Hydraulic control system for upper roll balancing device of rotary forging mill

A technology of hydraulic control system and balance device, which is applied in the direction of rolling mill control device, metal rolling, metal rolling, etc., can solve problems such as safety accidents, and achieve the effects of avoiding system pressure shock, overcoming internal leakage, and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

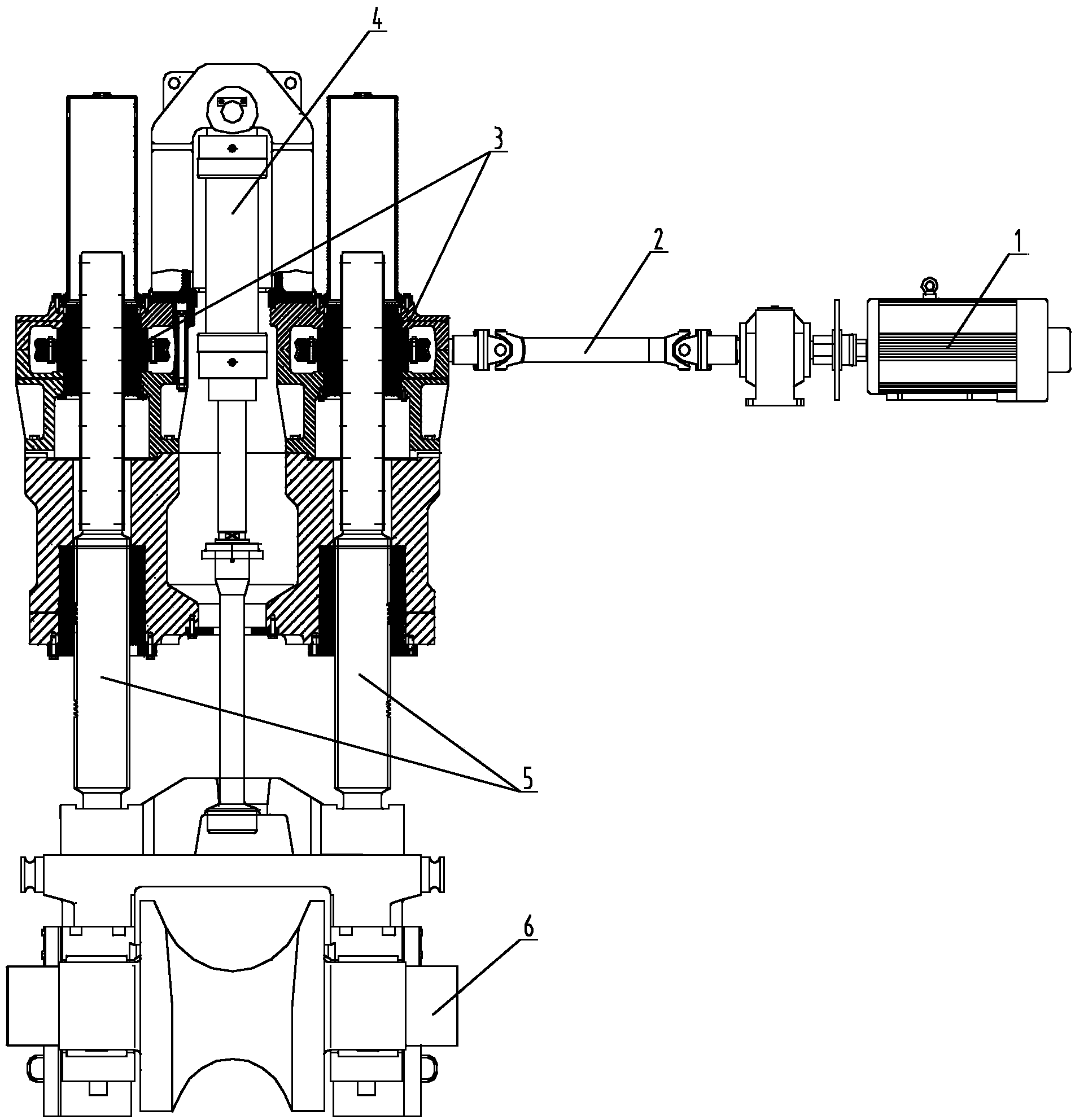

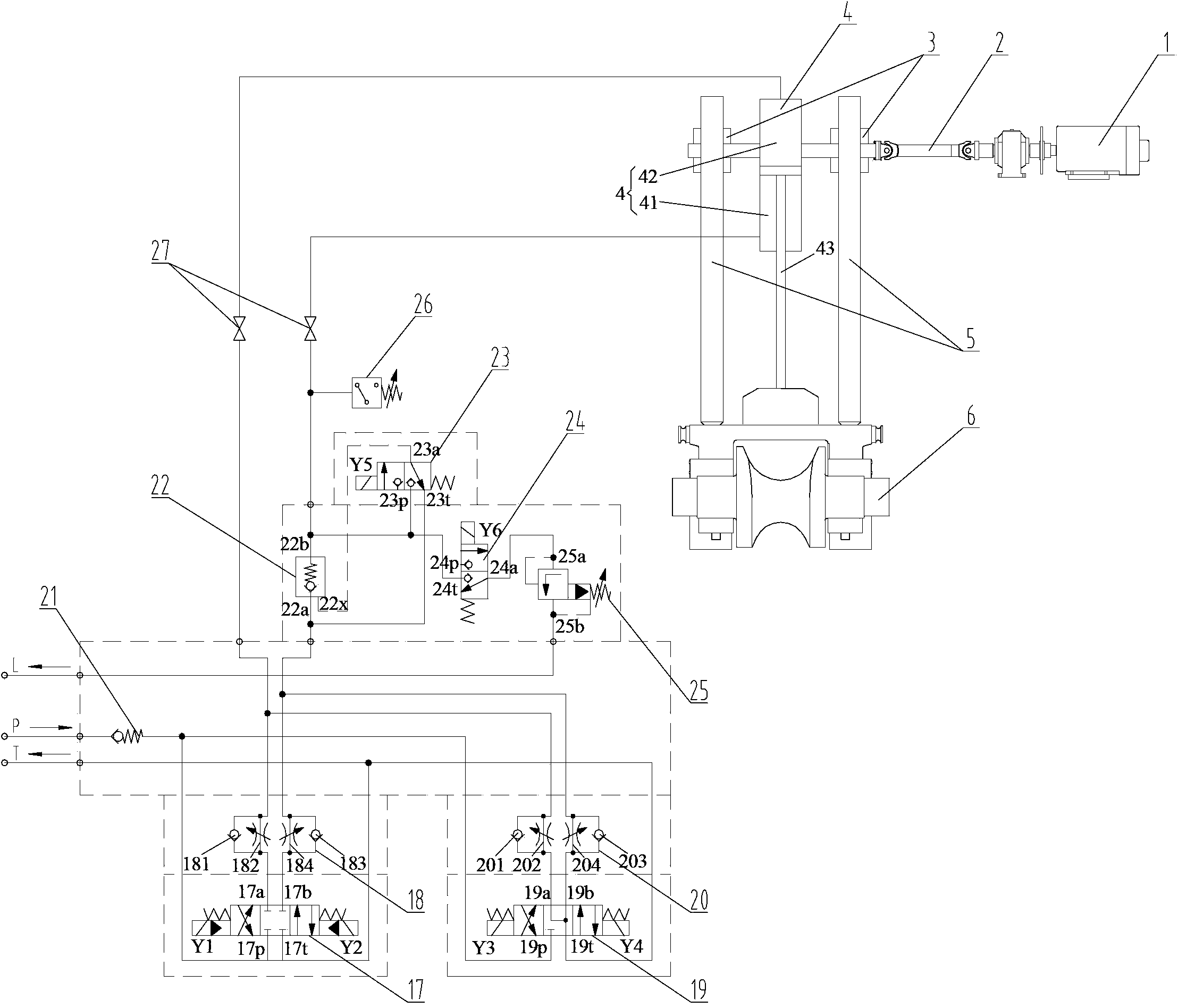

[0033] Such as image 3 As shown, an embodiment of the present invention proposes an upper roll balancing device for a periodic pipe rolling mill. The upper roll balancing device of the present invention includes a frequency conversion motor 1, a shaft coupling 2, a screw elevator 3, an upper roll balancing cylinder 4, a pressing Lead screw 5, upper roll box 6, its connection mode is the same as the connection mode of each part of existing upper roll balancing device, no longer repeat them here. In addition, the upper roll balancing device of the present invention also includes a hydraulic control system and a control device (not shown in the figure).

