Method and apparatus for starting up gasifying reactors operated with combustible dust

A technology of gasification reactor and powdered fuel, which is applied in the direction of granular/powdered fuel gasification, gasification process, manufacture of combustible gas, etc., to achieve the effect of avoiding adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

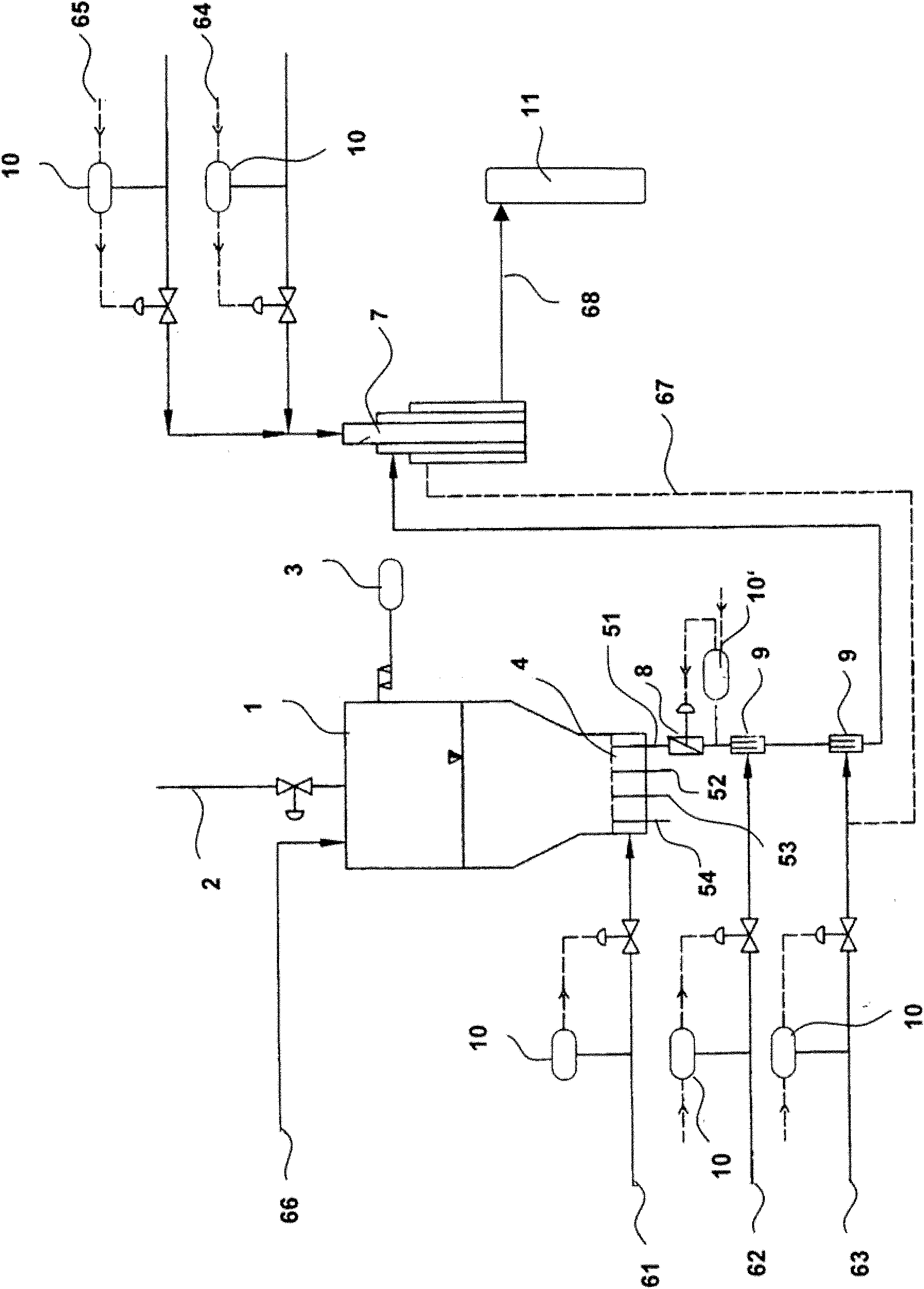

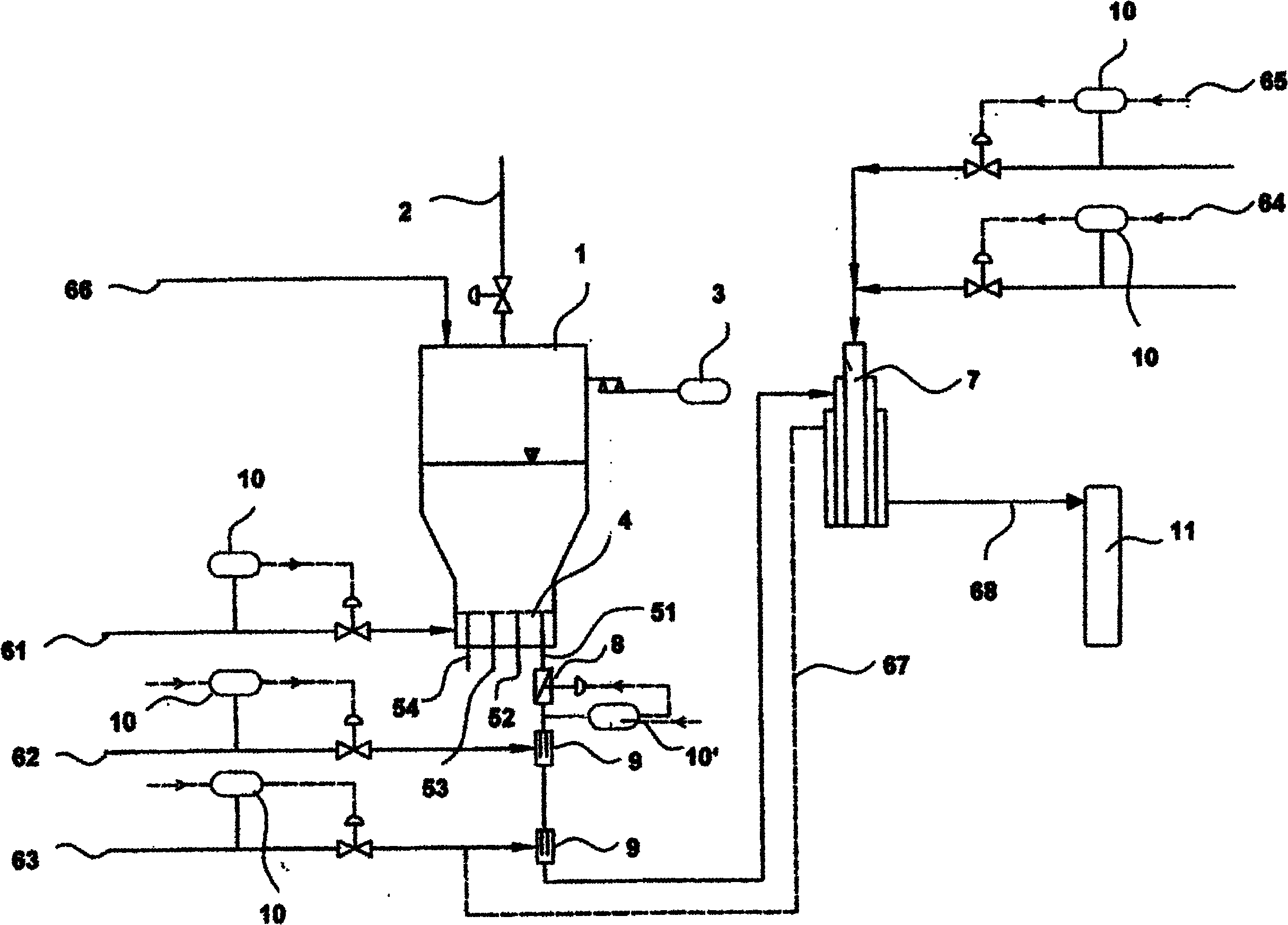

Image

Examples

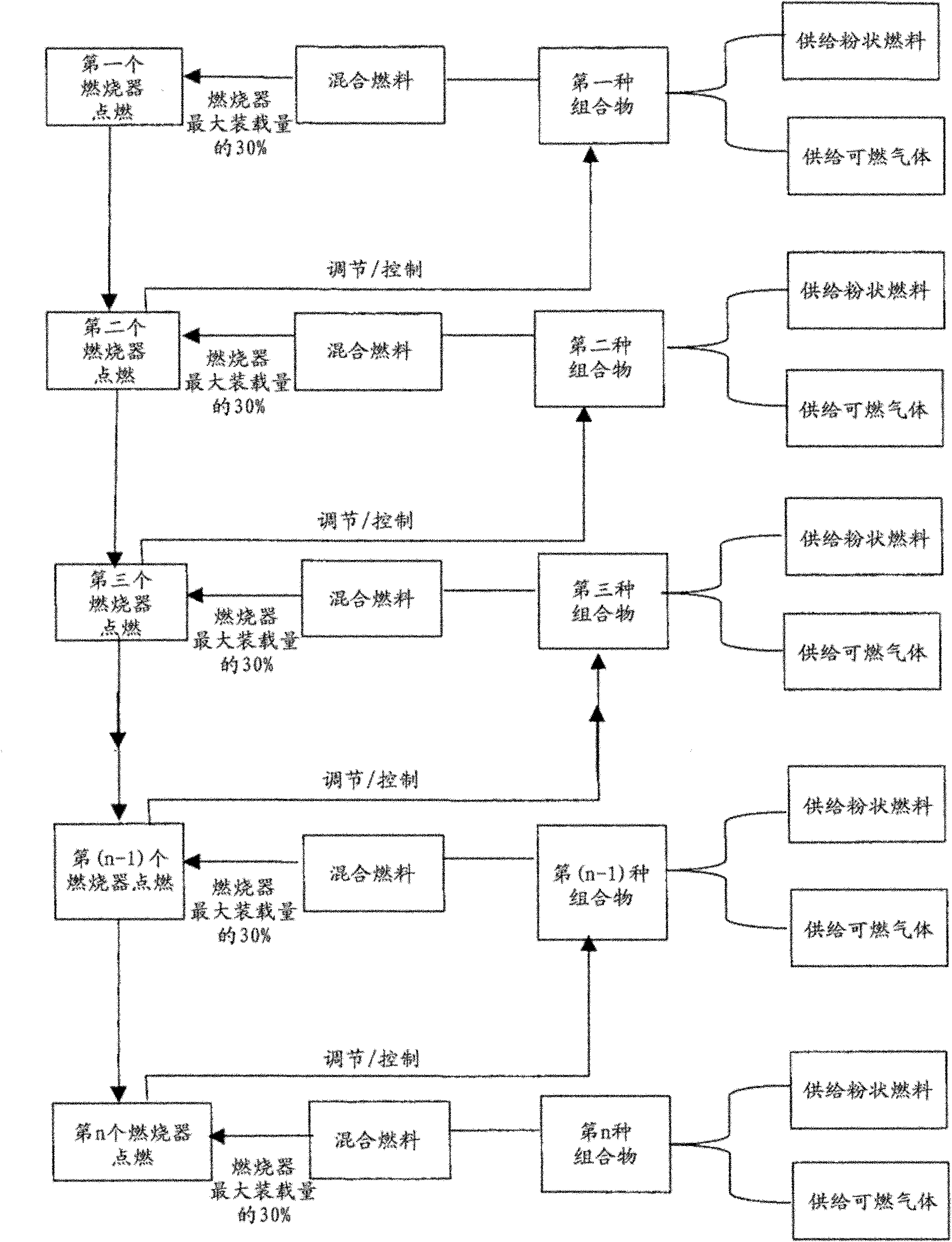

Embodiment Construction

[0019] In order to illustrate the meanings of related terms and concepts, as they should be understood in the present invention, some following terms and concepts are defined below.

[0020] "Start-up" of the gasification reactor is understood to start operation by igniting the burner. If all burners of the gasification reactor are firing, the start-up is ended and the gasification reactor works in normal operation.

[0021] The concept of "fuel charge" refers to the mass flow or volume flow of fuel, which may be gaseous, liquid and / or solid fuel converted by the gasification reactor. The burner of the gasification reactor must operate at a "minimum output velocity" at the burner outlet when ignited, which is in the range of 3 to 5 m / s to avoid flame backlash (flashback).

[0022] In a gasification reactor, a "synthesis gas" comprising carbon monoxide and hydrogen is obtained from the fuel employed, and the resulting synthesis gas is further utilized in downstream processing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com