Efficient solar large assembly vertical stacker crane equipment

A technology of solar energy and large components, applied in the direction of object destacking, object stacking, transportation and packaging, etc., can solve the problems of unreachable expectations, high labor costs, low operating efficiency, etc., and achieve the possibility of preventing landing , save space and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

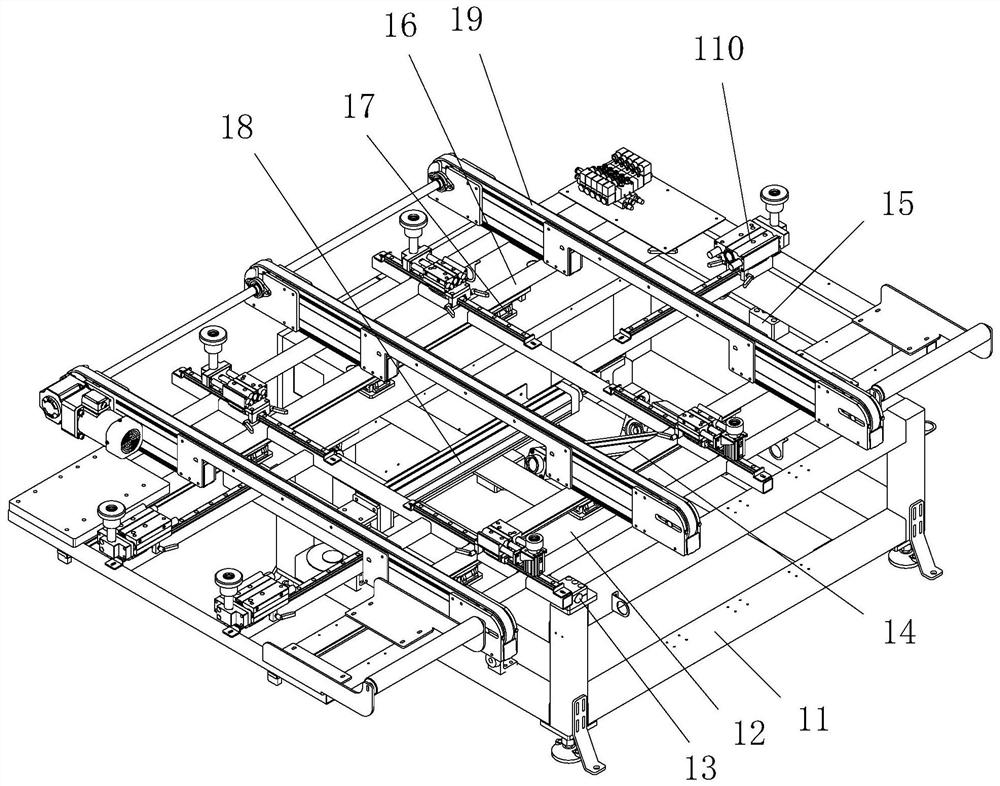

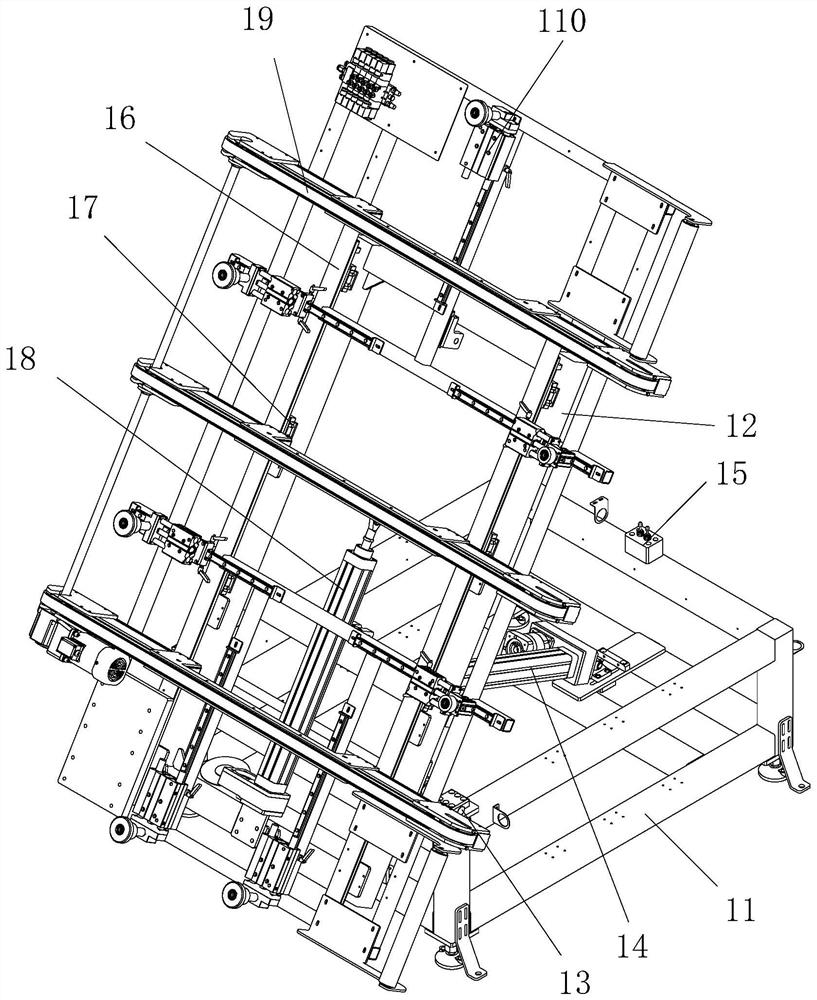

[0033] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0034] see Figure 1 to Figure 12 , the embodiment of the present invention includes:

