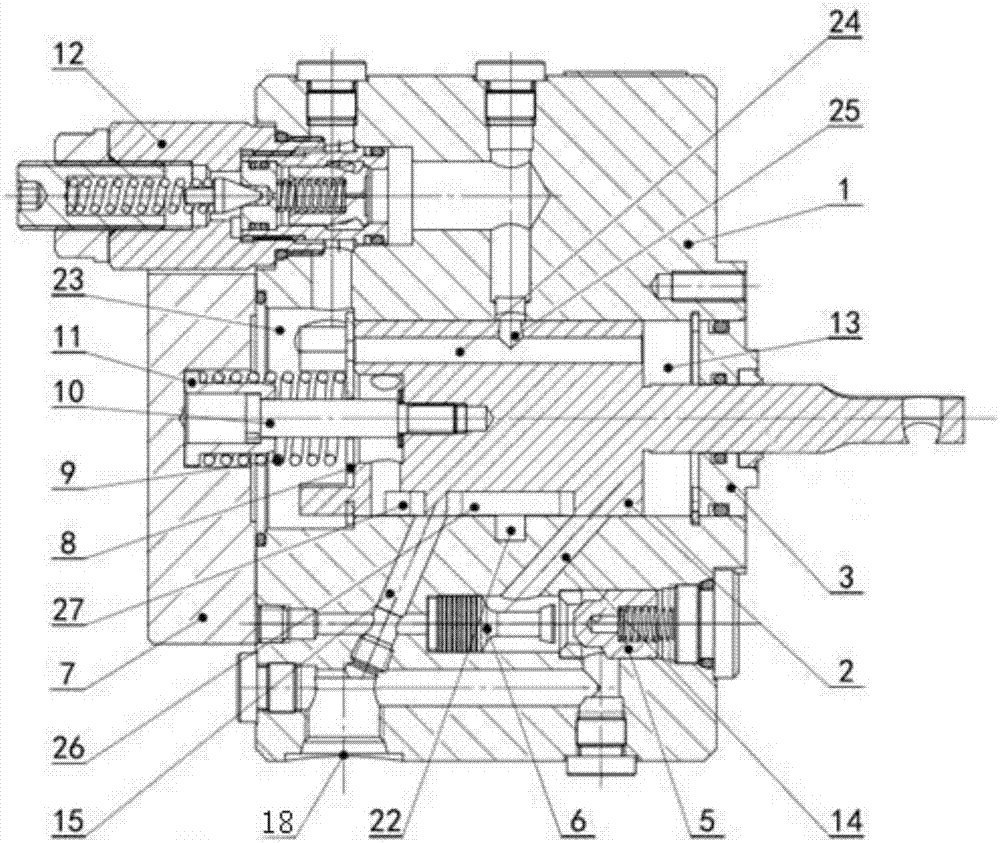

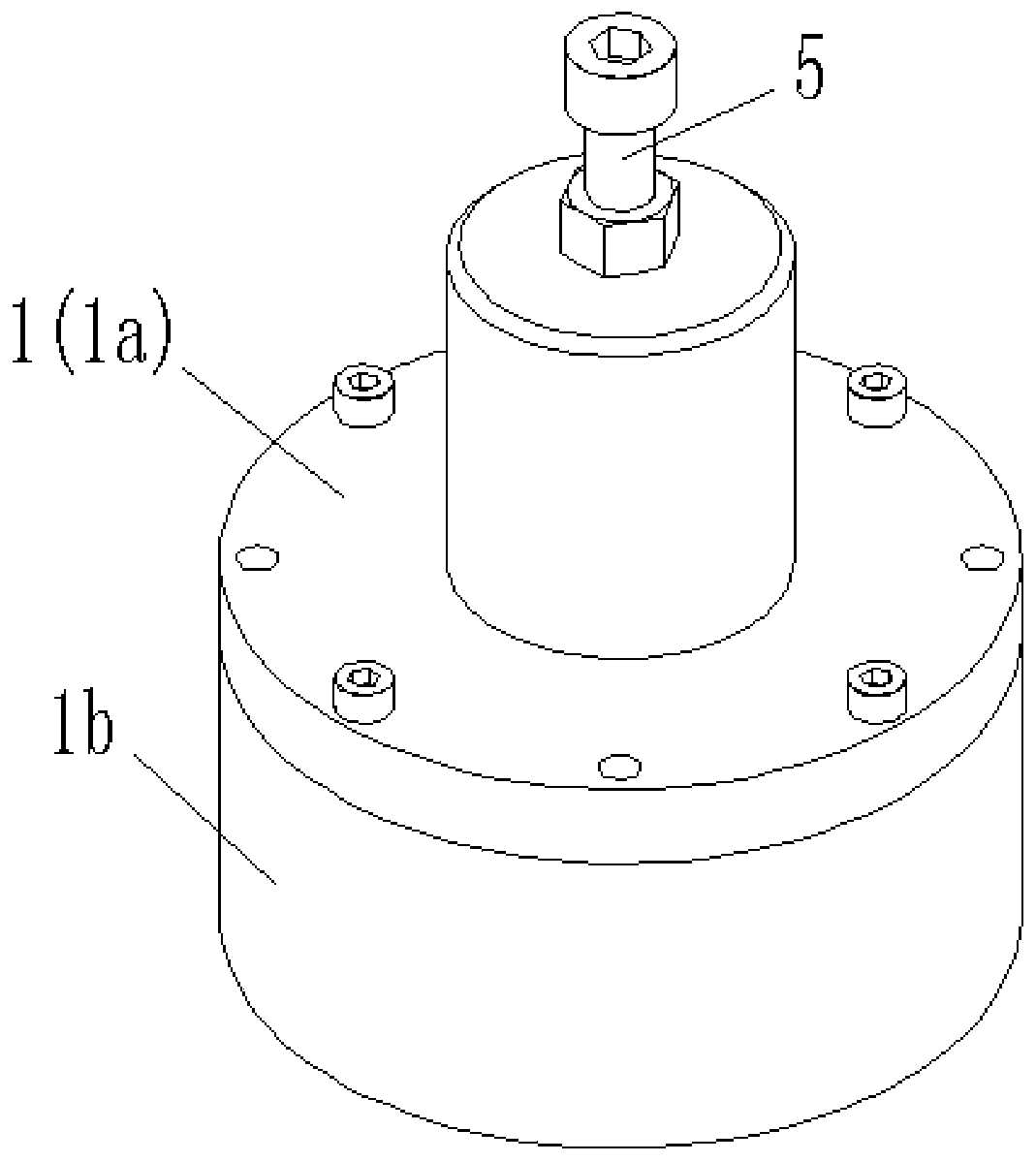

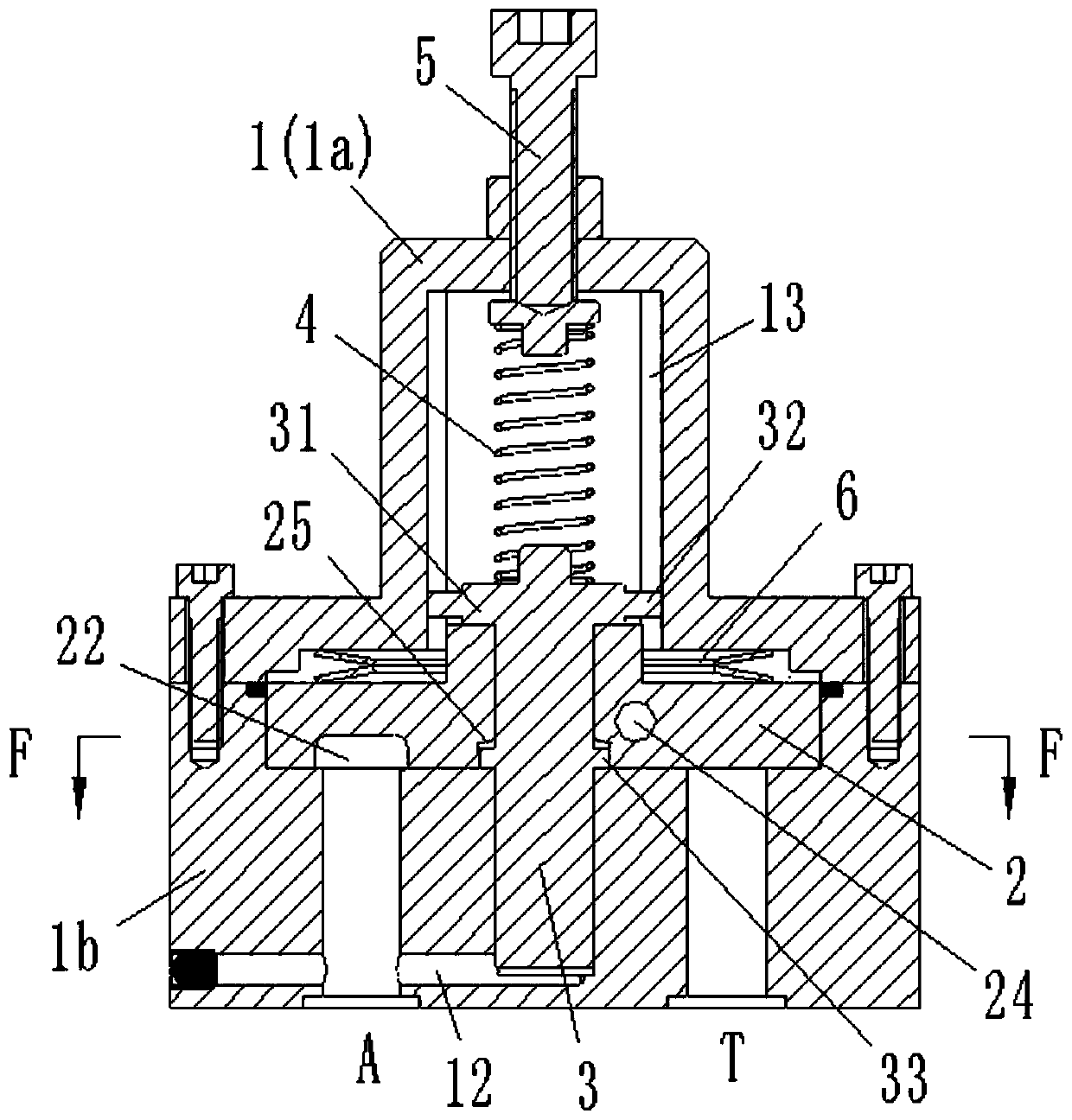

Rotary multi-way valve with pressure maintaining and shock preventing functions

ActiveCN107035738AAvoid pressure fluctuationsGuaranteed non-interferenceServomotor componentsMultiple way valvesSet screwEngineering

The invention relates to a rotary multi-way valve with pressure maintaining and shock preventing functions, and belongs to the technical field of fluid reversing valves. The technical problems that for an existing valve, a pressure maintaining function can not be achieved, operation is tedious, and misoperation is liable to be caused are solved. According to the technical scheme, the rotary multi-way valve with the pressure maintaining and shock preventing functions comprises a valve body, a valve element, a front end cover, a back end cover and a safety valve assembly and further comprises a valve element positioning sheet, a reset spring, a fastening screw and a spring base; a valve element hole is formed in the center of the valve body, a P-cavity annular groove is formed in the middle of the valve element hole, a T-cavity annular groove is formed in the end, close to the back end cover, of the valve element hole, the P-cavity annular groove communicates with an oil inlet, and the T-cavity annular groove communicates with an oil return inlet; the valve element is arranged in the valve element hole and can rotate around the axis of the valve element and axially move; two groups of inclined fluid working channels and two groups of parallel vertical fluid working channels are formed in the axial cross section of the valve body.

