Superstructure rotary hydraulic control system and crane with same

A rotary motor and system pressure technology, applied in cranes, load suspension components, transportation and packaging, etc., can solve the problems of reducing the service life of hydraulic components, large resistance torque change rate, affecting the stability of the whole vehicle, etc., to achieve stable growth performance, overcome pressure shock, and improve the effect of slewing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

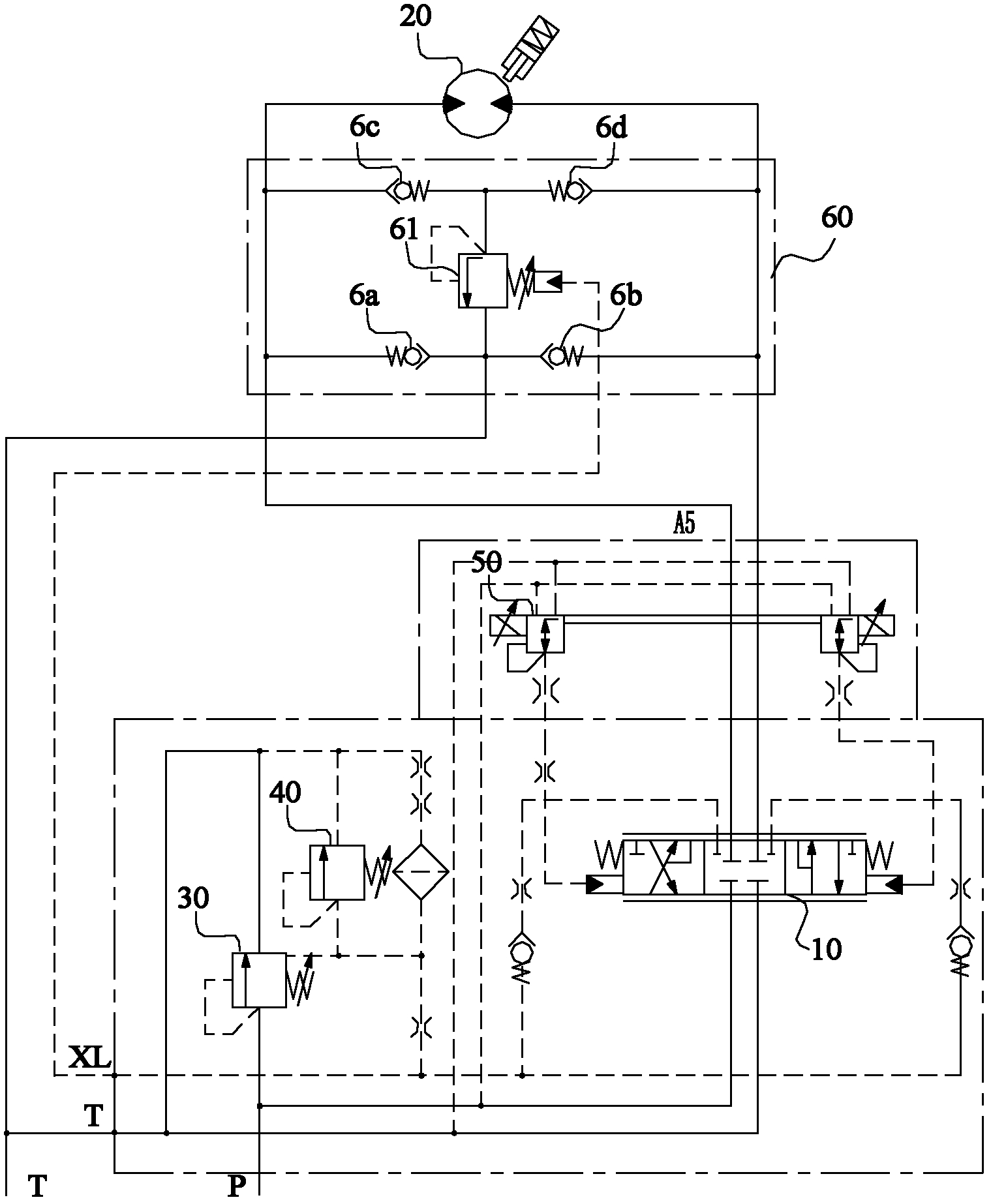

