Metal round cover character imprinting equipment

A technology of metal and text, which is applied in the field of text printing and embossing equipment on metal domes, can solve the problems of manpower consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

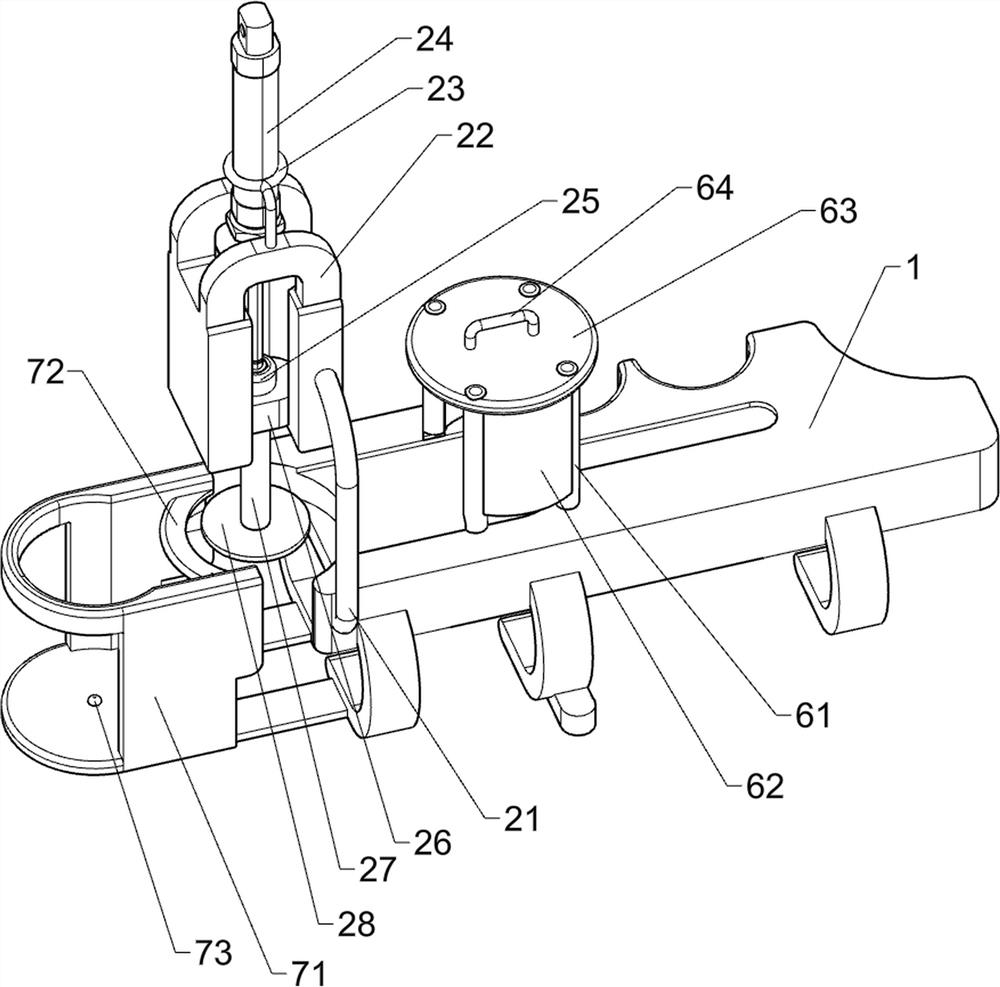

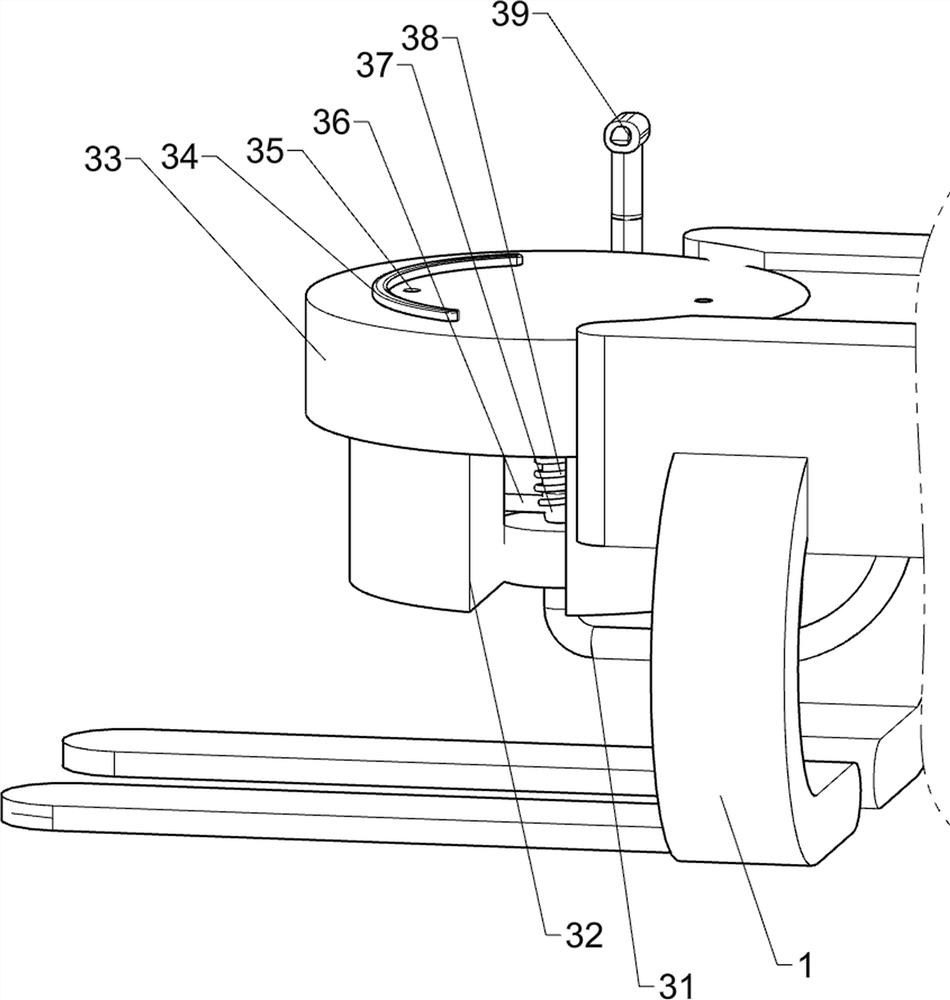

[0074] A kind of metal round cover text embossing equipment, such as figure 1As shown, it includes a base 1, a pressing mechanism 2, a supporting mechanism 3 and a pushing mechanism 4, the pressing mechanism 2 is provided on the left side of the top of the base 1, the supporting mechanism 3 is provided on the left side of the top of the base 1, and the right side of the top of the base 1 A pushing mechanism 4 is provided.

[0075] Such as figure 2 As shown, the pressing mechanism 2 includes a first connecting rod 21, a first connecting frame 22, a fixed frame 23, a cylinder 24, a first connecting block 25, a first slider 26, a second connecting rod 27 and a first pressing Block 28, the left side of the base 1 is symmetrically provided with the first connecting rod 21, the first connecting rod 21 is connected with the first connecting frame 22, the top of the first connecting frame 22 is provided with a fixed frame 23, and the fixed frame 23 is provided with Cylinder 24, the...