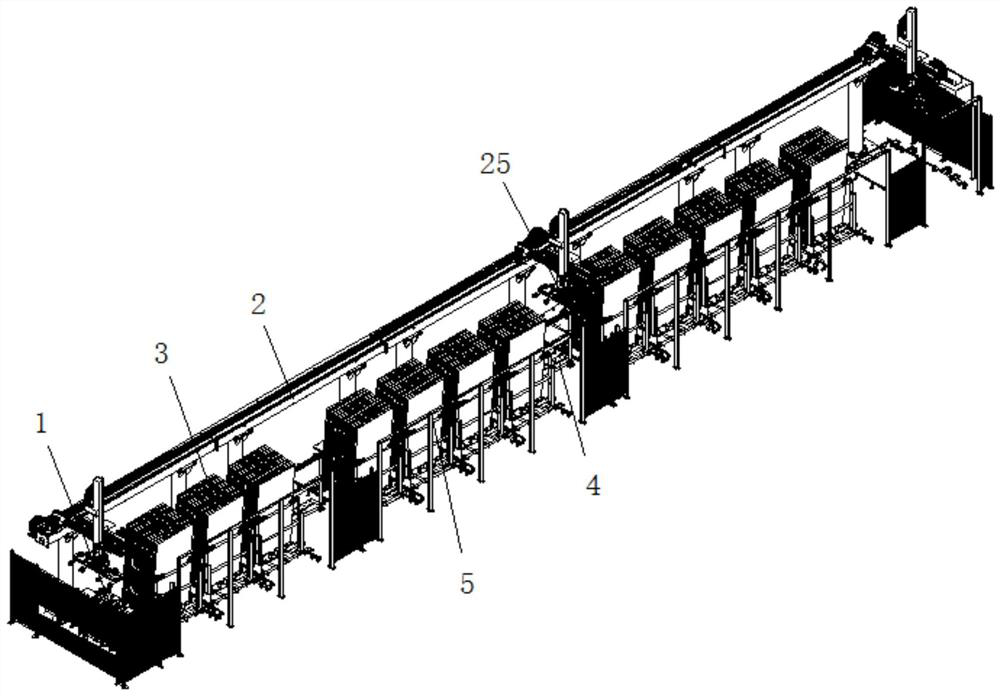

[0035] A high-efficiency solar large component vertical palletizer equipment, the high-efficiency solar large component vertical palletizer equipment includes a flip conveyor line 1, a displacement gripper mechanism 2, a short-side vertical trolley mechanism 3, and a component temporary storage rack 4 and the protective net 5, the right side of the overturning conveying line 1 is docked with a displacement gripper mechanism 2, and the displacement gripper mechanism 2 is provided with a three-station displacement gripper 25 for grabbing operations in different strokes,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com