Steel sheet and method for manufacturing same

A manufacturing method and technology of steel plates, applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., can solve problems such as unproposed solutions and undisclosed issues, and achieve the effect of excellent beauty and improved design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0194] Next, an embodiment of the present invention will be described. The conditions in the examples are for example only to confirm the implementability and effects of the present invention, and the present invention is not limited to this example. The present invention can adopt a variety of conditions as long as the object of the present invention is not separated from the spirit of the invention.

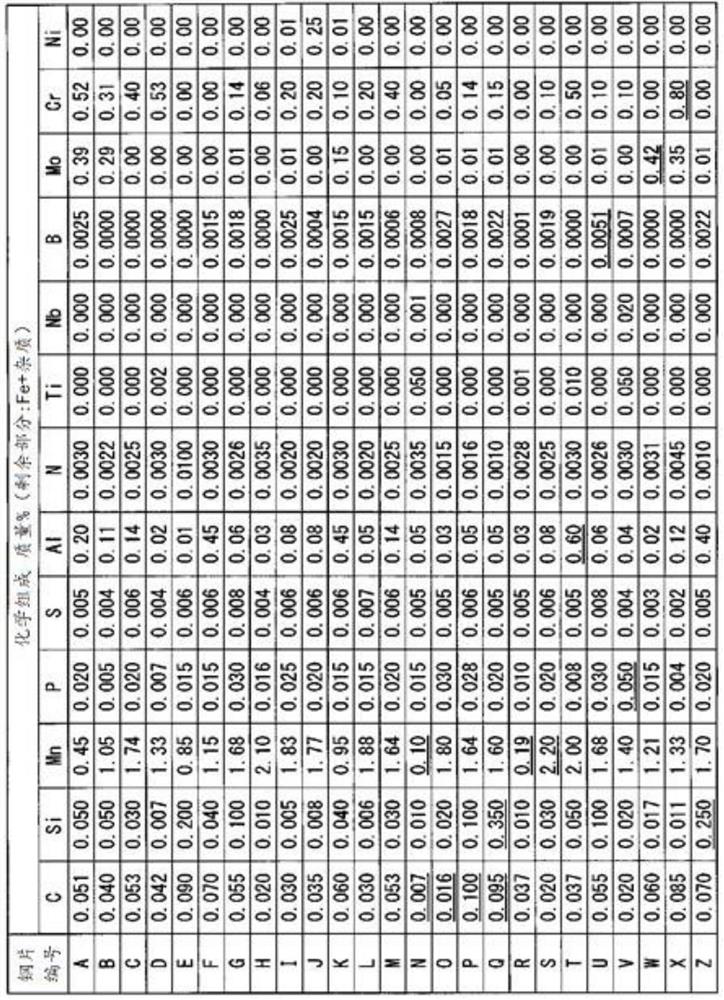

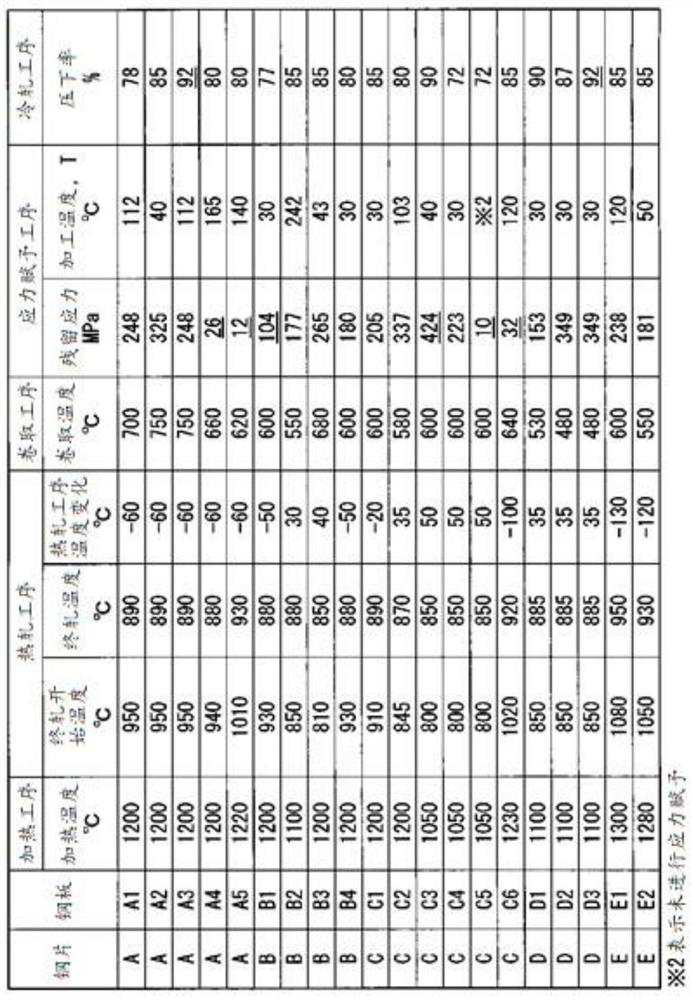

[0195] Steel having a chemical component shown in the steel sheets NO.A to Z of Table 1 performs smelt, and produces a blank having a thickness of 240 to 300 mm by continuous casting. The resulting blank was heated to the temperature shown in Tables 2a to Table 2C. The heated blank is hot rolled under the conditions shown in Tables 2A to T 1 2 and is taken.

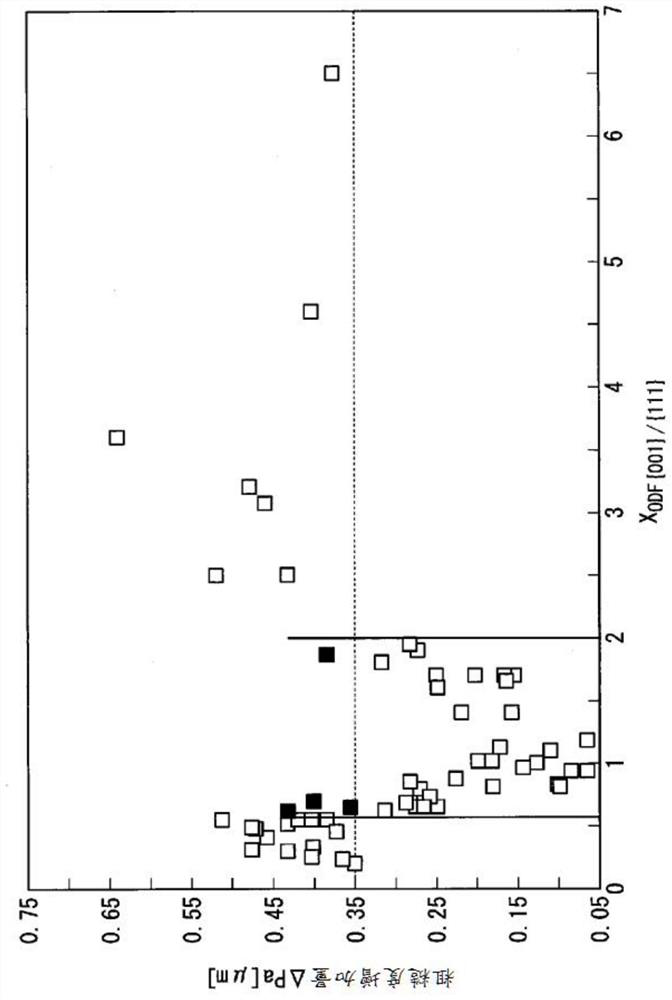

[0196]Then, the coil is discharged, and the hot-rolled steel sheet is applied. At this time, the surface residual stress of the surface of the steel sheet is measured on the surface of the steel sheet surface by means of a sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com