Heat conduction oil leakage detection system and method for steam generation systems of photo-thermal power station

A generation system, CSP technology, applied in the direction of steam generation, solar heating system, steam boiler, etc., can solve the problems of inability to generate electricity, prone to leakage, damage to the steam generation system, etc., to facilitate maintenance, ensure normal operation, improve The effect of reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in detail below in conjunction with accompanying drawing:

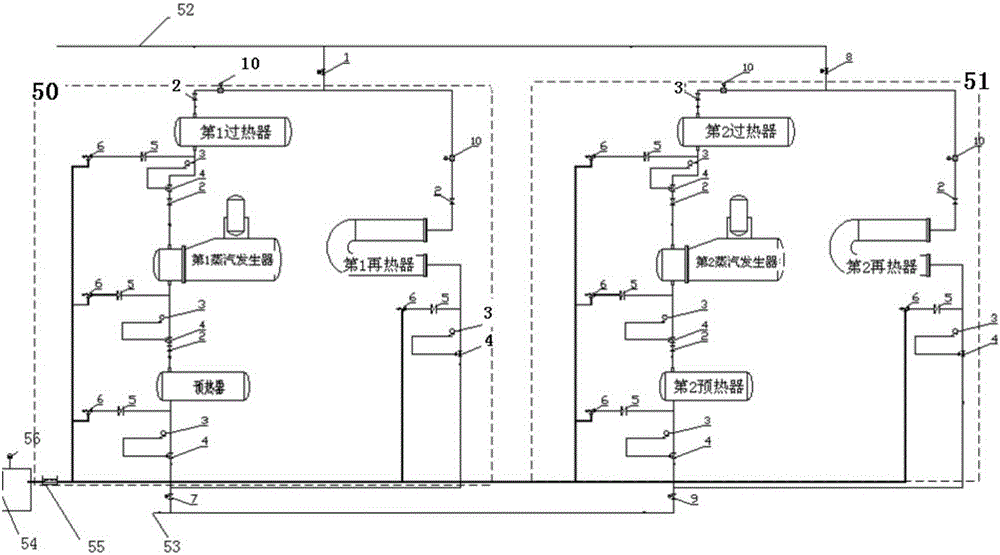

[0033] to combine figure 1 , the present invention provides a detection system for heat transfer oil leakage in a steam generation system of a photothermal power station, comprising a first row of steam generation system 50, a second row of steam generation system 51, a main heat oil delivery pipeline 52, a heat transfer oil pump 53, an emergency oil Pool 54, the first electric stop valve 1, the second electric stop valve 7, the third electric stop valve 8, the fourth electric stop valve 9;

[0034] Among them, the steam generating system 50 of the first row includes the first superheater, the first reheater, the first steam generator and the first preheater; the steam generating system 51 of the second row includes the second superheater, the second reheater generator, the second steam generator and the second preheater;

[0035] The main thermal oil delivery pipeline 52 le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com