Friction pendulum shock insulation support

A technology of shock-isolation bearings and friction pendulums, which is applied in the field of building shock absorption, can solve problems such as detachment, structural overturning, failure of friction pendulum bearings, etc., and achieve the effects of protecting safety, preventing falling off, and avoiding uncontrollable situations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

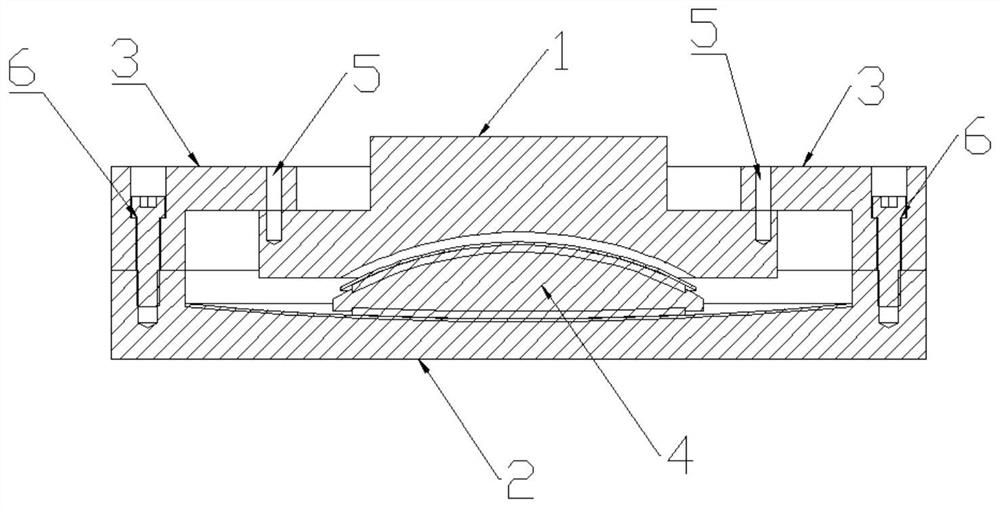

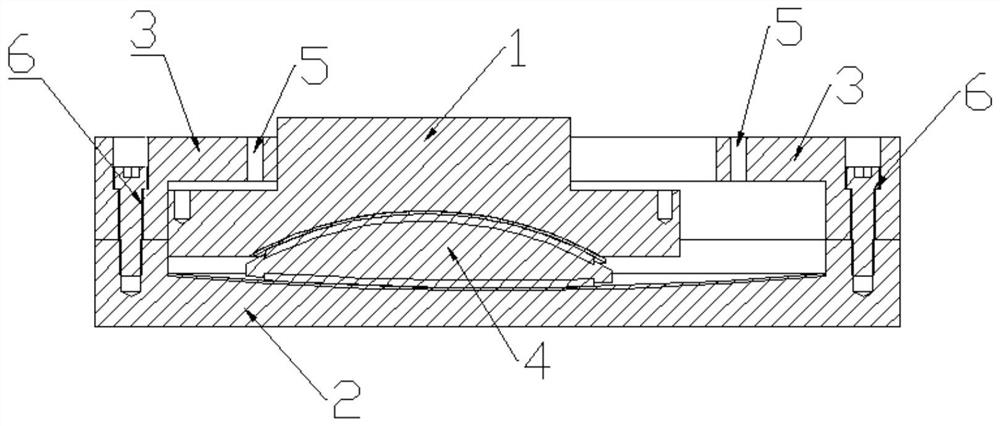

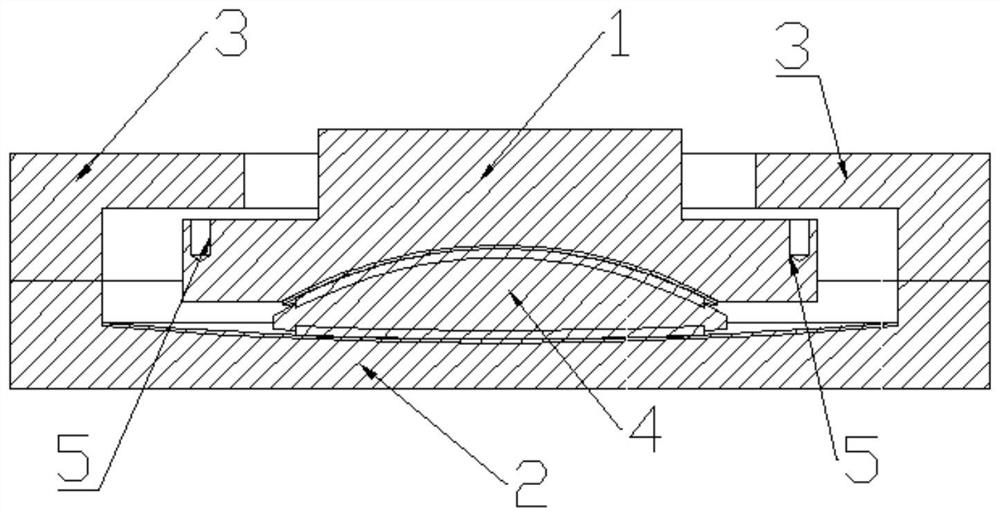

[0031] see Figure 1-Figure 6 As shown, the present invention discloses a friction pendulum shock-isolation bearing, which includes an upper seat plate 1, a lower seat plate 2, a gland 3 and a spherical crown 4; the spherical crown 4 is arranged between the upper seat plate 1 and the lower seat plate 2 between;

[0032] The upper seat plate 1 includes a convex portion 11 extending vertically upward, a first step portion 12 and a second step portion 13 extending horizontally to both ends, and a concave spherical portion 14 provided on the lower surface; The concave spherical surface 14 has the same curvature as the upper surface of the spherical cap 4;

[0033] The lower seat plate 2 is a concave structure, including a first convex portion 21, a second convex portion 22 and a middle portion 23 extending vertically at both ends; A spherical surface with the same surface curvature; the two ends of the spherical surface respectively extend to the first convex portion 21 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com