Micro LED display with stacked structure

A technology of LED display and stacking structure, which is applied in the direction of instruments, identification devices, electrical equipment casings/cabinets/drawers, etc. It can solve the problems of LED display vibration, current interference, and poor device stability, so as to avoid current interference, fix and stabilize, The effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

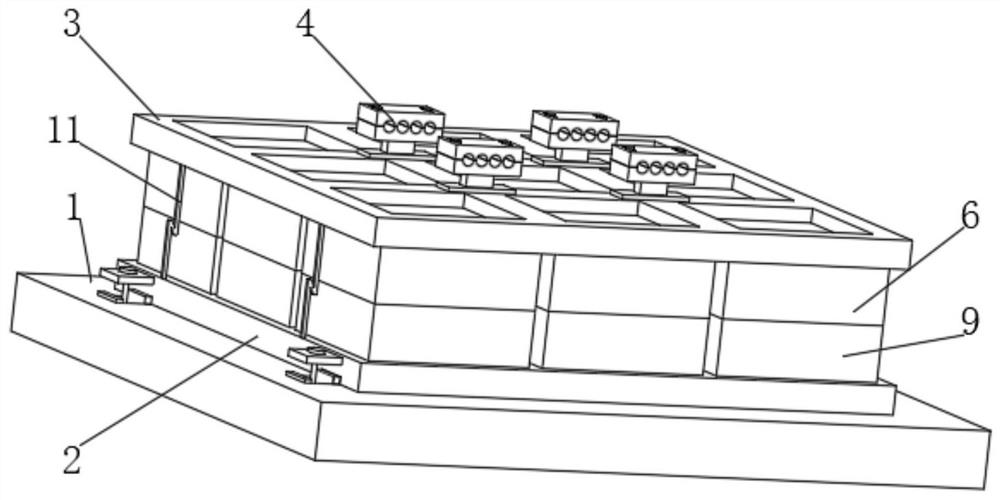

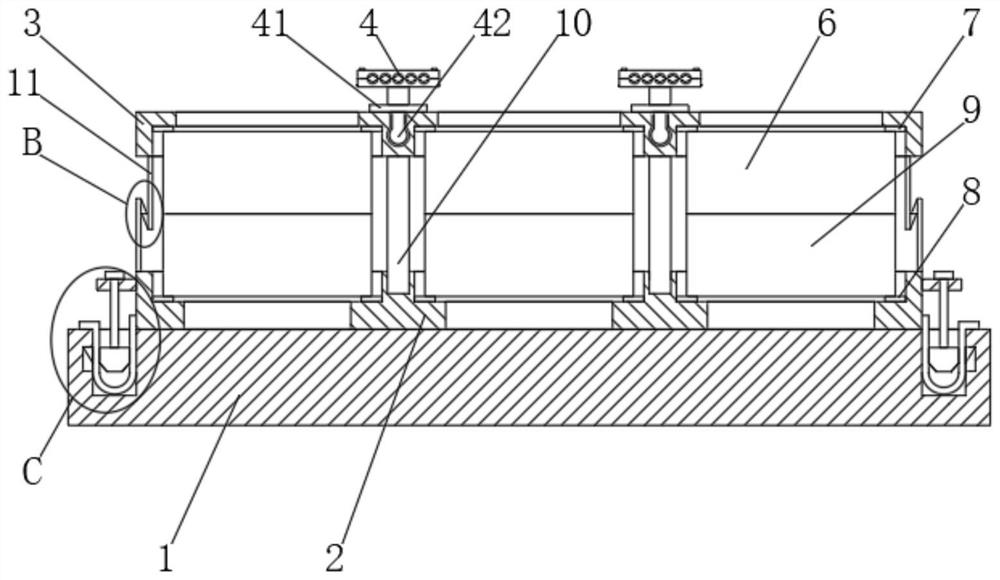

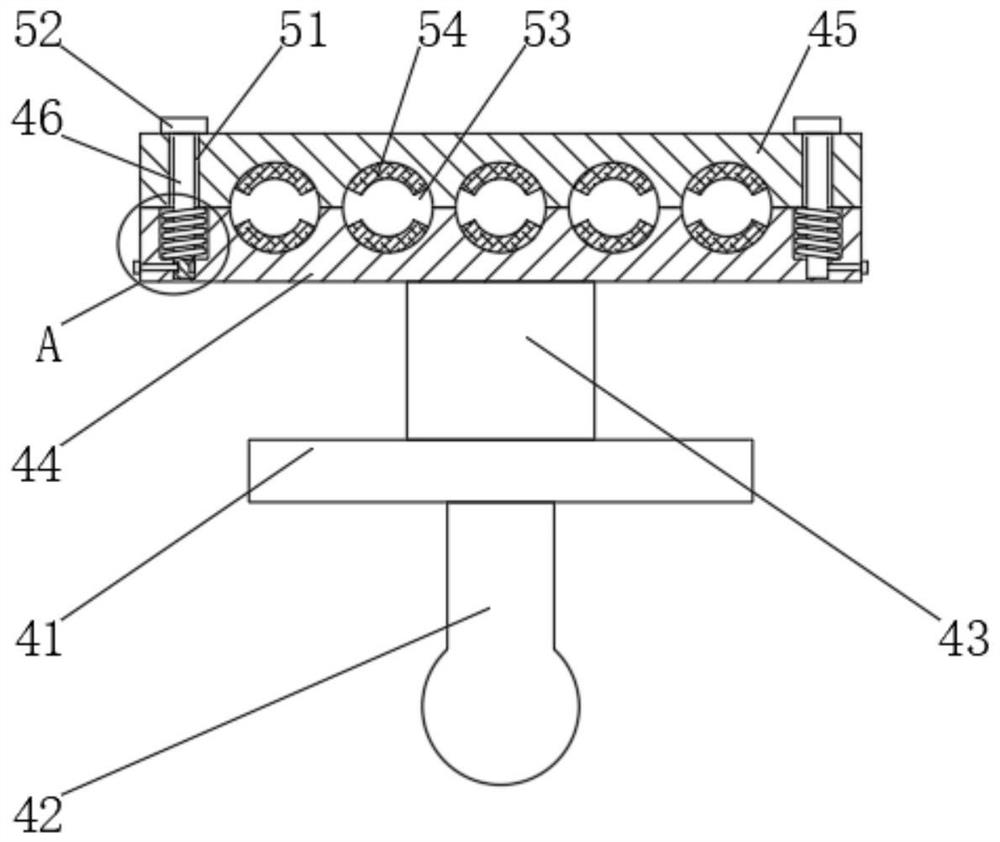

[0028] A micro-LED display with a stacked structure, including a mounting seat 1, a support frame 2, a pressing frame 3, a comb mechanism 4, a base 41, a block 42, a connecting seat 43, a support plate 44, a pressure plate 45, a guide rod 46, and an annular groove 47. Limit pin 48, spring 49, accommodation groove 50, special-shaped hole 51, stop rod 52, limit groove 53, sponge block 54, first LED module 6, first rubber pad 7, second rubber pad 8, The second LED module 9, the limit rod 10, the shrapnel 11, the first inclined block 12, the U-shaped plate 13, the installation groove 14, the second inclined block 15, the card slot 16, the support block 17, the connecting rod 18, the top block 19 , the mounting seat 1 is in contact with the support frame 2, the wire combing mechanism 4 is fixedly connected to the press frame 3, the first LED module 6 is slidably connected to the press frame 3, and the press frame 3 is bonded with The first rubber pad 7, the first rubber pad 7 is bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com