Device for bottling beverages

A bottling and valve device technology, applied in the direction of valve operation/release device, valve device, safety device of filling device, etc., can solve problems such as gasket failure, high pressure, impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

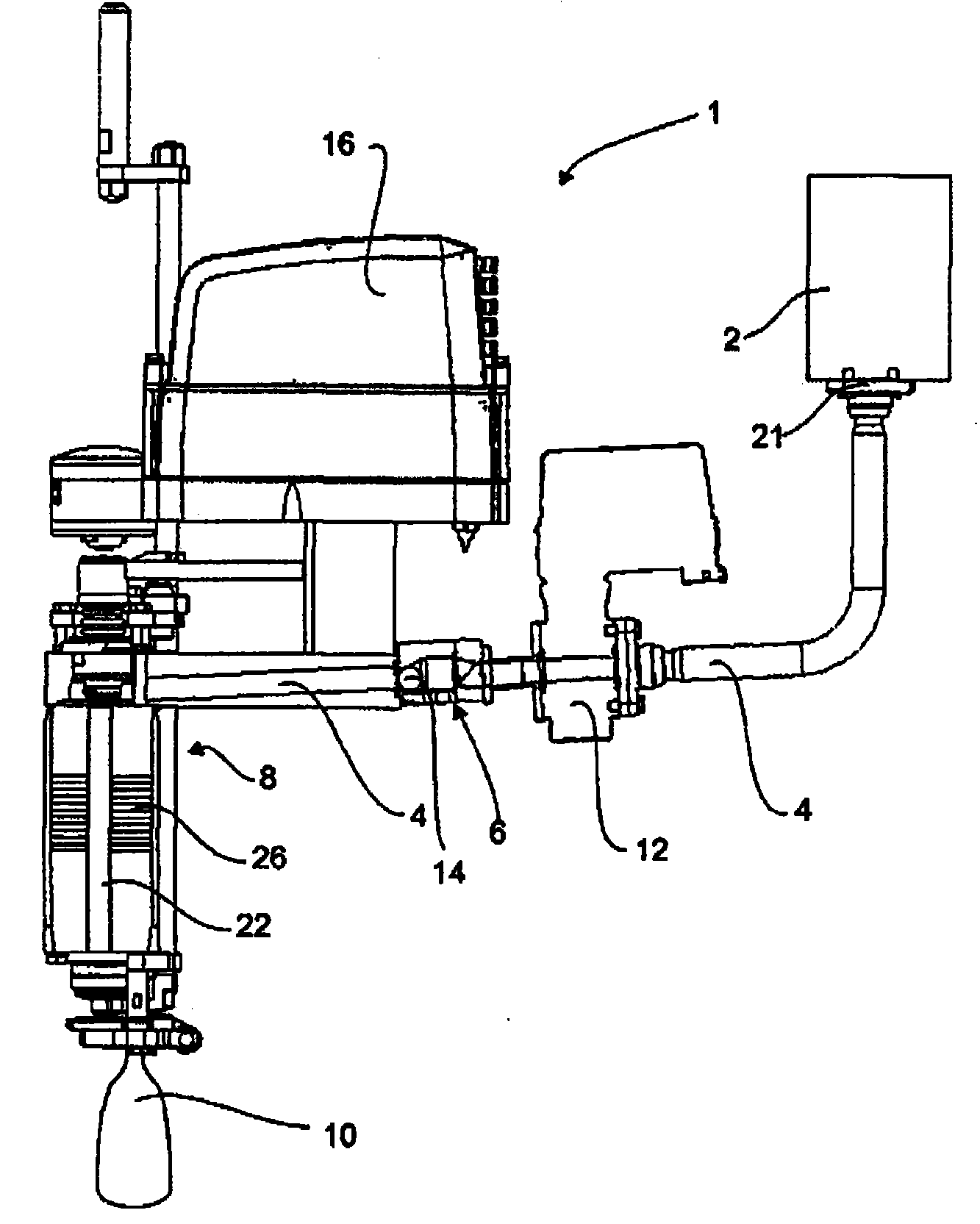

[0026] Figure 1 shows a general view of the device for filling containers according to the invention. Here, reference numeral 2 designates a storage container (shown only schematically) from which medium or beverage is filled into the container (not shown) by means of a delivery line 4 . Reference numeral 22 denotes a supply line, for example by means of which a gaseous medium such as carbon dioxide or nitrogen is supplied to the container 10 . The beverage to be bottled passes around this air line 22 . For this purpose, a bellows-type seal 26 (shown only schematically) is provided, which controls the supply of beverage into the container.

