A low-cost vacuum coating target

A vacuum coating, low-cost technology, applied in vacuum evaporation coating, sputtering coating, ion implantation coating and other directions, can solve the problems of vacuum leakage of the tube body, reduce the overall cost, and cannot distinguish the use state of the target, and achieve Improve the safety of use, reduce the overall cost, and improve the effect of short target life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

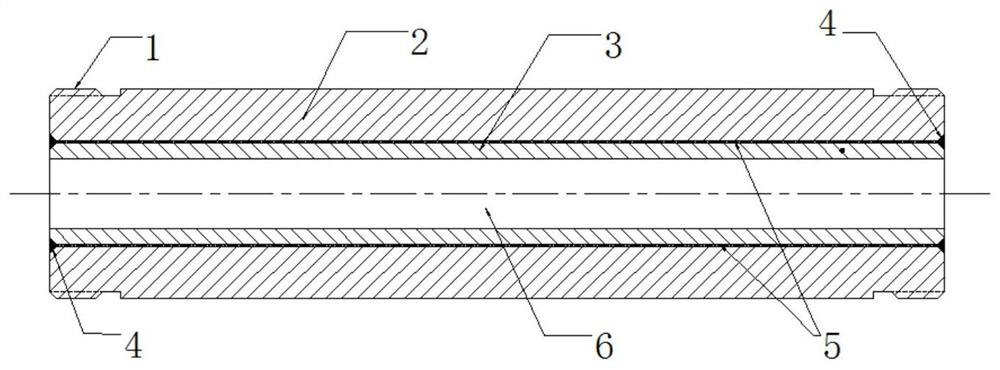

[0044] Such as figure 1 The shown embodiment 1 of the present invention discloses a low-cost vacuum coating target, which includes a target body tube, a transition layer and a liner tube that are sequentially socketed from outside to inside; the hollow structure of the liner tube forms a cooling pipeline.

[0045] Among them, the two ends of the target tube are provided with threaded structures, which can be connected with the coating chamber of the coating equipment through the threaded structure, which is convenient for disassembly and connection; and the outer diameter of the target tube is 160mm, the wall thickness is 10mm, and the length is 1600mm. The material is pure zirconium.

[0046] The inner liner is made of 6061 aluminum alloy with an outer diameter of 139.5mm, a thickness of 6mm and a length of 1600mm.

[0047] The transition layer is made of graphite foil nested with a thickness of 0.5mm.

[0048] Moreover, the two ends of the target tube, the transition layer...

Embodiment 2

[0057] Such as figure 1 As shown, Embodiment 2 of the present invention provides a low-cost vacuum coating target, including a target body tube, a transition layer, and a liner tube that are sequentially socketed from outside to inside; the hollow structure of the liner tube forms a cooling pipeline; After the target tube and the liner tube are sequentially socketed through the transition layer, they are rolled and calendered to obtain the final size of the product.

[0058] Among them, the two ends of the target tube are provided with threaded structures, which can be connected with the empty coating cavity of the coating equipment through the threaded structure, which is convenient for disassembly and connection; and the outer diameter of the target tube is 160mm, the thickness is 10mm, and the length is 1600mm, and the material is pure titanium;

[0059] The lining pipe is made of Q235 seamless steel, with an outer diameter of 136mm, a thickness of 3mm, and a length of 160...

Embodiment 3

[0069] Such as figure 1 As shown, Embodiment 3 of the present invention provides a low-cost vacuum coating target, including a target body tube, a transition layer, and a liner tube that are sequentially socketed from outside to inside; the hollow structure of the liner tube forms a cooling pipeline; After the target tube and the liner tube are sequentially socketed through the transition layer, they are rolled and calendered to obtain the final size of the product.

[0070] Among them, the two ends of the target tube are provided with threaded structures, which can be connected with the empty coating cavity of the coating equipment through the threaded structure, which is convenient for disassembly and connection; and the outer diameter of the target tube is 160mm, the thickness is 10mm, and the length is 1600mm, and the material is pure niobium;

[0071] The lining pipe is made of 304 seamless stainless steel, with an outer diameter of 136mm, a thickness of 3mm, and a lengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap