Patents

Literature

36results about How to "Realize automatic loading work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

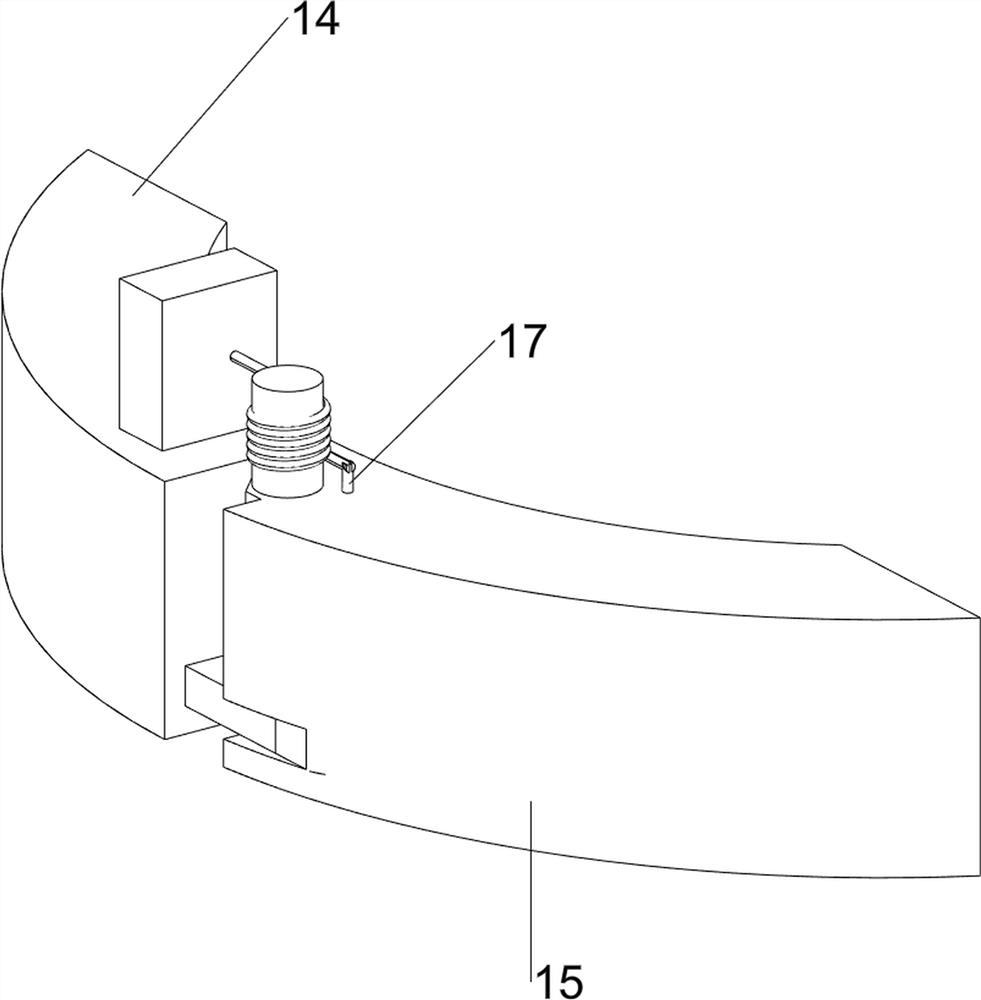

Inventor

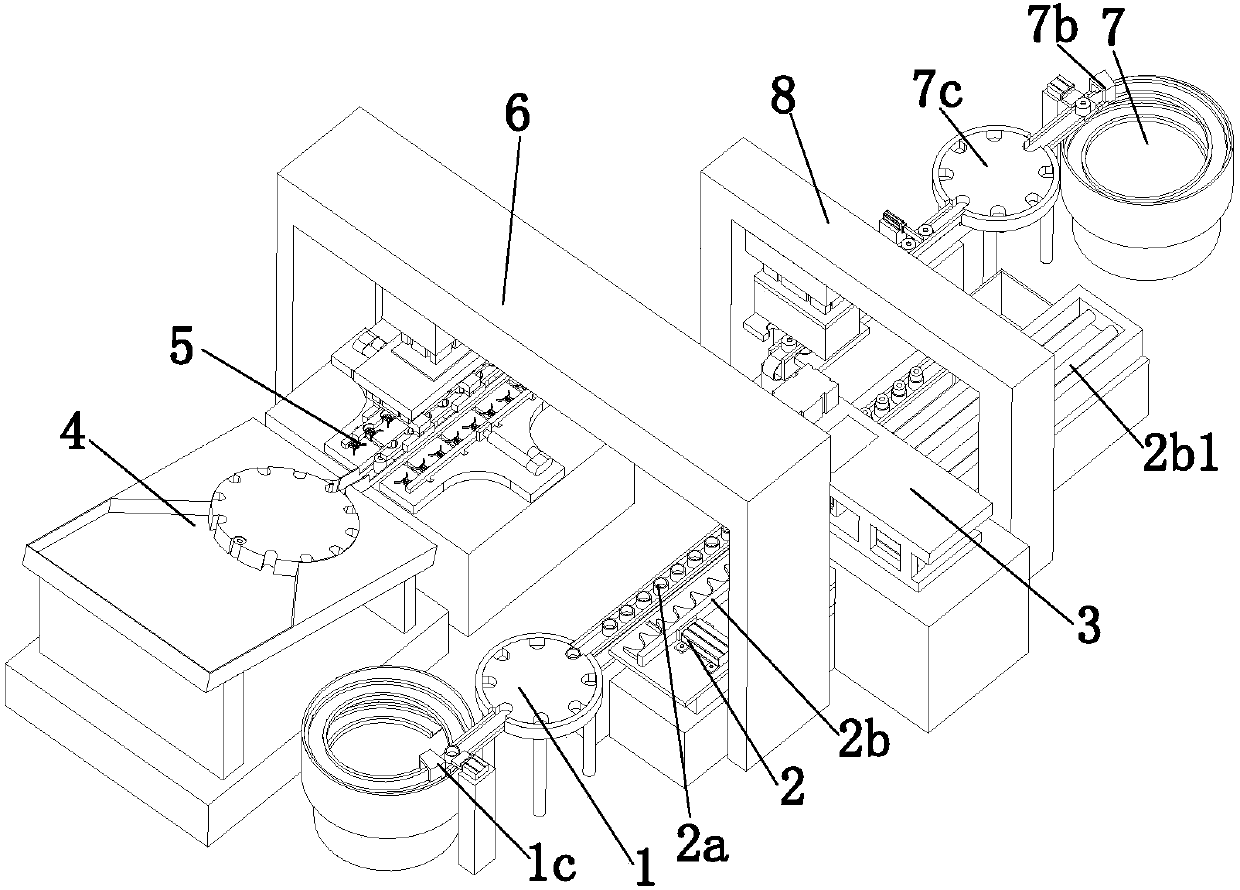

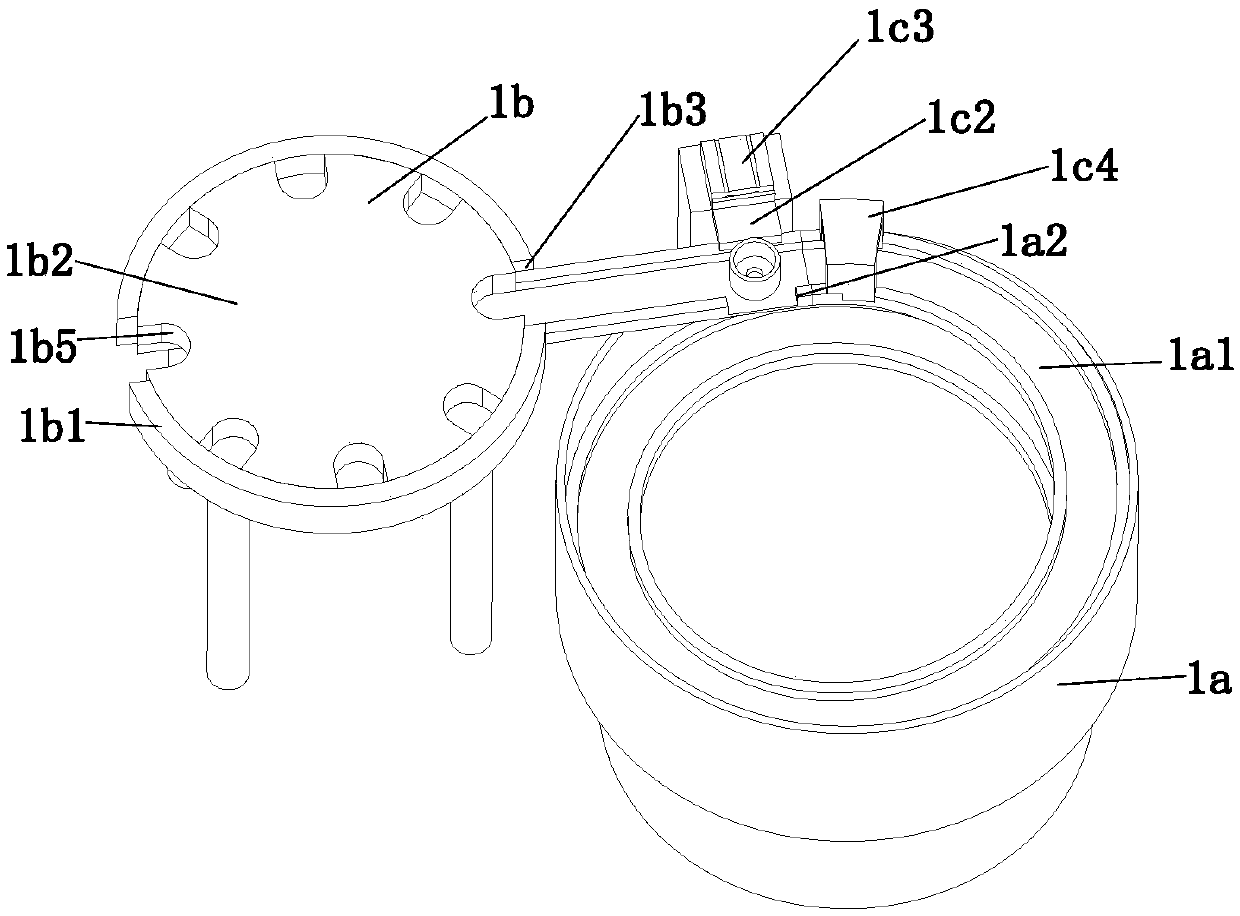

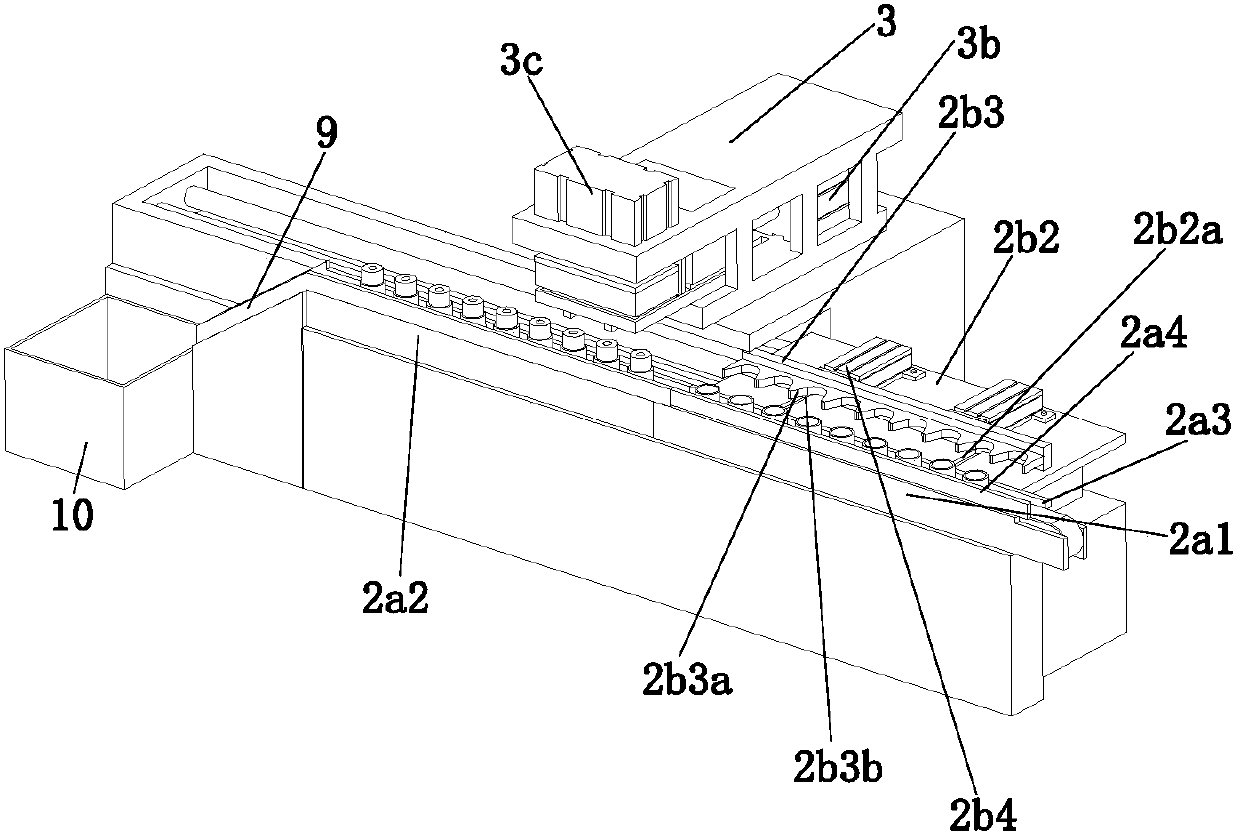

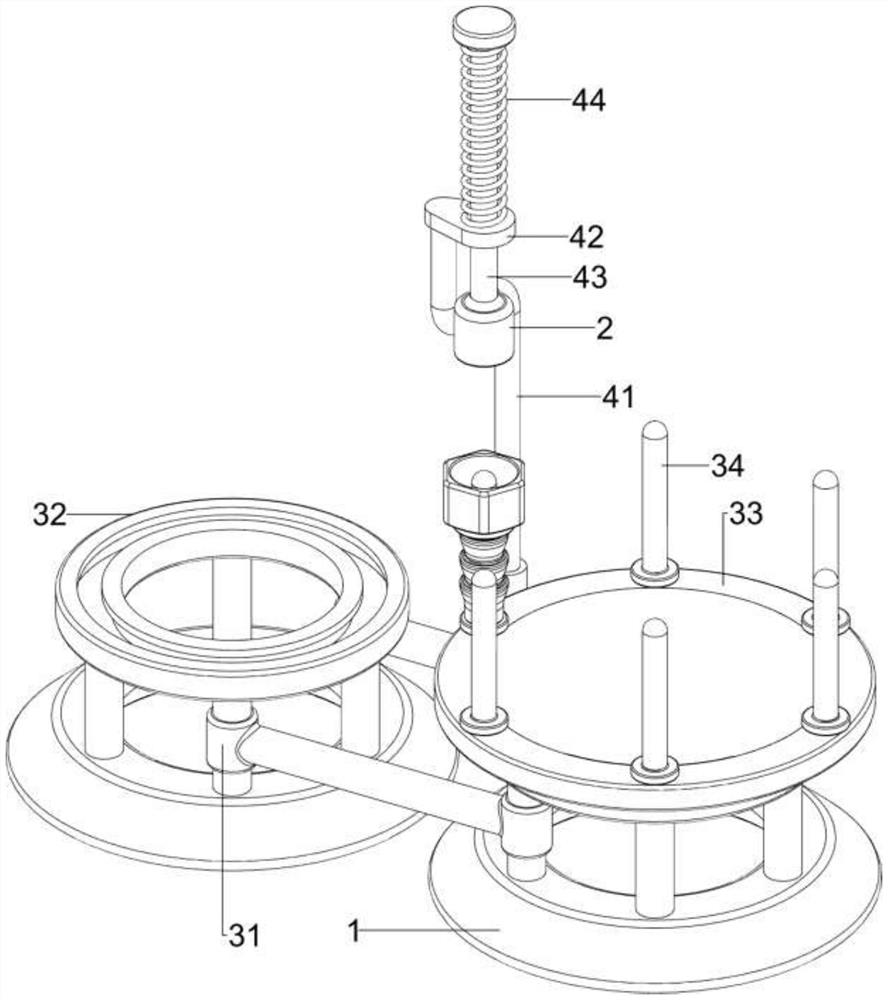

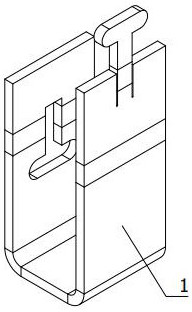

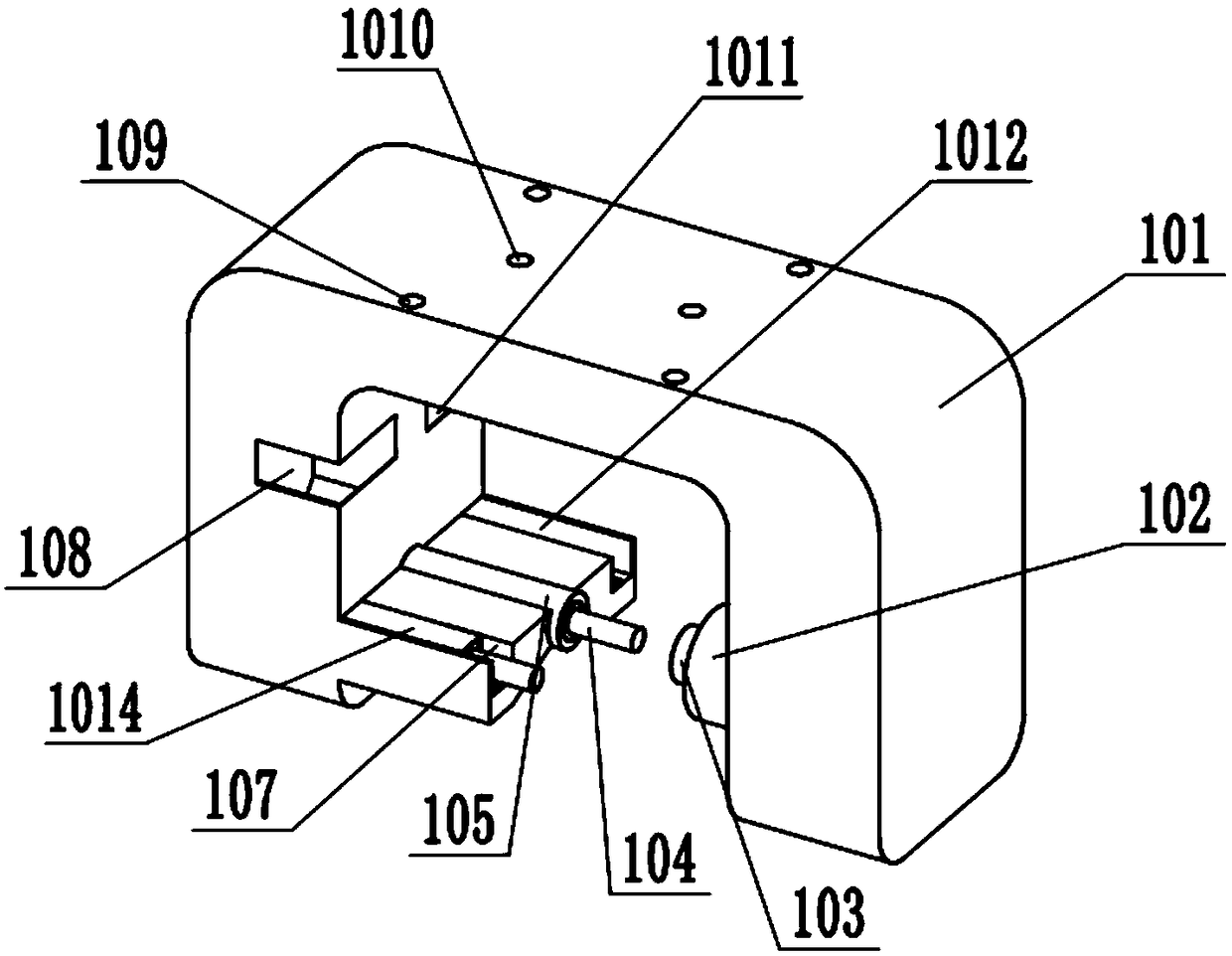

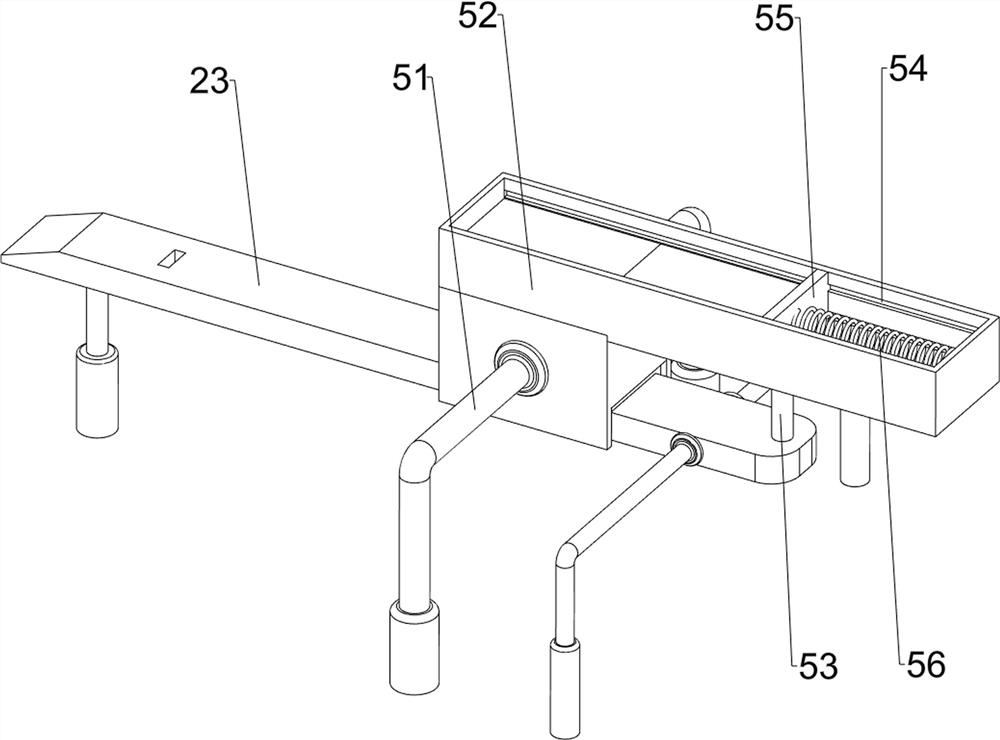

Feeding mechanism of electromagnet core assembling equipment

InactiveCN108032053ARealize automatic loading workAvoid harmMetal working apparatusEngineeringMechanical engineering