Owner:TAIZHONG GRP YUCI HYDRAULIC IND

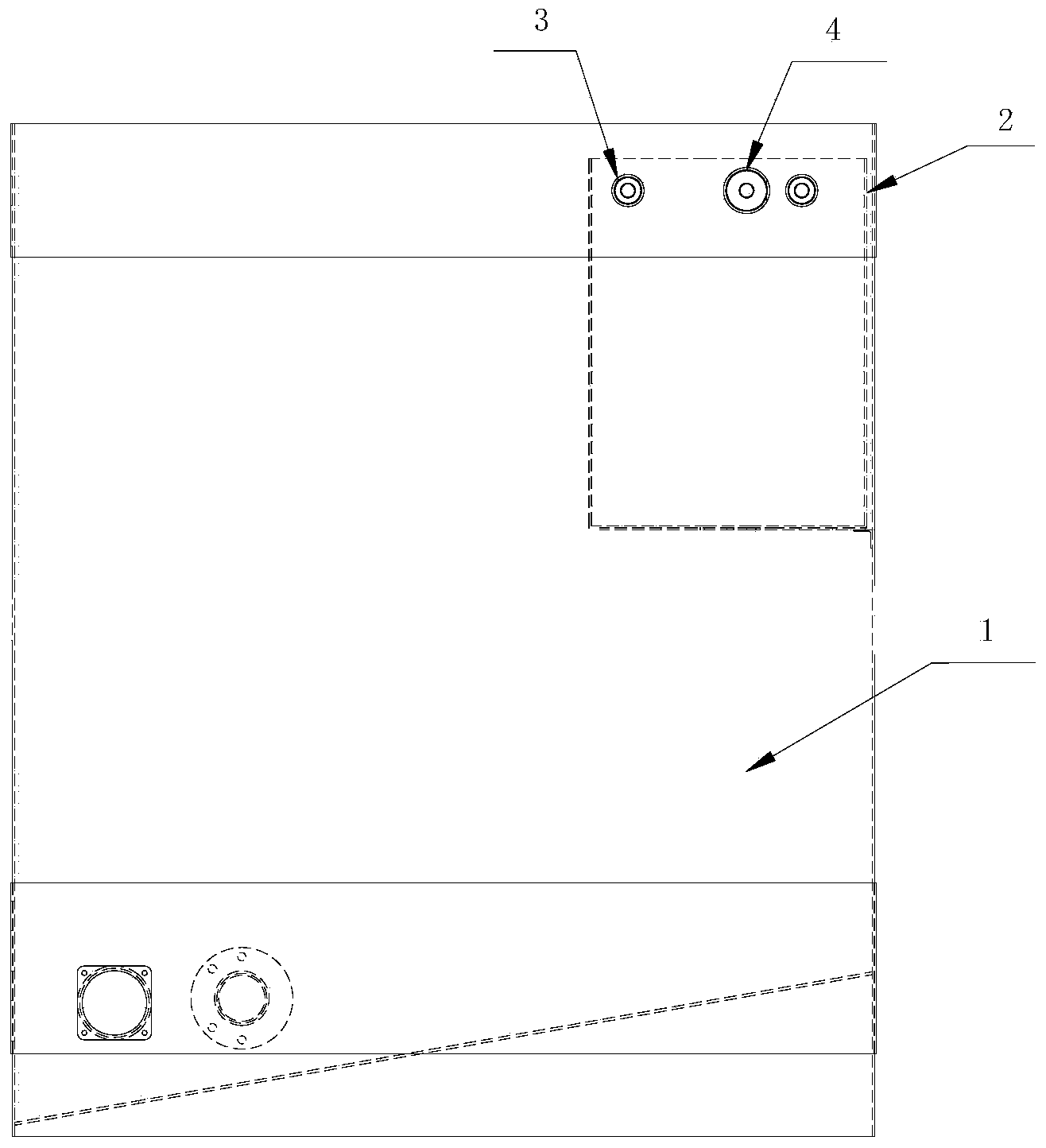

Novel oil tank structure of compressed natural gas (CNG) hydraulic gas-filling substation prying body

InactiveCN103557189AAvoid stress shocksGood stable structurePump assembliesCompressed natural gasFuel tank

The invention provides a novel oil tank structure of a compressed natural gas (CNG) hydraulic gas-filling substation prying body. The novel oil tank structure comprises a main oil tank, a pressure detection hole and an oil return hole, wherein the pressure detection hole and the oil return hole are arranged in the main oil tank. An oil return detection oil tank is arranged in the main oil tank, the pressure detection hole and the oil return hole are communicated with the oil return detection oil tank, and the oil return detection oil tank is provided with an oil return diffusion hole communicated with the main oil tank. Thick plates and the firmer structure is adopted for the oil return detection oil tank, the main oil tank avoids direct pressure impact, the integrated structure is easy to stabilize, even thin plates can be adopted, and gas loss caused by detection of oil return pressure is greatly reduced.

Owner:GTE GLOBAL TIANJIN

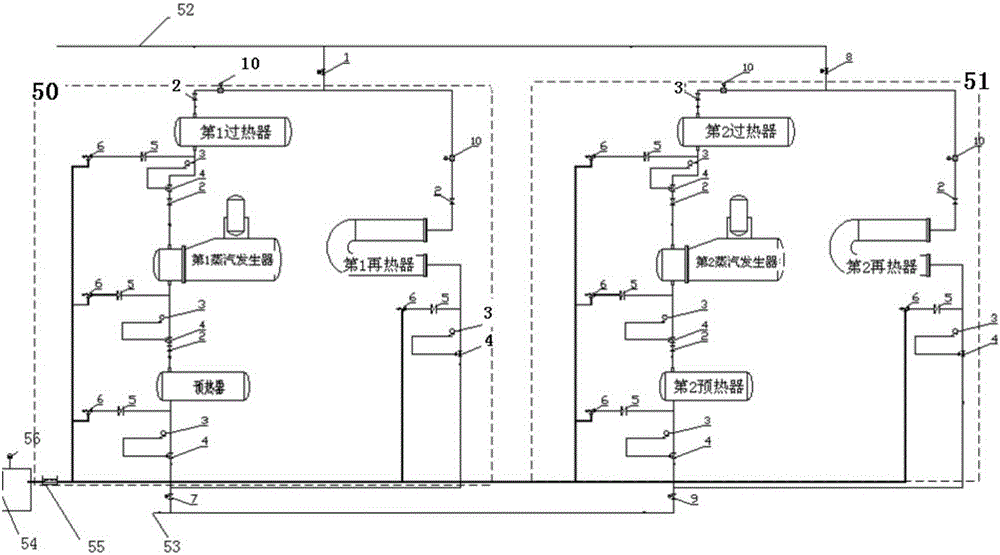

Heat conduction oil leakage detection system and method for steam generation systems of photo-thermal power station

InactiveCN106595080AEasy to maintainGuaranteed uptimeSolar heating energySolar heat devicesSuperheaterPower station

The invention provides a heat conduction oil leakage detection system and method for steam generation systems of a photo-thermal power station. The steam generation systems of a photo-thermal power station are arranged in two rows; each row of steam generation system includes a pre-heater, a steam generator, a super-heater and a re-heater; accordingly, the heat load of each row of steam generation system is 50% of the total load of the power station; and compared with one row of steam generation system, the heat load of each device in each row of steam generation is decreased, and then the probability of leakage can be decreased from the source. A safe protective device for preventing pressure impact is arranged on each row of steam generation system, once leakage occurs, the pressure can be reduced timely and effectively; the whole row of steam generation system with leakage can be isolates timely, thereby facilitating maintaining it; and the other row of steam generation system works normally, it is ensured that the photo-thermal power station can normally work, and the reliability of the whole system can be improved.

