Rotary multi-way valve with pressure maintaining and shock preventing functions

A multi-way valve, anti-shock technology, applied in the direction of multi-way valve, valve device, fluid pressure actuating device, etc., can solve the problems of no pressure holding, cumbersome operation, easy to cause misoperation, etc., to avoid pressure fluctuation and action. Flexible, stable and reliable reversing action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

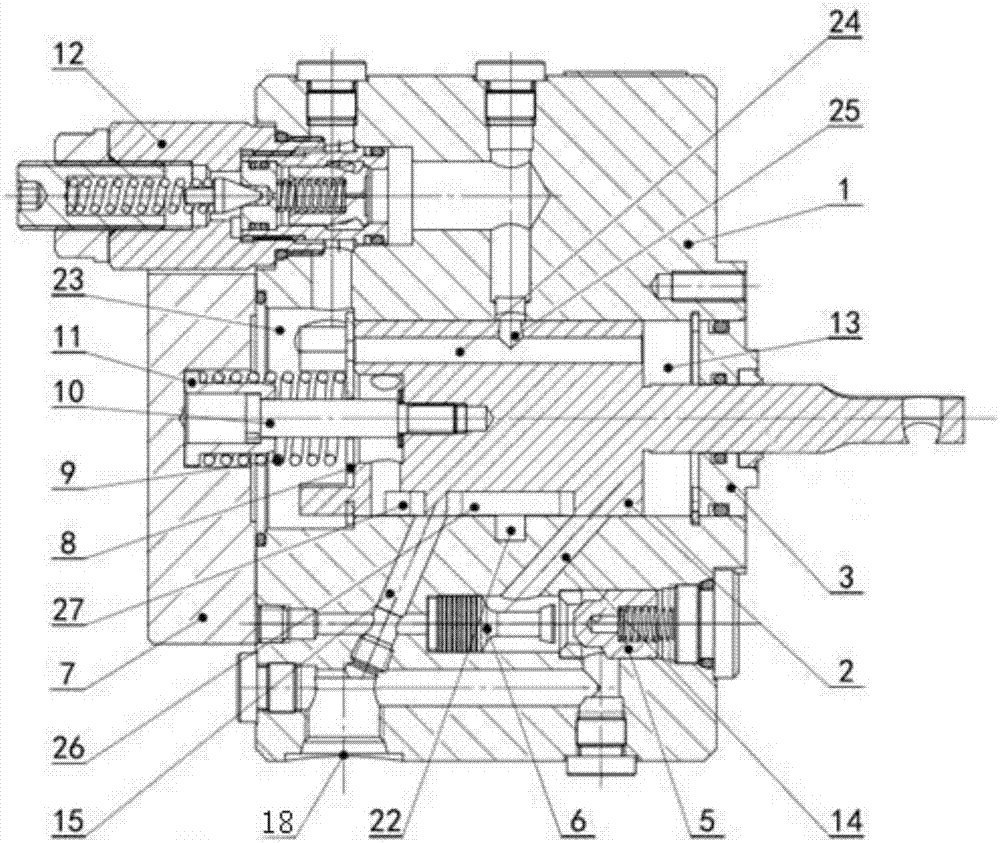

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

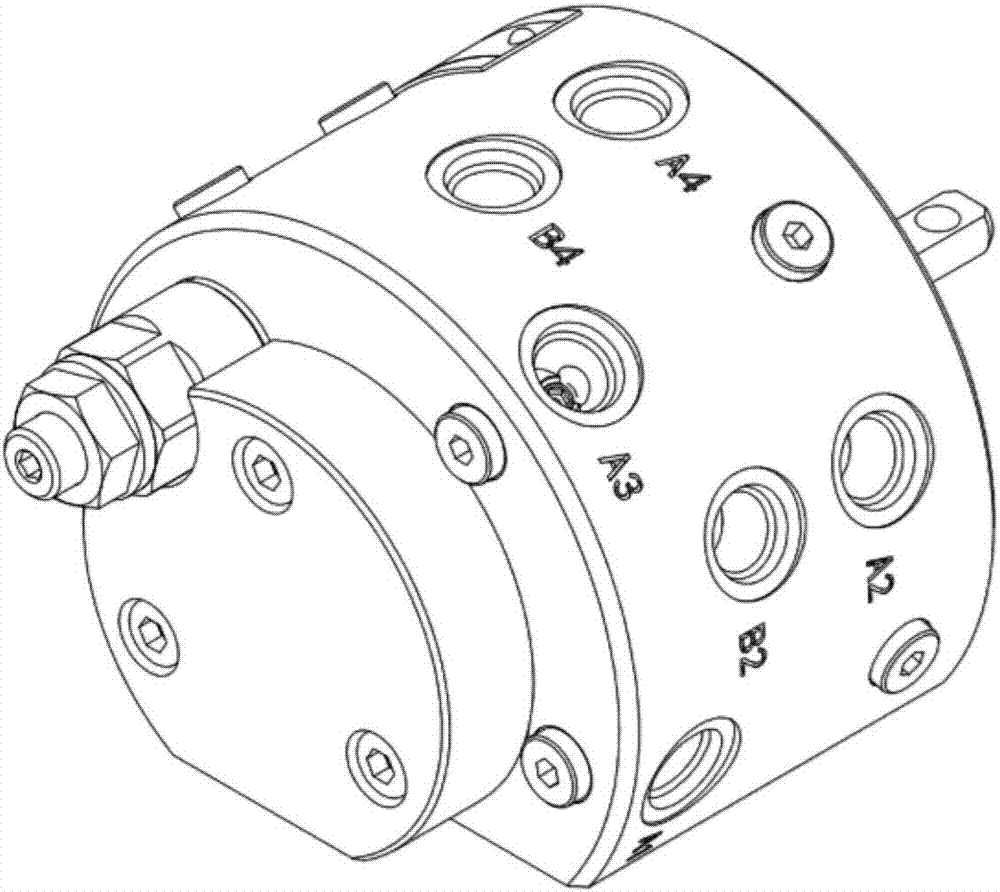

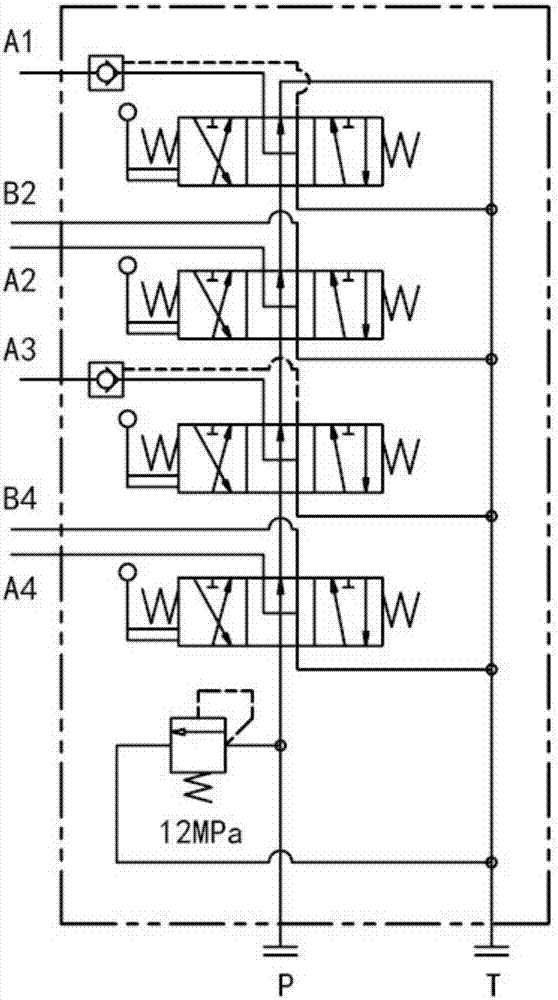

[0024] Such as Figure 1 to Figure 7 As shown, a rotary multi-way valve with pressure maintaining and anti-shock includes a valve body 1, a valve core 2, a front end cover 3, a rear end cover 7 and a safety valve assembly 12, wherein: it also includes a valve core positioning piece 8, a reset Spring 9, set screw 10 and spring seat 11;

[0025] The center of the valve body 1 is provided with a spool hole 13, the middle part of the spool hole 13 is provided with a P cavity annular groove 22, and the end of the spool hole 13 near the rear end cover 7 is provided with a T cavity annular groove 23. P cavity annular groove 22 communicates with the oil inlet, and the T cavity annular groove 23 communicates with the oil return port; the front end cover 3 is arranged in the valve core hole 13 and is located at one end of the valve core hole 13, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com