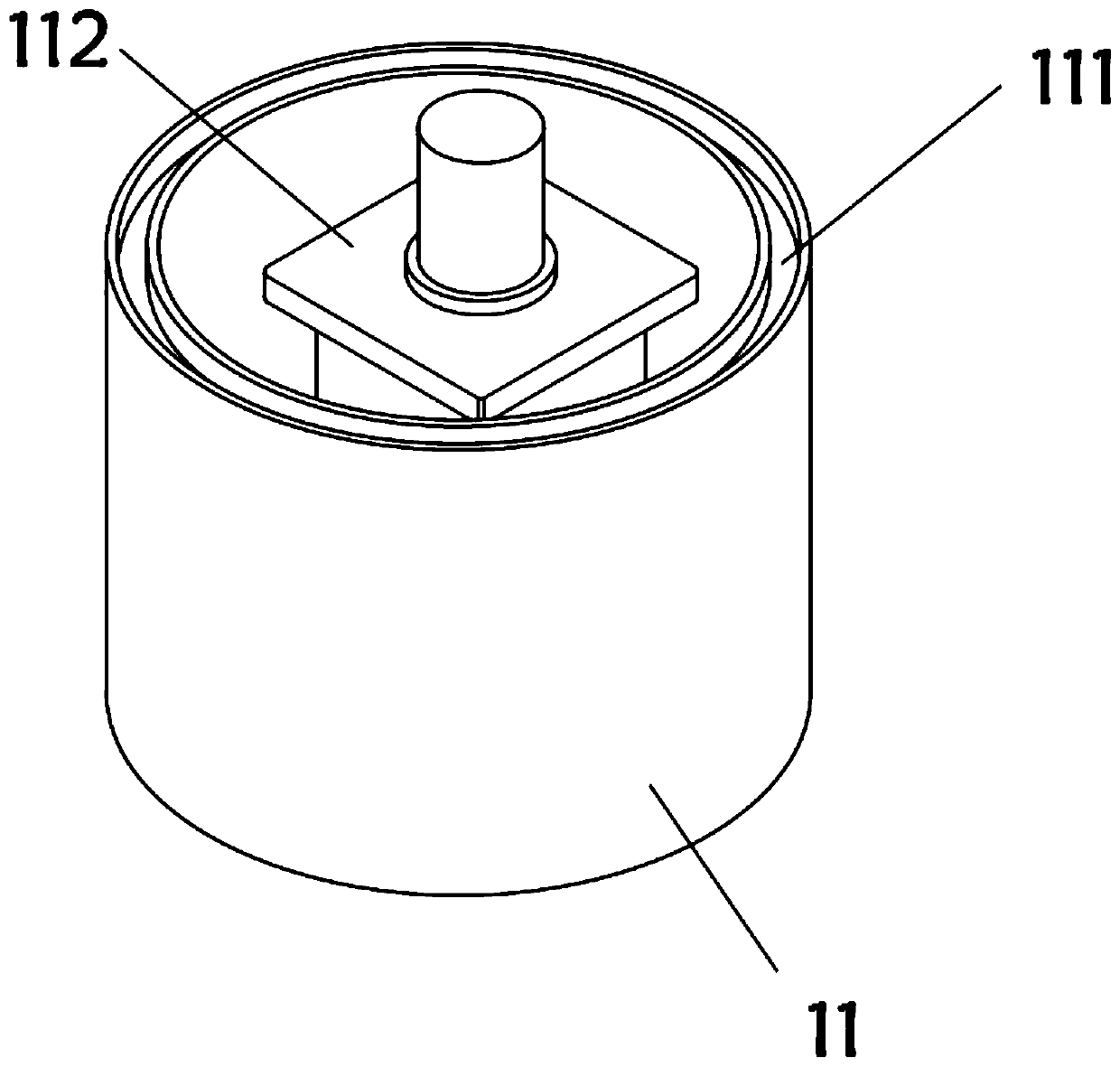

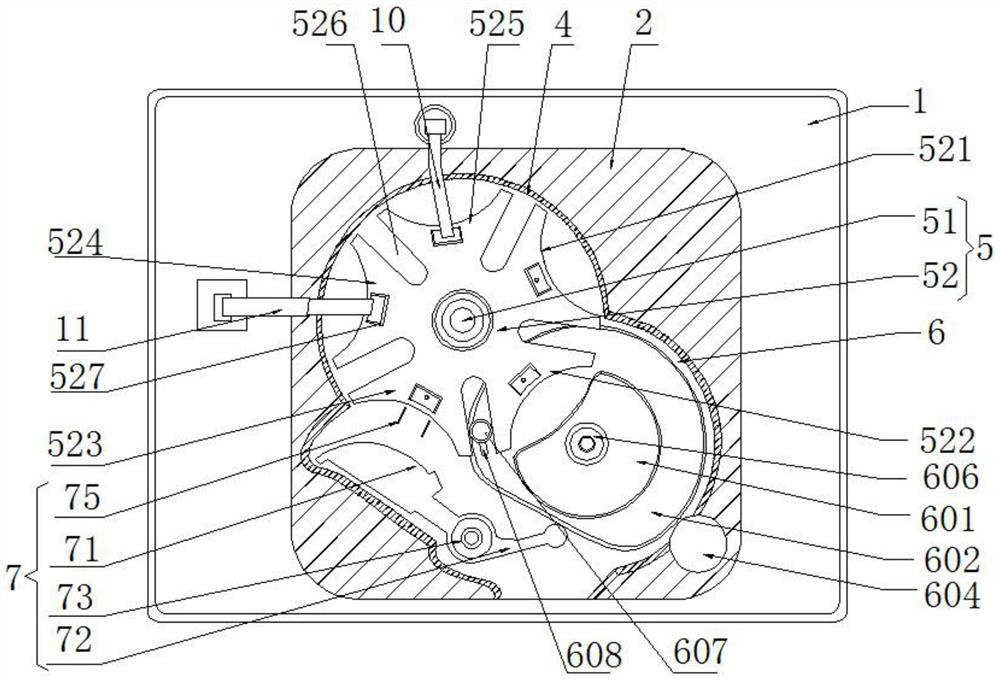

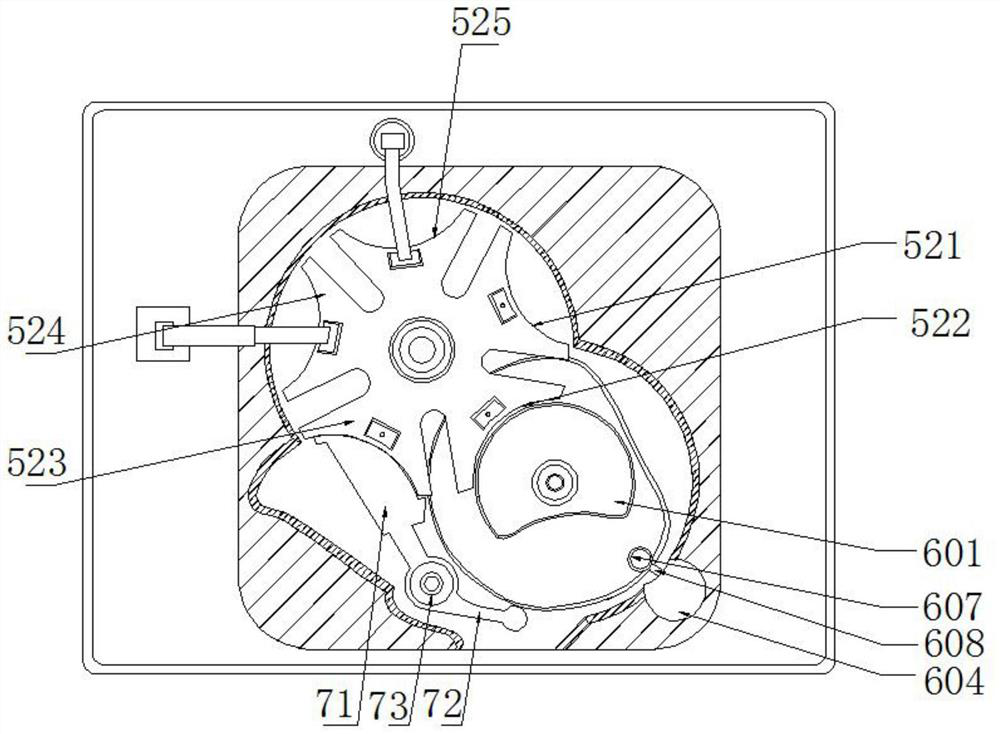

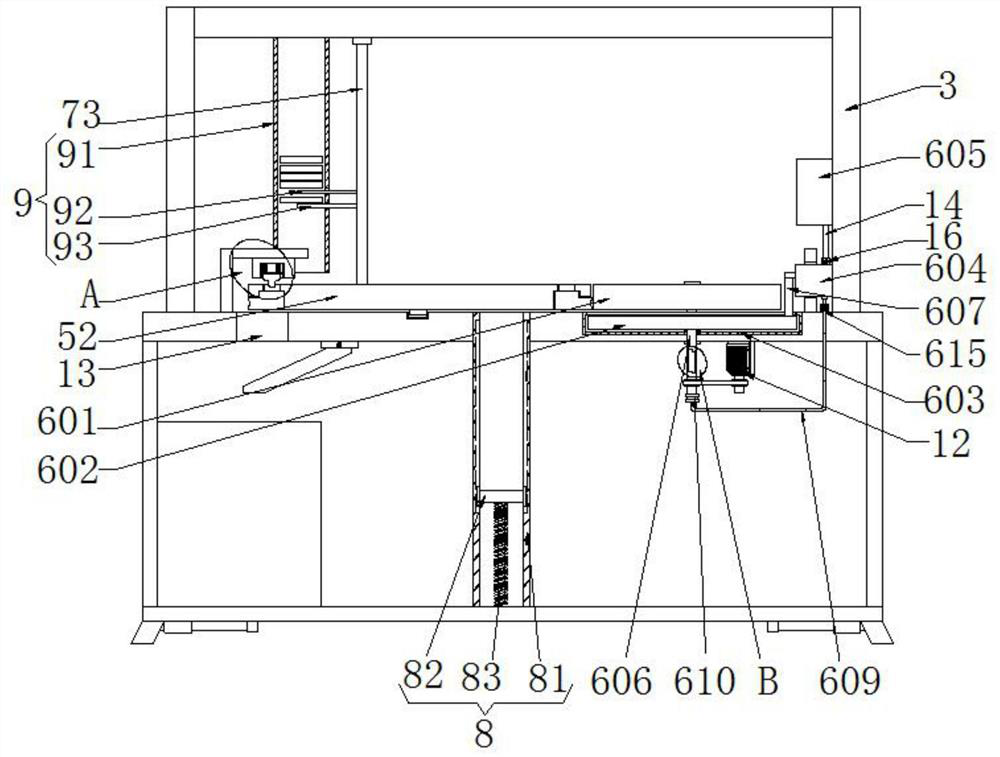

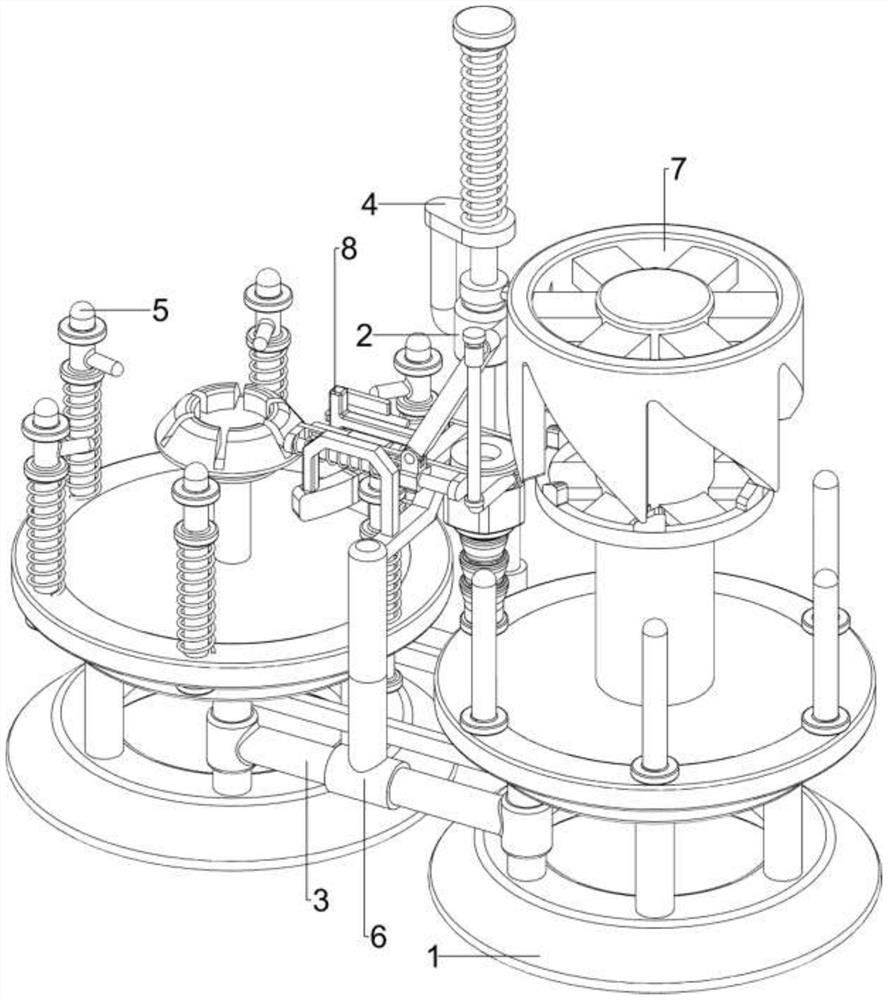

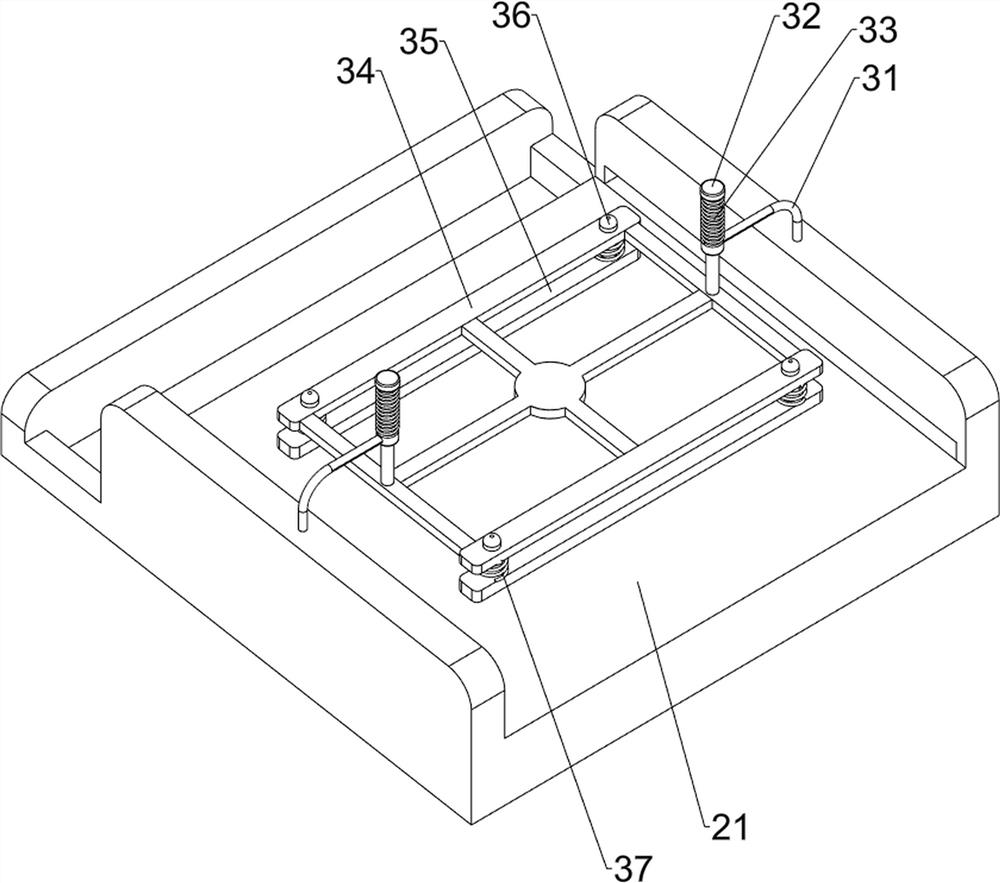

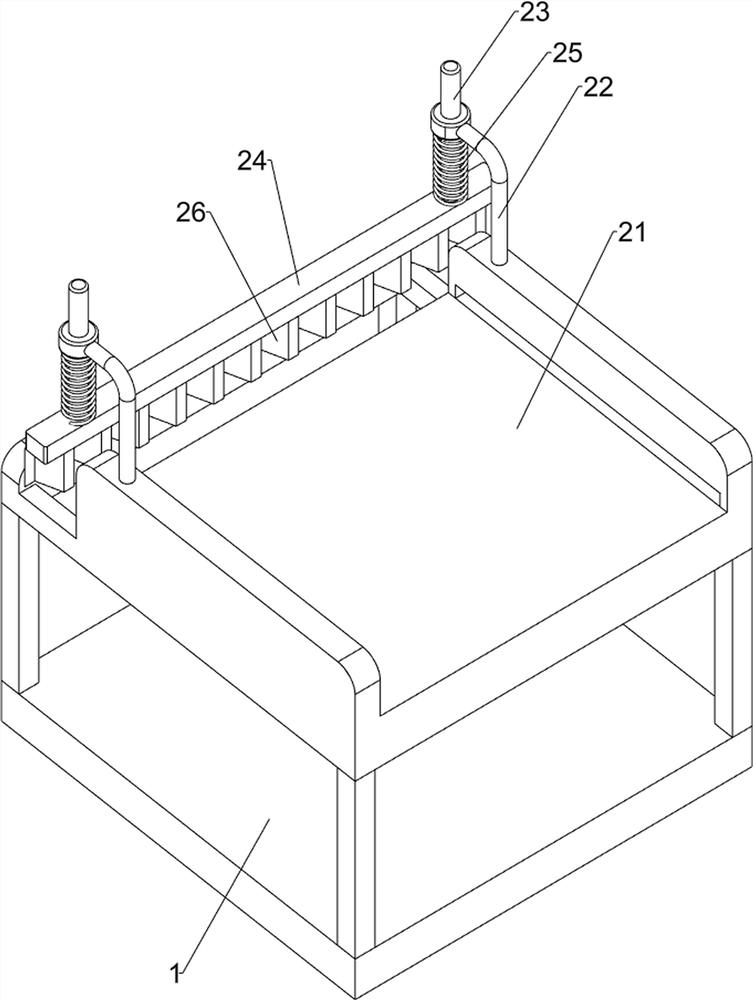

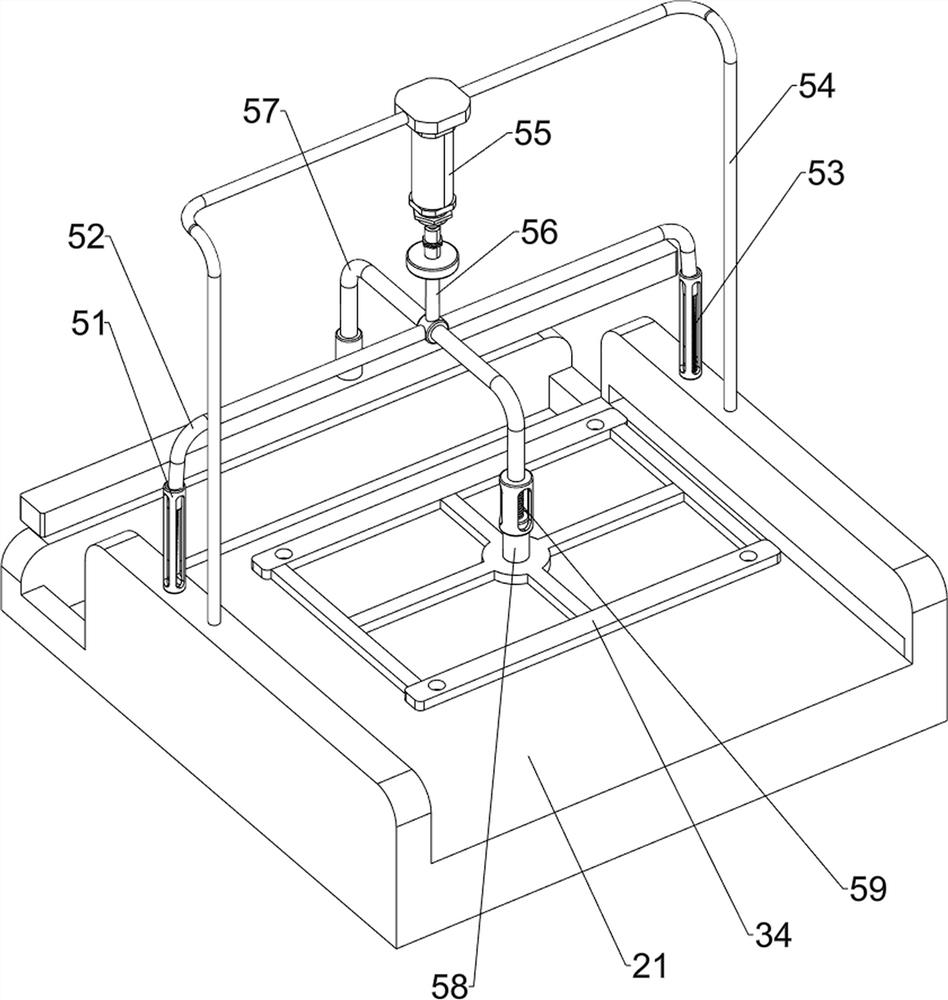

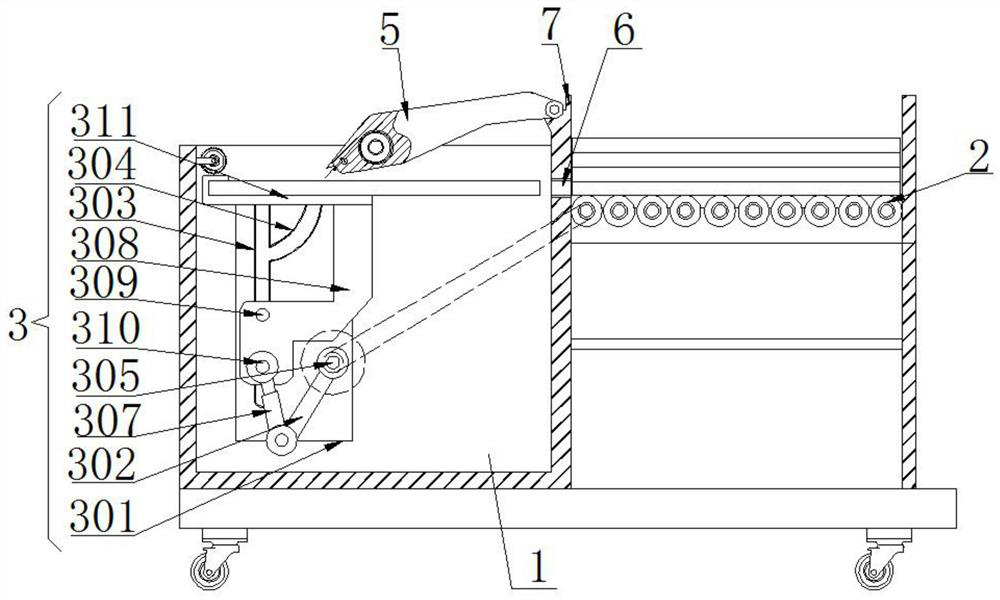

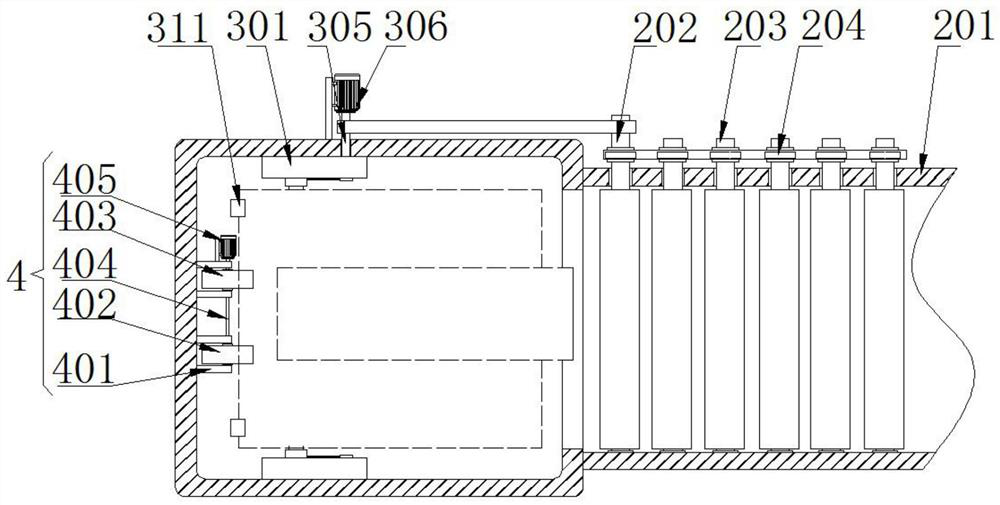

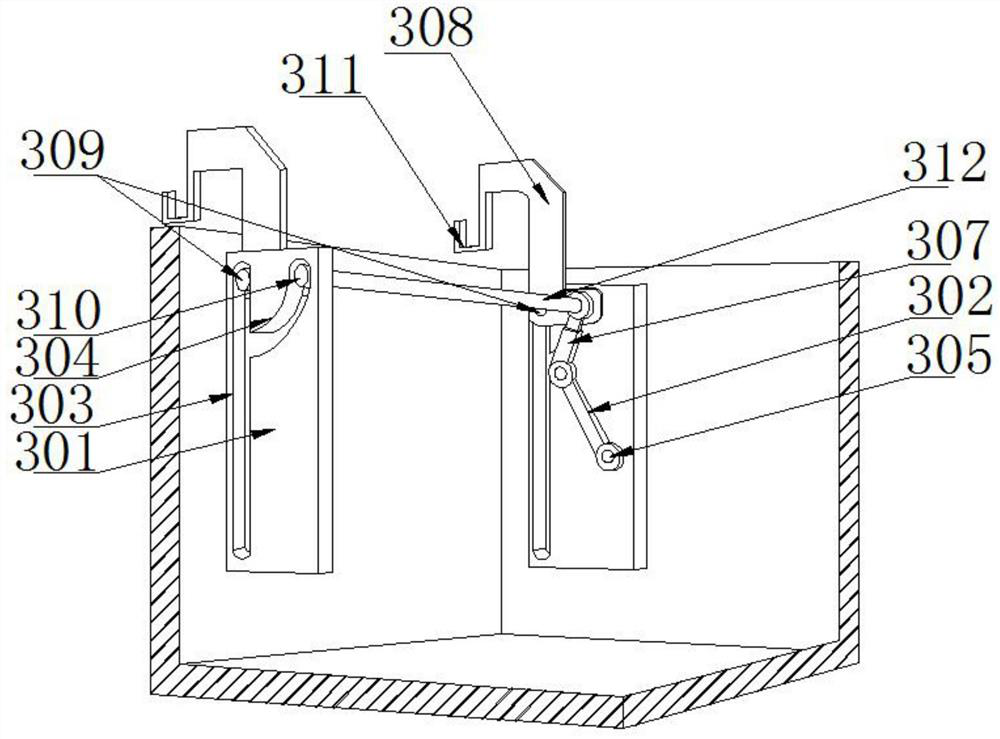

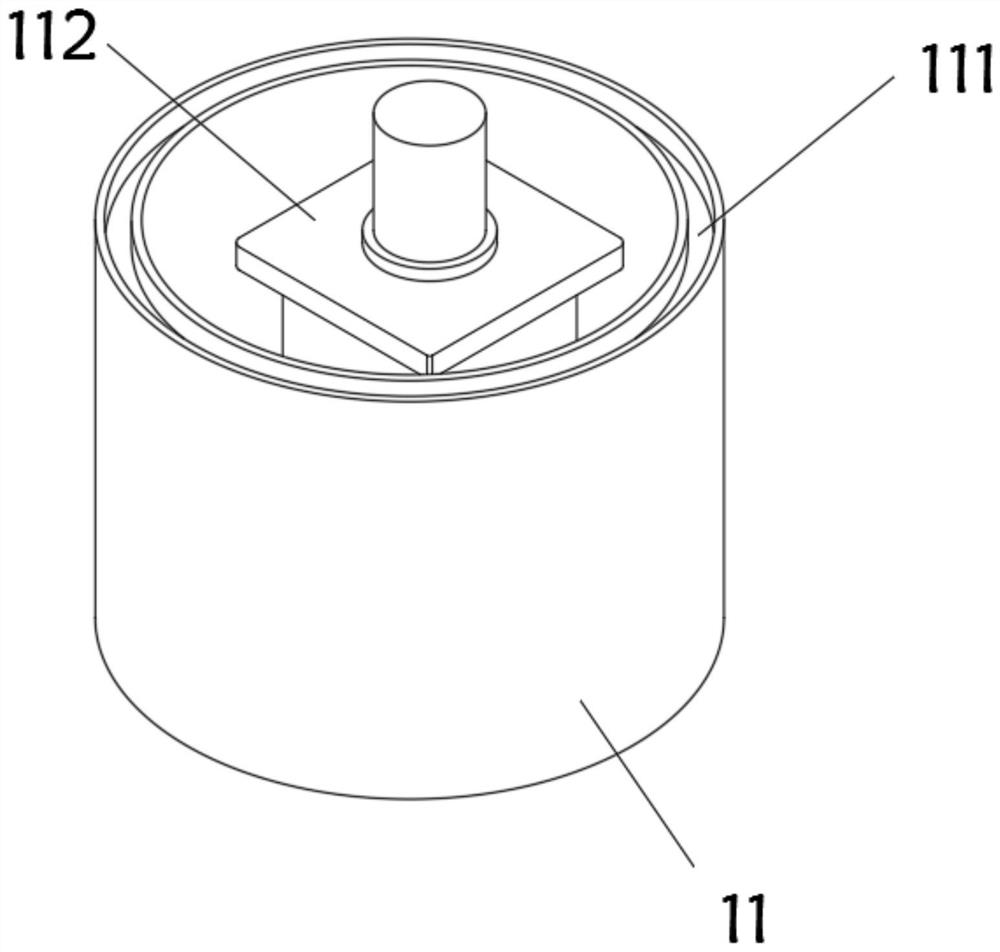

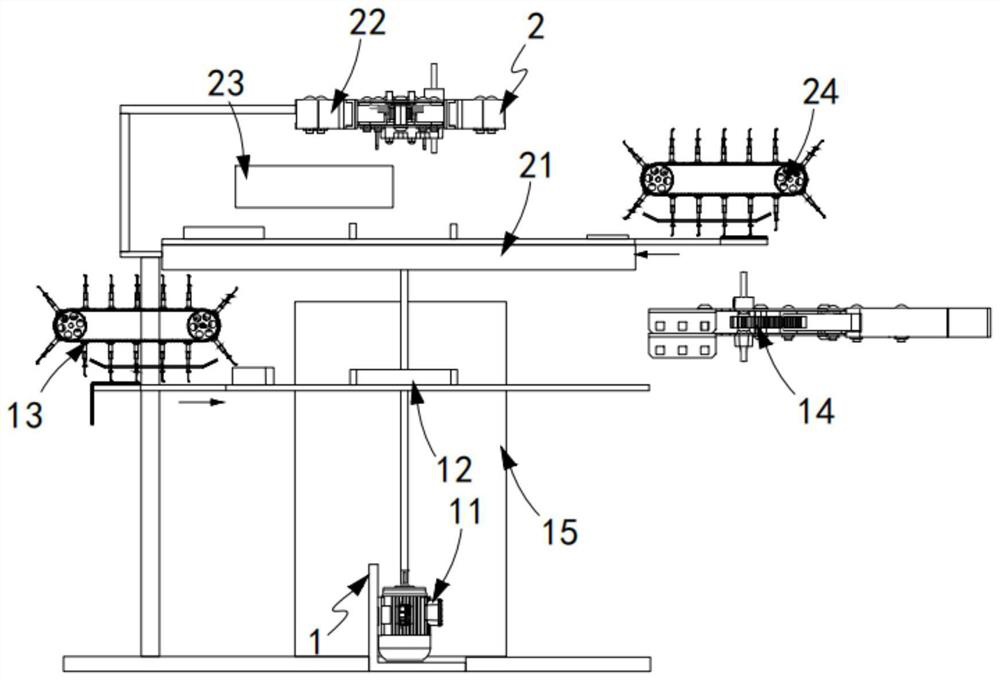

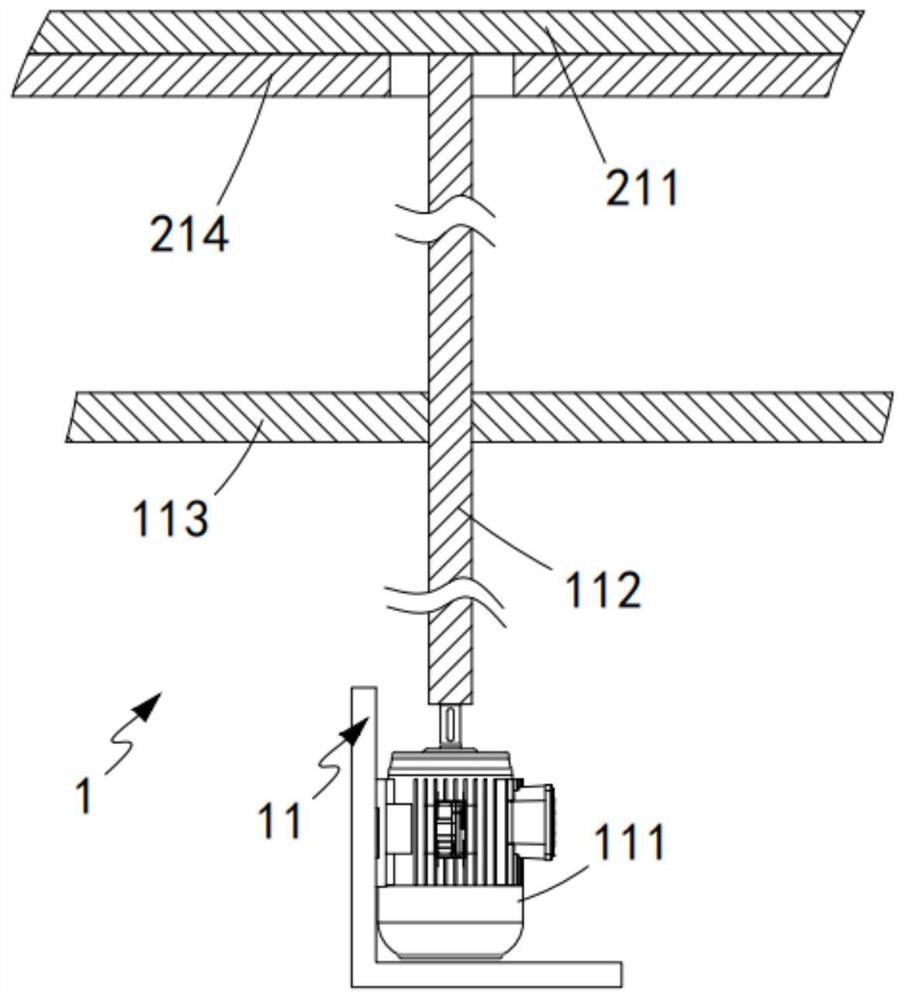

The invention relates to the field of mechanical production equipment, in particular to a feeding mechanism of electromagnet core assembling equipment. The mechanism comprises a lower cover feeding device, an iron core feeding device, an iron core positioning device, an iron core carrying device and an upper cover feeding device; the lower cover feeding device comprises a lower cover vibration feeding tray, a lower cover distance control assembly and a lower cover detection assembly; the lower cover vibration feeding tray is provided with a first material channel, and a first notch is formed in one side of the first material channel; the lower cover detection assembly comprises a first sensor, a first push plate and a first detection cylinder, the first detection cylinder is horizontally arranged, an output end of the first detection cylinder faces the first notch formed in the first material channel, and one end of the first push plate is fixedly connected with an output end of the first detection cylinder. Accordingly, automatic feeding work in the electromagnet core assembling process is achieved, manual labor is reduced, and the harm of a production workshop to human bodies isavoided; meanwhile, the production efficiency is improved, and the production cost is lowered.

Owner:ZHEJIANG UNIV OF TECH FENGHUA SMART ECONOMY RES INST

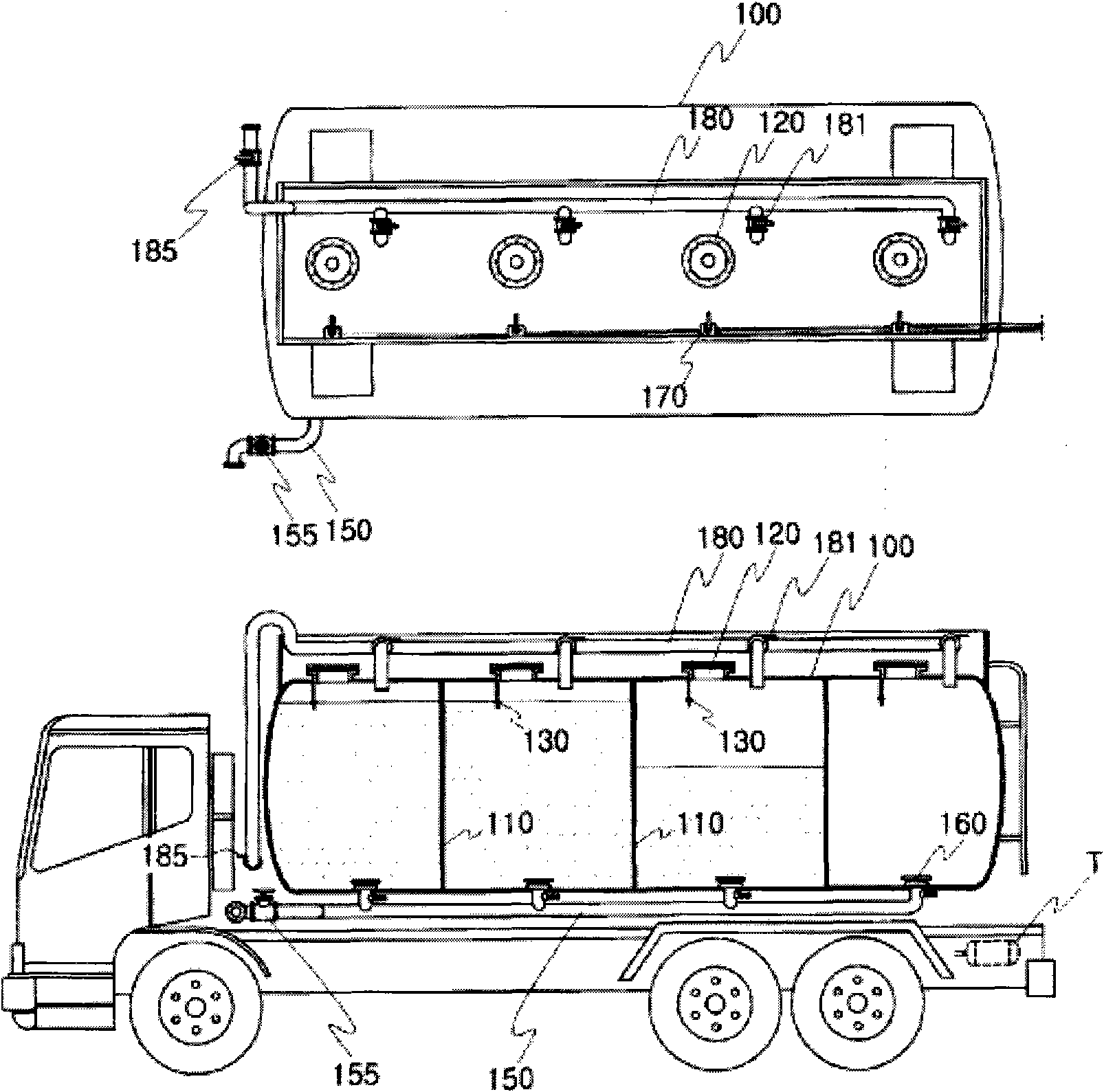

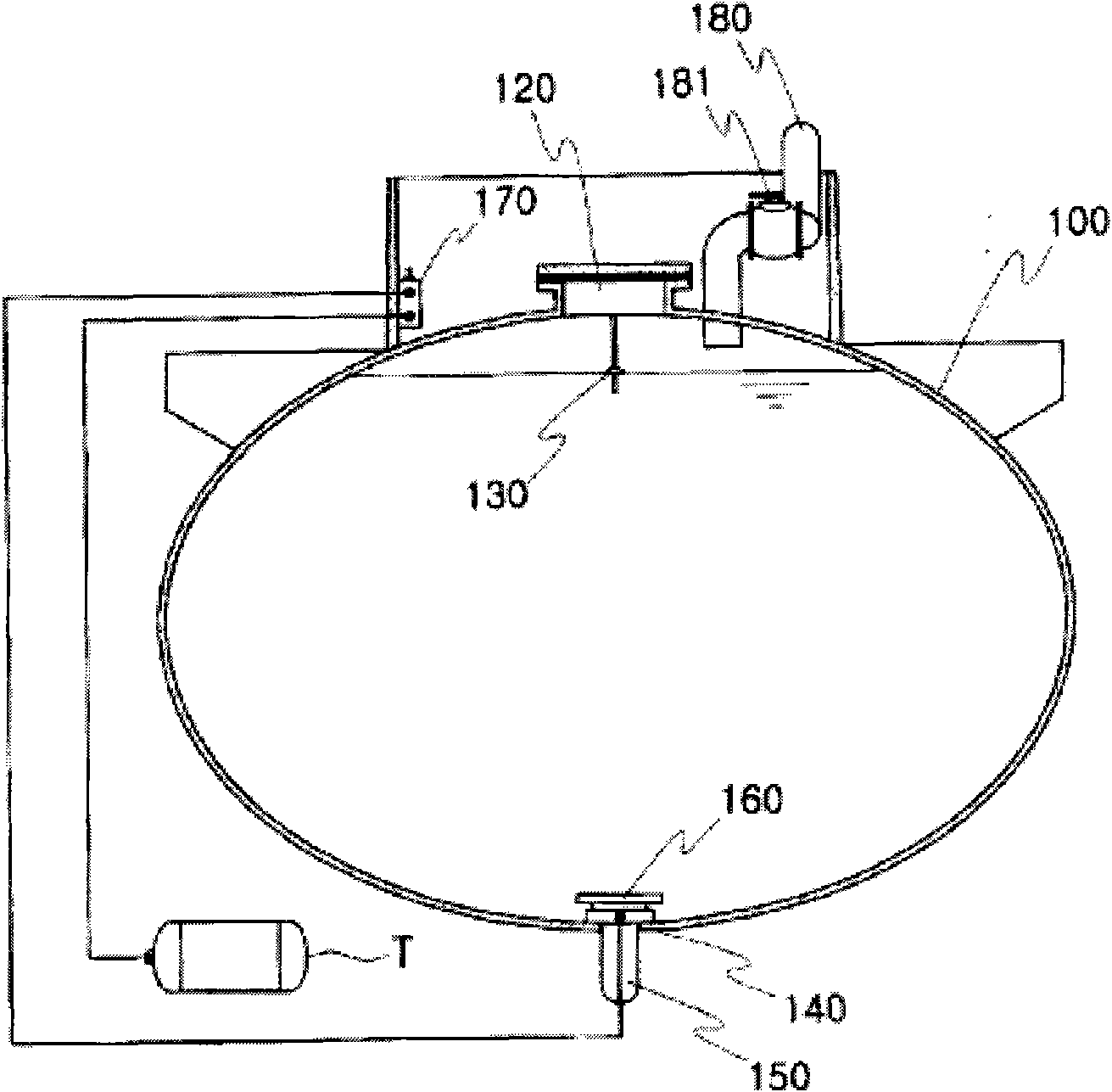

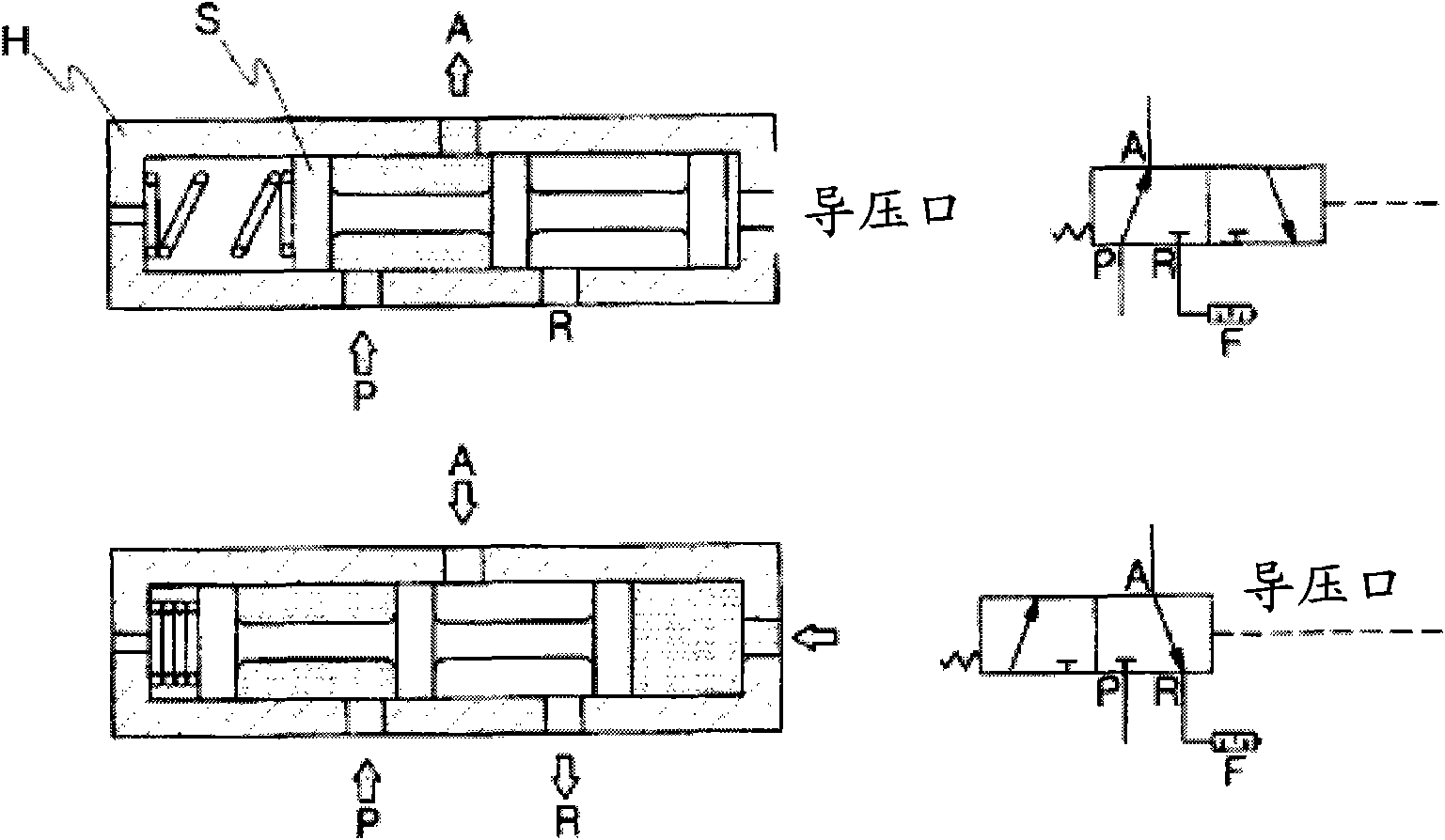

Valve control unit of tank lorry

InactiveCN101583816ARealize automatic loading workEnsure safetyTank vehiclesLarge containersAutomatic balancing valvesPneumatic circuit

Disclosed therein is a valve control apparatus for a tank lorry. The valve control apparatus for the tank lorry includes a first control valve for opening and closing the oil feed valve by supplying compressed air to the oil feed valve or discharging the supplied compressed air to the outside, a second control valve for actuating the first control valve by the user's manual manipulation, an automatic closing valve for actuating the first control valve, a third control valve for selecting an operation of the automatic closing valve, and a pneumatic circuit for realizing functions of the control valves, wherein the control valves are general direction conversion valves for converting a flow of the compressed air and can be controlled on the road. So, a user can carry out a loading work in more convenient and safe when the user loads oil articles or chemicals on a storage tank mounted on the tank lorry.

Owner:崔荣守

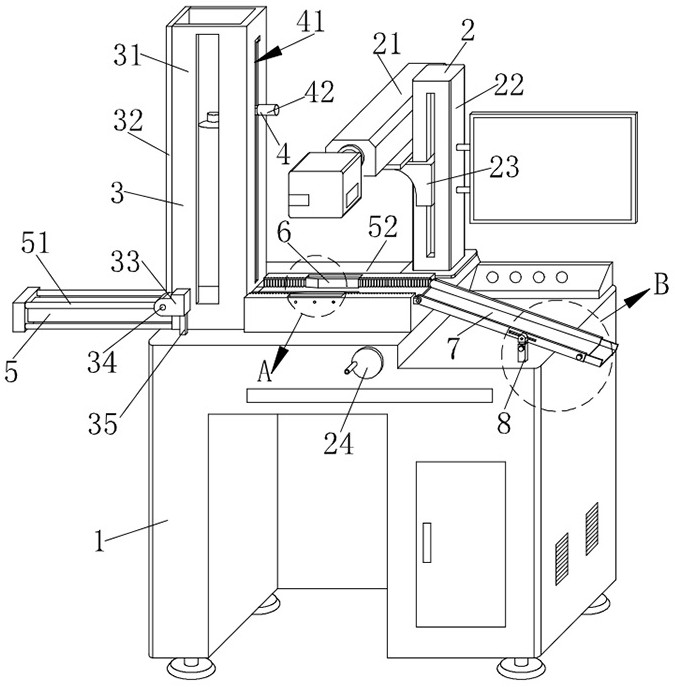

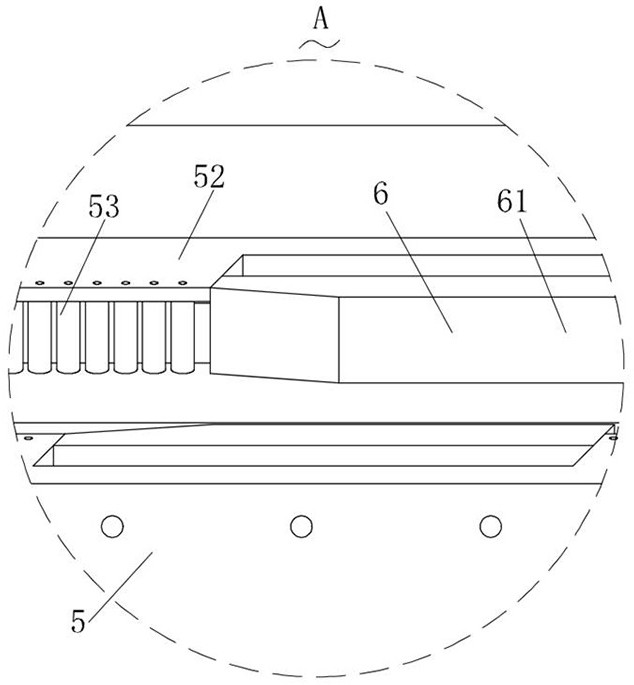

Mobile phone shell laser marking machine

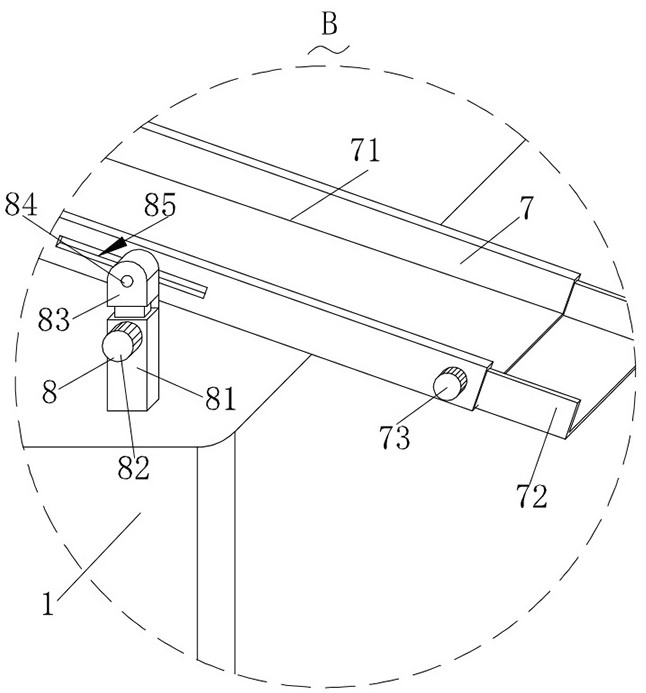

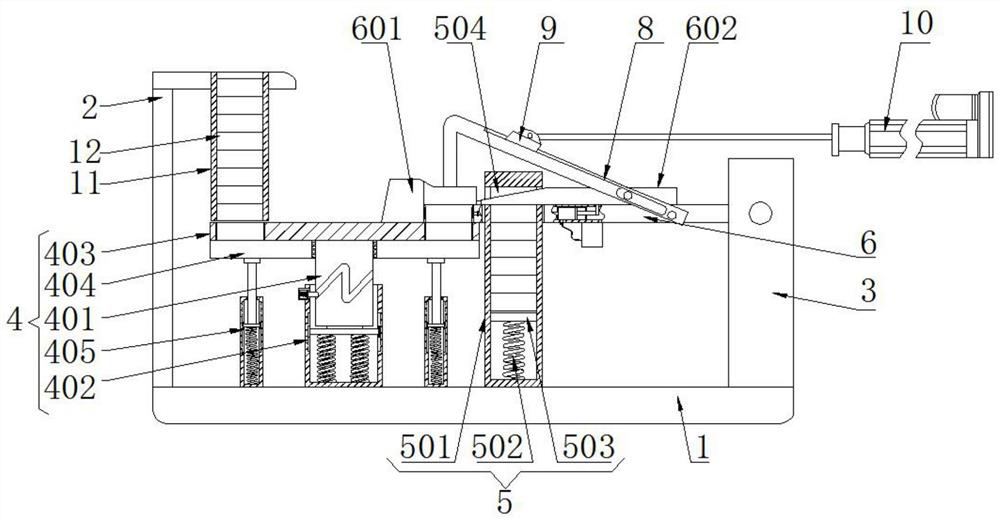

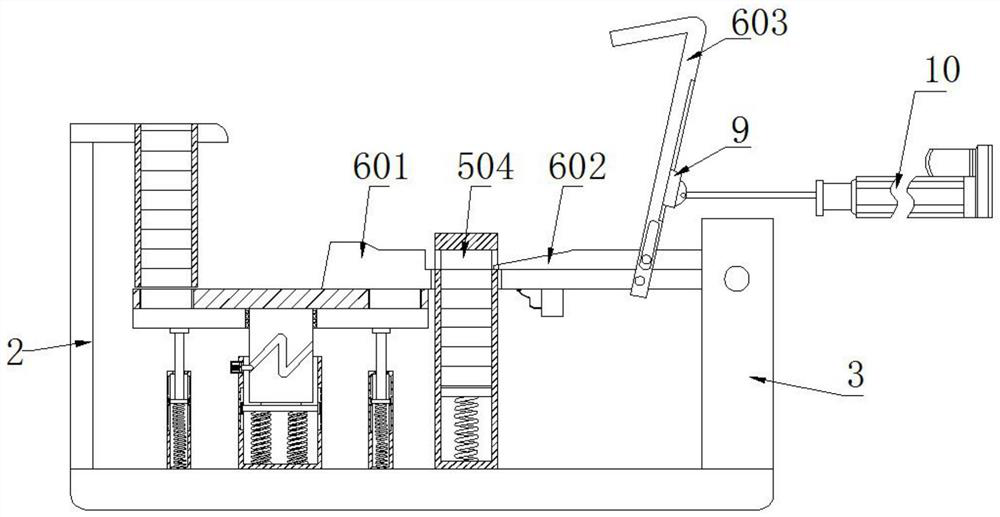

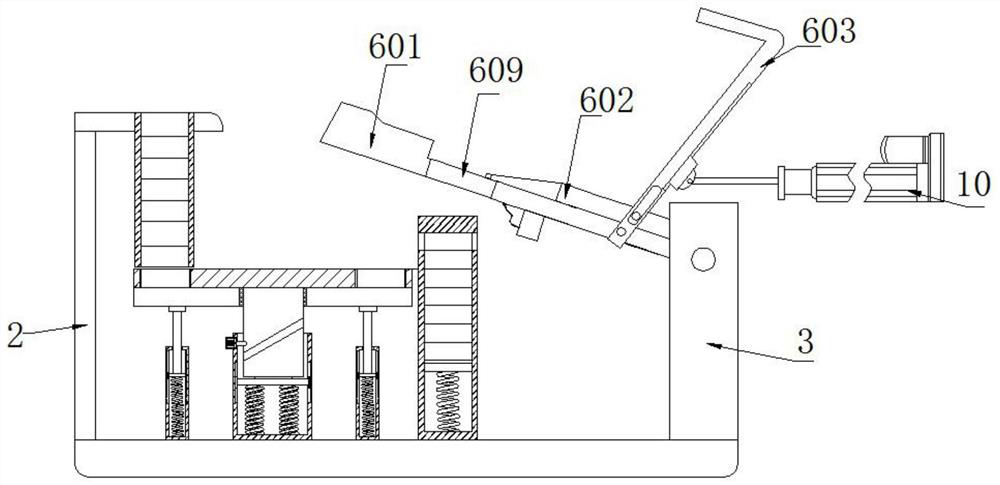

ActiveCN113352003ARealize lifting adjustmentEasy to replaceWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachine

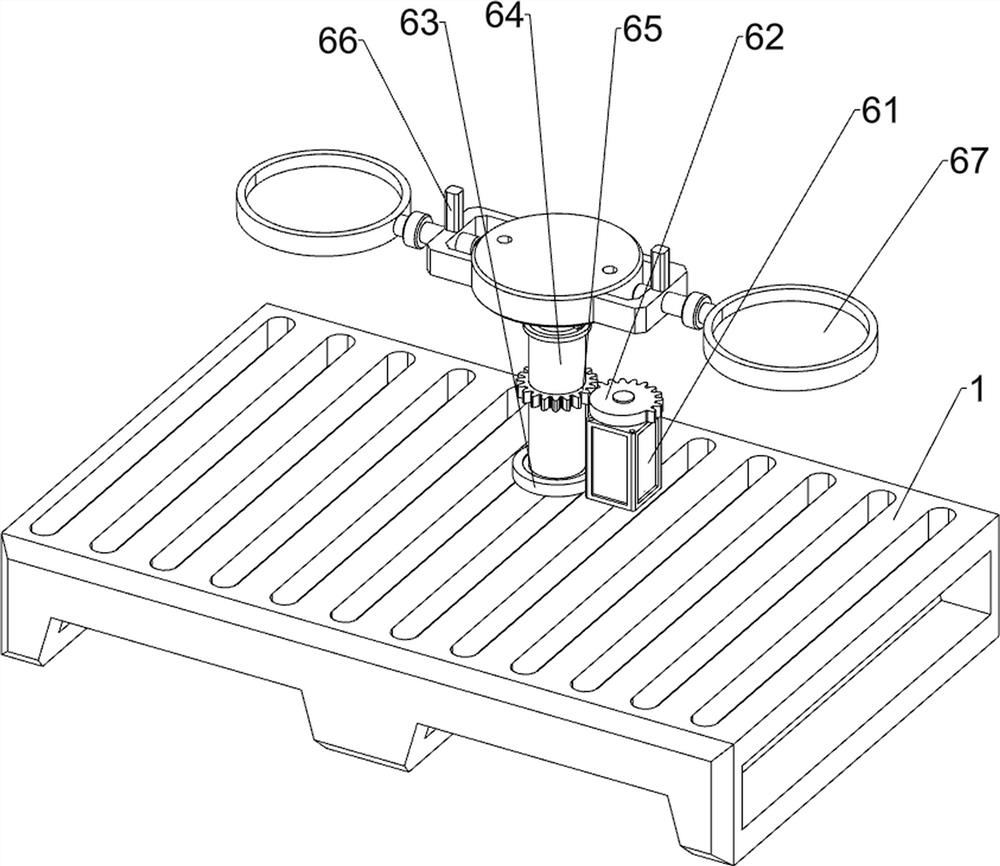

The invention relates to the technical field of laser marking devices, in particular to a mobile phone shell laser marking machine. The mobile phone shell laser marking machine comprises a machine body, an adjusting structure is installed on the machine body, a feeding structure is arranged on the machine body, a pressing structure is arranged in the feeding structure, a pushing structure is installed on the machine body, a positioning structure is arranged in the pushing structure, a discharging structure is arranged on the machine body, and a fixing structure is arranged on one side of the discharging structure. By installing the adjusting structure on the machine body, lifting adjustment of a laser head can be achieved in a labor-saving mode so that the marking effect can be conveniently replaced according to actual needs, traditional top end adjustment can be changed into front face side end adjustment, the marking effect can be conveniently watched at a short distance during adjustment, and the marking precision is higher.

Owner:江苏众旺鑫智能设备有限公司

Chip processing equipment

InactiveCN112373802ARealize automatic loading workHigh degree of automationPackagingComputer hardwareEmbedded system

The invention discloses chip processing equipment, and particularly relates to the field of chip processing. The chip processing equipment comprises a base, a first supporting frame and a second supporting frame. The first supporting frame and the second supporting frame are both located above the base, a mobile processing mechanism and a box cover feeding mechanism are arranged between the firstsupporting frame and the second supporting frame, the mobile processing mechanism comprises a rotating cylinder, an outer sleeve, a first rotating disc, a second rotating disc and a telescopic connecting rod, and the first rotating disc and the second rotating disc are both located at the top end of the rotating cylinder. Through the arrangement of the mobile processing mechanism, the box cover feeding mechanism, a cover pressing mechanism and an automatic gluing mechanism, automatic processing of chips can be achieved, the processing efficiency is high, the processing quality is good, operation is easy, automatic gluing work can be achieved in the processing process, meanwhile, automatic feeding and discharging work can be achieved, manual operation is reduced, the automation degree of achip processing device is greatly enhanced, and the practicability and convenience of the chip processing equipment in use are improved.

Owner:江航舟

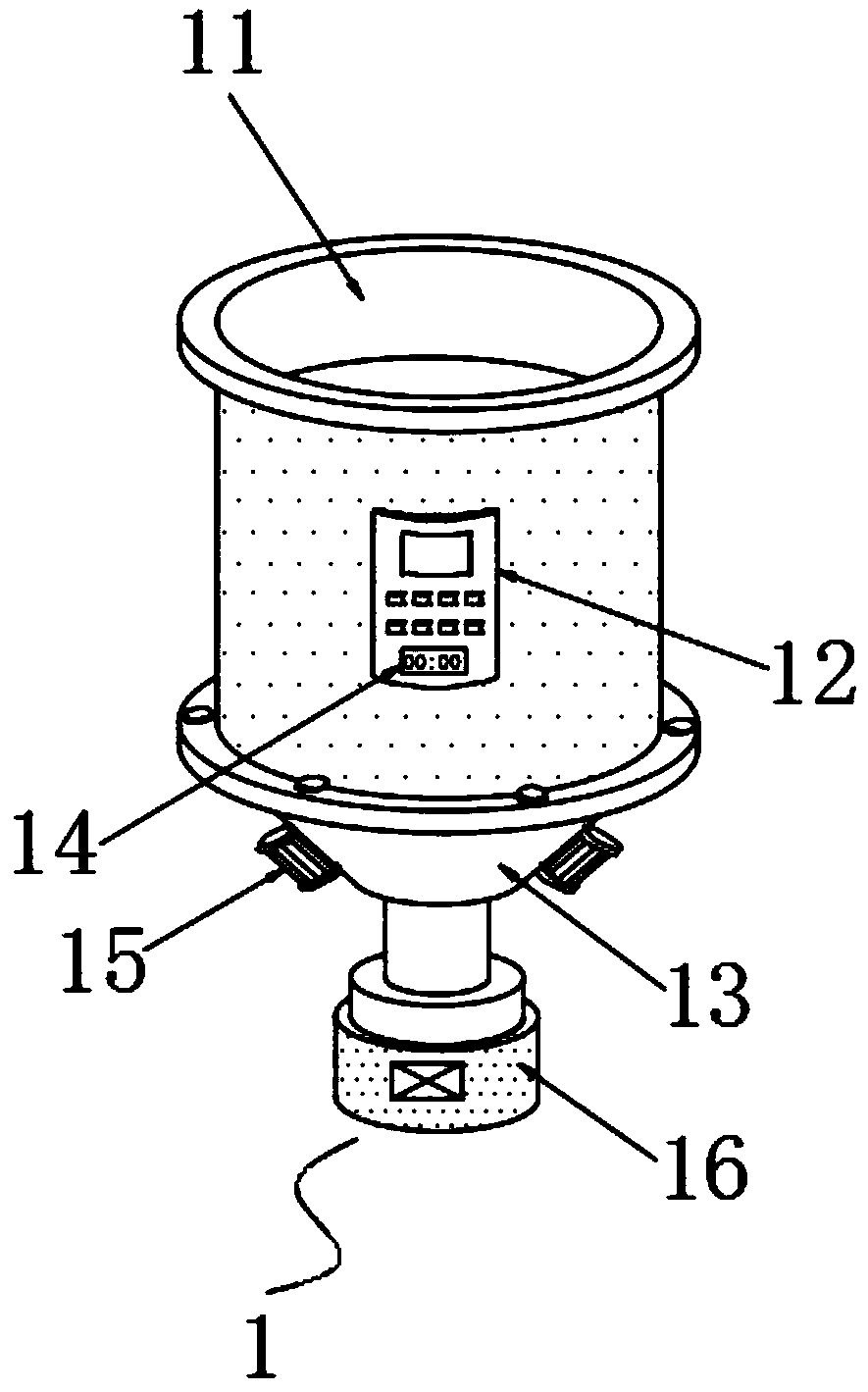

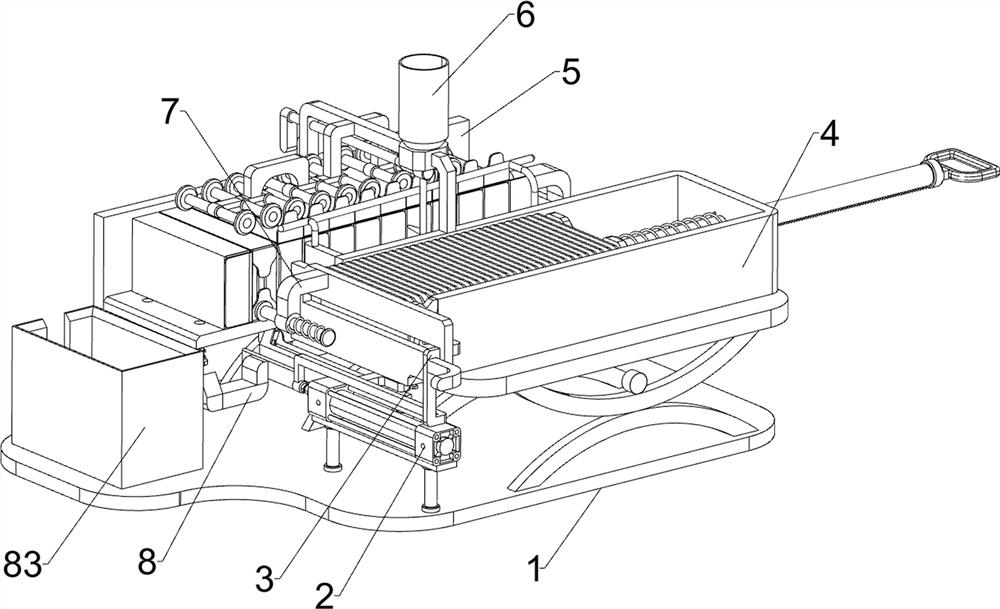

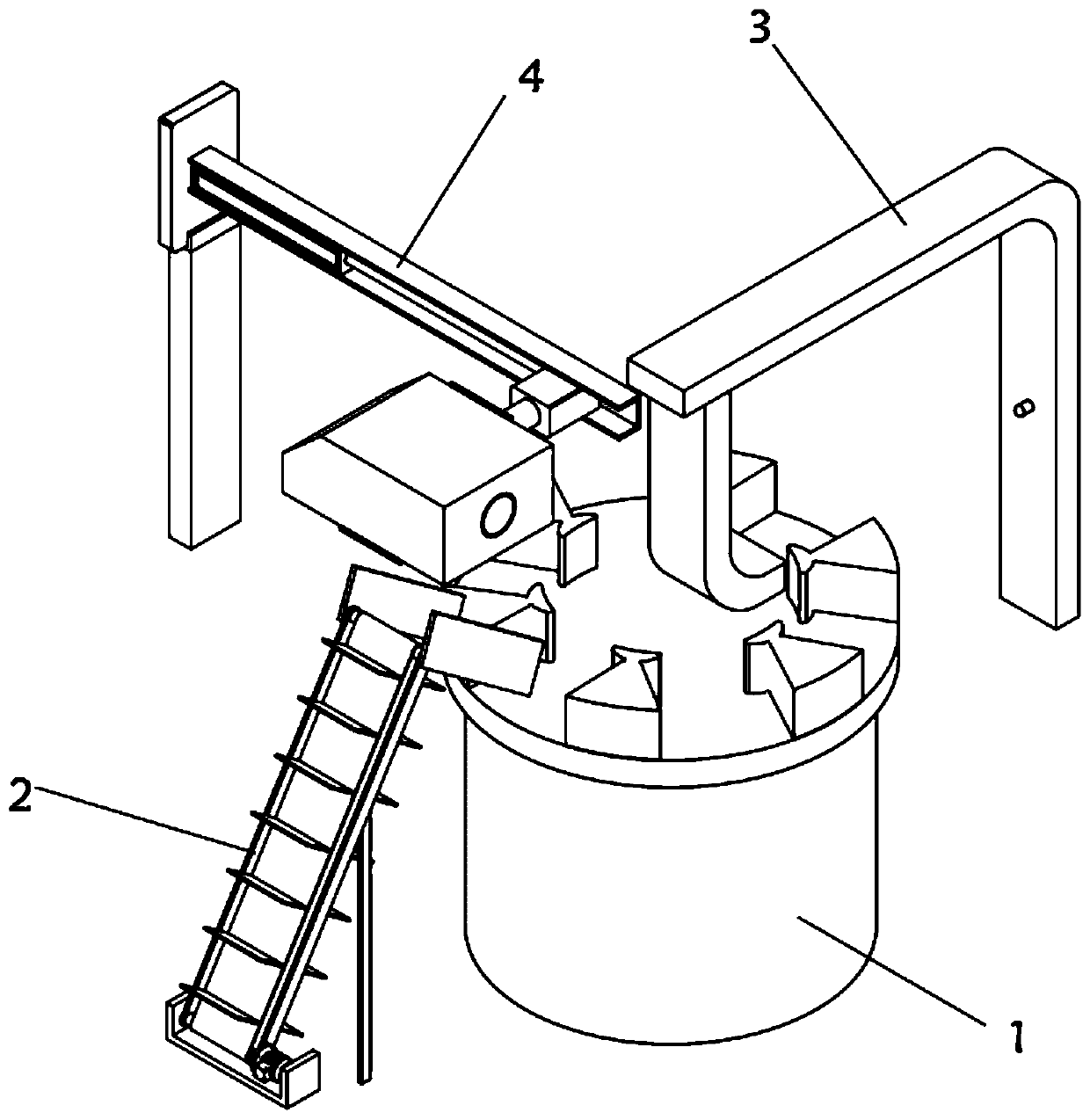

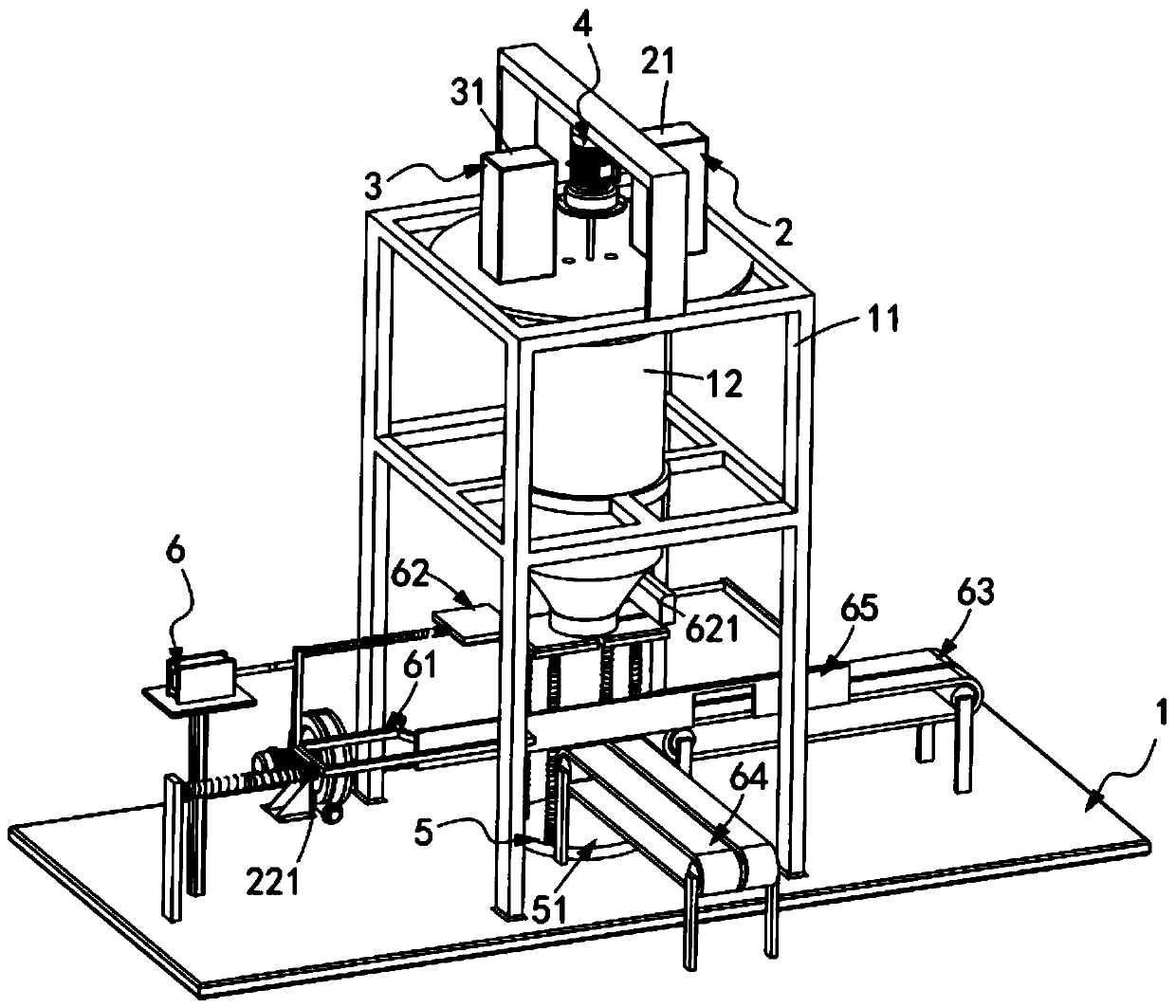

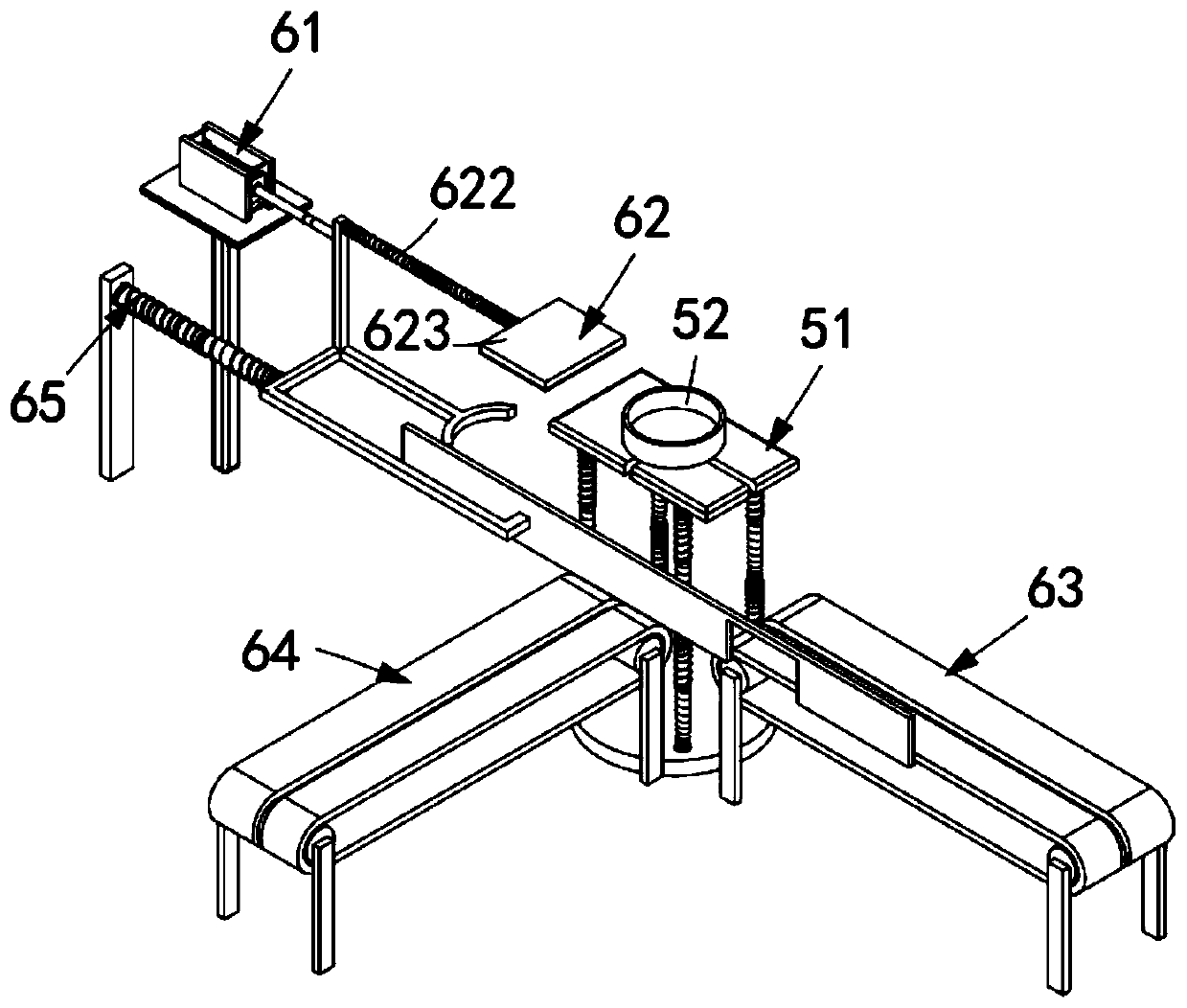

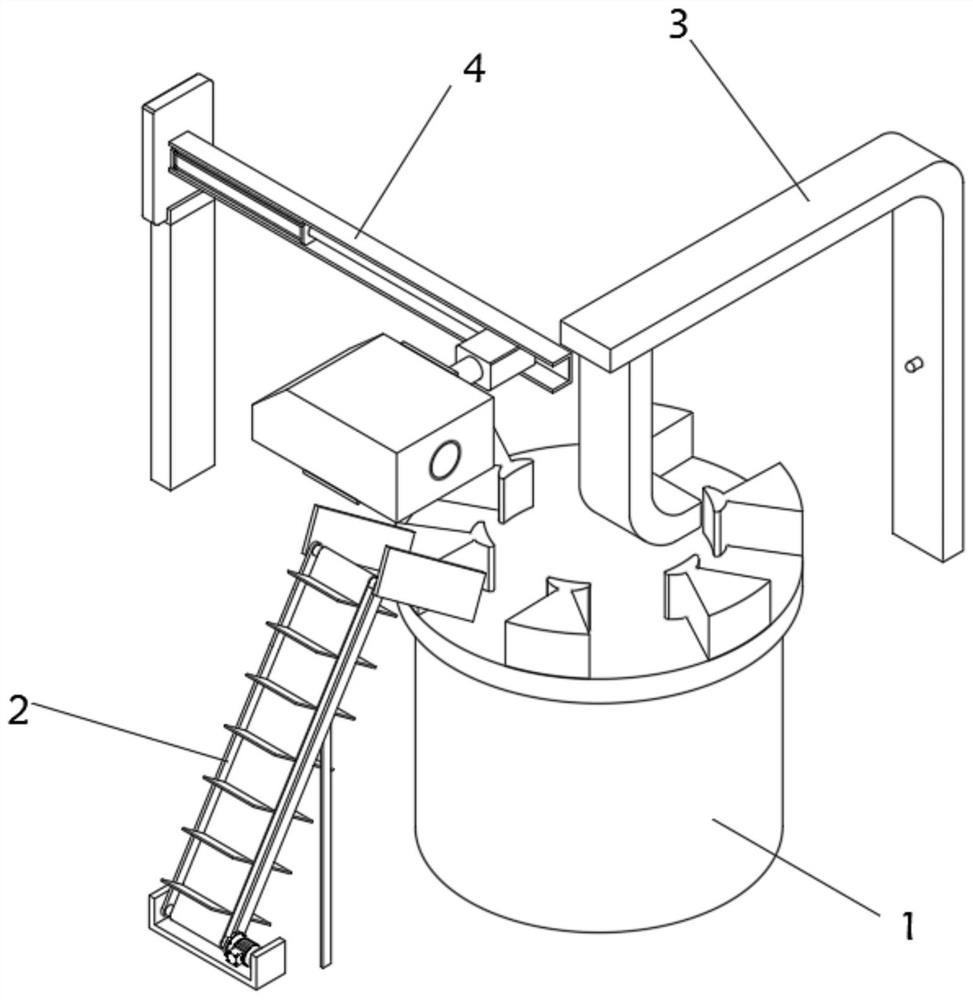

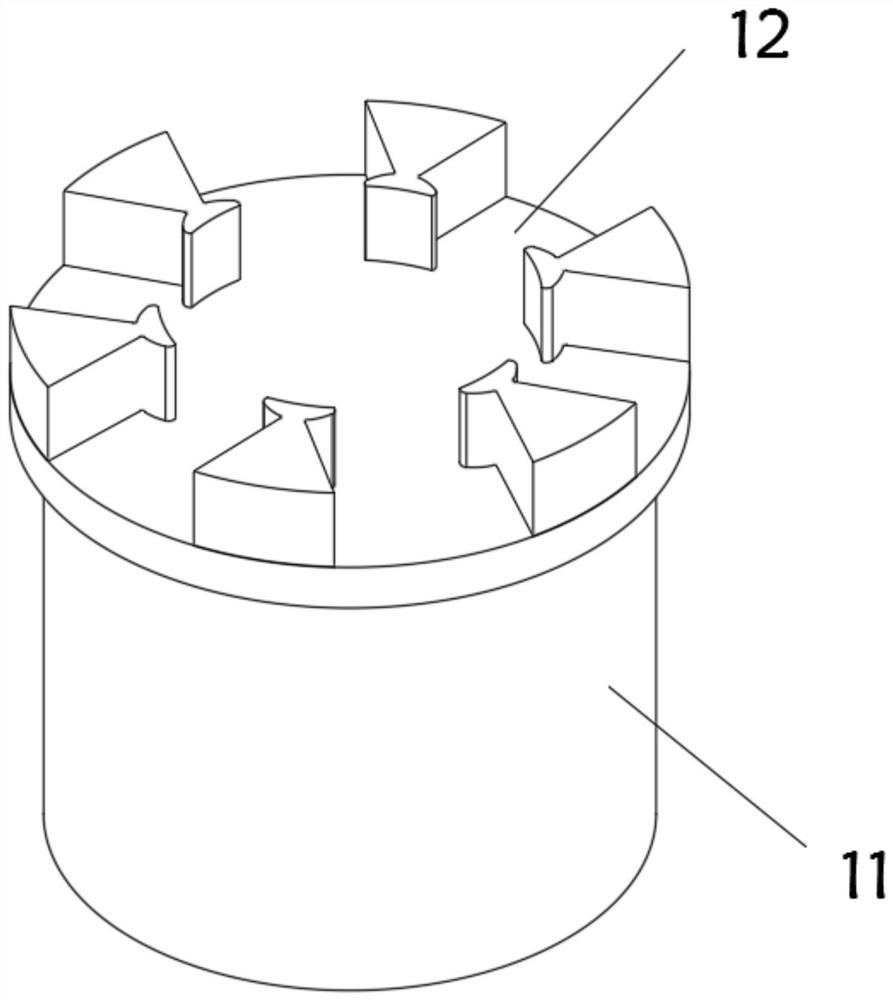

Powder feeding device of electrical automation equipment

InactiveCN110980319ARealize automatic loading workOvercome the defects of manual feedingConveyorsLarge containersEngineeringProcess engineering

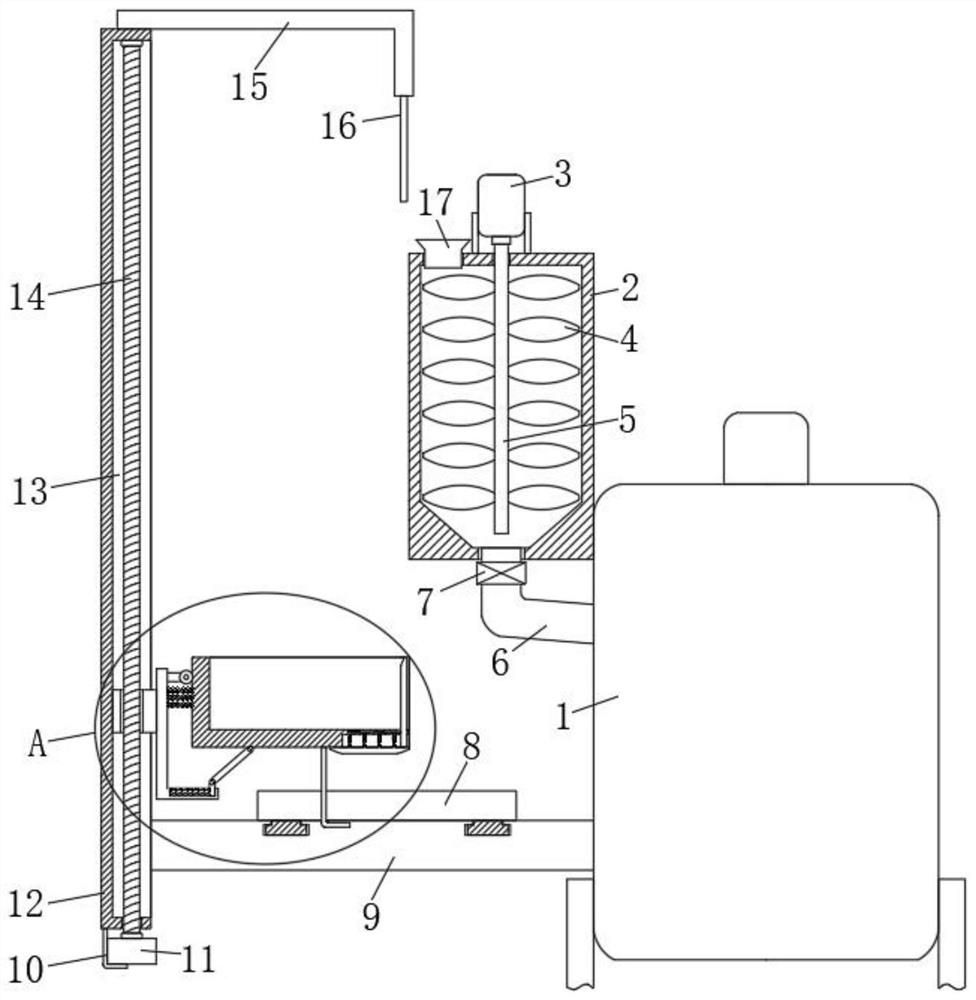

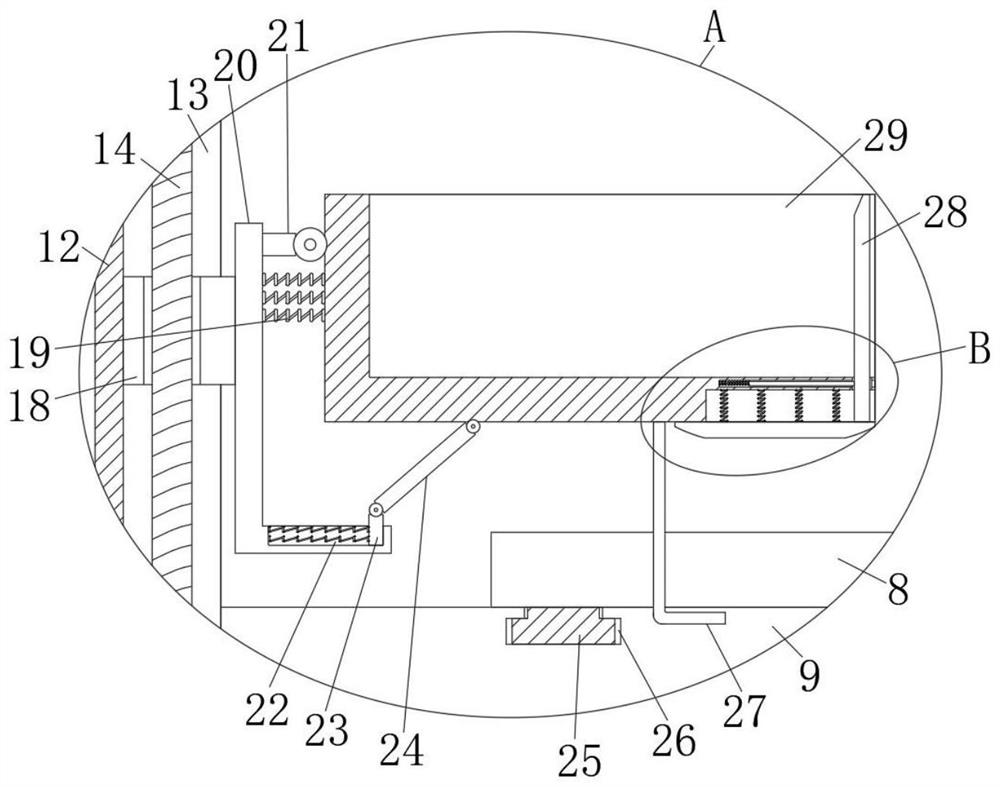

The invention discloses a powder feeding device of electrical automation equipment, and relates to the technical field of electrical automation equipment. The device comprises a storage barrel, and ischaracterized in that a feeding mechanism is arranged on one side of the storage barrel, a conveying mechanism is mounted below the storage barrel, a fixing base is mounted at the bottom end of the conveying mechanism, an electric telescopic rod is mounted at the joint of the conveying mechanism and the fixing base, and the conveying mechanism is fixedly connected with the fixing base through theelectric telescopic rod. The powder feeding device is scientific and reasonable in structure and convenient to operate, the feeding mechanism is arranged to realize automatic feeding of materials, the defect of manual feeding of traditional equipment is overcome, manpower is effectively saved, the working efficiency is improved, timing feeding can be achieved through the arranged storage barrel,the automation control of electrical equipment is improved, the practicability is improved, the automatic conveying of materials can be achieved through the arranged conveying mechanism, the automaticconveying function of the equipment is achieved, and the automation degree of the equipment is improved.

Owner:SHAOYANG UNIV

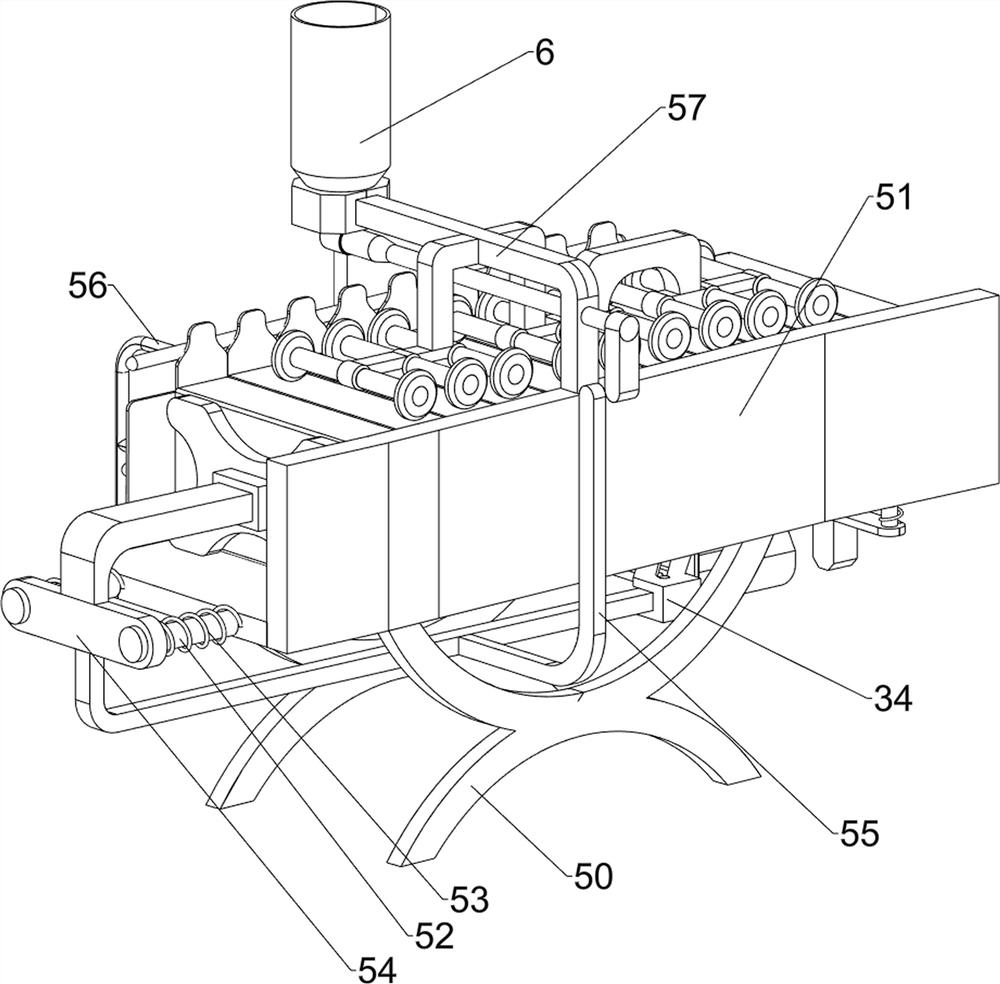

Automatic feeding device used for metal powder metallurgy

The invention discloses an automatic feeding device used for metal powder metallurgy and relates to the technical field of metallurgy. The automatic feeding device comprises a rack. A feeding mechanism is fixedly installed on the upper surface of the rack, and supporting legs are fixedly installed on the lower surface of the rack. A first feeding mechanism is fixedly installed on one side of the upper surface of the feeding mechanism, and on the upper surface of the feeding mechanism, a second feeding mechanism is fixedly installed on one side of the first feeding mechanism. The automatic feeding device has reasonable structure and convenient operation. The dispersion treatment of metal powder can be realized through the dispersion mechanism so that the problem that the feed hopper is blocked due to metal powder hardening can be avoid, the smoothness of the feeding work can be ensured, and the practicability is high; the automatic filtering of the metal powder can be realized through the filter box so that the metallurgical precision can be improved; and the automatic feeding of different metal powders can be realized through the first feeding mechanism and the second feeding mechanism so that the work efficiency can be effectively improved.

Owner:NANJING HANXIYUE AUTOMATION TECH CO LTD

Saw blade quality detection equipment for building materials and buildings

InactiveCN112611714ARealize automatic loading workEasy to distinguishMechanical counters/curvatures measurementsOptically investigating flaws/contaminationArchitectural engineeringStructural engineering

Owner:朱艳珍

Stomach invigorating and digestion promoting tablet boxing equipment for medical drug production and packaging

PendingCN113071742ARealize automatic loading workWon't fall apartWrapper twisting/gatheringBiotechnologyPharmaceutical drug

The invention relates to boxing equipment, in particular to stomach invigorating and digestion promoting tablet boxing equipment for medical drug production and packaging. The stomach invigorating and digestion promoting tablet boxing equipment for the medical drug production and packaging which can automatically transport stomach-invigorating and digestion-promoting tablets and push the stomach-invigorating and digestion-promoting tablets into a box is provided. The stomach invigorating and digestion promoting tablet boxing equipment for the medical drug production and packaging comprises a bottom plate, a pushing mechanism and a storage mechanism, wherein an air cylinder is arranged on one side of the top of the bottom plate, the pushing mechanism is arranged on the air cylinder, and the storage mechanism is arranged on one side of the top of the bottom plate. Through cooperation of the arranged pushing mechanism and the storage mechanism, automatic feeding work of the stomach-invigorating and digestion-promoting tablets can be achieved, and a worker only needs to receive the stomach-invigorating and digestion-promoting tablets and conduct sealing work on a packaging box.

Owner:林祥卫

Colored manhole cover manufacturing equipment applied to city appearance beautification

ActiveCN112354773ARealize automatic loading workColorfulLiquid surface applicatorsCleaning using toolsMechanical engineeringIndustrial engineering

The invention relates to manufacturing equipment, in particular to colored manhole cover manufacturing equipment applied to city appearance beautification. The technical problem to be solved is to provide the colored manhole cover manufacturing equipment applied to city appearance beautification, which can automatically color a manhole cover and make the color clear. According to the technical scheme, the colored manhole cover manufacturing equipment applied to city appearance beautification comprises a base, a rotating mechanism and a coloring mechanism, wherein a first mounting plate is arranged at the top of the base; the rotating mechanism is arranged on one side of the top of the base; and the coloring mechanism is arranged on the rotating mechanism. Through the cooperation of the rotating mechanism and the coloring mechanism, the manhole cover can be automatically colored. Dyestuffs intermittently drip from a rubber hose, so that the printed color is brighter when the manhole cover is colored.

Owner:HUNAN DONG QUAN CASTING

Loading and unloading integrated cigarette bar two-dimensional code detection device

ActiveCN110980243AImprove detection efficiencyOperational process automationConveyor partsConverting sensor output opticallyStructural engineeringWorkbench

The invention relates to the technical field of cigarette bar detection devices, in particular to a feeding and discharging integrated cigarette bar two-dimensional code detection device, which comprises a workbench, a feeding mechanism used for feeding cigarette bars, a discharging mechanism used for discharging the cigarette bars and a detection mechanism used for detecting cigarette bar two-dimensional codes. According to the feeding and discharging integrated cigarette bar two-dimensional code detection device, through transmission by a conveying belt, cigarette bars are conveyed to the bottom plate from the conveying belt; at the moment, the cigarette bar slides into the positioning groove along the bottom plate, and automatic feeding work is realized; automatic two-dimensional code scanning work is achieved by scanning a cigarette bar two-dimensional code in a positioning groove through a detection camera; low level is output through a photoelectric sensor, a first telescopic electric cylinder is controlled to be ejected out, at the moment, a sliding block slides in a sliding groove, a pushing block is pushed into the positioning groove, cigarette bars in the positioning groove are pushed out, and automatic discharging work is achieved.

Owner:NANJING DASHU INTELLIGENT SCI & TECH CO LTD

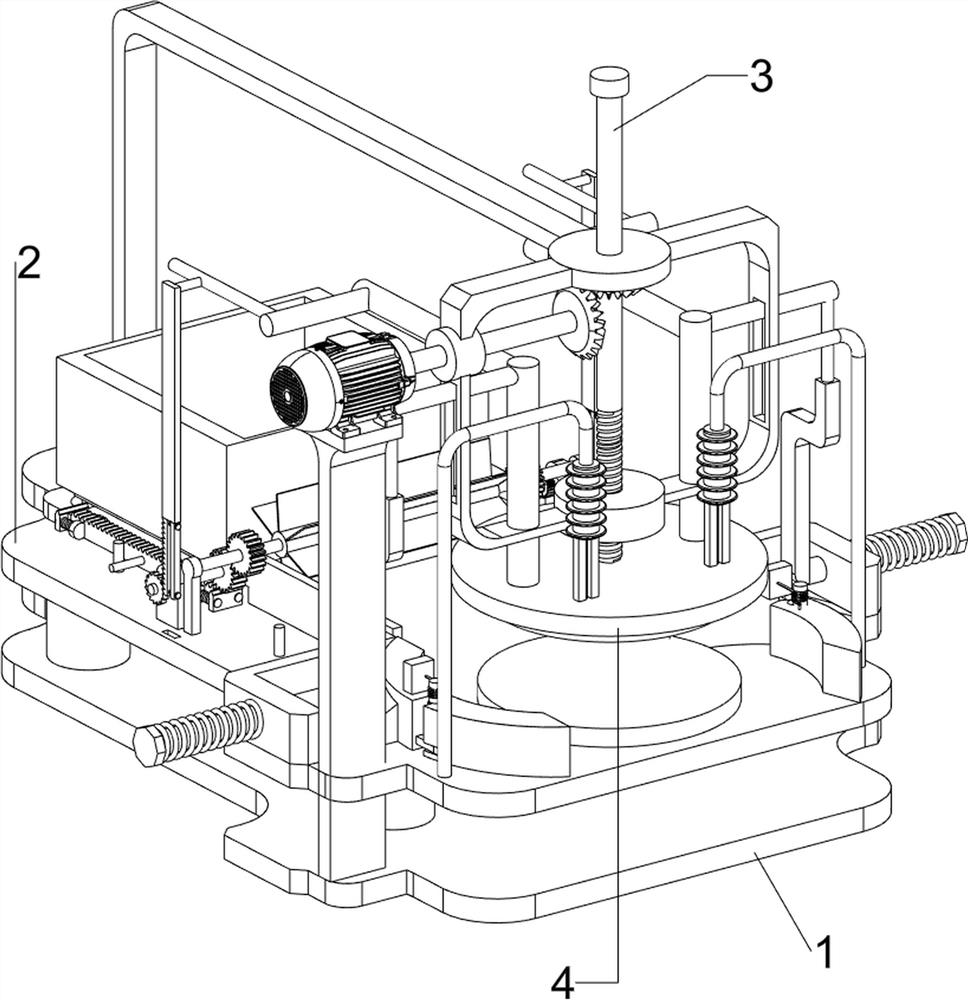

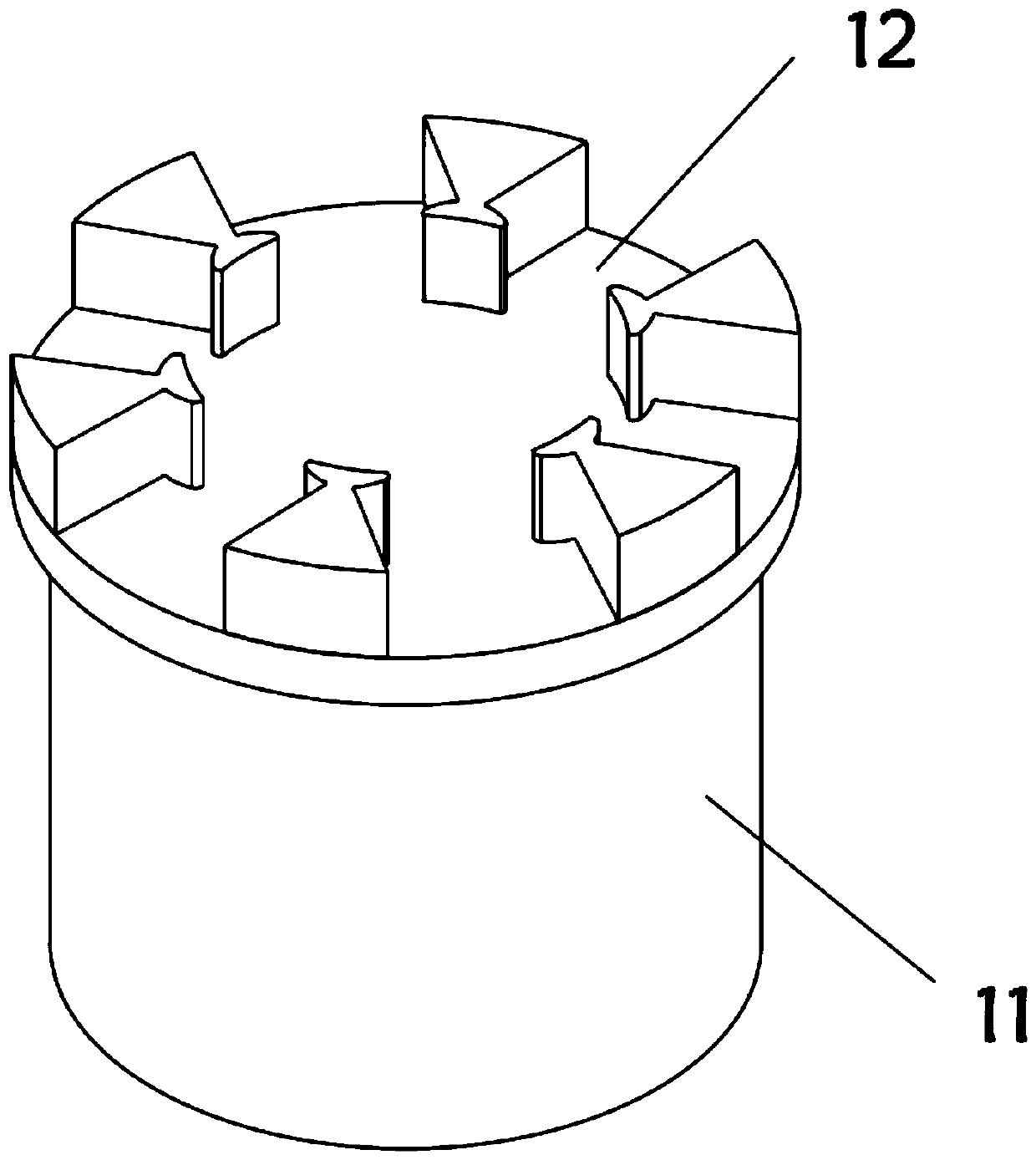

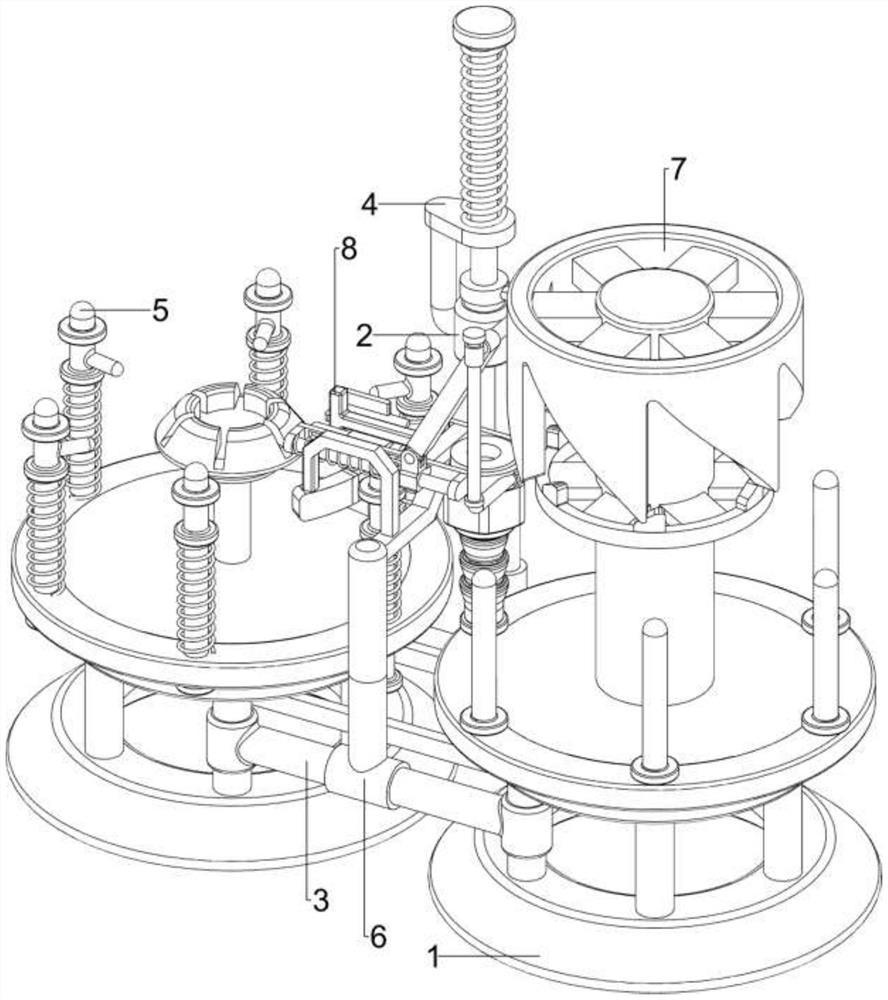

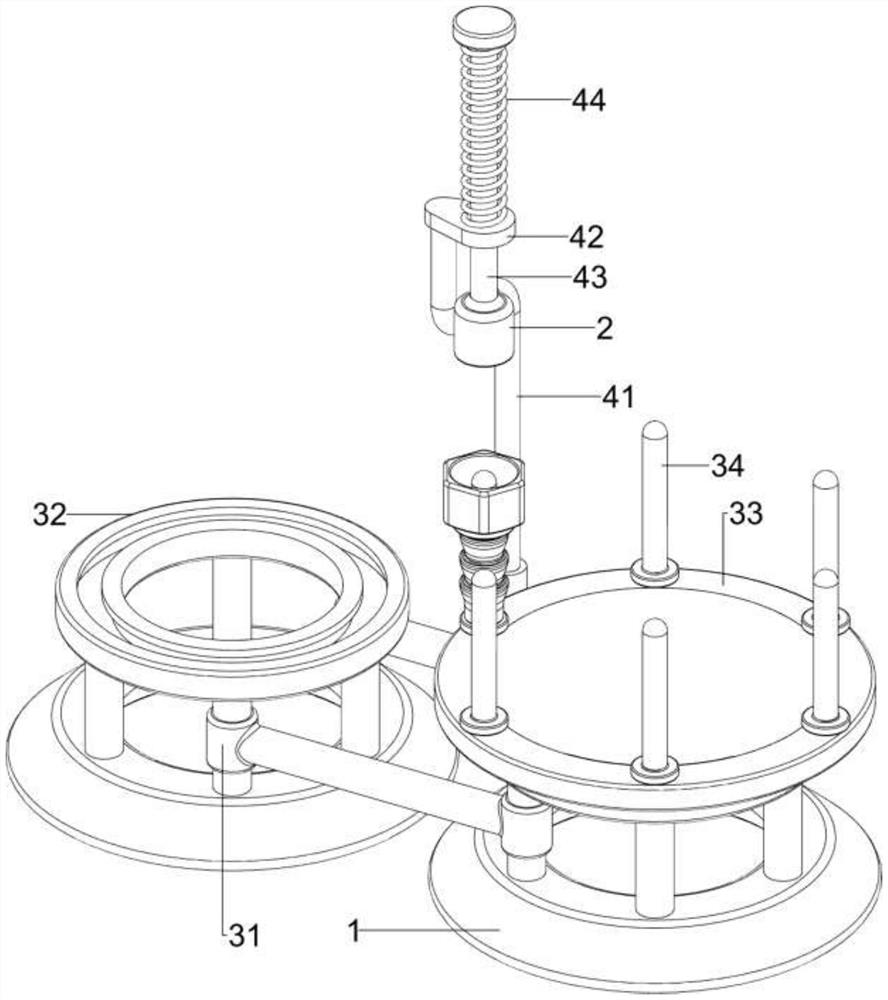

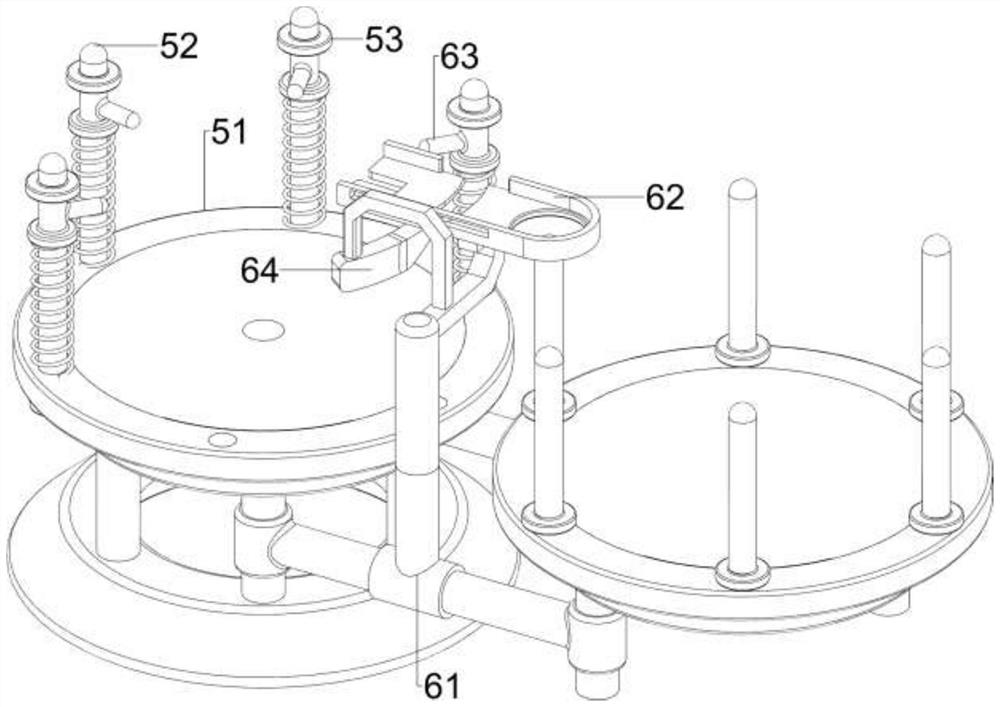

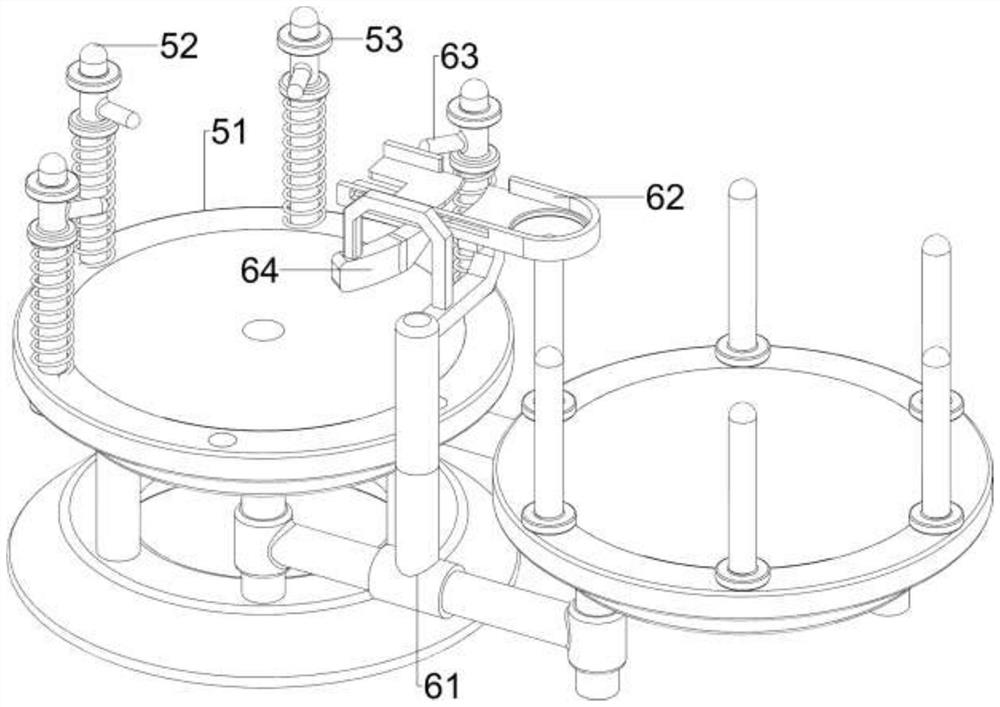

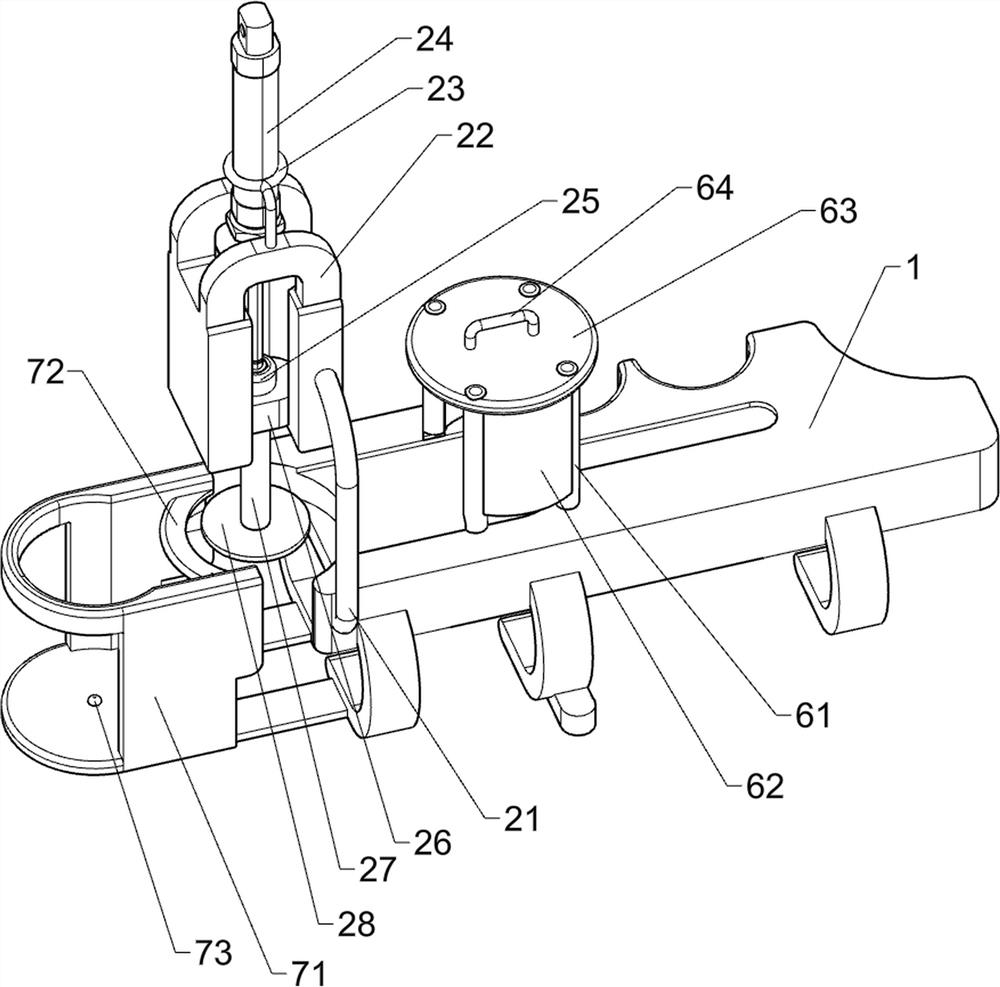

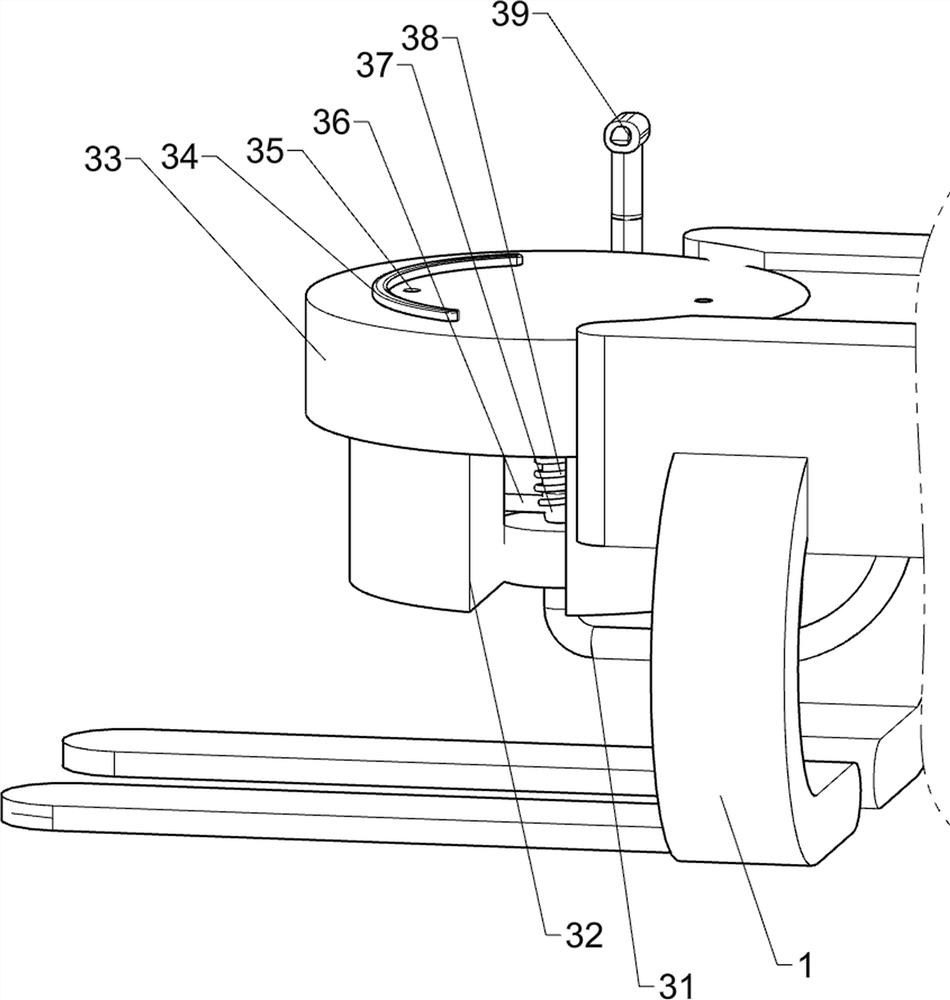

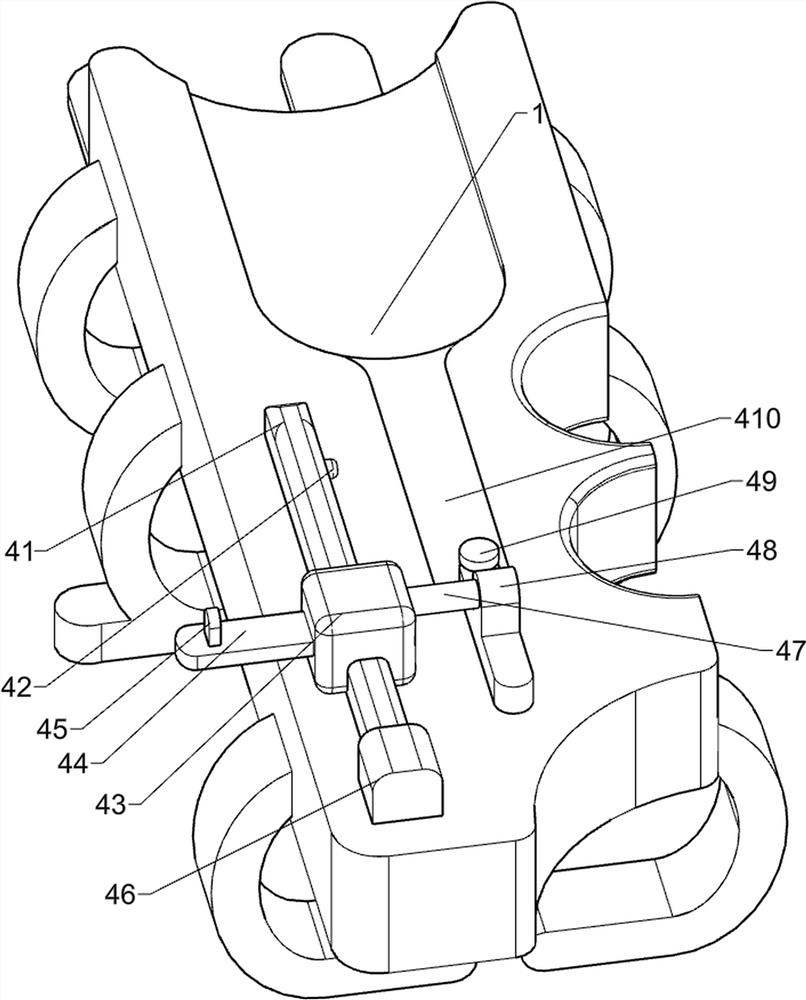

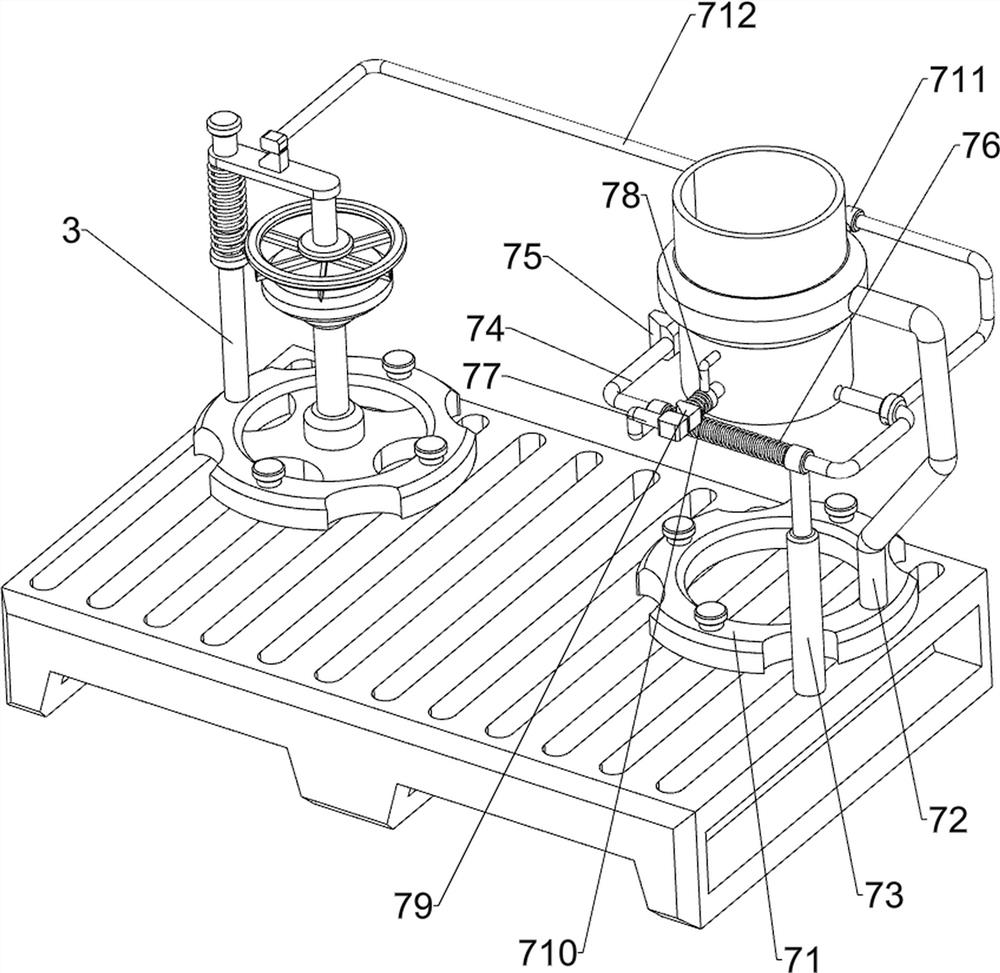

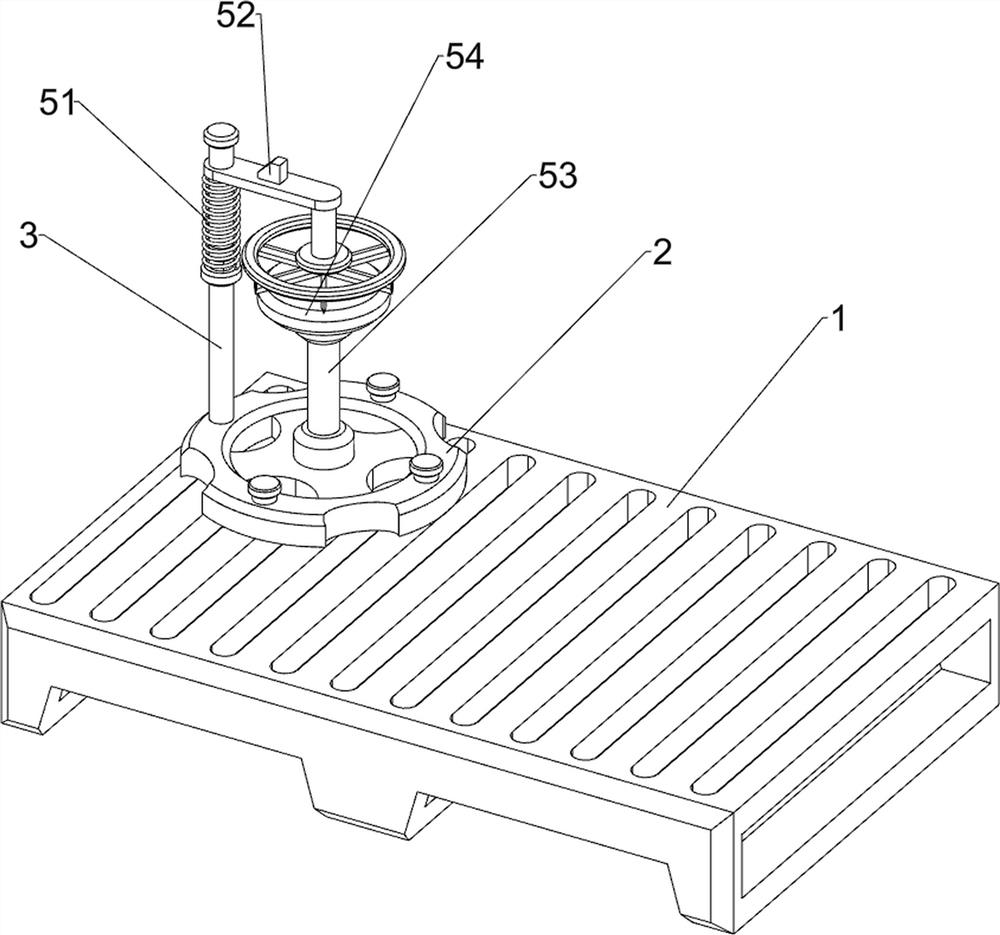

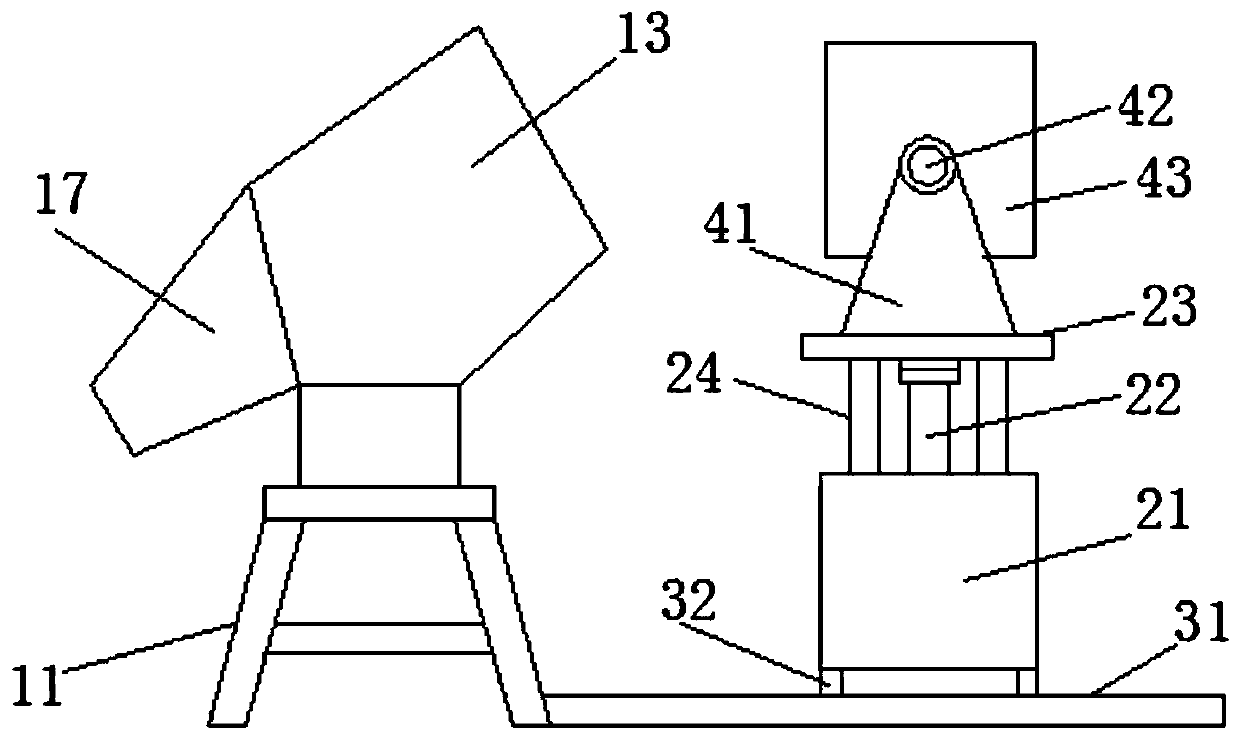

Extrusion mounting equipment for sealing washer of gas pipe connecting end

ActiveCN112894704AConvenient loading workRealize automatic loading workMetal working apparatusMetal-working hand toolsEngineeringWasher