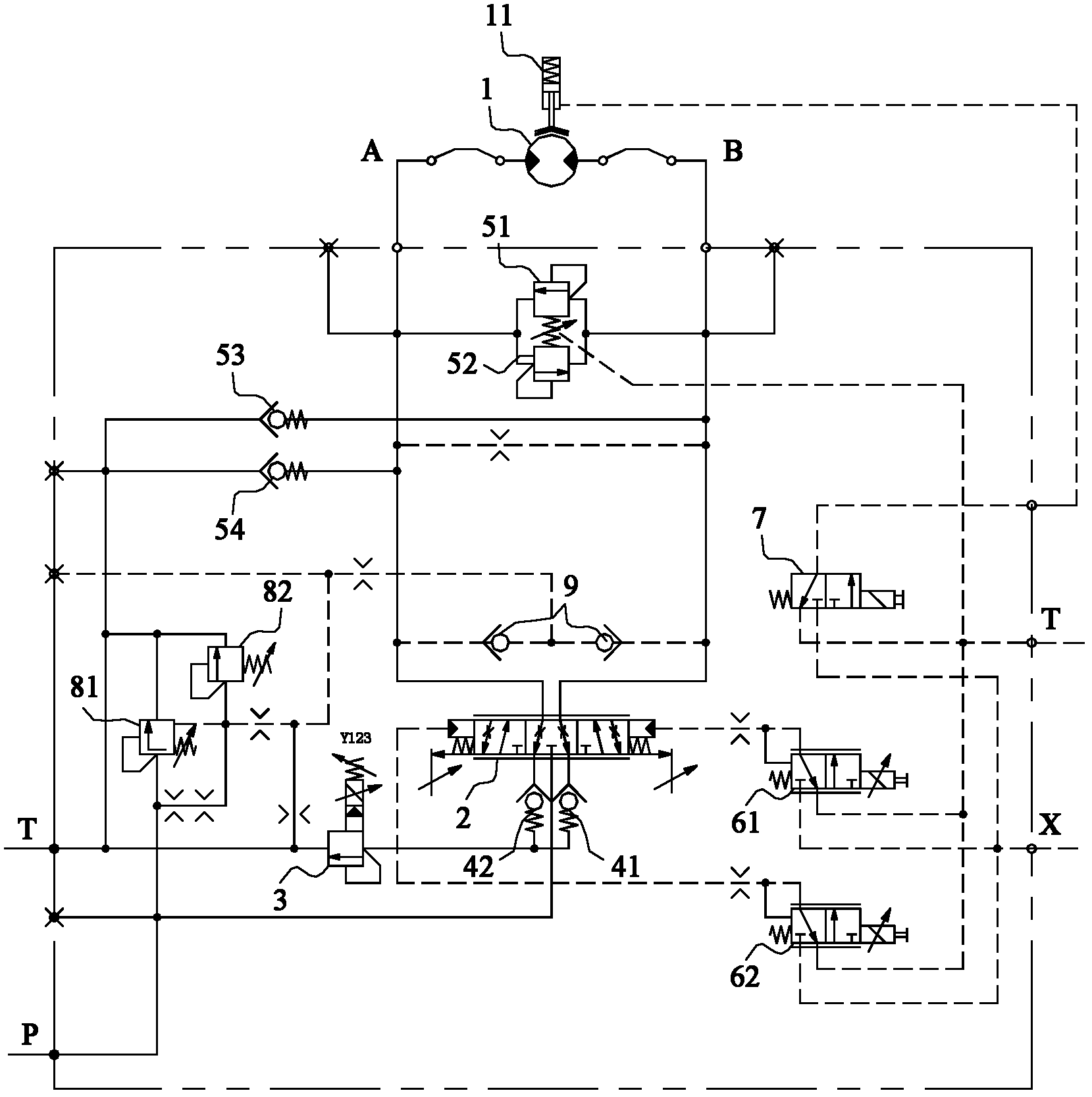

[0029] The core of the present invention is to provide a turning hydraulic control system for boarding, which is optimized and improved based on the stability requirements of the turning motion, so as to avoid the phenomenon of turning impact during the turning process of boarding. The present embodiment will be described in detail below in conjunction with the accompanying drawings.

[0030] Without loss of generality, this embodiment will be described in detail with a wheeled crane as the main body.