Owner:中广核太阳能开发有限公司 +1

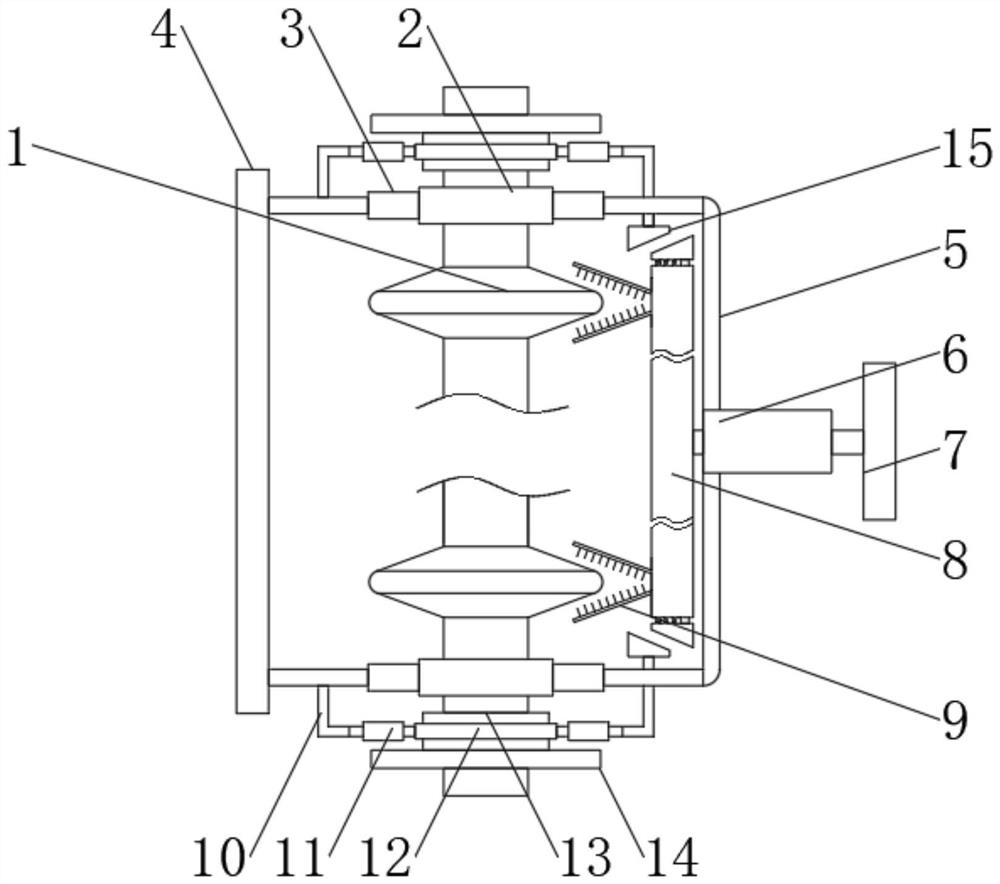

High mountain windproof porcelain insulator

The invention relates to the technical field of porcelain insulators, and discloses a high-mountain windproof porcelain insulator, which solves the problem that the use performance of a common porcelain insulator is easily reduced due to long-time wind blowing in the process of using the porcelain insulator in a high mountain. The porcelain insulator comprises an insulator body, bearings are symmetrically and rotatably arranged on the insulator body, and telescopic rods are symmetrically installed on the bearings, a wind shield is installed at one end of one telescopic rod, vertically-arranged connecting rods are installed at one end of the other telescopic rod, the connecting rods are symmetrically installed on a driver, a wing plate is installed at one end of the driver, a positioner is installed at the other end of the driver, and brush frames are symmetrically installed on the positioner. According to the invention, through cooperative use of the wind shield, the wing plates, the bearings and the like, the wind shield can be located on the front wind surface through the wing plates when there is wind, and the wind is blocked through the wind shield so that the insulator body on the inner side is well protected.

