Pull across roll up screen assembly and method of assembly

A technology of barriers and components, applied in the direction of shading screens, building components, door/window protection devices, etc., can solve problems such as increasing the time required for assembly, balance damage, and difficulty for installers to rebalance the barriers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

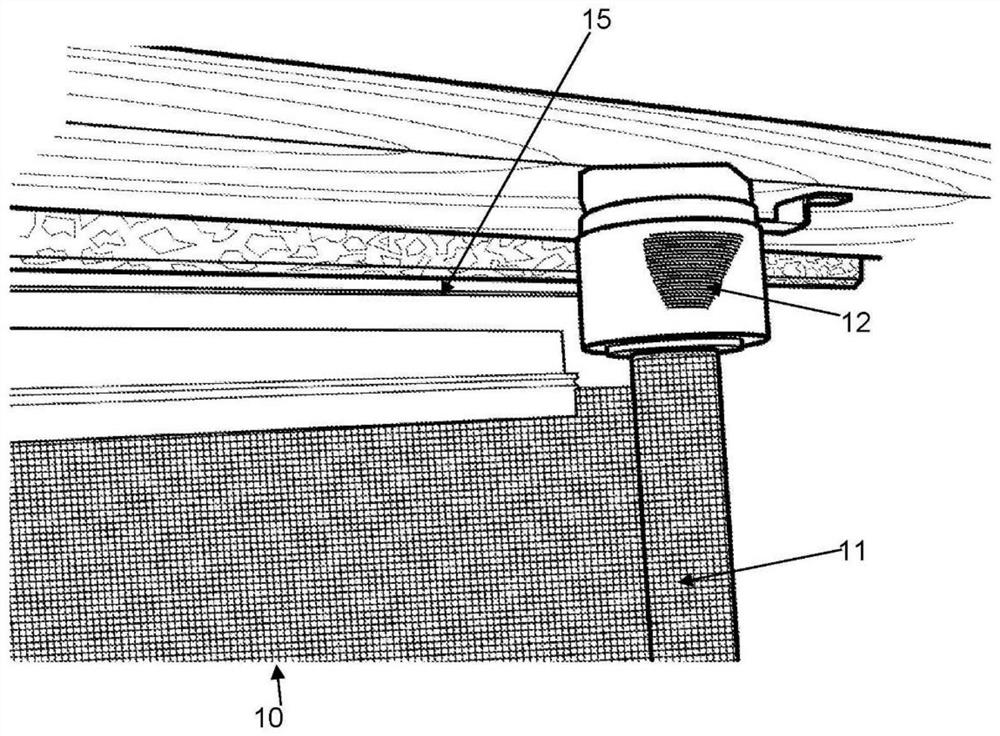

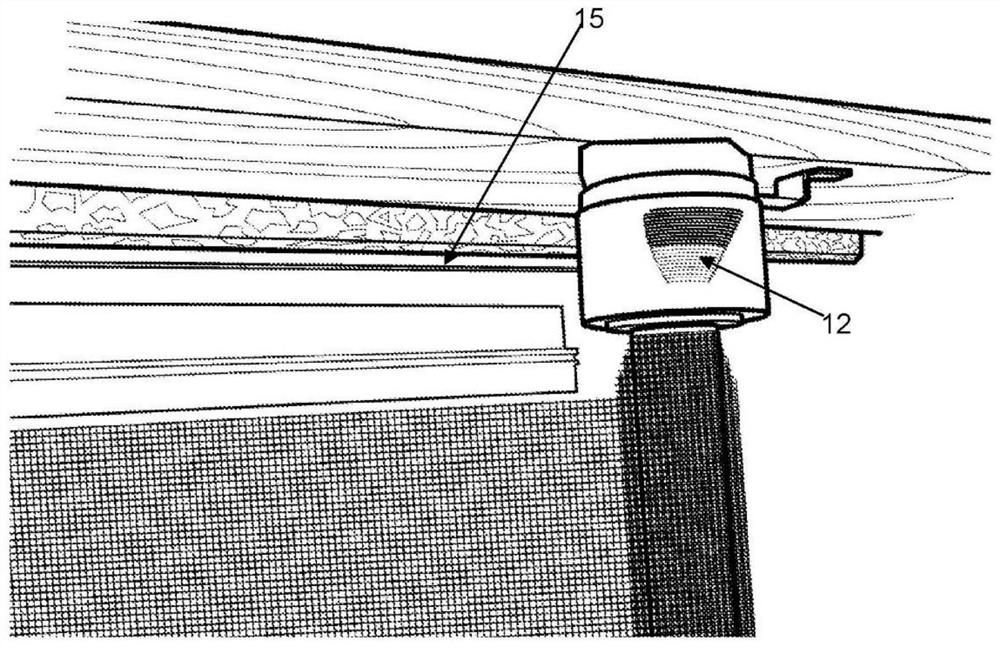

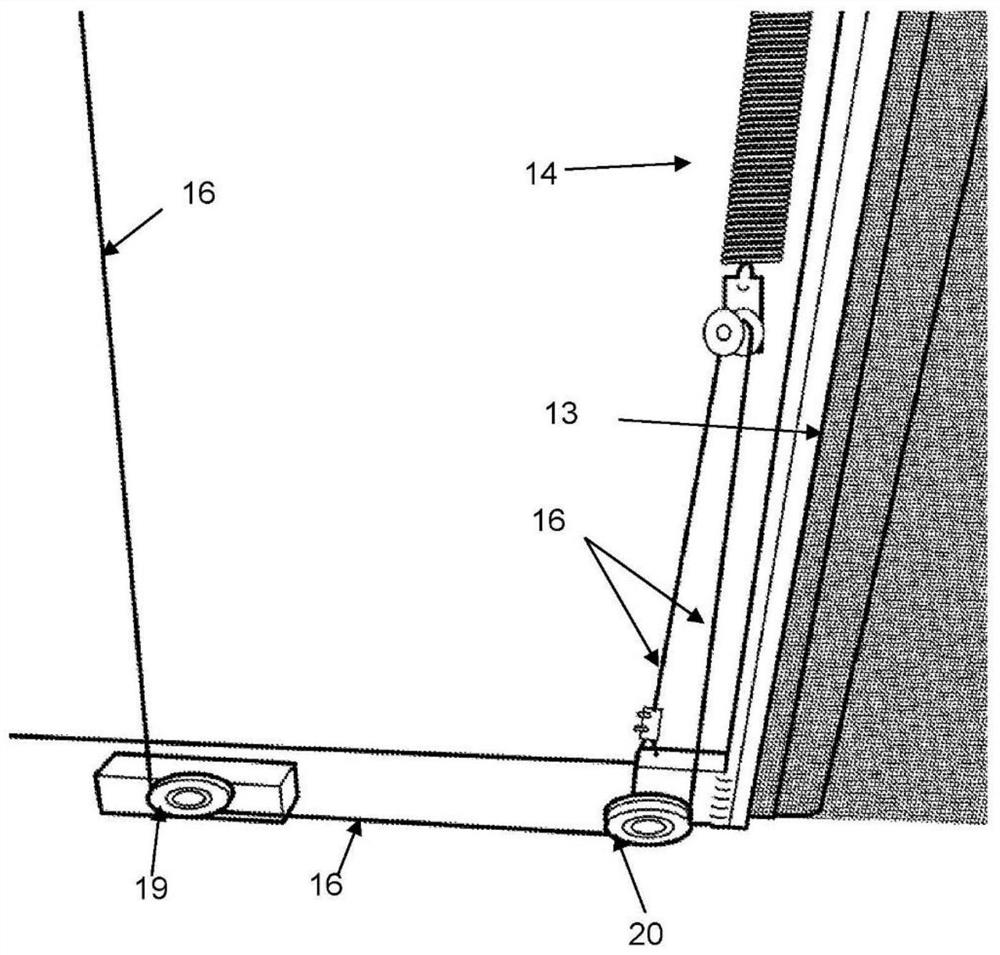

[0097] According to a particularly preferred embodiment of the present invention, there is provided a transverse tensioned roll-up barrier assembly and method of assembly.

[0098] The illustrated pull-down wrap-up barrier assembly includes: a flexible barrier having stiles located at a front edge region of the flexible barrier; a substantially vertical support member around which the flexible barrier can be wound / unwound, and which The support member has an upper end and a lower end; at least one biasing device associated with the stile to generate tension in the flexible barrier; at least one drum associated with the support member; a wire member that can be wound on the drum and Winding out of the spool, the wire member is operatively associated with the stile such that when the flexible barrier is extended, the wire member is wound onto the spool, and when the flexible barrier is retracted, the wire member is wound out of the spool, the wire member uses include the followin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com