Hydraulic system adopting independent compound control

A technology of hydraulic system and compound control, applied in the field of hydraulic system, can solve the problems of frequent opening and closing of safety valve, affecting the rapidity of acceleration process, prolonging adjustment time, etc., so as to improve system rigidity and dynamic performance, improve stability and efficiency, The effect of reducing throttling loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] specific implementation plan

[0029] In conjunction with accompanying drawing, introduce content of the present invention in detail:

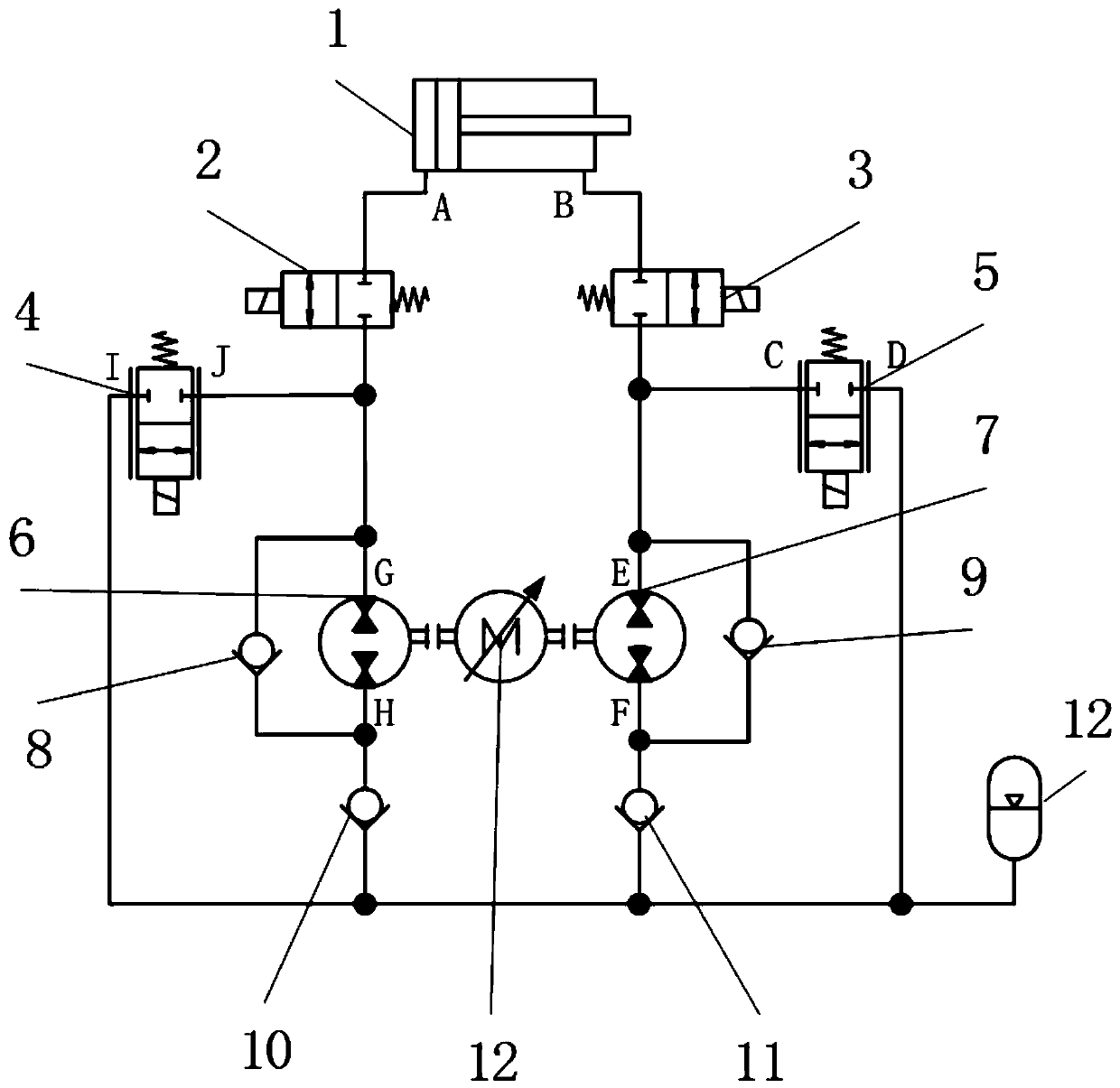

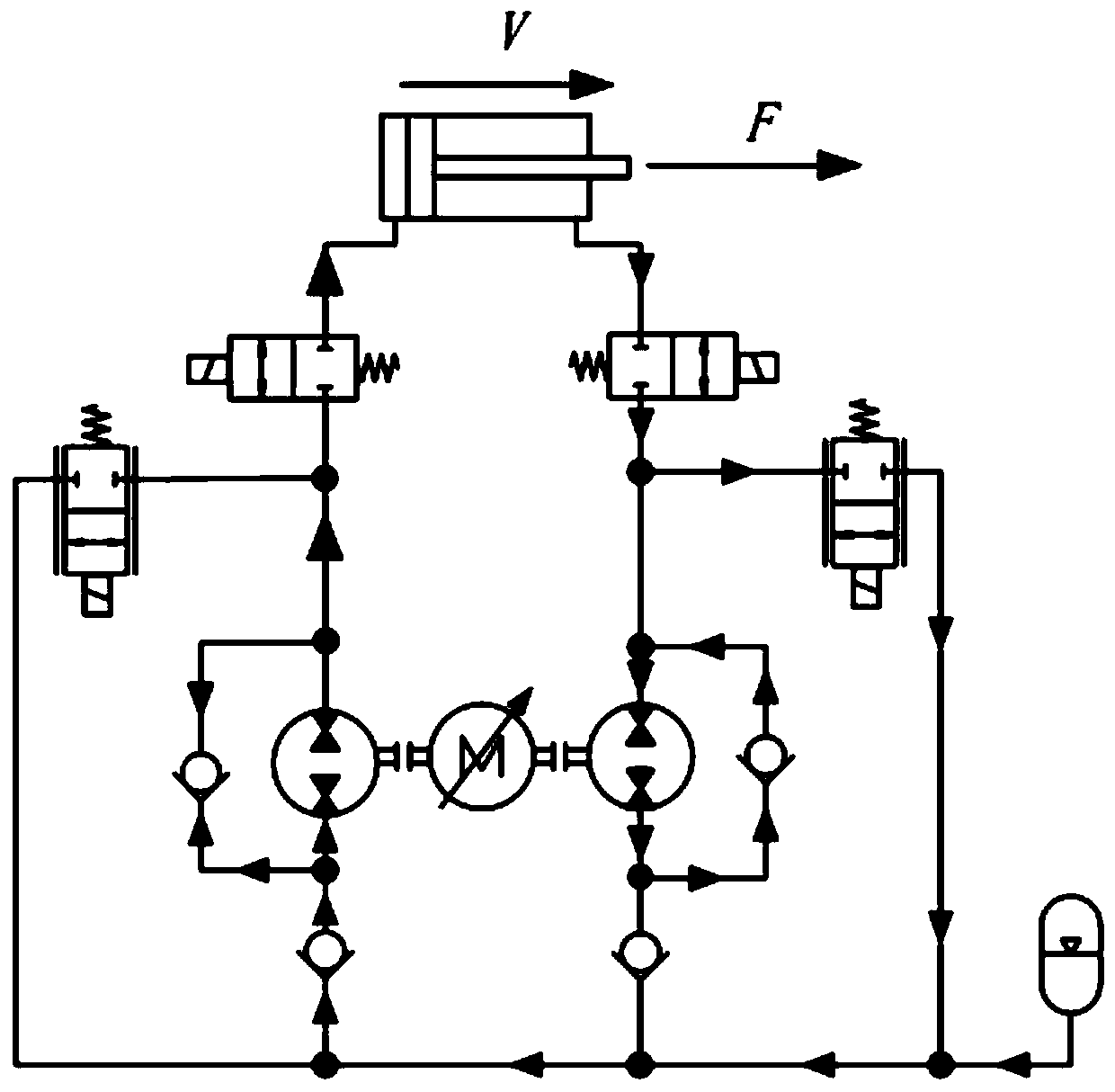

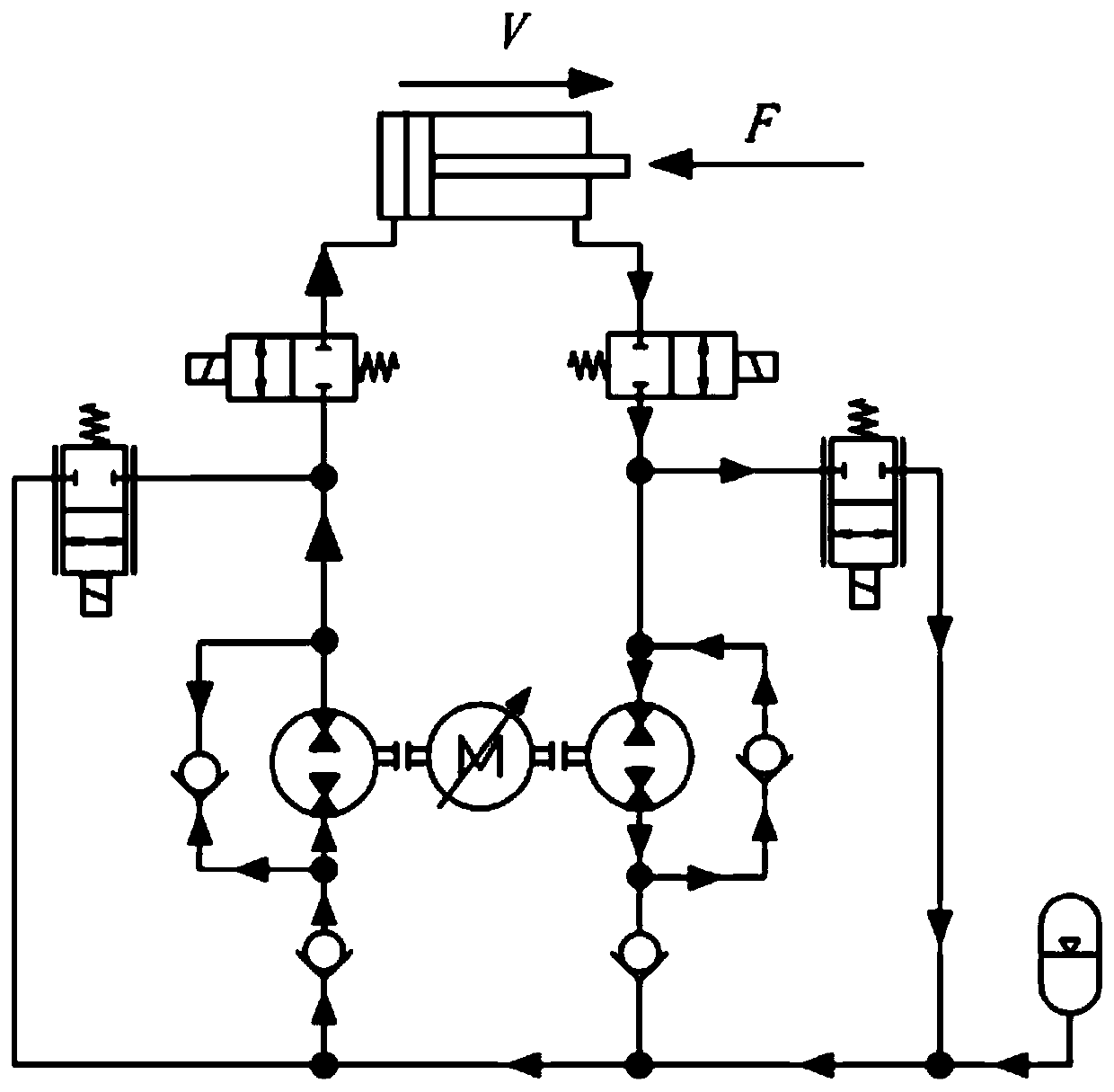

[0030] The hydraulic principle diagram of the technical scheme of the present invention is as follows figure 1 Shown:

[0031] 1. Hydraulic cylinder; 2, 3, two-position two-way solenoid valve; 4, 5, two-position two-way proportional throttle valve; 6, 7, two-way quantitative pump; 8, 9, 10, 11, one-way valve; 12 , variable speed motor; 13, accumulator.

[0032] As shown in the figure, hydraulic cylinder 1 has rod chamber end B oil port connected to E oil port of bidirectional quantitative pump 7, and a two-position two-way solenoid valve 3 is connected in series between BE oil ports, and two-position two-way solenoid valve 3 is used in the system The position of the hydraulic cylinder is fixed when it is not working or when it is necessary to keep the hydraulic cylinder in a static state; a check valve 9 is connected in parallel to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com