Sorting and transporting device capable of conveying cargoes in middle and facilitating turning of cargoes

A technology for transportation devices and goods, which is applied in the field of sorting and transportation devices, which can solve the problems that goods are easy to fall out of the conveyor belt, easy to be thrown out of the transportation track, and high cost, so as to achieve the effects of saving expenses, reducing costs and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

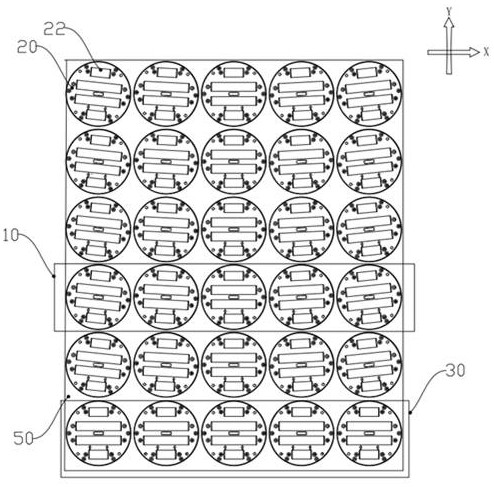

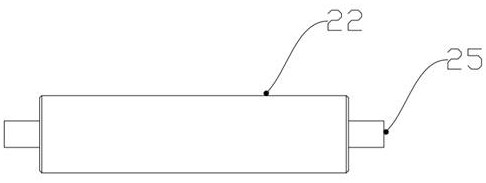

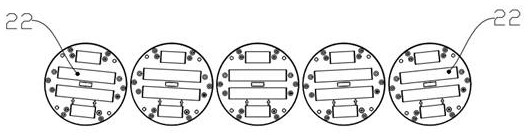

[0046] Example 1, such as Figure 5-7 As shown, when the goods are transported in a straight line and the number of sorters 20 in the rotary sorting unit 10 is an even number, the sorters 20 are arranged symmetrically at this time, specifically, the sorters 20 with an even number are arranged symmetrically, The angle of the rolling shaft 25 on the sorter 20 in the same rotating sorting unit 10 is adjusted by the controller so that a certain inward angle is formed between the two to ensure that the goods are aligned to the middle during transportation and will not fall Out of the transport device, to further illustrate, the sorter 20 is arranged on both sides of the central axis of the rotating sorting unit 10, and the sorters 20 on both sides are symmetrically arranged, and further explained, as Figure 7 As shown, the angle between the rotation axis 25 and the X axis on the leftmost sorter 20 is -7.5°, then the angle between the scroll axis 25 and the X axis on the sorter 20 ...

Embodiment 2

[0049] Example 2, such as Figure 3-4 As shown, there are an odd number of sorters 20 in each rotary sorting unit 10 during linear transportation. At this time, a central sorter 20 will be set at the center of the rotary sorting unit 10. This central sorter 20 The rolling axis 25 is parallel to the X-axis direction, that is, it is perpendicular to the transport direction of the goods, and the sorters 20 are arranged symmetrically on both sides of the central sorter 20 ( image 3 shown), further description, such as Figure 4 As shown, the angle between the rotation axis 25 and the X axis on the leftmost sorter 20 is -7.0°, then the angle between the scroll axis 25 and the X axis on the sorter 20 from left to right is -7.0°, -3.5°, 0°, 3.5° and 7.0° (the initial angle difference between adjacent sorters 20 in the same sorting unit 10 is generally between 2°-5°), satisfying The above-mentioned initial angles of the rolling shafts 25 set on the adjacent sorters 20 in the same r...

Embodiment 3

[0051] Example 3, such as Figure 8-13 As shown, when the goods need to be turned and transported, at this time we need to adjust the rotation angle of the sorter 20 in each rotating sorting unit 10, that is, rotate a certain angle under the condition of its initial angle, so that the outer angle becomes larger. , a structure with a small inner angle, so that it can always be transported towards the middle without falling out of the transport device.

[0052] Specifically, with Figure 9-10 As an example, it can be seen that there are three groups of rotating sorting units 10 (the number of rotating sorting units 10 is determined according to the specific usage scenario, three groups in this embodiment), and the rotation angles of the three groups of rotating sorting units 10 are adjusted along the Y axis. The trend of is getting larger and larger, and the rotation value of the sorter 20 in the same rotary sorting unit 10 at the initial angle is the same. For example, it can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com