Owner:江西尚高电瓷电气有限公司

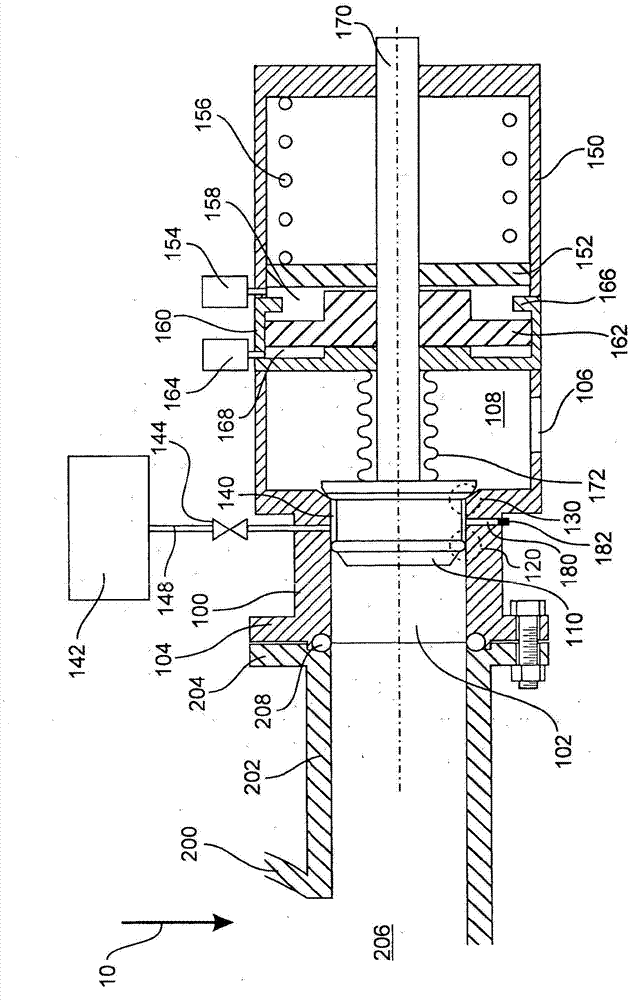

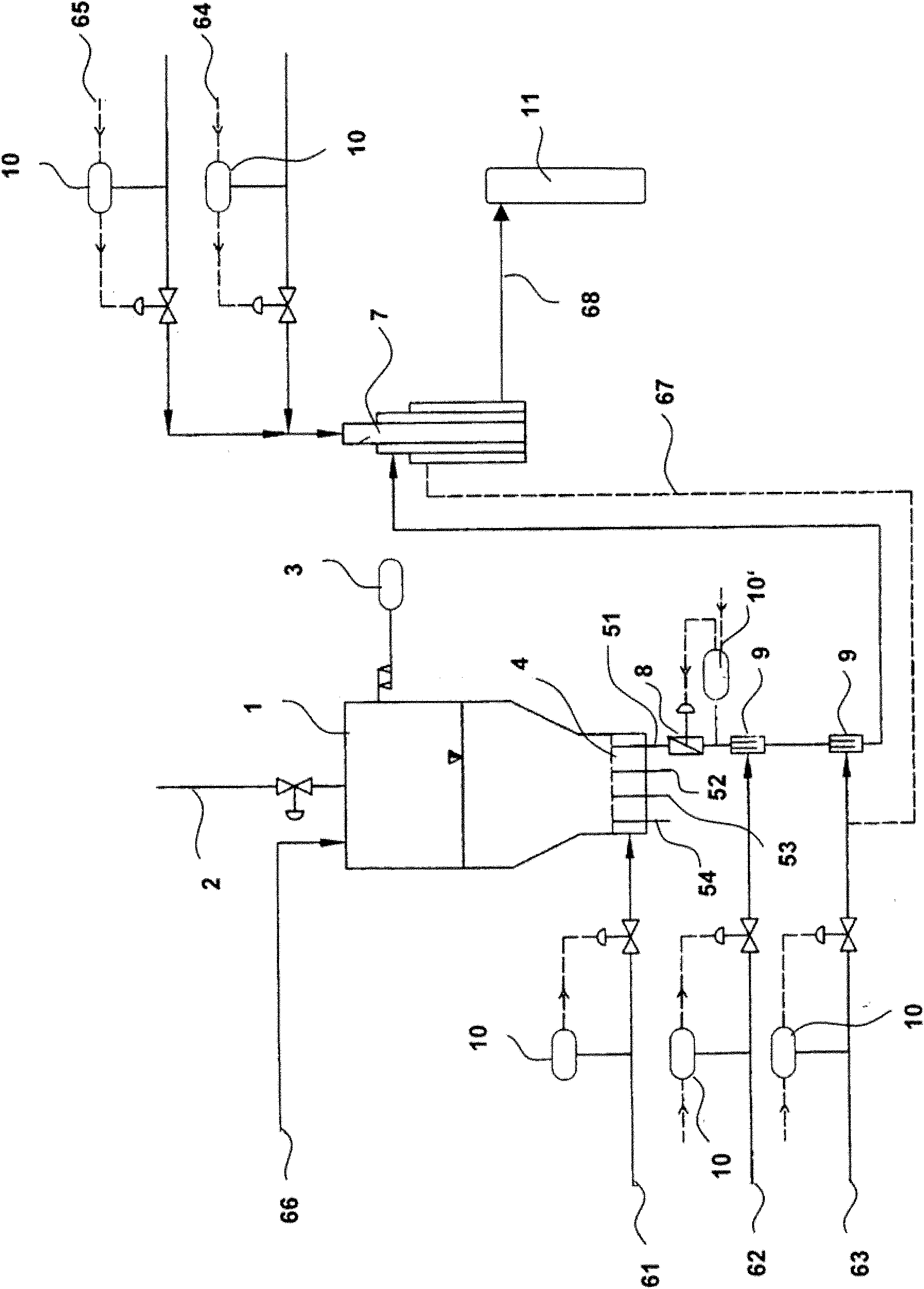

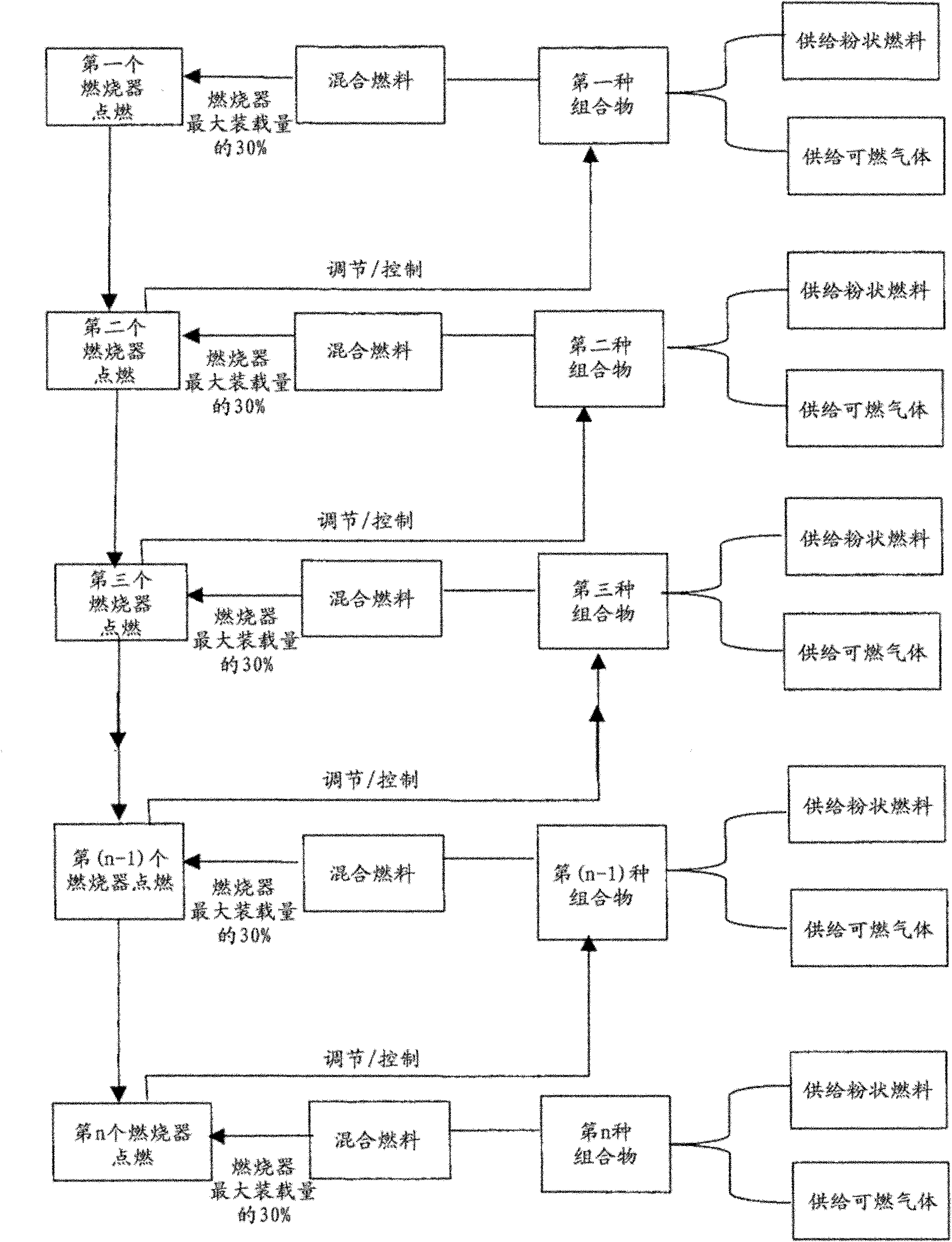

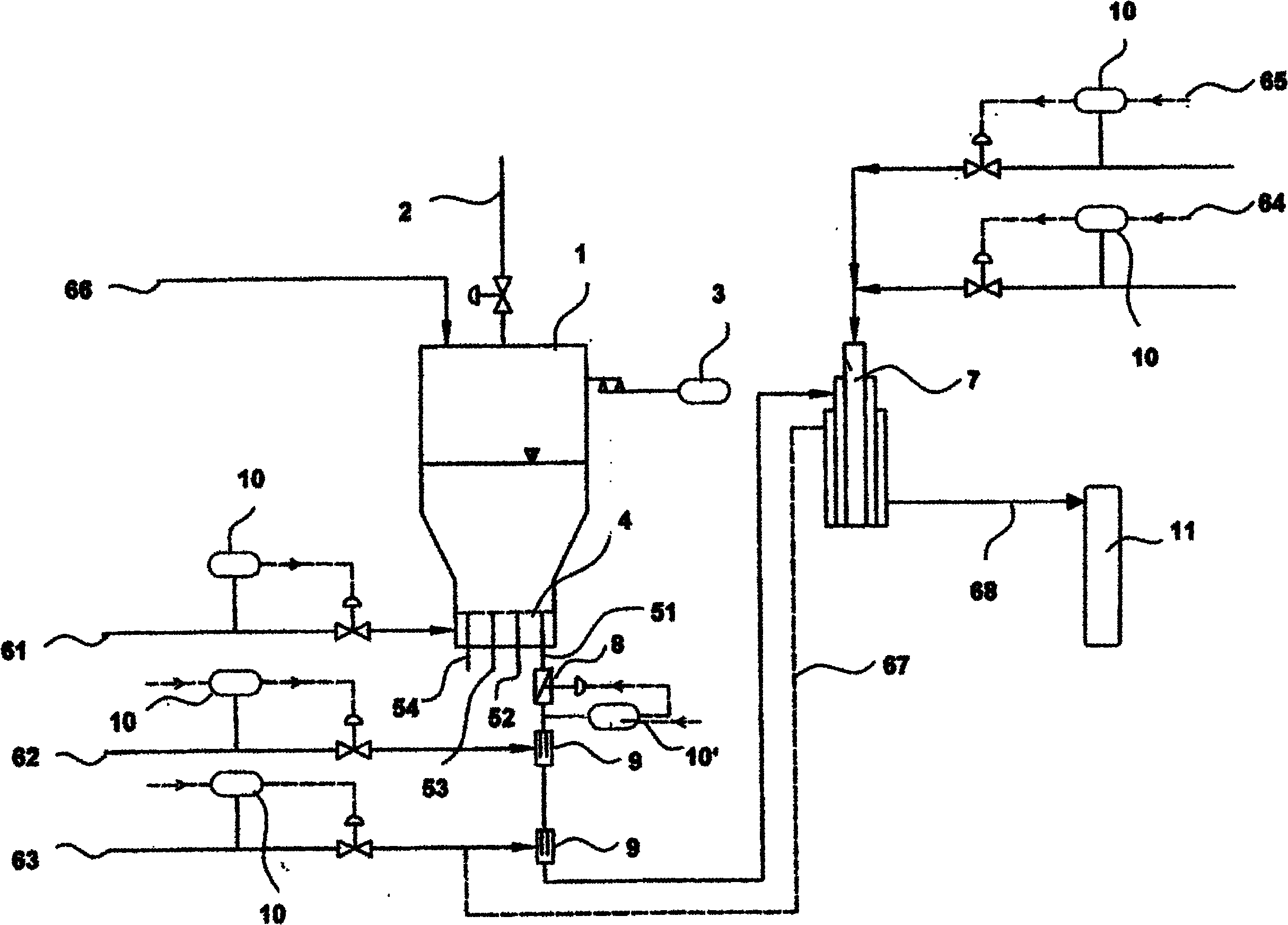

Method and apparatus for starting up gasifying reactors operated with combustible dust

ActiveCN102105567AAvoid stress shocksAvoid pressure fluctuationsGasification processes detailsCombined combustion mitigationCombustorCombustible gas

The invention relates to a method for starting up a gasifying reactor comprising a plurality of burners. In this case, each burner is charged via a dense-stream delivery line (51, 52, 53, 54) assigned to it with combustible dust from a metering vessel (1) and charged via a gas delivery line (62, 63) with combustible gas, wherein a fuel mixture of combustible dust and combustible gas is provided before a point in time at which a burner is ignited, wherein a first composition of combustible dust and combustible gas with which a first burner is charged for ignition is controlled in dependence on the amount of fuel fed to the second burner for ignition, said second burner being charged with a second composition of combustible dust and combustible gas for ignition, after the ignition of a second burner following the ignition of the first burner,; and so the starting up of each of the plurality of burners of the gasifying reactor takes place with a controlled supply of the fuel load. The invention also relates to a gasifying reactor (7) for carrying out the method according to the invention.

