A phosphorus-free fully bio-based flame-retardant epoxy resin with excellent thermal and mechanical properties and its green preparation method

A technology of epoxy resin and compound, which is applied in the field of phosphorus-free all-bio-based flame-retardant epoxy resin and its green preparation, can solve problems such as no new breakthroughs, and achieve strong substitutability, high rigidity, and phase transition temperature high effect

Active Publication Date: 2022-06-03

NANJING TECH UNIV

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In addition, there are no new breakthroughs in the reports of high flexural strength epoxy resin materials, especially bio-based epoxy resin materials with high flexural strength.

[0004] Combined with the development of bio-based polymer green chemistry, there is less research on the development of epoxy resins with multifunctional and high mechanical properties. The present invention proposes a phosphorus-free all-bio-based flame-retardant epoxy resin with excellent thermal and mechanical properties and its Green preparation method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Login to View More

Abstract

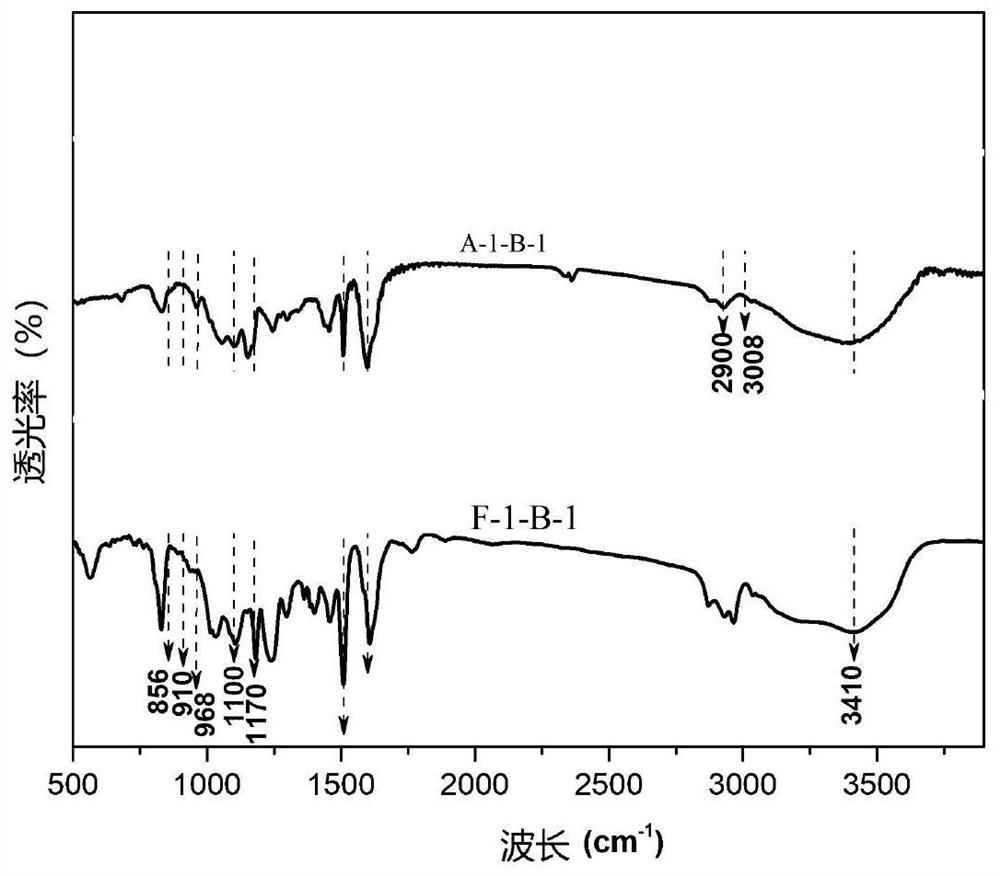

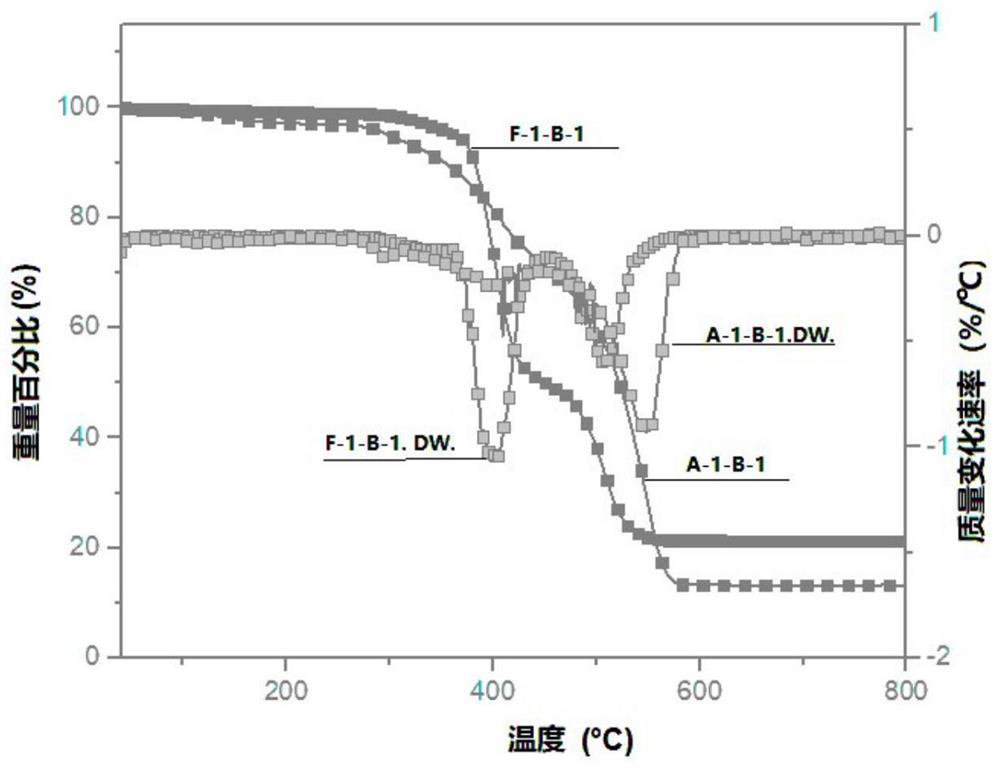

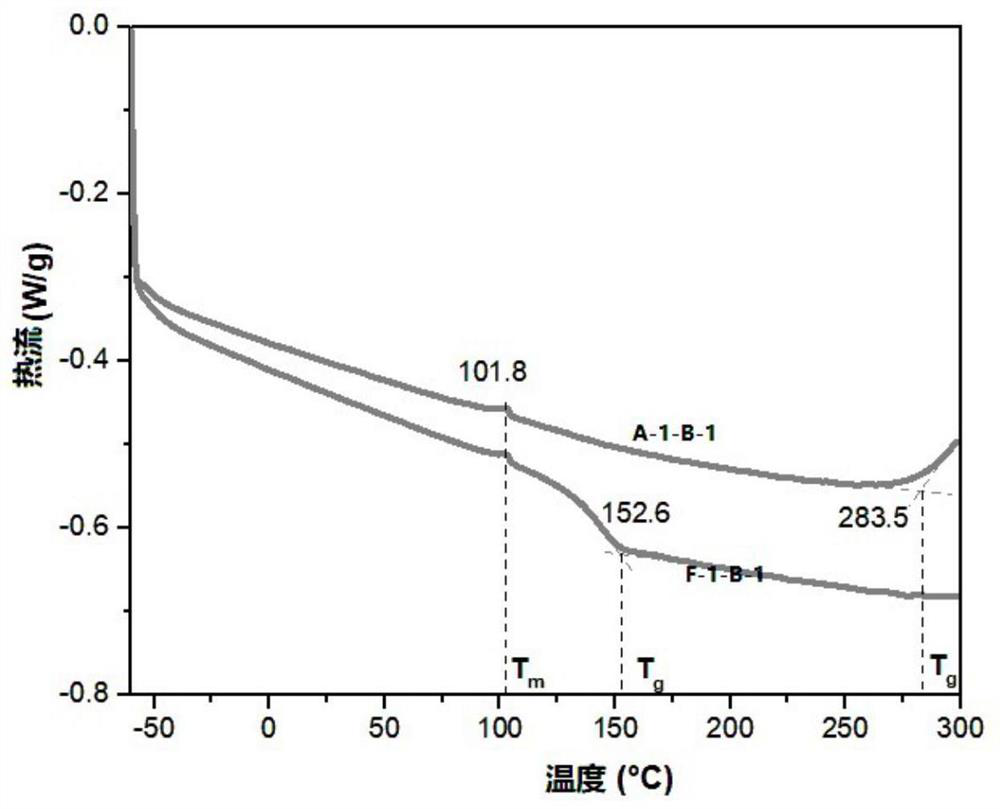

The invention discloses a phosphorus-free all-bio-based flame-retardant epoxy resin with excellent thermal and mechanical properties and a green preparation method thereof. The main structure of the epoxy resin is a network polymer composed of a first unit and a second unit; the first unit is shown as unit