Safety lifting cabin for coal mine rescue

A safety and coal mine technology, applied in the field of safety hoisting cabins for coal mine rescue, can solve problems such as insufficient functions, stuck tanks, instability, etc., and achieve the effects of improving smoothness, reducing energy consumption, and improving smoothness and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

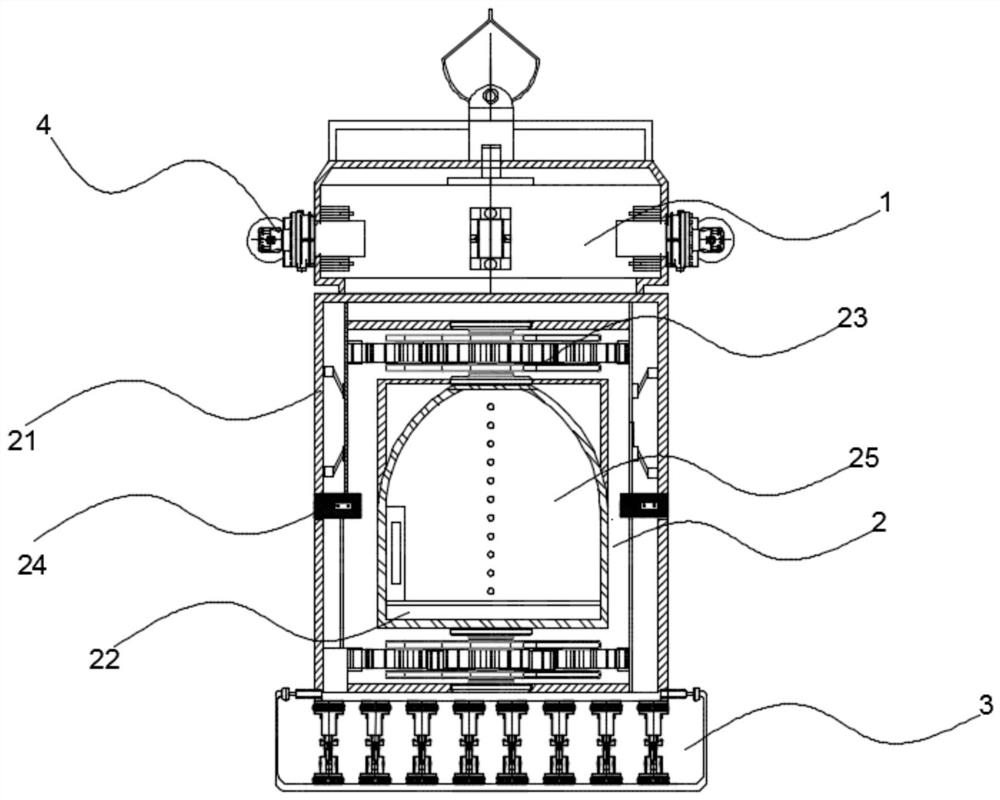

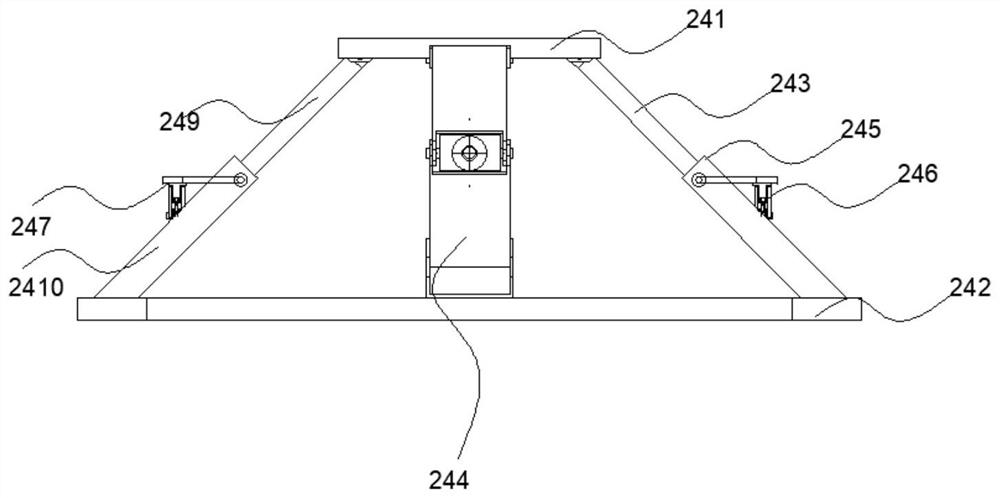

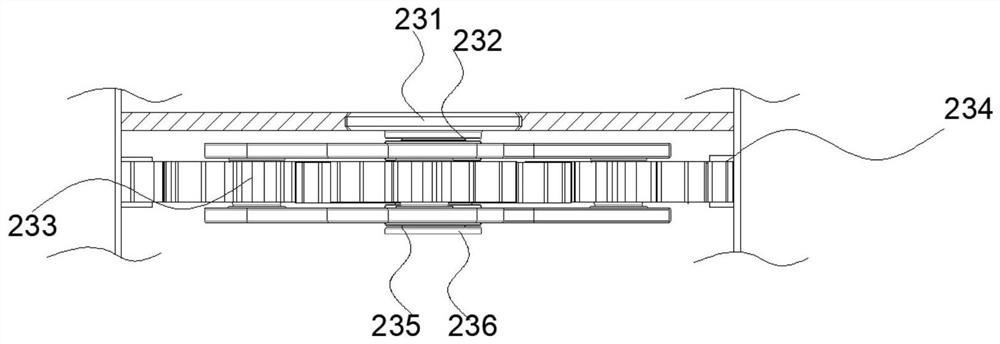

[0034] see Figure 1-6, in an embodiment of the present invention, a safety hoisting cabin for coal mine rescue, which is used for a mine vertical rescue hoisting system with a maximum lifting speed of at least 2m / s and a maximum load of 1000Kg, which includes guides connected sequentially from top to bottom The cabin 1, the life cabin 2 and the buffer cabin 3 are characterized in that the outer peripheral surface of the guide cabin is provided with a plurality of guide travel anti-jamming mechanisms 4 in an array at intervals, each of the guide travel anti-jamming mechanisms is horizontally extended, and each The guiding walking anti-jamming mechanism can be telescopically arranged in the horizontal extension direction, and the front end of the guiding walking anti-jamming mechanism is a walking guide wheel 42. 42 turn the corner hydraulic cylinder for walking, and the output end of the corner hydraulic cylinder is connected with the drive shaft 43 of the walking guide wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com