[0027] In the event of a failure, such as sometimes occurs in the event of a bottle breaking, the beverage to be bottled flows through the valve arrangement 24 under high pressure and may damage the valve arrangement 24 .

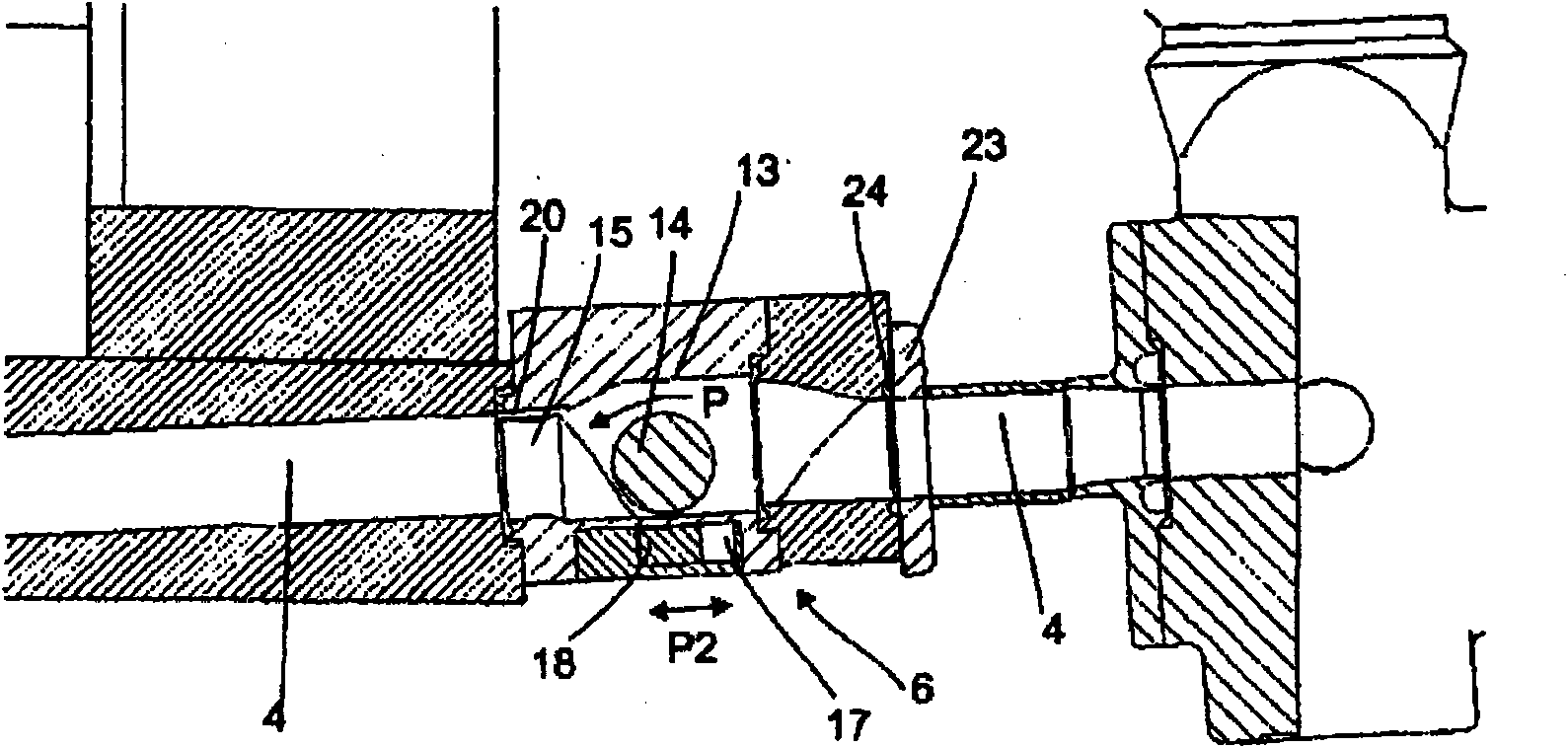

[0028] In order to avoid such damage, a valve device 6 , embodied as a non-return valve, is arranged inside the del...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com