A; the second unit is unit B, unit C, unit D and Any one or several combinations of units E; the molar ratio of the first unit and the second unit is 2-5000:2-5000. The phase transition temperature of the prepared all bio-based resin material of the present invention is high (T g,DSC , 283.5°C), high rigidity (4.14GPa), wide operating temperature range, strong rigidity, belonging to special functional materials.

Description

A phosphorus-free fully bio-based flame retardant epoxy resin with excellent thermal and mechanical properties and the same green preparation method technical field The invention belongs to the technical field of macromolecular compounds, be specifically related to a kind of phosphorus-free complete thermal and mechanical properties excellent Bio-based flame retardant epoxy resin and green preparation method thereof. Background technique Epoxy resin macromolecule polymer materials are widely used in soft and hard decoration industries such as coatings and adhesives, and are also widely used. It is widely distributed in the field of electronics and electrical appliances, and it also has good engineering and technical applications in research fields such as functional composite materials. but At present, petroleum-based products are still the main applications in the market, among which petroleum-based bisphenol A system epoxy resin materials Commercial application,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08G59/32C08G59/38C08G59/62

CPCC08G59/3218C08G59/38C08G59/621

Inventor 郭凯孟晶晶徐钦龙管浩李春雨陈鹏飞

Owner NANJING TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com