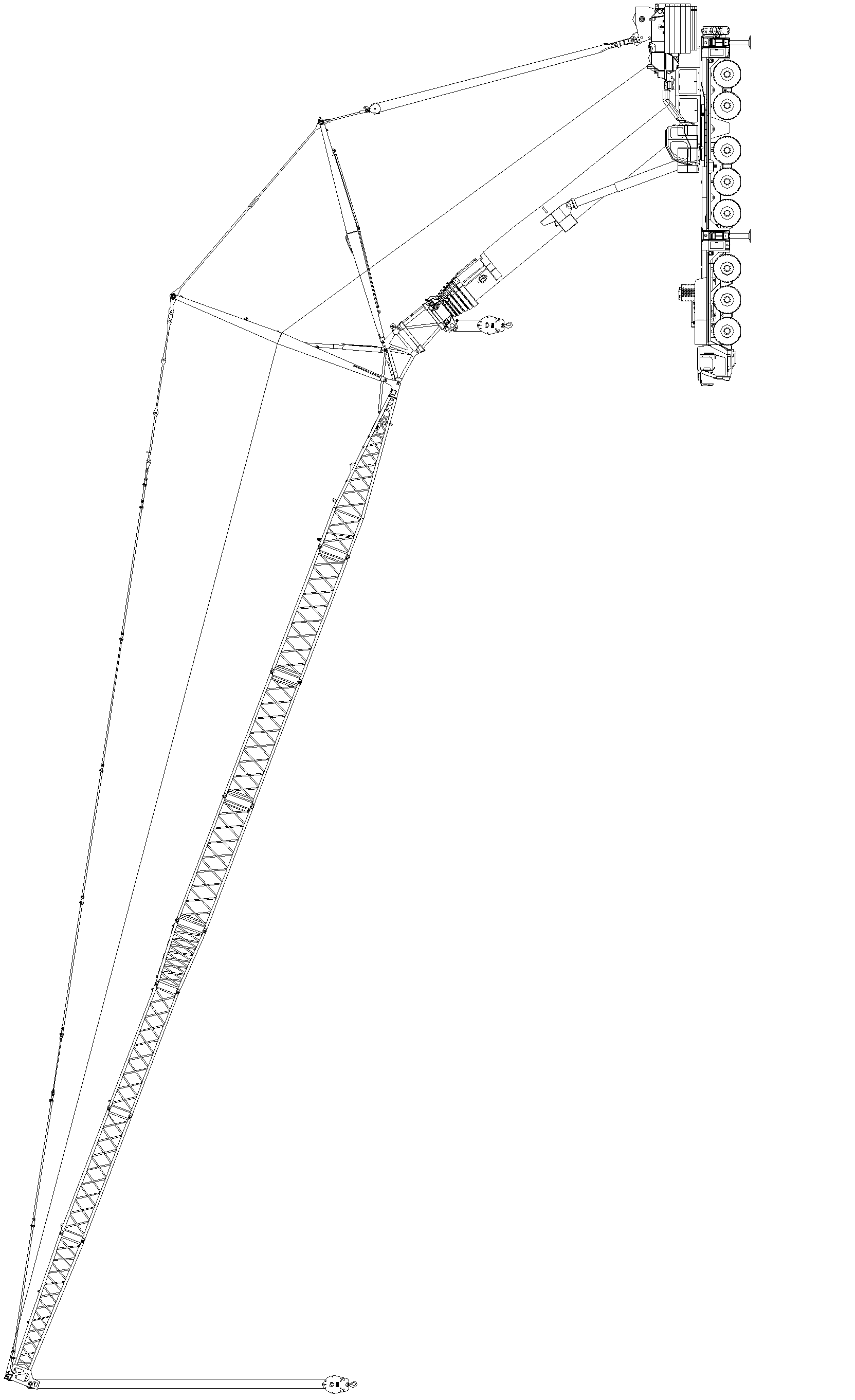

[0031] See figure 2 , which is a schematic diagram of the overall structure of the wheeled crane described in this embodiment.

[0032] As shown in the figure, the crane includes main functional components such as a wheeled chassis, a turntable that can rotate relative to the chassis, a boom device hinged at the front of the turntable, and a winch device that provides driving force for lifting and lowering heavy objects. Same as the prior art, there is a rotary seat between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com