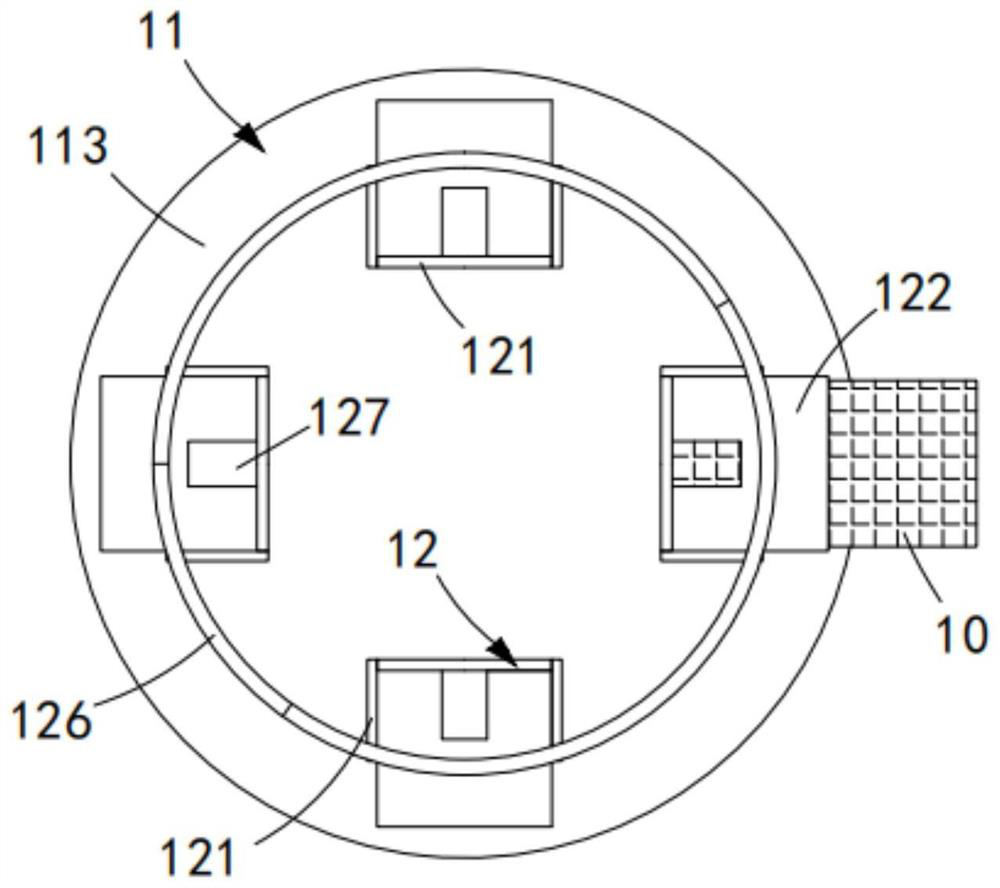

The invention relates to mounting equipment, in particular to extrusion mounting equipment for a sealing washer of a gas pipe connecting end. Aiming at the defects in the prior art, the extrusion mounting equipment for the sealing washer of the gas pipe connecting end does not need to be manually held by a hand to perform washer mounting work. According to the technical scheme, the extrusion mounting equipment for the sealing washer of the gas pipe connecting end comprises a base, a sleeve, a first discharging mechanism and an extrusion mechanism; the first discharging mechanism is arranged at the top of the base; the extrusion mechanism is arranged on the first discharging mechanism; and the sleeve is arranged on the extrusion mechanism. Through cooperation of a rotating mechanism and a pushing mechanism, automatic feeding work of washers can be achieved, the washers do not need to be manually pushed to move, and a second rotating disc and a first rotating disc do not need to be manually rotated.

Owner:HANGZHOU HENGTONG FLEXIBLE METAL TUBING CO LTD

Packaging equipment for integrated circuit box

InactiveCN112201603AImprove gluing efficiencyRealize automatic packagingSemiconductor/solid-state device manufacturingIntegrated circuitManufacturing engineering

The invention discloses packaging equipment for an integrated circuit box, and particularly relates to the field of integrated circuit box processing equipment. The packaging equipment comprises a packaging table, a packaging outer frame and support frames, and is characterized in that the packaging outer frame and the support frame are both located over the packaging table, the packaging outer frame is located between the support frames, and a working groove is formed in the packaging outer frame; and a material moving mechanism, a gluing mechanism and a cover pressing mechanism are arrangedin the working groove, the material moving mechanism comprises a groove wheel shaft and a groove wheel, the groove wheel is rotationally connected with the packaging table through the groove wheel shaft, and the groove wheel comprises a first groove wheel piece, a second groove wheel piece, a third groove wheel piece, a fourth groove wheel piece and a fifth groove wheel piece. Through arrangementof the material moving mechanism, the gluing mechanism, the cover pressing mechanism and the material pushing mechanism, automatic packaging of the integrated circuit box can be achieved, the packaging efficiency is high, the packaging quality is good, automatic feeding and discharging can be achieved, the automation degree of the packaging equipment is enhanced, and the use practicability and convenience of the packaging equipment are improved.

Owner:李俊全

Gas pipe connection end sealing gasket extrusion installation equipment

ActiveCN112894704BConvenient loading workRealize automatic loading workMetal working apparatusMetal-working hand toolsEngineeringPipe

Owner:HANGZHOU HENGTONG FLEXIBLE METAL TUBING CO LTD

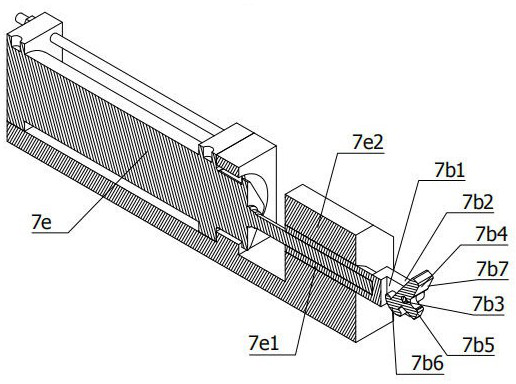

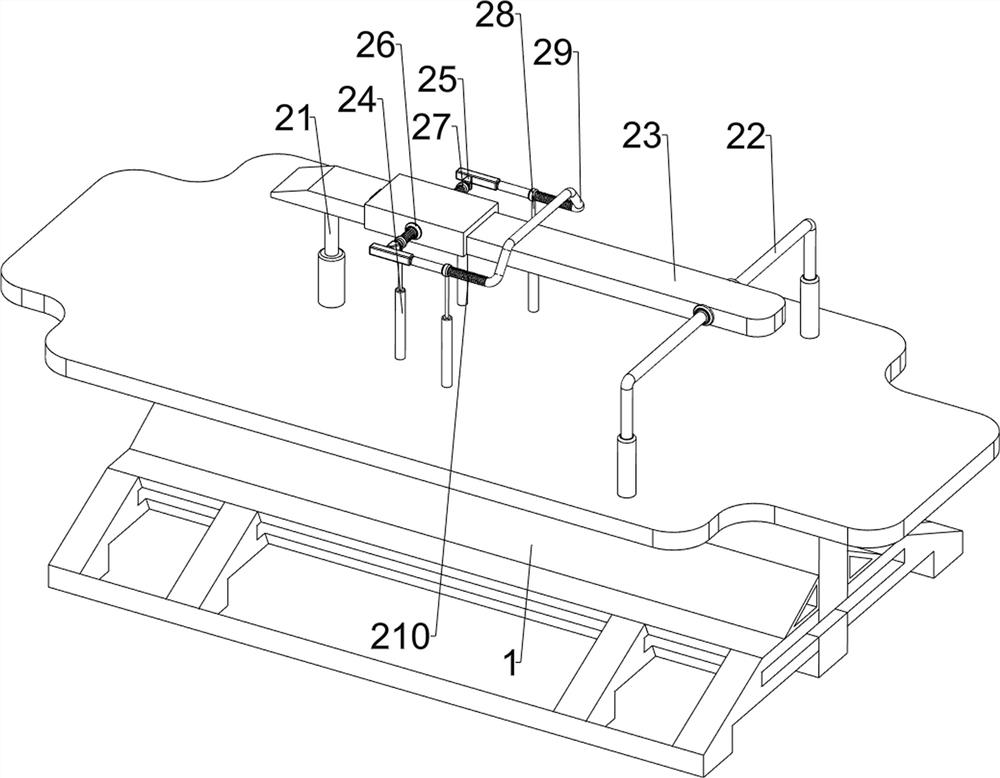

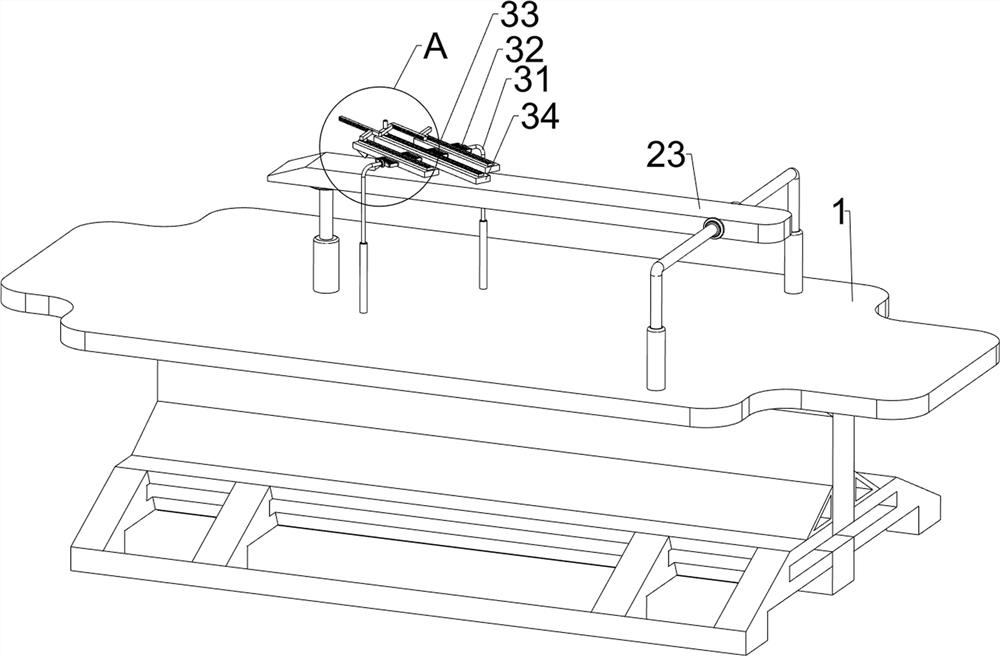

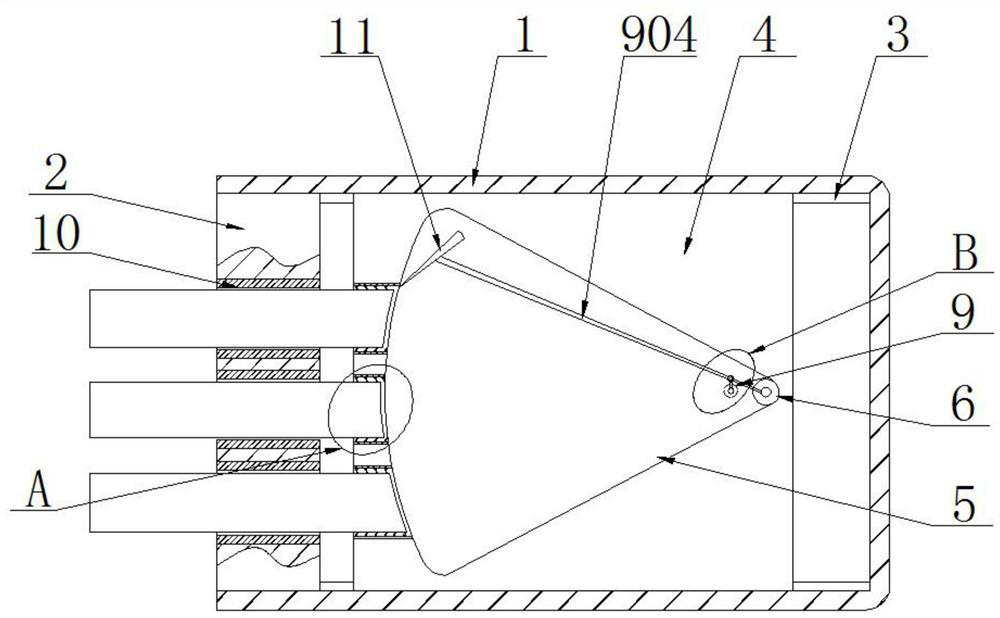

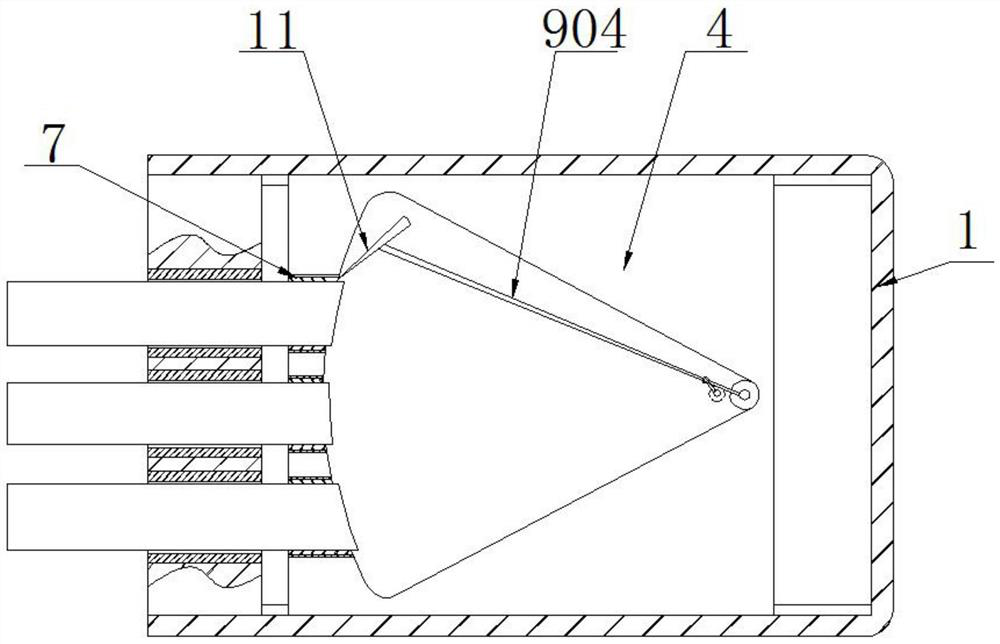

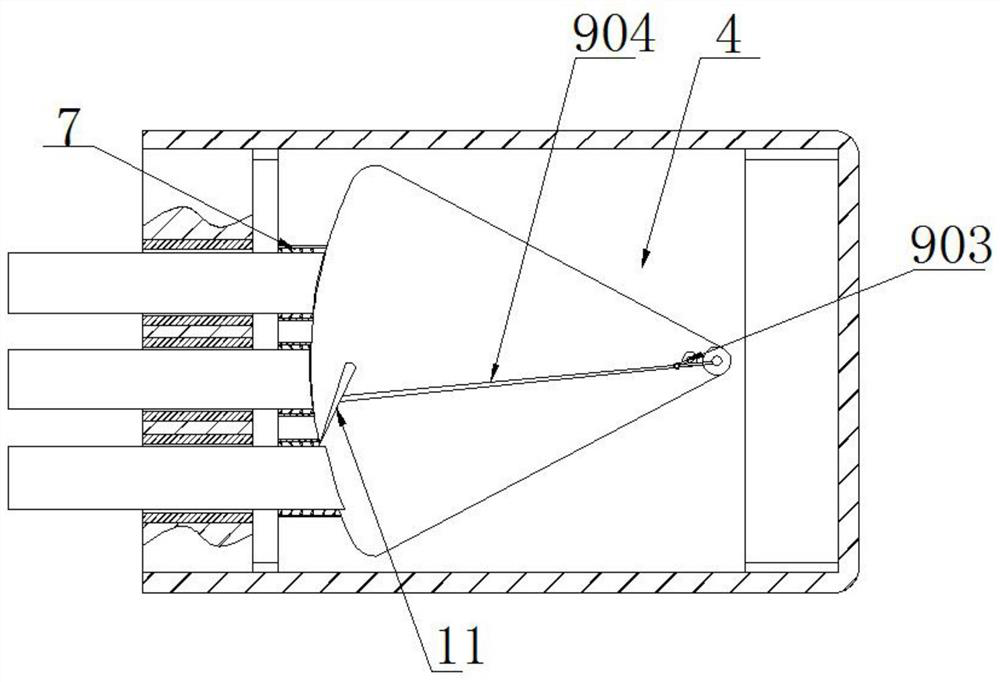

Automatic loading and once-bending equipment for binding post semi-finished product

InactiveCN111702041ARealize automatic loading workShaping toolsContact member manufacturingStructural engineeringTransfer mechanism

The invention relates to the field of automatic equipment, in particular to automatic loading and once-bending equipment for a binding post semi-finished product. The automatic loading and once-bending equipment is applied to bending and processing a binding post, so that the binding post is bent to a second forming state from a first forming state. The automatic loading and once-bending equipmentcomprises a workbench, a controller as well as a loading mechanism, a first transfer mechanism and a first bending mechanism, which are sequentially arranged, wherein the loading mechanism, the firsttransfer mechanism and the first bending mechanism are in communication connection to a controller. The equipment can automatically bend the binding post to the second forming state from the first forming state, and realizes automatic loading work of the binding post.

Owner:芜湖挺优机电技术有限公司

Automatic edging process for refrigerator interlayer glass

InactiveCN112762656ARealize automatic loading workRealize the loading operationLiquid surface applicatorsLighting and heating apparatusIceboxEngineering

The invention discloses an automatic edging process for refrigerator interlayer glass, and belongs to the technical field of refrigerators. The automatic edging process comprises the following steps: step 1, one piece of glass is automatically fed; step 2, the piece of glass is moved to a rotating assembly; step 3, the rotating assembly drives the piece of glass to rotate; step 4, the piece of glass is overturned and two edges of the piece of glass are coated with glue; step 5, plastic strips are automatically fed and limited; step 6, one plastic strip is mounted on one edge of the piece of glass; step 7, the plastic strip is cut; step 8, another plastic strip is mounted on the other edge of the piece of glass; and step 9, the piece of glass with the edges with the plastic strips mounted are automatically discharged. The automatic edging process for the refrigerator interlayer glass is ingenious in process design, smooth in procedure connection and high in automation degree, automatic edging of the refrigerator interlayer glass can be implemented, one person can take charge of one machine, labor is saved, the edges of glass will not crack, the yield is high, the production efficiency is greatly improved, and remarkable economic value is achieved.

Owner:李瑞明

Convenient pastry pattern edge cutting device

ActiveCN112514943ARealize automatic loading workAvoid distractionBaked article cutting/slicingStructural engineeringMechanical engineering

The invention relates to a pattern edge cutting device, in particular to a convenient pastry pattern edge cutting device. The invention provides the convenient pastry pattern edge cutting device for solving the technical problems, wherein the pattern edges of cut pastries are smooth, and the pattern edges of the pastries are attractive. According to the technical scheme, the convenient pastry pattern edge cutting device comprises a mounting base and a pressing mechanism, wherein an edge cutting mechanism is arranged at the top of the mounting base; and the pressing mechanism is arranged on theedge cutting mechanism. Through the arrangement of the edge cutting mechanism and the pressing mechanism, a worker can firstly clamp pastries and then conduct edge cutting work, and therefore the situation that the edges of the cut pastries are excessively scattered can be avoided, and the cut pastries are still integrated as a whole .

Owner:唯品客(安徽)食品有限公司

Building coaming lofting device

InactiveCN112627632ARealize automatic loading workRealize automatic stakeoutFencingTraffic signalsMechanical engineeringConstruction engineering

The invention discloses a building coaming lofting device, and particularly relates to the field of building construction. The building coaming lofting device comprises a lofting box body and a feeding mechanism, wherein the feeding mechanism is located on one side of the outer wall of the lofting box body, lofting mechanisms are arranged on the two sides of the inner wall of the lofting box body, each lofting mechanism comprises a fixing plate and a rotating connecting rod, the rotating connecting rods are located below the inner sides of the fixing plates, a vertical groove and an arc-shaped groove are formed in one side of the interior of each fixing plate, and the arc-shaped grooves are located on one sides of the upper parts of the vertical grooves. According to the building coaming lofting device, the feeding mechanism, the lofting mechanisms, a grooving mechanism and an automatic strip pasting mechanism are arranged so that automatic lofting of a building coaming can be realized, the installation of the building coaming is facilitated, and the labor burden is reduced; and meanwhile, automatic grooving and reflective strip pasting work of the building coaming can be realized in the lofting process, additional manual reprocessing is not needed, the lofting efficiency and quality of the building coaming are greatly improved, and the practicability and functionality of the building coaming lofting device are improved.

Owner:孟星雨

An automatic reactor device for producing artificial graphite

ActiveCN111686888BRealize automatic loading workGuaranteed feeding efficiencyChemical/physical/physico-chemical processesGrain treatmentsElectric machineStructural engineering

The invention discloses an automatic reactor device for producing artificial graphite, which comprises a reactor body, a mixing mechanism is fixedly connected to the side wall of the reactor body, and the output end of the mixing mechanism extends into the reactor body , the side wall of the reaction kettle body is fixedly connected with a mounting plate, the side wall of the mounting plate is fixedly connected with a lifting mechanism, the upper end of the lifting mechanism is fixedly connected with a pressing mechanism, and the side wall of the lifting mechanism is fixedly connected There is a material discharging mechanism, and a material receiving mechanism is installed on the mounting plate. The material mixing mechanism includes a shell fixed on the side wall of the reactor body, and the upper end of the shell is symmetrically fixedly connected with two first mounting brackets , the first motor is fixedly connected to the opposite side walls of the two first installation frames. The invention has a reasonable structural design, can not only combine the crushing process and the pressing process to improve the processing efficiency, but also can improve the feeding efficiency to meet the current production demand.