Owner:西门子能源全球两合公司

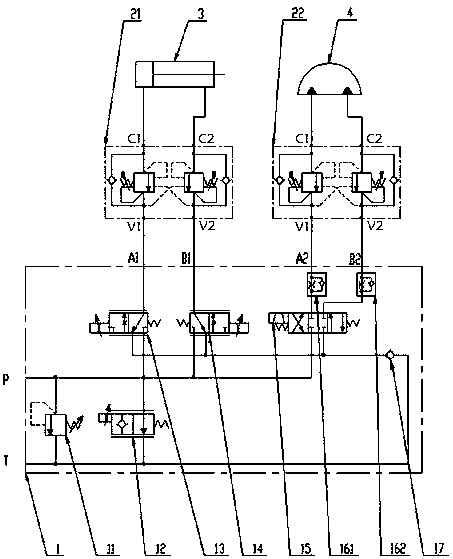

Multifunctional working bucket electro-hydraulic leveling valve group

PendingCN107605843AAvoid stress shocksRealize micro controlServomotor componentsElectro hydraulicSelf compensation

The invention discloses a multifunctional working bucket electro-hydraulic leveling valve group. The working bucket electro-hydraulic leveling valve group communicates with the V1 end and the V2 end of a first balance valve and the V1 end and the V2 end of a second balance valve. The C1 end and the C2 end of the first balance valve communicate with two end openings of a leveling oil cylinder. TheC1 end and the C2 end of the second balance valve communicate with two end openings of a swing oil cylinder. Load self compensation two-position three-way electronic proportional valves directly complete pressure load sensitive compensation control. The two two-position three-way electronic proportional valves are combined to control the direction and speed of the leveling oil cylinder. Rated flowof two valve cores are arranged asymmetrically to easily achieve small-flow high-resolution flow precision control of the leveling oil cylinder of asymmetric compression areas. An unloading electronic proportional valve and a one-way return throttle valve are combined to control the swing speed of a working bucket to realize small flow micro-control, and meanwhile, the swing speed ratio of the working bucket is adjustable. A one-way backflow valve isolates pressure impact caused by rapid emergency unloading of the unloading electronic proportional valve.

Owner:XCMG XUZHOU TRUCK MOUNTED CRANE

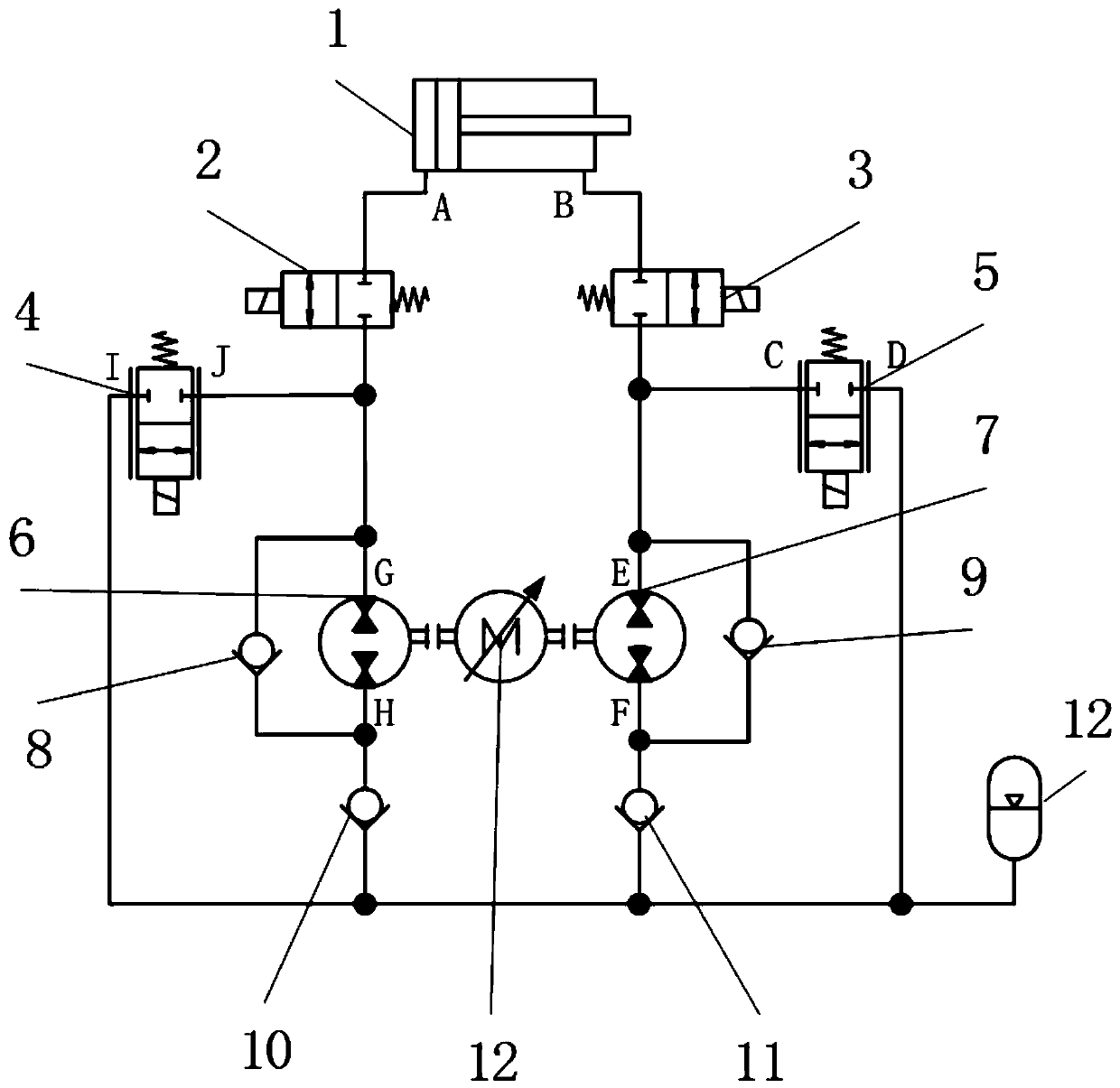

Hydraulic system adopting independent compound control

InactiveCN111271327AShorten the timeAvoid stress shocksFluid-pressure actuator safetyServomotor componentsHydraulic cylinderSolenoid valve

