Steel sheet and method for producing same

A manufacturing method and steel plate technology, which is applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems that the relationship between rough surface appearance and structure has not been disclosed, and achieve the effects of excellent appearance, suppressed surface unevenness, and excellent formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

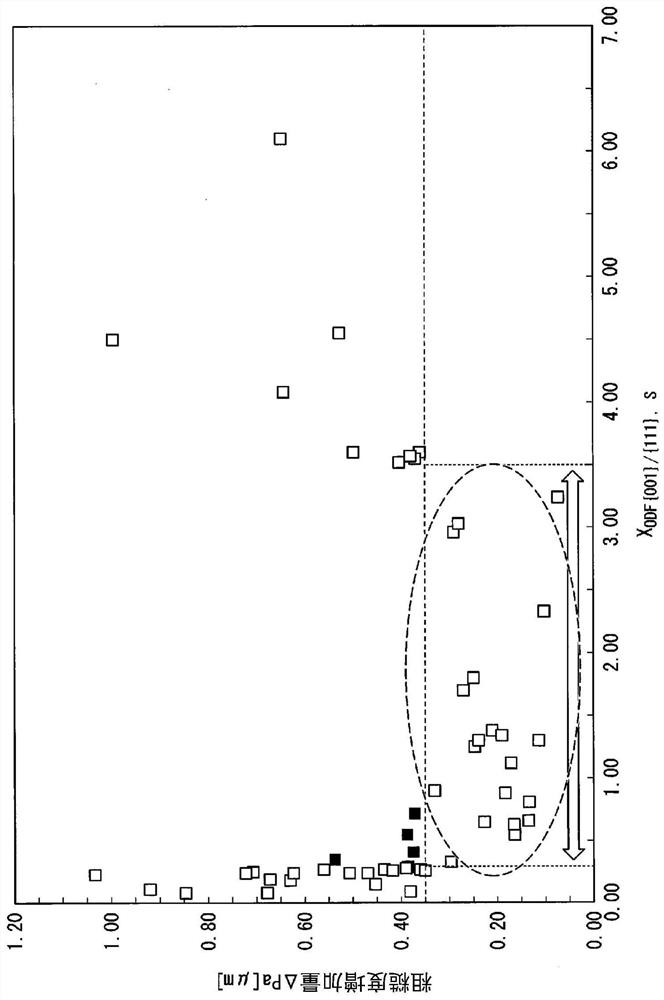

[0190] Next, examples of the present invention will be described. The conditions in the examples are an example of conditions adopted for confirming the practicability and effects of the present invention, and the present invention is not limited to the examples of conditions. Various conditions can be employed in the present invention as long as the object of the present invention is achieved without departing from the gist of the present invention.

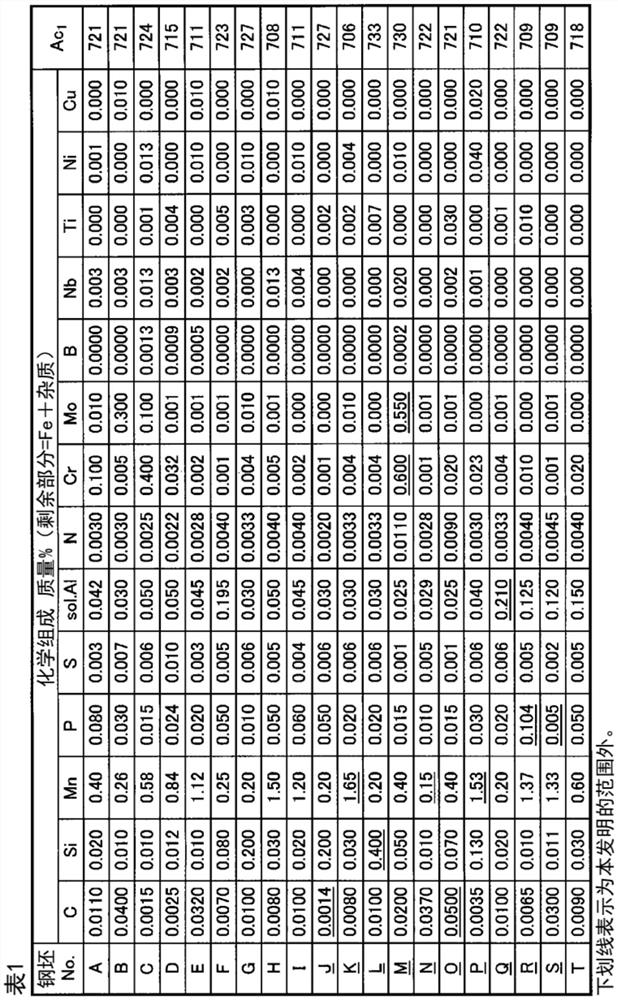

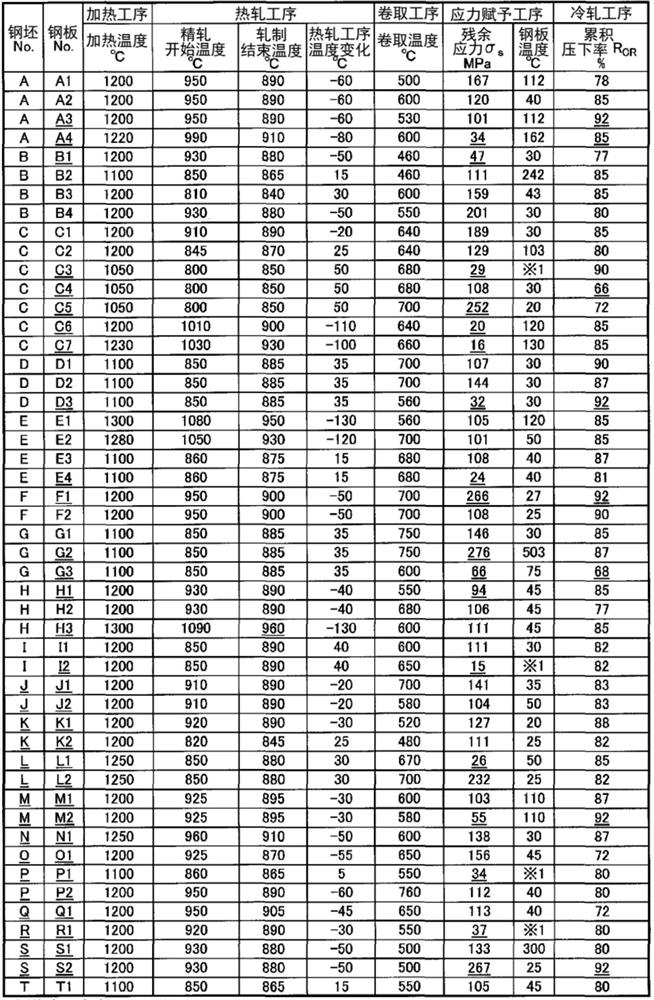

[0191] Steels having the chemical compositions shown in billets No.A to T in Table 1 were melted and continuously cast to manufacture slabs with a thickness of 240 to 300 mm. The resulting slabs were heated to the temperatures indicated in the table. The heated slabs were hot-rolled under the conditions shown in Table 2, and coiled.

[0192] Thereafter, the coil was uncoiled, and stress was applied to the hot-rolled steel sheet. At this time, using the processing temperature (steel plate temperature) shown in Table 2, a porta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com