Owner:大冶市都鑫摩擦粉体有限公司

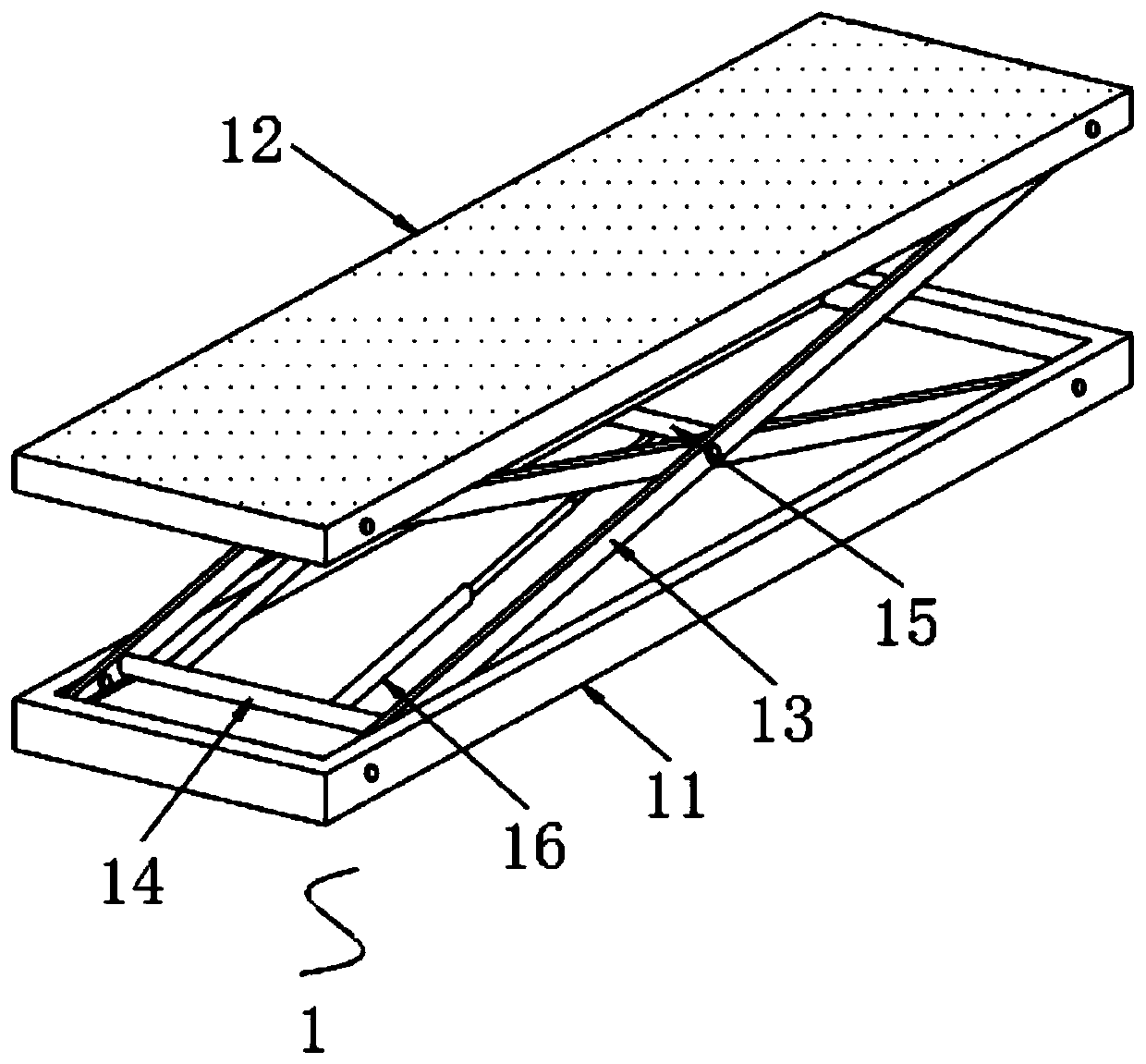

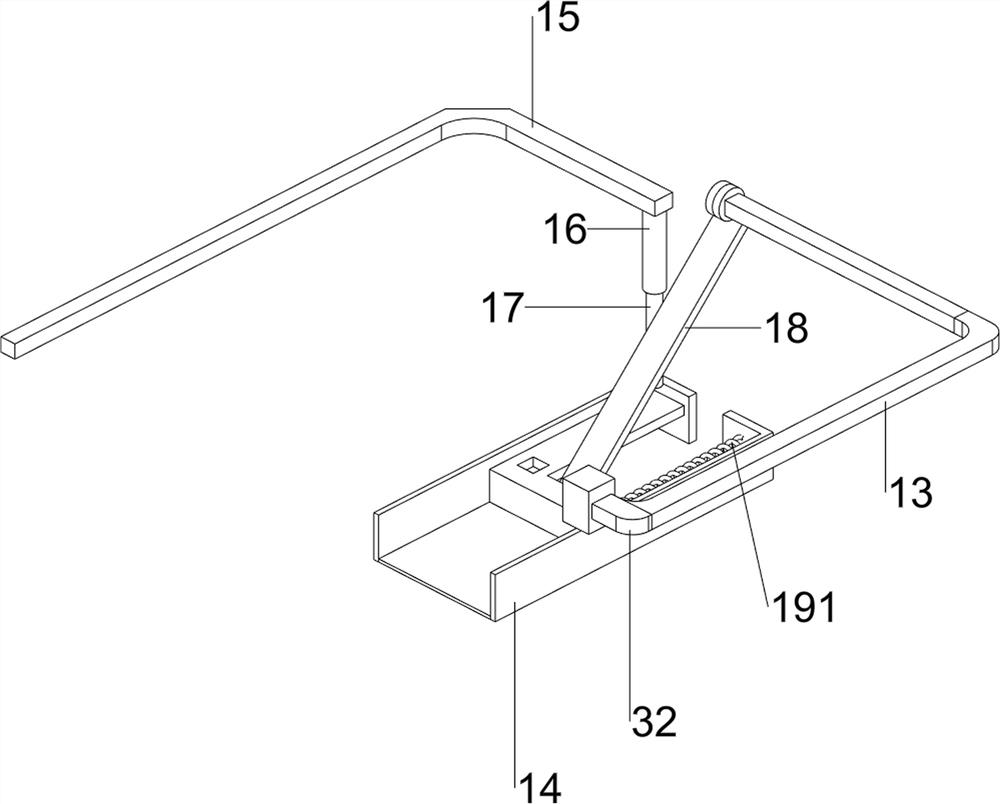

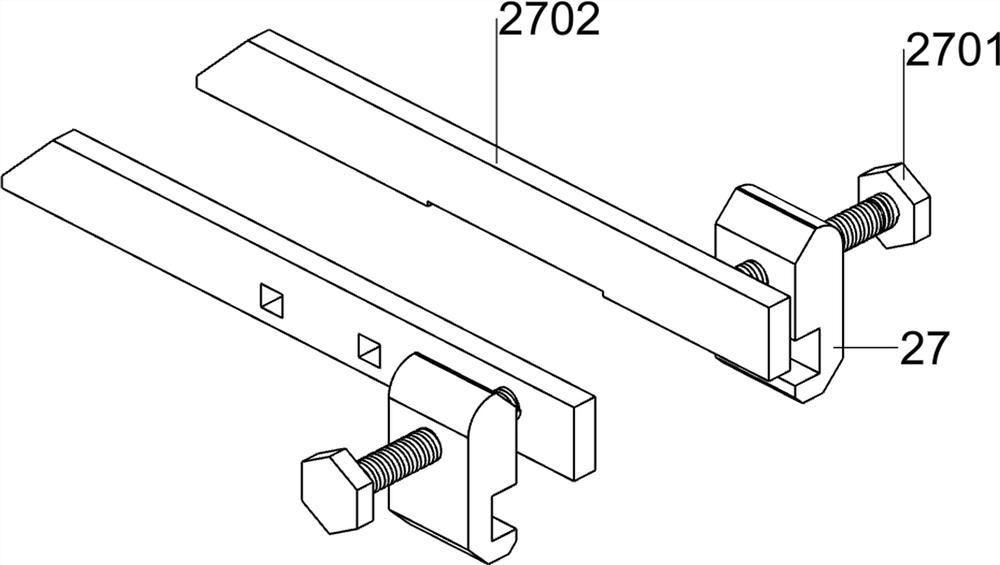

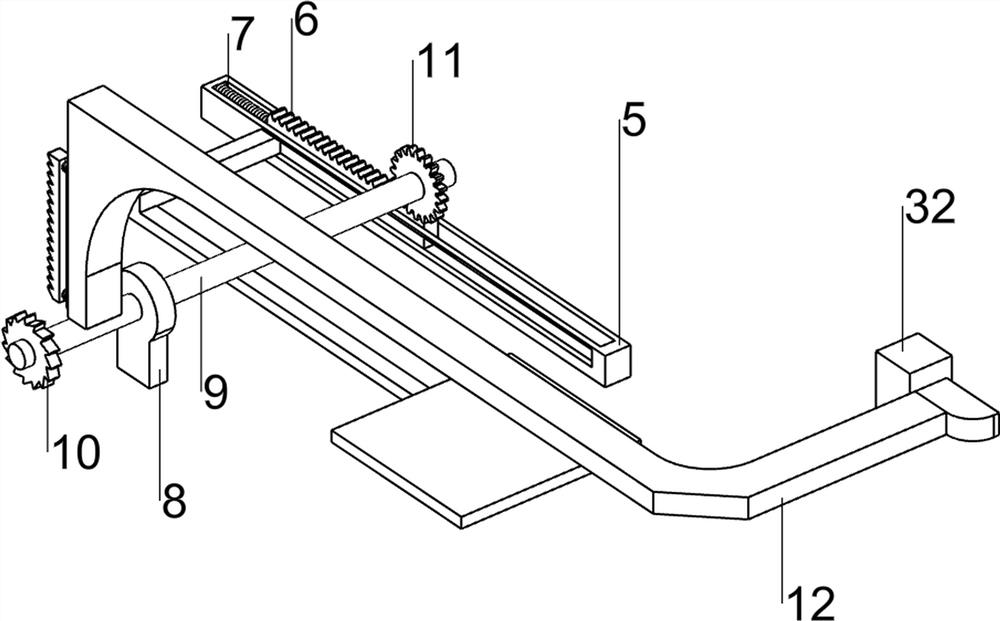

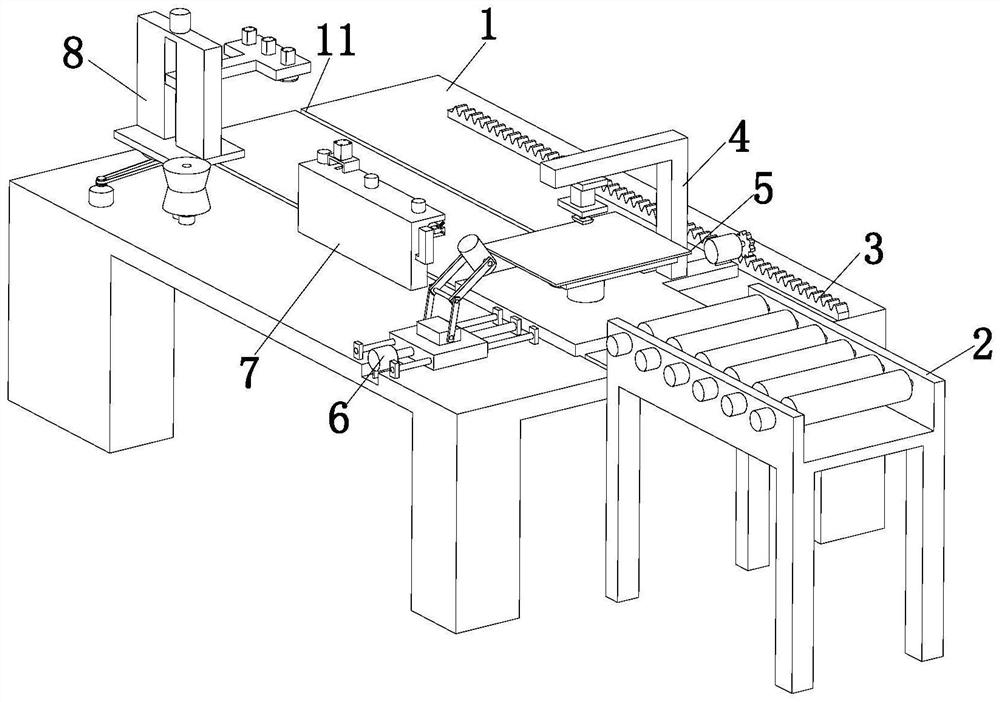

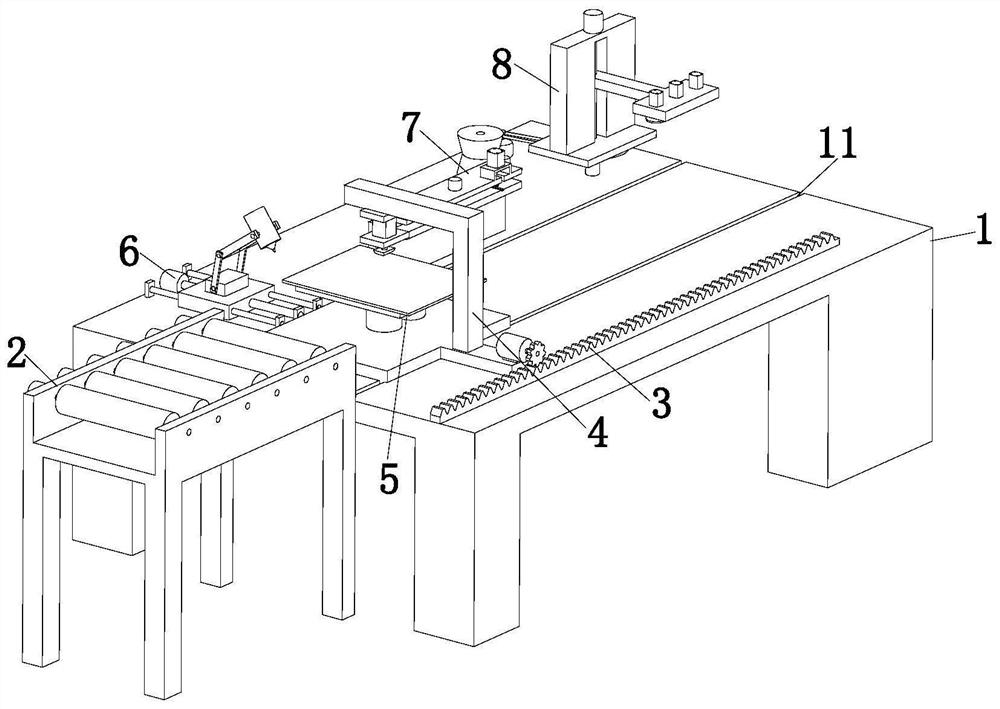

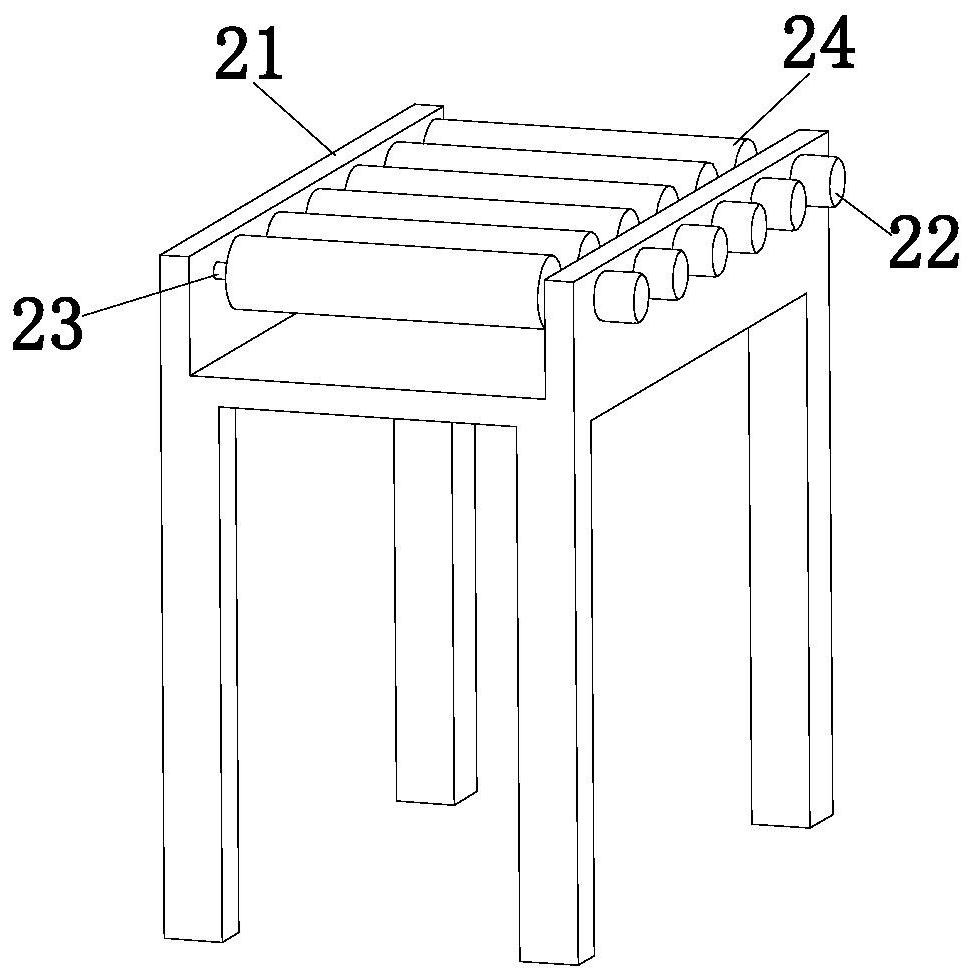

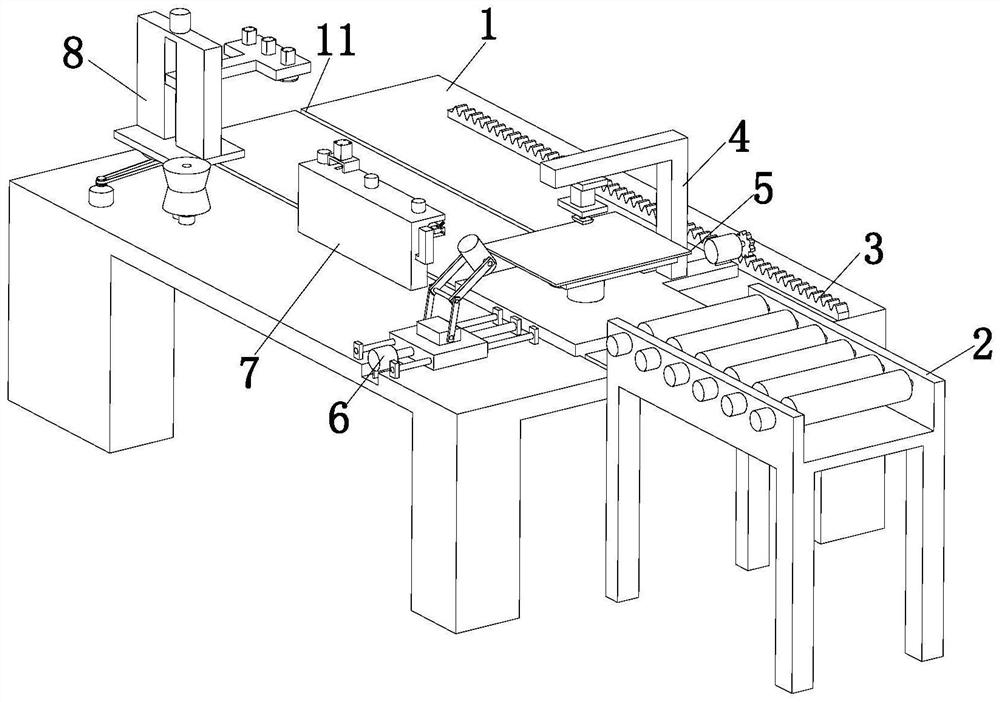

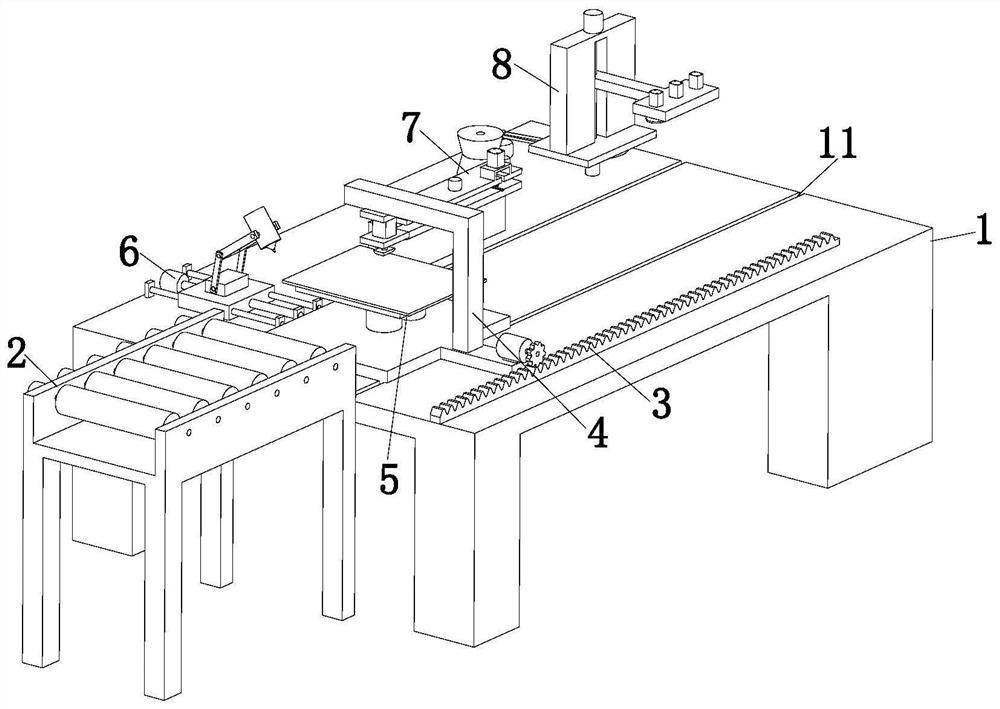

Car trunk cover plate production equipment with special-shaped corner cutting function

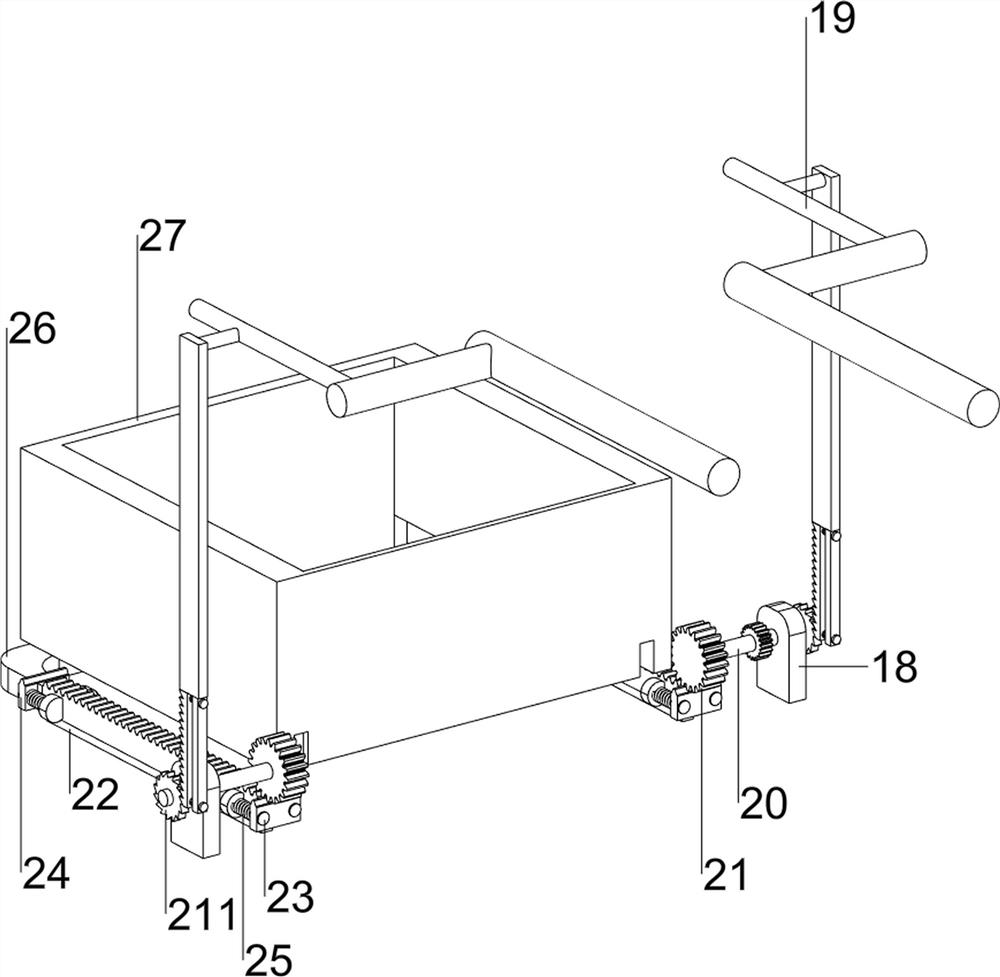

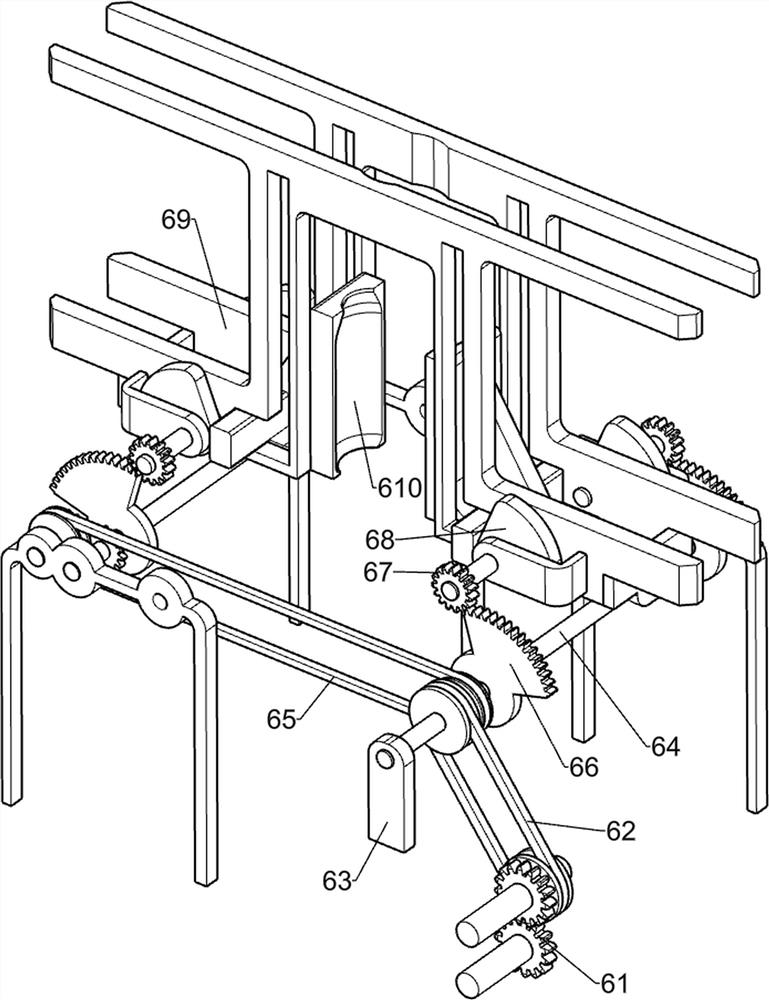

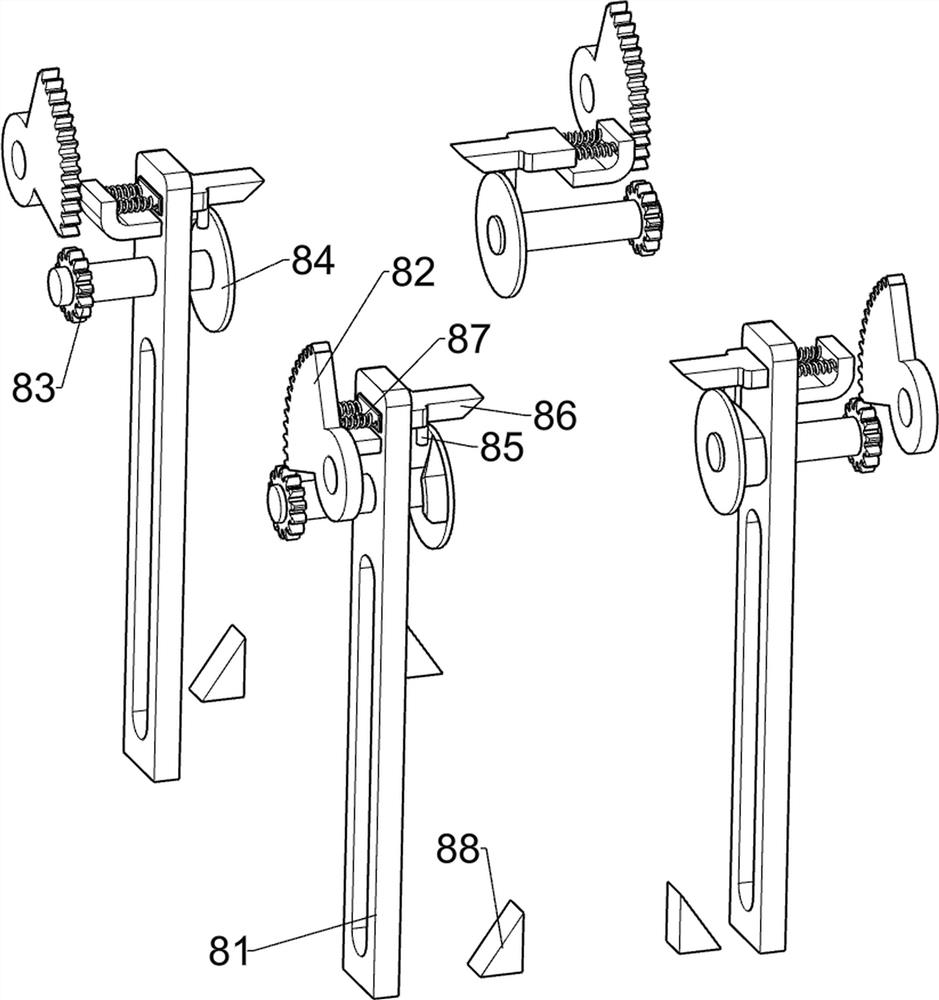

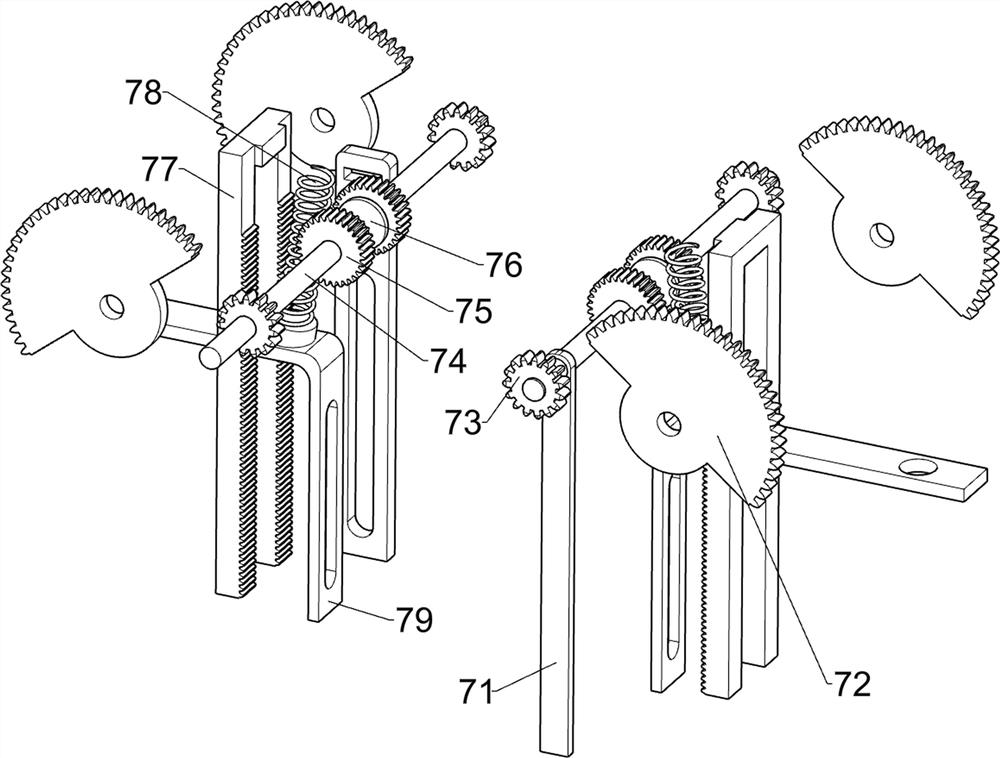

InactiveCN112122701ASmooth transmissionRealize automatic loading workMetal working apparatusPositioning apparatusTrunk compartmentGear drive

The invention discloses a car trunk cover plate production equipment with a special-shaped corner cutting function. The equipment comprises a main body frame, an object carrying table is arranged on the left side of the lower portion of the interior of the main body frame, a first air cylinder is welded to the lower portion of the object carrying table, a telescopic rod is welded to the right sideof a first air rod, a first gear meshes with the upper portion of a rack, and the right side of a first lock pin is rotationally connected with a first connecting rod. Compared with existing common visual inspection equipment, the car trunk cover plate production equipment with the special-shaped corner cutting function has the advantages that the first connecting rod is arranged, the first air cylinder drives the telescopic rod to move through the first air rod, the telescopic rod drives the first gear to rotate through the rack, the first gear drives the first gear to rotate through the first lock pin, and the rotating angle of the first gear is 120 degrees, so that a rotating plate is transferred to the object carrying table from the conveying belt, and the automatic feeding work is achieved; and a second connecting rod is arranged between the first connecting rod and a third connecting rod so that raw materials can be stably conveyed.