The invention discloses a hydraulic system adopting independent compound control. The hydraulic system comprises a hydraulic cylinder, wherein a rod cavity end of the hydraulic cylinder is connected to a first two-way metering pump through a first solenoid valve; the first two-way metering pump is connected to a second two-way metering pump through a first one-way valve and a second one-way valve;the second two-way metering pump is connected to a piston cavity of the hydraulic cylinder through a second solenoid valve; the first two-way metering pump and the second two-way metering pump are driven by a variable-speed motor; an energy accumulator is further arranged between the first one-way valve and the second one-way valve; a third one-way valve is connected on the first two-way meteringpump in parallel; a fourth one-way valve is connected on the second two-way metering pump in parallel; a first proportional throttle valve is connected on the first two-way metering pump and the first one-way valve in parallel; a second proportional throttle valve is connected on the second two-way metering pump and the second one-way valve in parallel; and the solenoid valves, the proportional throttle valves and the variable-speed motor are controlled by a master controller.

Owner:FUJIAN UNIV OF TECH

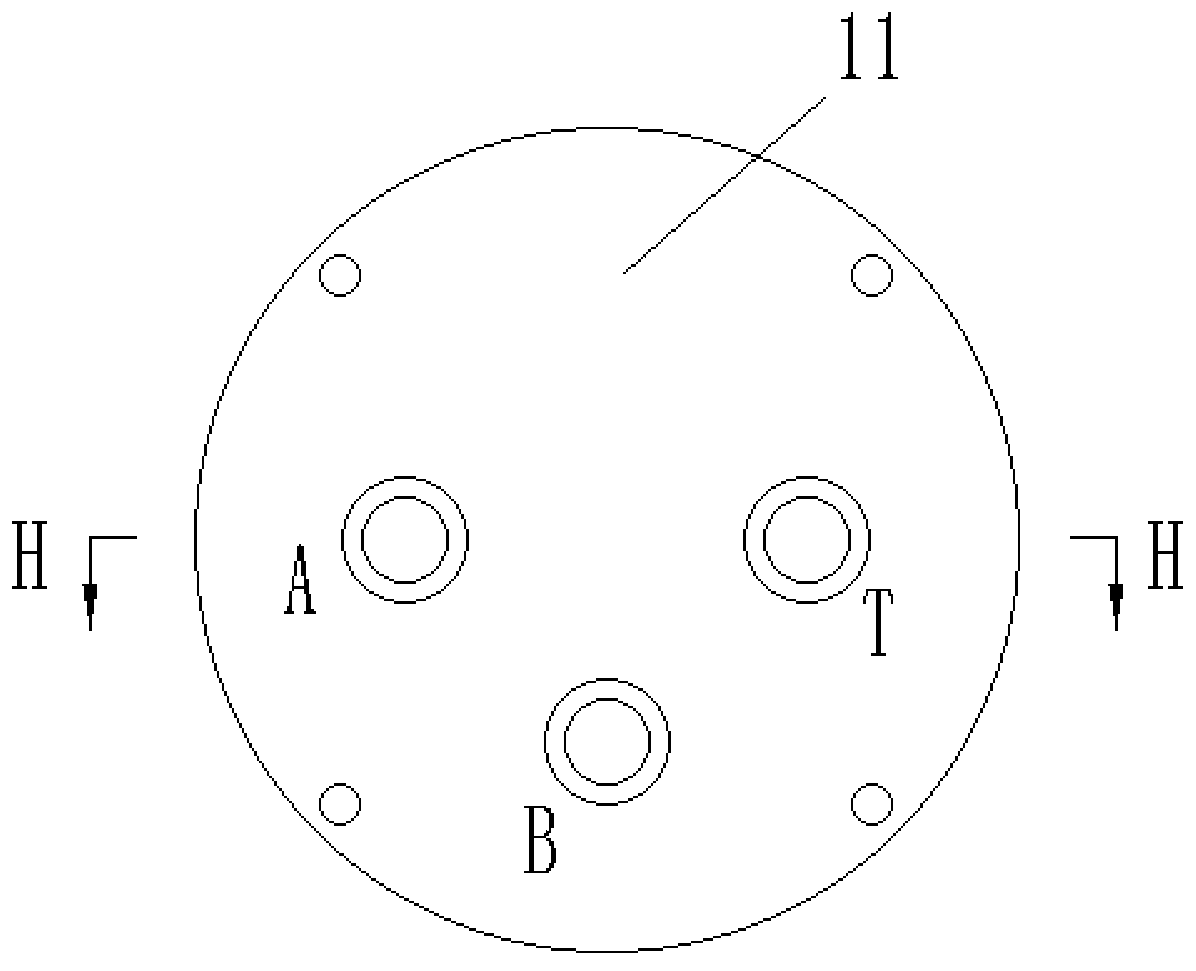

Combination flow control valve of double pump

ActiveCN110762253AReduce volumeExtended service lifeOperating means/releasing devices for valvesMultiple way valvesEngineeringControl valves

The invention belongs to the technical field of hydraulic valves, and discloses a combination flow control valve of a double pump. The combination flow control valve comprises a valve body, a valve element and a control rod. An opening A, an opening B and an opening T are arranged on the valve body. The control rod is located in the valve body and can do axial relative movement relative to the valve body. The valve element is of a disc type structure and is arranged on the control rod in the valve body in a sleeved manner, and the valve element is driven to rotate when the control rod axiallymoves. An arc groove and an auxiliary hole which are communicated through an inner duct are formed in the work end face of the valve element. In the process that the valve element rotates around the control rod, the opening B is communicated with one of the opening A and the opening T through the arc groove and the auxiliary hole, or the opening B, the opening A and the opening T are communicatedat the same time. When the opening B is communicated with the opening A through the arc groove, the opening T and the auxiliary hole keep closed. When the opening B is communicated with the opening Tthrough the arc groove, the opening A and the auxiliary hole keep closed or communicated. The combination flow control valve of the double pump is small in structural size and low in manufacturing cost, and multiple control functions can be achieved at the same time.

Owner:江苏军源装备制造有限公司

Device for bottling beverages

ActiveUS8757226B2No excessive loadingSmall flow cross-sectionLiquid fillingOperating means/releasing devices for valvesEngineeringFill device

Owner:KRONES AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com