Longitudinally and transversely connected belt type pontoon bridge

A horizontal connection and pontoon technology, which is applied in the field of belt pontoon bridges, can solve the problems that the horizontal connection of the bridge section box unit cannot be realized, and the horizontal connection function of the bridge section box unit is not considered.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

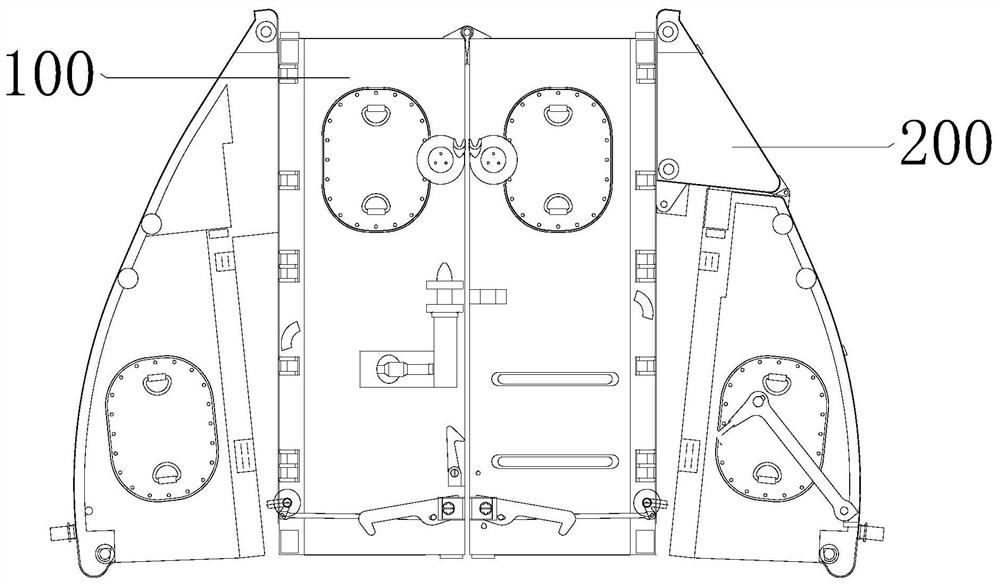

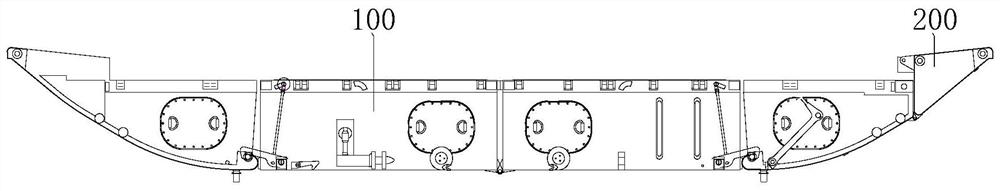

[0035] See Figure 1 to 9 The present invention provides a vertical and horizontally connected belt-like bridge, including the boat bridge unit body 100 and the prime assembly 200, the boat bridge unit body 100 and the prostleate assembly 200 to form a ribbon boat, for the frame, easy to use A cross river.

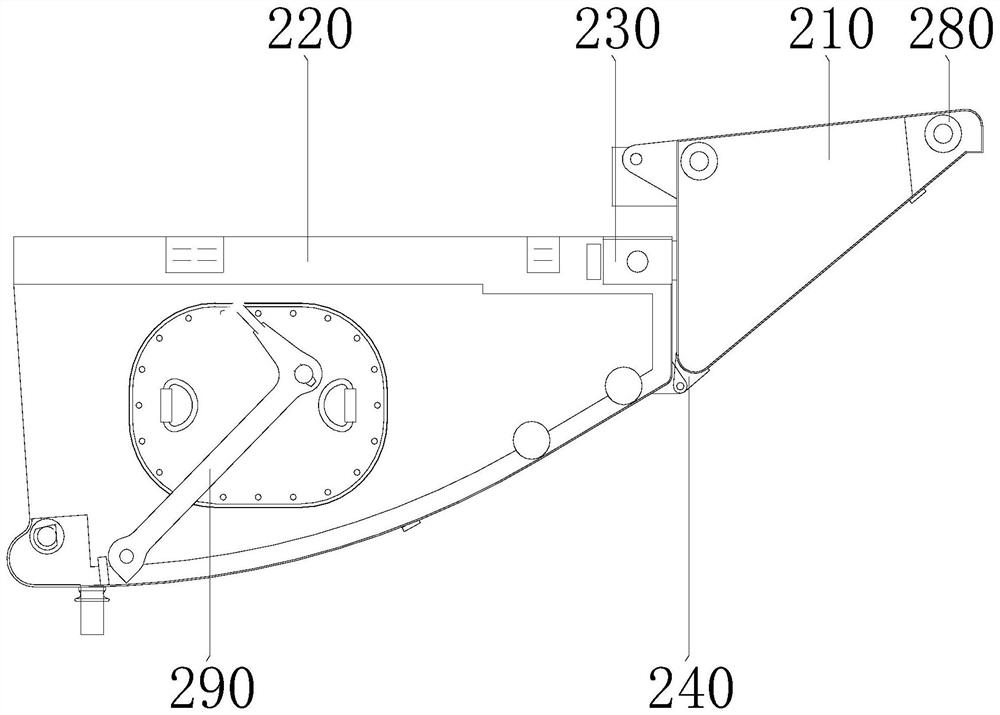

[0036] See image 3 The prime assembly 200 includes a cross-stranded boat 220, a cross-linking Ark 220, a first connecting member 230, a flip hinge 240, a deck transverse fastener 250, lateral connection joint 260, lateral connection ear plate 270, a throne fixed ear plate The 280 and the second connecting member 290, the lower side of the crosslinking pleasure 210 is hinged by the flip hinge 240, and the upper side of the crosslinked Ark 220 is hinged. Specifically, the flipping hinge 240 is fixed to the cross-stranded boat 210 and the horizontal arcade. On the lower side of the 220, the upper side of the cross-straightening shoe 210 is fixed to the upper side of the crosslinks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com