A prestressed intelligent tensioning system

An intelligent tensioning and prestressing technology, applied in the direction of applying stable tension/pressure to test the strength of materials, instruments, measuring devices, etc., can solve the problem of difficult to define the starting point of prestressing test, etc., and achieve the effect of easy downward movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

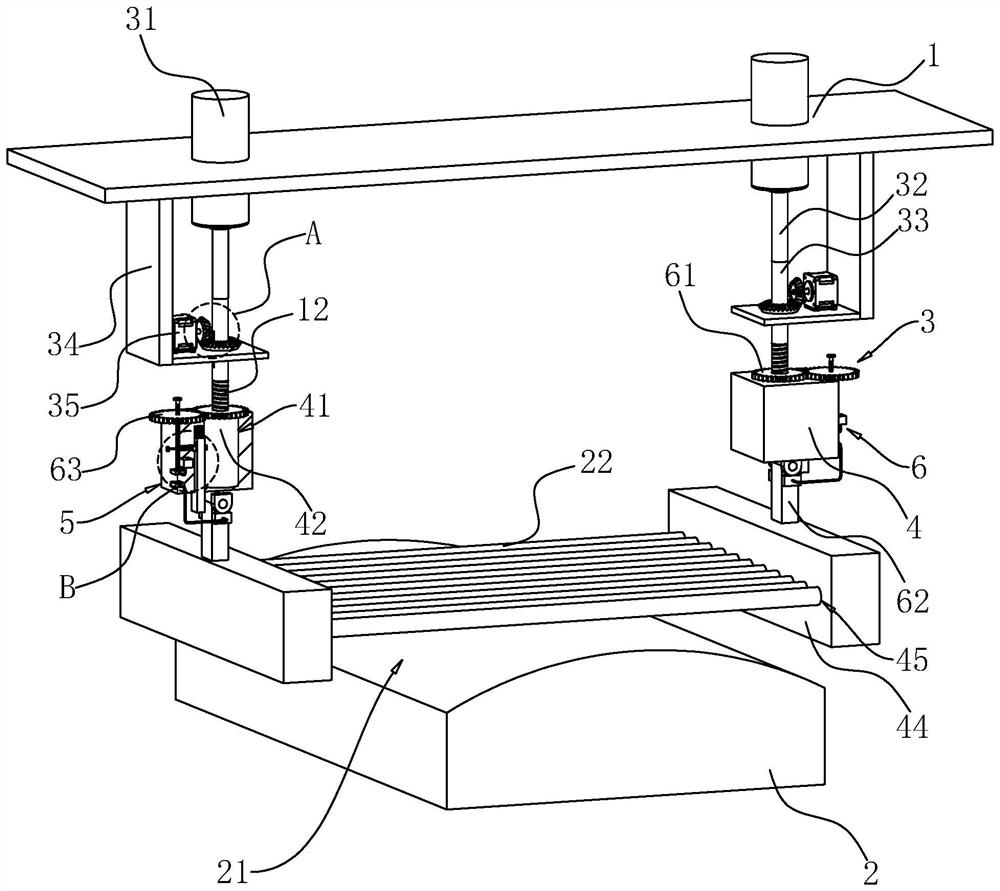

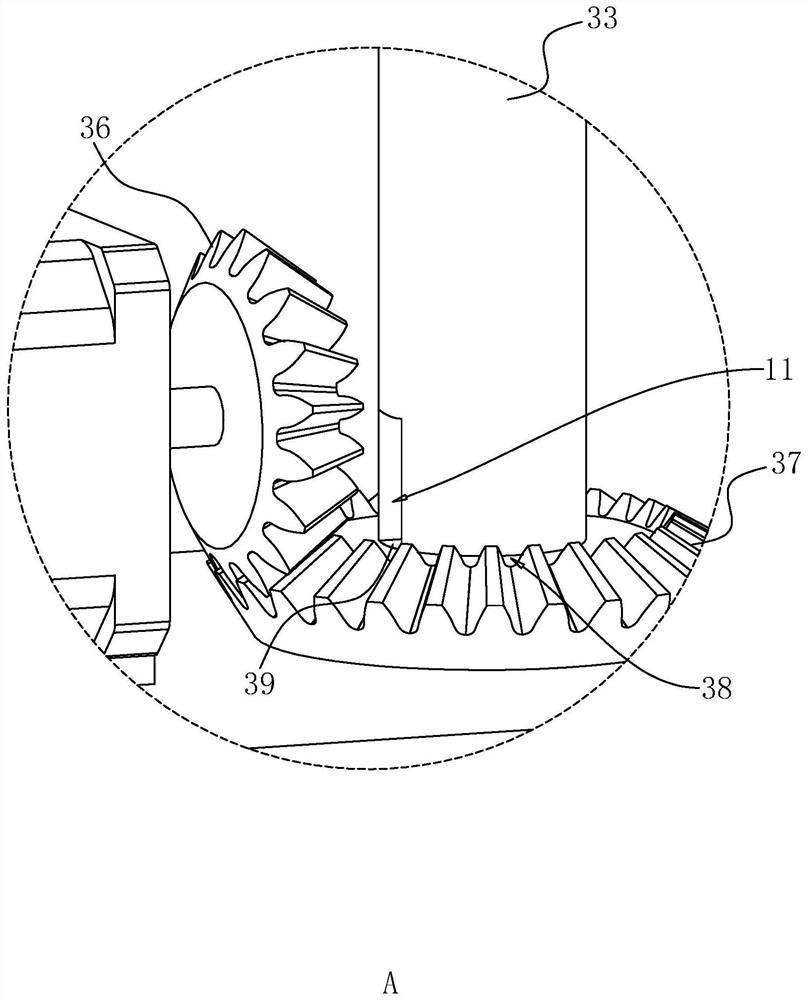

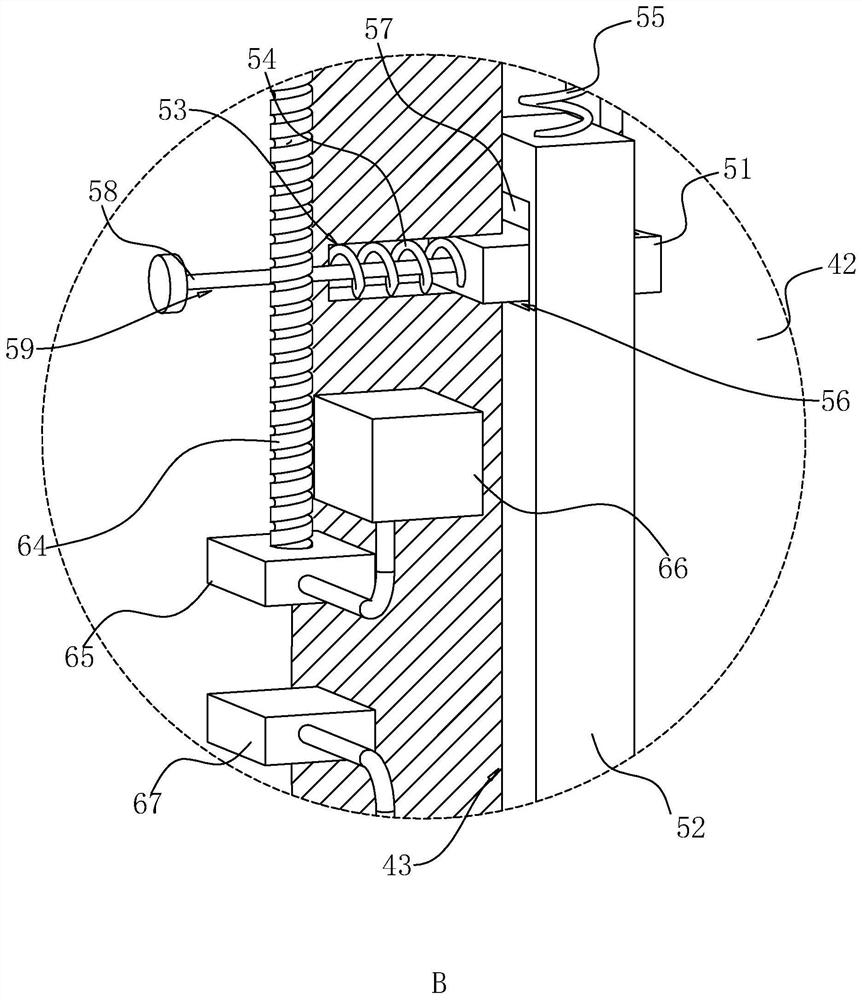

[0033] The following combined attachment Figure 1-3 Further detailed explanation of this application.

[0034] Examples of this application disclose a prestressed intelligent tensor system. Reference figure 1 and figure 2 , A prestressed intelligent tensor system includes installation platform 1 and pressure blocks 2 setting below the installation platform 1. There are two sets of installation device 3 for installation of reinforcement 22 below the installation platform 1. Installation 3 includes the cylinder 31 that runs through the installation platform 1 and the first connection axis 32 fixed with the bottom end of the cylinder 31 piston rod; the cylinder 31 is used to promote the first connection axis 32 to move downward. The first connection axis 32 bottom rotation connection has a second connection axis 33. The installation platform 1 has a connection rack 34. The connection frame 34 has a motor 35, the output end of the motor 35 is fixed with the first cone gear 36, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com