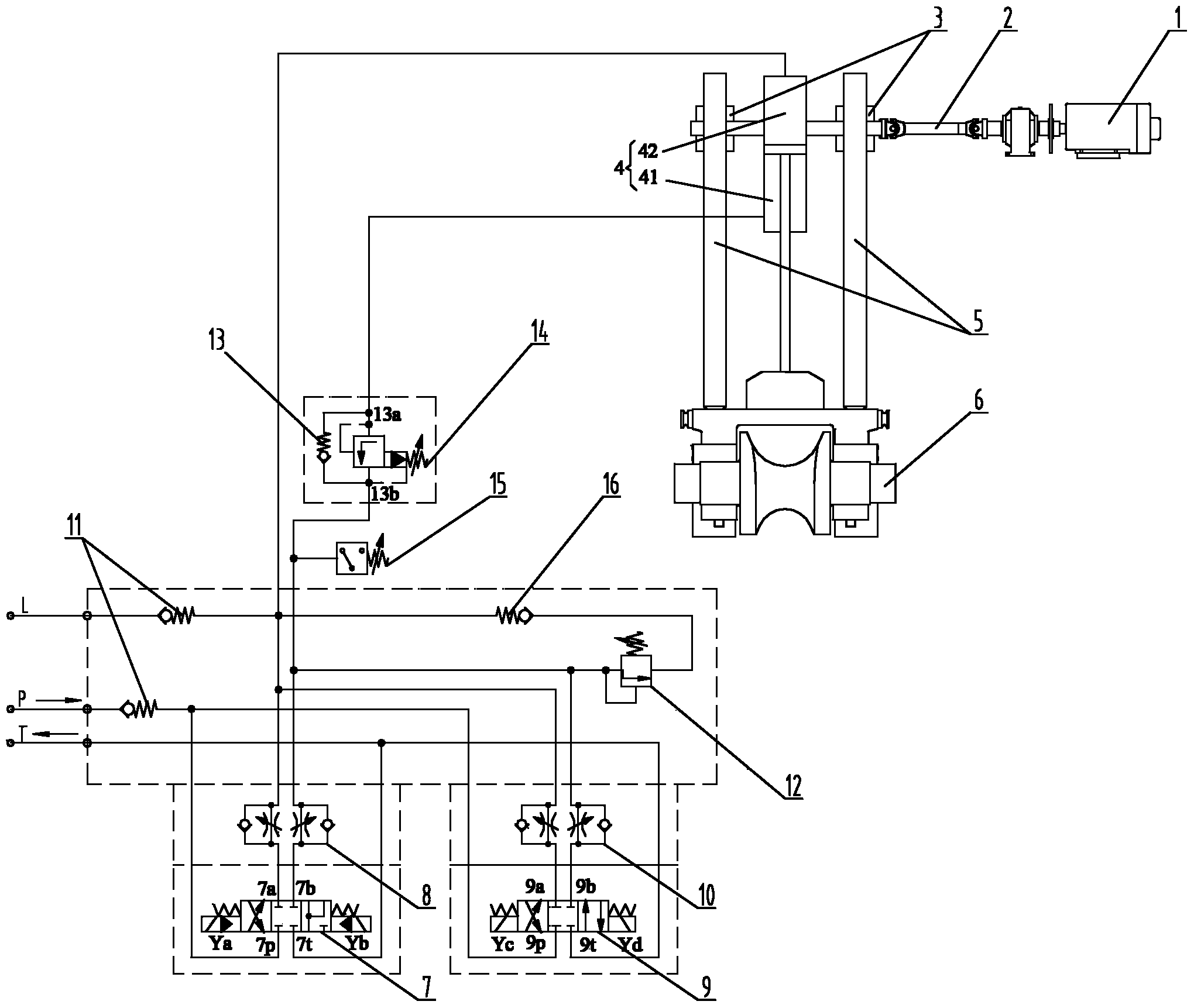

[0034] The hydraulic control system of the upper roll balancing device includes the system oil inlet P and the system oil inlet pipeline, the system oil return port T and the system oil return pipeline, the system oil drain port L and the system oil drain pipeline, and also includes the The first electro-hydraulic reversing va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com