Embodiment 2

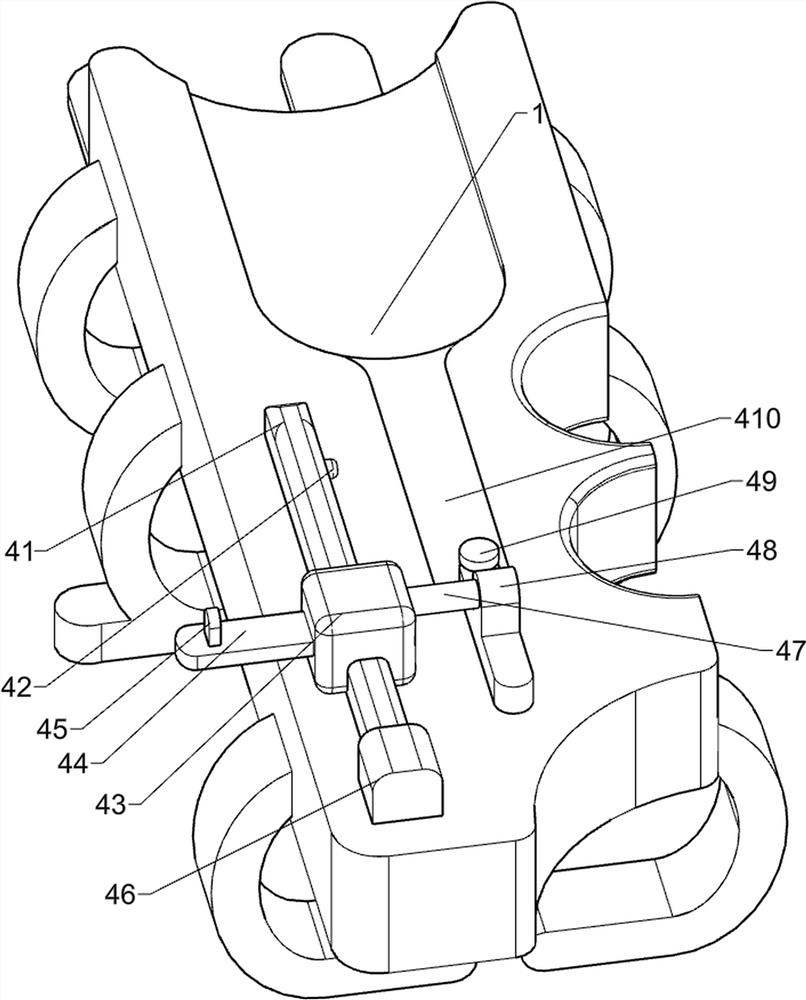

[0080] On the basis of Example 1, such as Figure 5 As shown, a driving mechanism 5 is also included, and the driving mechanism 5 includes a supporting column 51, a second connecting frame 52, a rotating plate 53, a seventh connecting rod 54, a balance bar 55, a second pressing block 56, and a fourth connecting block 57. Connecting assembly 58, eighth connecting rod 59 and bolt 510. The front side of the first slider 26 is provided with a second lower pressing block 56. The front side of the top of the base 1 is provided with a supporting column 51. The top of the supporting column 51 is provided with a second Connecting frame 52, on the second connecting frame 52, the seventh connecting rod 54 is rotatably provided with, the seventh connecting rod 54 is provided with a rotating plate 53, and the rotating plate 53 is provided with a balance bar 55, and the balancing rod 55 and the second pressing down block 56, the right side of the balance bar 55 is provided with a fourth con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com