Owner:CHONGQING TECH & BUSINESS UNIV

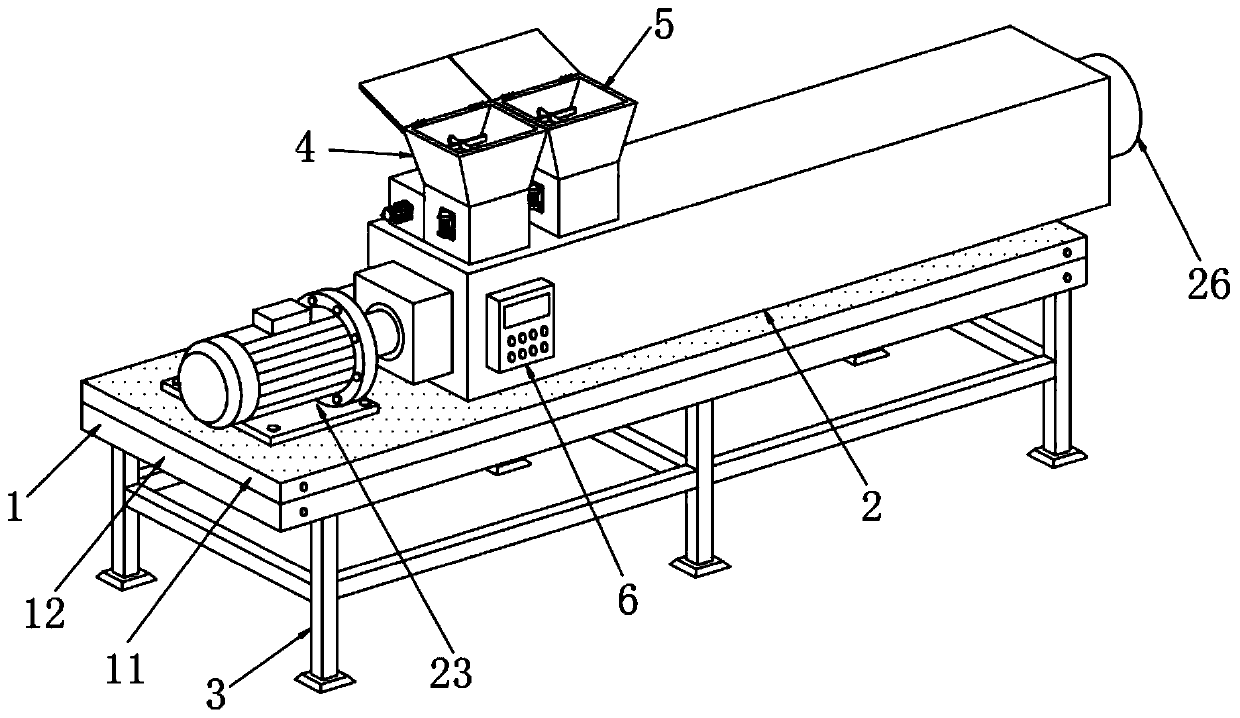

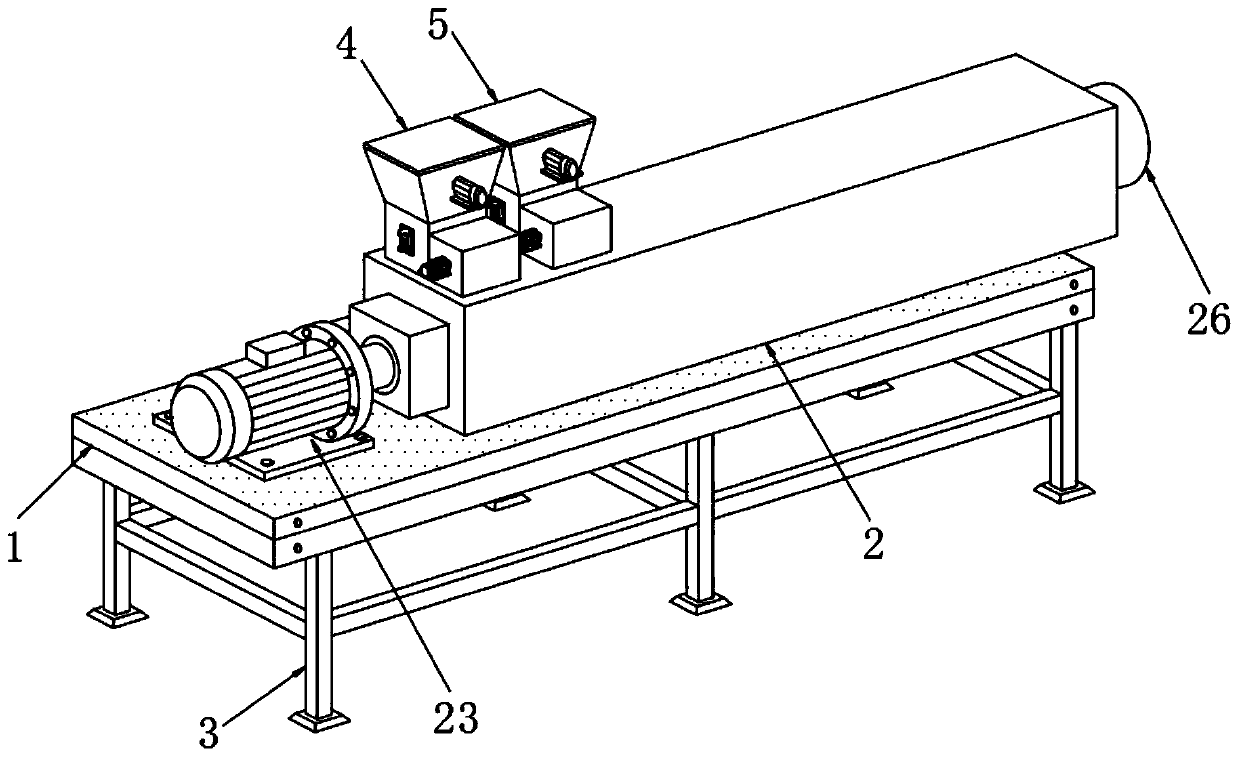

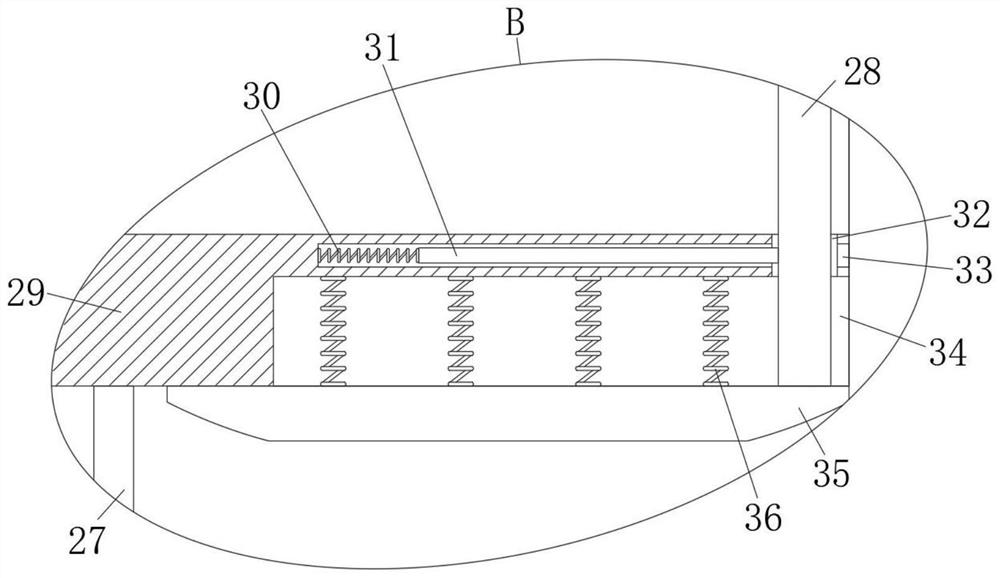

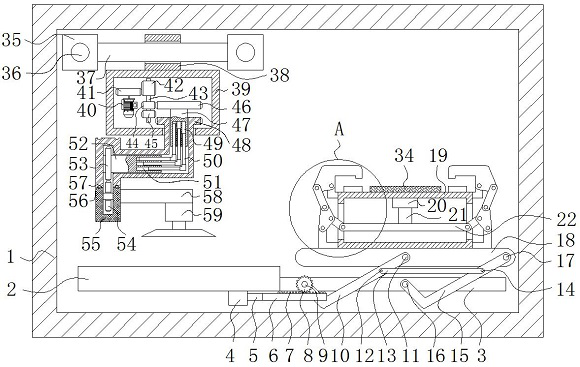

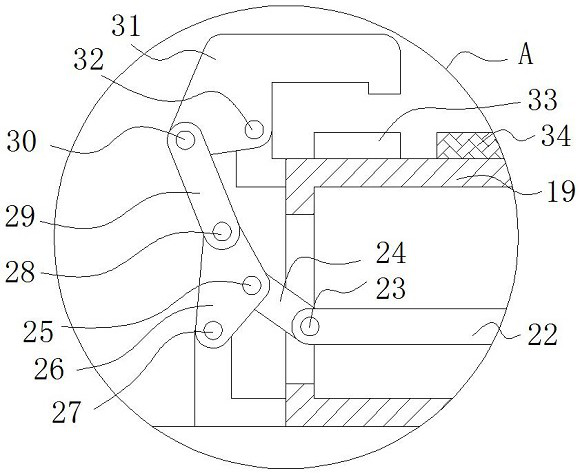

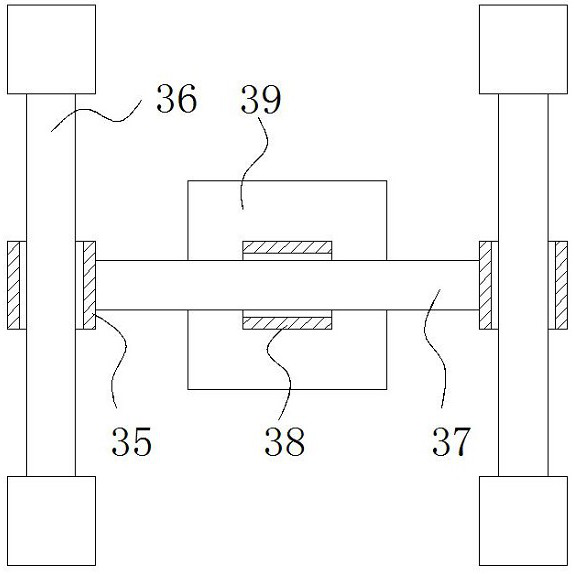

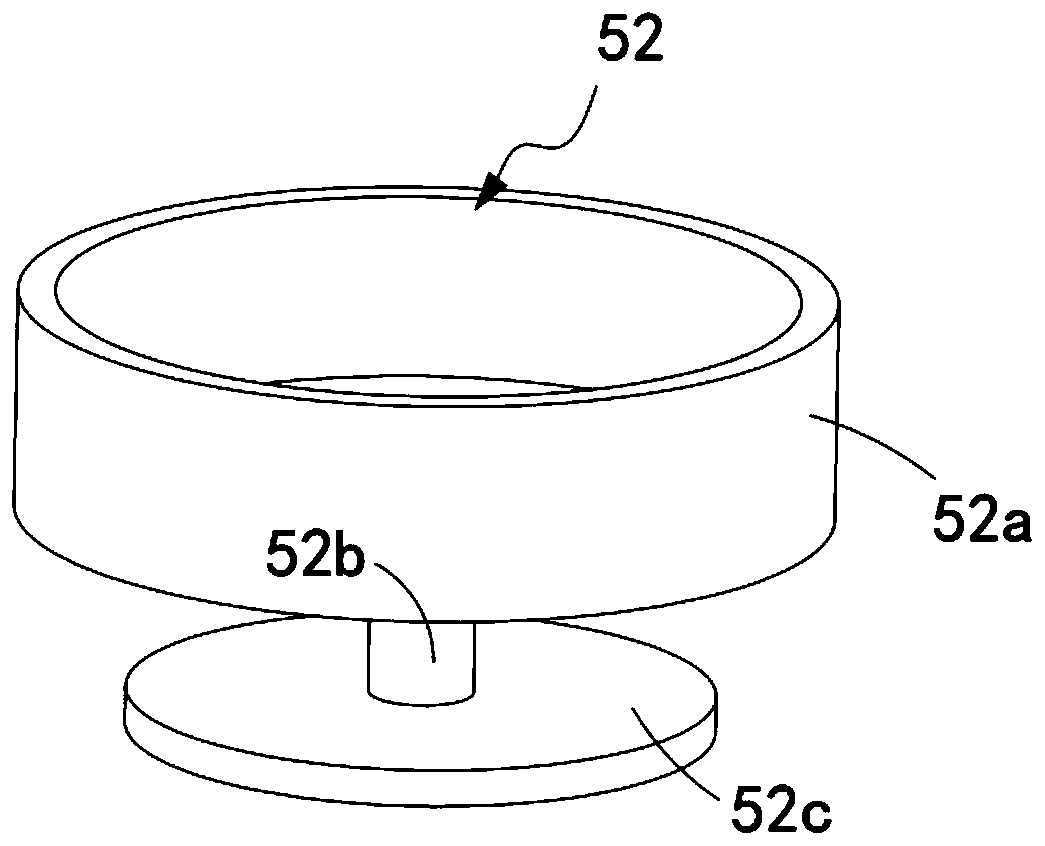

Automatic epoxy powder coating mixing equipment for high-steel-grade pipeline

InactiveCN111569752AIncrease profitImprove product qualityTransportation and packagingMixer accessoriesEpoxyEngineering

The invention relates to automatic epoxy powder coating mixing equipment for a high-steel-grade pipeline, which comprises: a supporting mechanism that includes a rack and a reaction kettle; a materialA conveying mechanism that comprises a first storage bin and a material scattering assembly; the B material conveying mechanism that comprises a second storage bin and a thinning assembly; the driving mechanism that is mounted on the rack and is used for driving the material scattering assembly and the thinning assembly to be rotationally arranged in the reaction kettle along the circumference; the dish feeding mechanism that comprises a lifting assembly, a material containing dish and a distance sensor, and the material containing dish is of an H-shaped structure and is sequentially composedof a dish device, a connecting column and a round base in the vertical direction; the discharging mechanism that comprises a horizontal pushing assembly, a material blocking assembly, an output assembly, an input assembly and a control assembly; according to the invention, the technical problems that epoxy resin is a thick fluid, is not easy to stir and is easily adhered to the stirring shaft during mixing, so that the epoxy resin is not easy to be fully and uniformly mixed with fillers and pigments, and the utilization rate of raw materials is low are solved.

Owner:浙江众鑫新材料科技有限公司

Metal round cover character imprinting equipment

The invention relates to imprinting equipment, and particularly relates to metal round cover character imprinting equipment. The metal round cover character imprinting equipment can continuously imprint metal round covers without manually carrying the metal round covers for multiple times. According to the technical scheme, the metal round cover character imprinting equipment comprises a base, a supporting mechanism and a pushing mechanism, wherein a pressing mechanism is arranged on one side of the top of the base; the supporting mechanism is arranged on one side of the top of the base; and the pushing mechanism is arranged on the other side of the top of the base. The pressing mechanism can be used for imprinting the metal round covers; and the supporting mechanism can be used for supporting the metal round covers, and the metal round covers can automatically fall off after imprinting.

Owner:惠州市致盛五金制品有限公司

An integrated loading and unloading two-dimensional code detection device for tobacco rods

ActiveCN110980243BImprove detection efficiencyOperational process automationConverting sensor output opticallyConveyor partsEngineeringStructural engineering

The invention relates to the technical field of tobacco rod detection devices, in particular to an integrated loading and unloading two-dimensional code detection device for tobacco rods, including a workbench, a feeding mechanism for tobacco rods, and a blanking device for tobacco rods. Mechanism and a detection mechanism for detecting the two-dimensional code of the cigarette bar. In the two-dimensional code detection device with integrated loading and unloading, the tobacco rods are sent from the conveyor belt to the bottom plate through the transmission of the conveyor belt. At this time, the tobacco rods slide into the positioning groove along the bottom plate to realize automatic feeding. The two-dimensional code of the cigarette bar inside the positioning slot realizes the automatic scanning of the two-dimensional code. The low level is output by the photoelectric sensor to control the ejection of the first telescopic electric cylinder. At this time, the slider slides in the chute, and the push block is pushed in Positioning groove, and push out the tobacco rod inside the positioning groove to realize automatic cutting work.

Owner:NANJING DASHU INTELLIGENT SCI & TECH CO LTD

A kind of beer bottle inner wall cleaning equipment for food processing

ActiveCN113058954BEasy to clean upRealize automatic loading workHollow article cleaningElectric machineryProcess engineering

The present invention involves a cleaning equipment, especially for the inner wall cleaning equipment of a beer bottle for food processing.Technical problem: Provide a cleaning work without artificial beer bottle, and will not make the inner wall of the inner wall of the beer bottle of food processing for beer bottles.The technical solution is as follows: an inner wall cleaning equipment for food processing, including: bottom plate, motor installation seat on one side of the bottom plate; power mechanism, power mechanism on the top of the bottom plate; installation rack, installation on the top of the bottom plate, installation of installationRangers; cleaning mechanism, cleaning mechanism on the installation rack.The staff of the setting of the power mechanism and cleaning agency only need to put the beer bottle to clean it; the setting of the setting agency can realize the automatic feeding work of the beer bottle.

Owner:NANJING YUQUN COMM TECH CO LTD

An automatic bag sticking machine

ActiveCN113308806BHigh degree of automationEasy to controlWork-feeding meansPressersControl systemSoftware engineering

Owner:WENZHOU GUTAI MACHINERY TECH CO LTD

Convenient and fast cutting equipment for energy-saving and environment-friendly materials

PendingCN113442187AGood cutting jobRealize automatic loading workMetal working apparatusManufacturing engineeringIndustrial engineering

The invention relates to cutting equipment, in particular to convenient and fast cutting equipment for energy-saving and environment-friendly materials. Aiming at the defects in the prior art, the convenient and fast cutting equipment for energy-saving and environment-friendly materials which does not need manual cutting and is flat in cutting surface is provided. According to the technical scheme, the convenient and fast cutting equipment for the energy-saving and environment-friendly materials comprises a base, a first mounting base, a guide column, a cutting disc, a cutting mechanism and a rotating mechanism, the first mounting base is arranged on one side of the top of the base, the guide column is arranged on one side of the top of the first mounting base, and the cutting disc is slidably arranged on the guide column; the cutting mechanism is connected among the first mounting base, the guide column and the cutting disc, and the rotating mechanism is arranged in the middle of one side of the top of the base. Automatic feeding work of materials can be achieved through an arranged feeding mechanism; and through an arranged discharging mechanism, workers do not need to take down the materials in the rotating process of the rotating disc.

Owner:林巧静

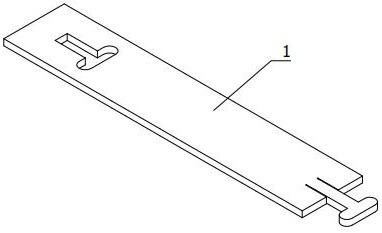

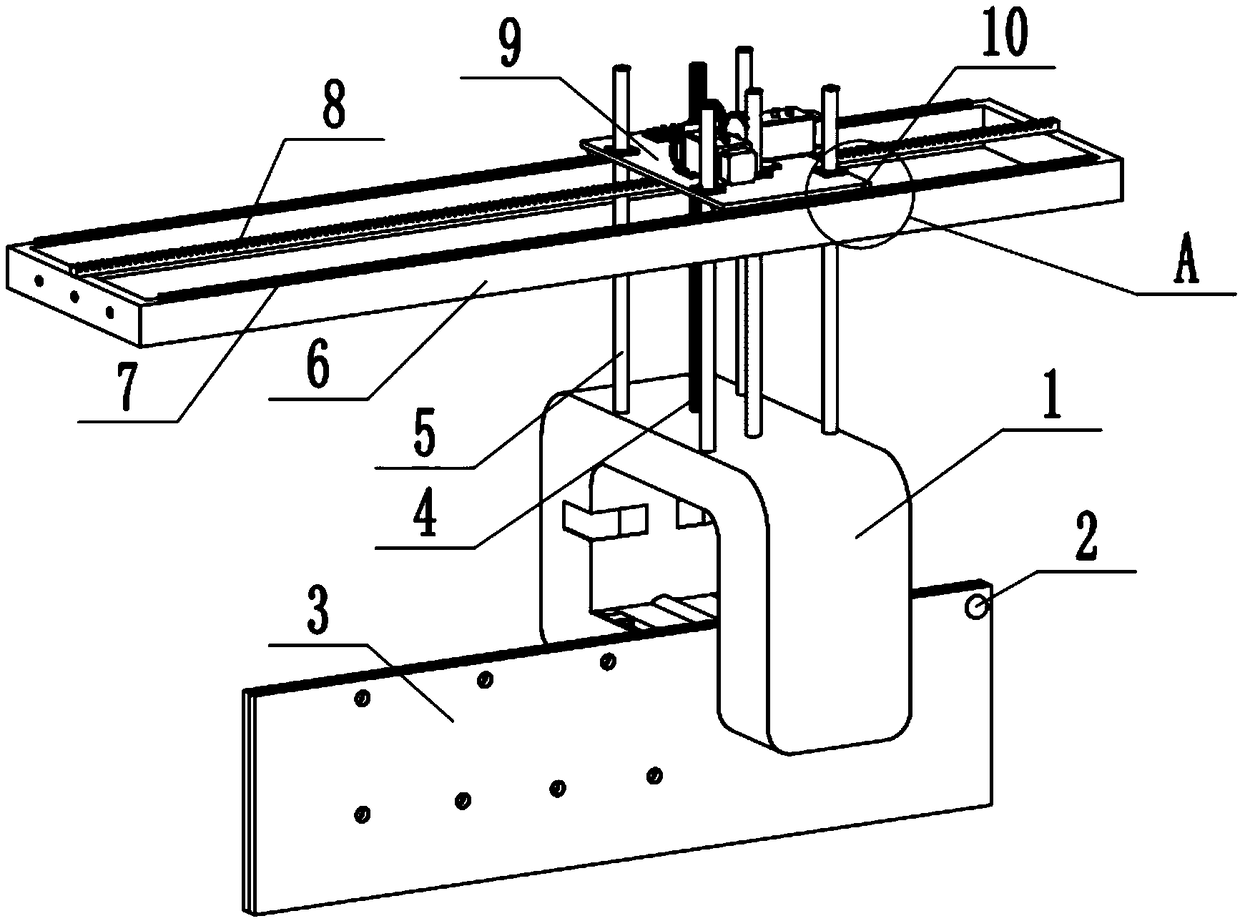

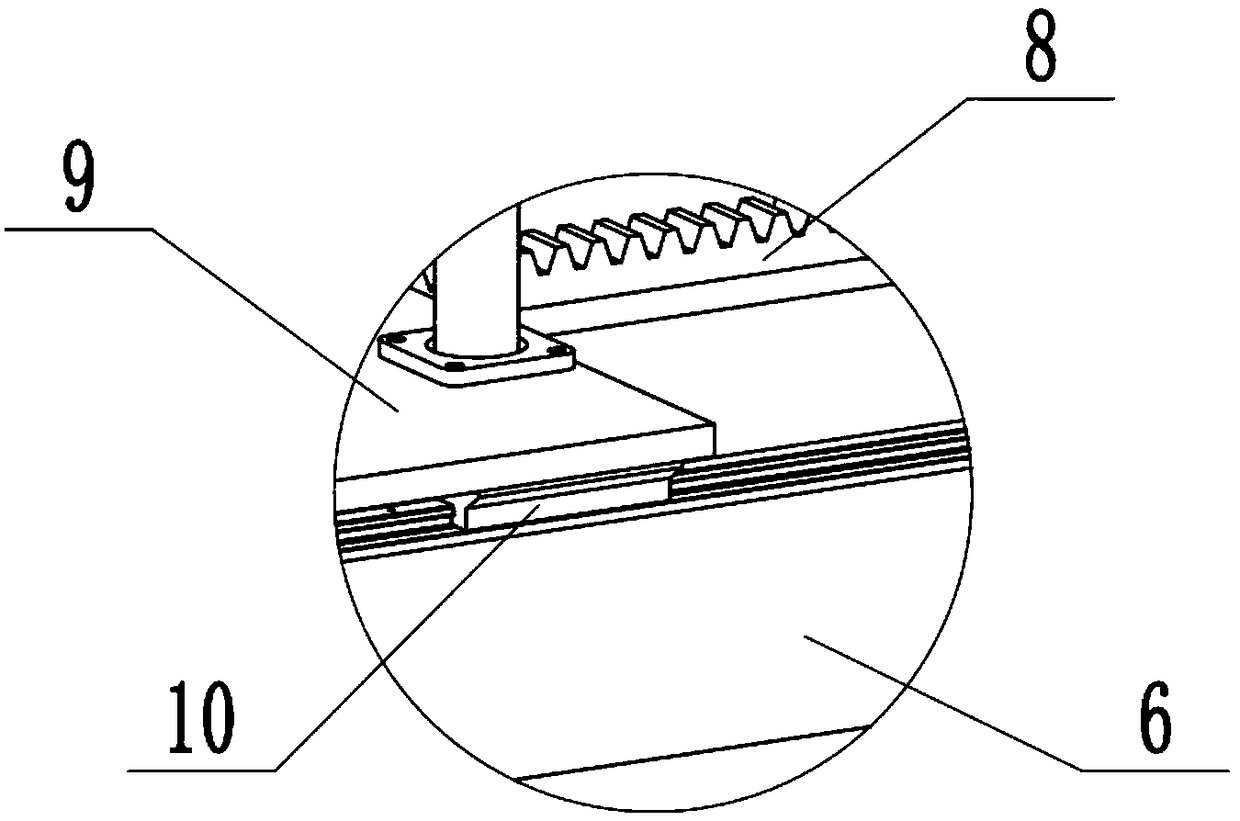

Large workpiece riveting device

InactiveCN109248986ARealize automatic loading workAchieving a single feed jobHydraulic cylinderResource utilization

The invention provides a large workpiece riveting device, and belongs to the field of machining of industrial plate products. The large workpiece riveting device consists of a lower assembly, a rivetfinishing piece, a large machining plate, a cylindrical surface rack, an unthreaded shaft, a supporting rack, a sliding track, a rack, an upper assembly and a slider, movement of two-degree of freedomof the integral device is realized through the upper assembly, the integral device is driven to move in the front-back direction and the up-down direction, and intelligent and multi-directional movement is realized; by the lower assembly, rivets are automatically extruded through combined effect of two hydraulic cylinders, and meanwhile, the rivets can further be automatically loaded by the lowerassembly; the integral device is intelligent, and multidirectional automatic riveting can be realized; and by the upper assembly, the lower assembly is driven to move in the front-back direction andthe up-down direction by a gear and rack assembly skillfully, movement of two-degree of freedom can be realized by two stepping motors, resource utilization rate is increased, and the cost is reduced.

Owner:王世霖

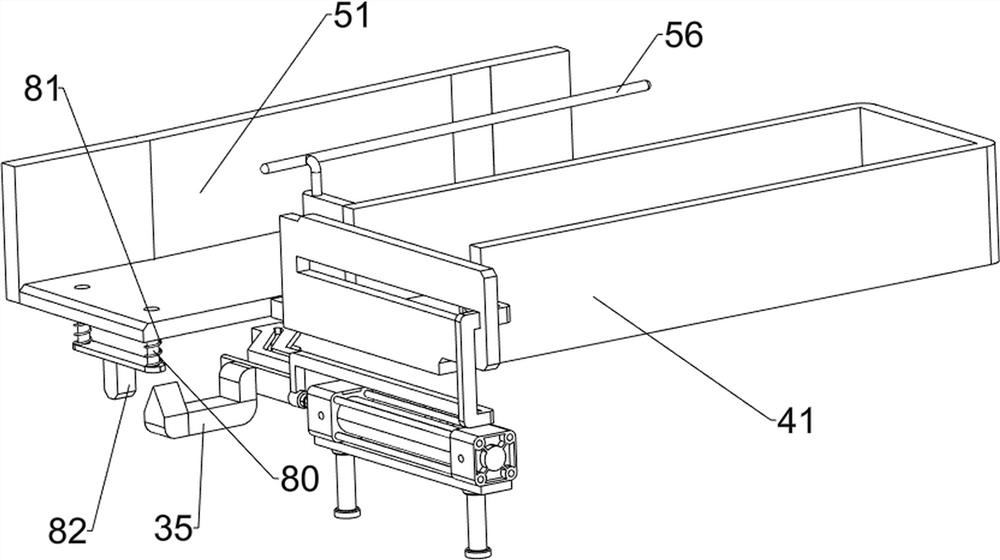

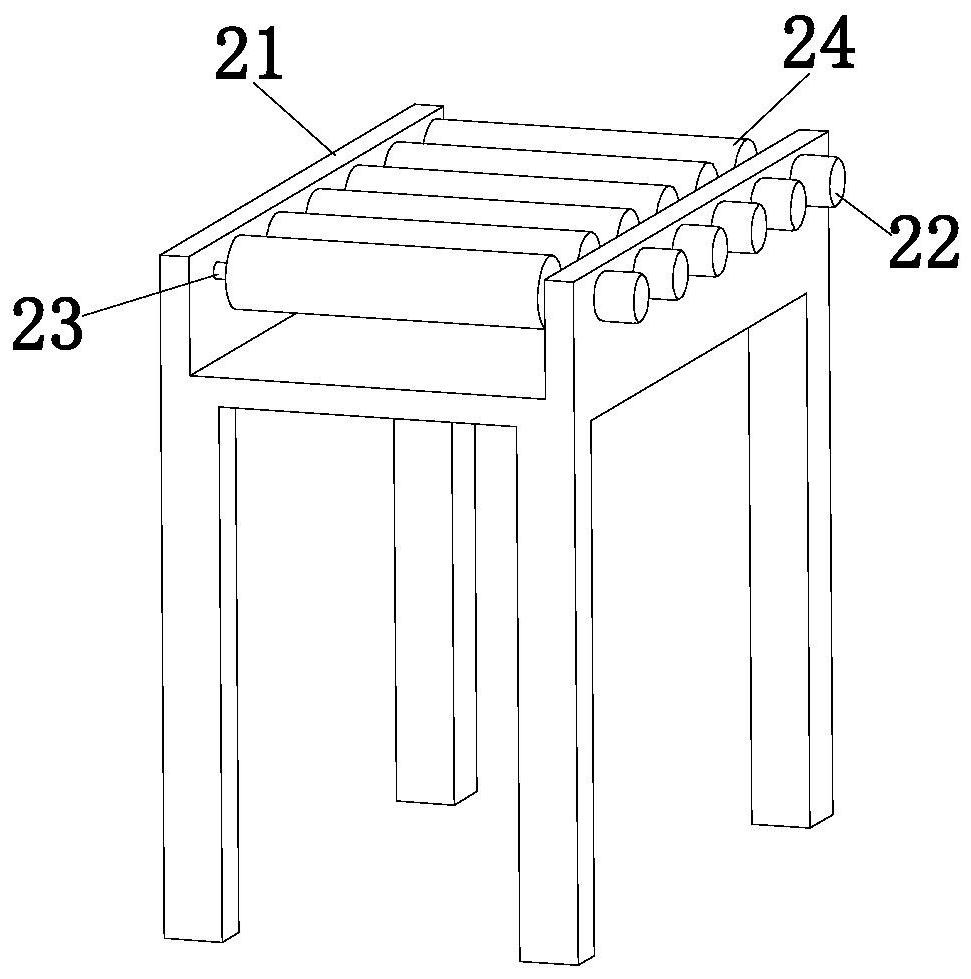

Automatic bordering equipment for refrigerator interlayer glass

InactiveCN112762657ARealize automatic loading workRealize the loading operationLiquid surface applicatorsLighting and heating apparatusEngineeringWorkbench

The invention discloses automatic bordering equipment for refrigerator interlayer glass and belongs to the technical field of refrigerators.The automatic bordering equipment comprises a workbench, a conveying assembly, a glass moving assembly, a pressing assembly, a rotating assembly, a gluing assembly, a bordering assembly and a discharging assembly, wherein the conveying assembly is horizontally arranged at the front end of the workbench, the glass moving assembly is arranged on the workbench and is in sliding fit with the workbench through two sliding grooves, the pressing assembly is fixedly connected to the glass moving assembly, the rotating assembly is arranged on the glass moving assembly and is fixedly connected with the glass moving assembly, the gluing assembly is arranged on the workbench and is in sliding fit with the workbench, the bordering assembly is fixedly connected to the workbench, and the discharging assembly is arranged at the rear end of the workbench and rotationally connected with the workbench. For the automatic bordering equipment disclosed by the invention, glass is automatically fed and discharged through the glass moving assembly and the discharging assembly, and operations of automatic gluing and automatic bordering on the glass is achieved through the gluing assembly and the bordering assembly.

Owner:李瑞明

Manufacturing device for anti-skid stripes of industrial foot mats

PendingCN112548225ARealize automatic loading workEasy to work with anti-skid patternPositioning apparatusMaintainance and safety accessoriesMechanical engineeringManufacturing engineering

Owner:梁喜先

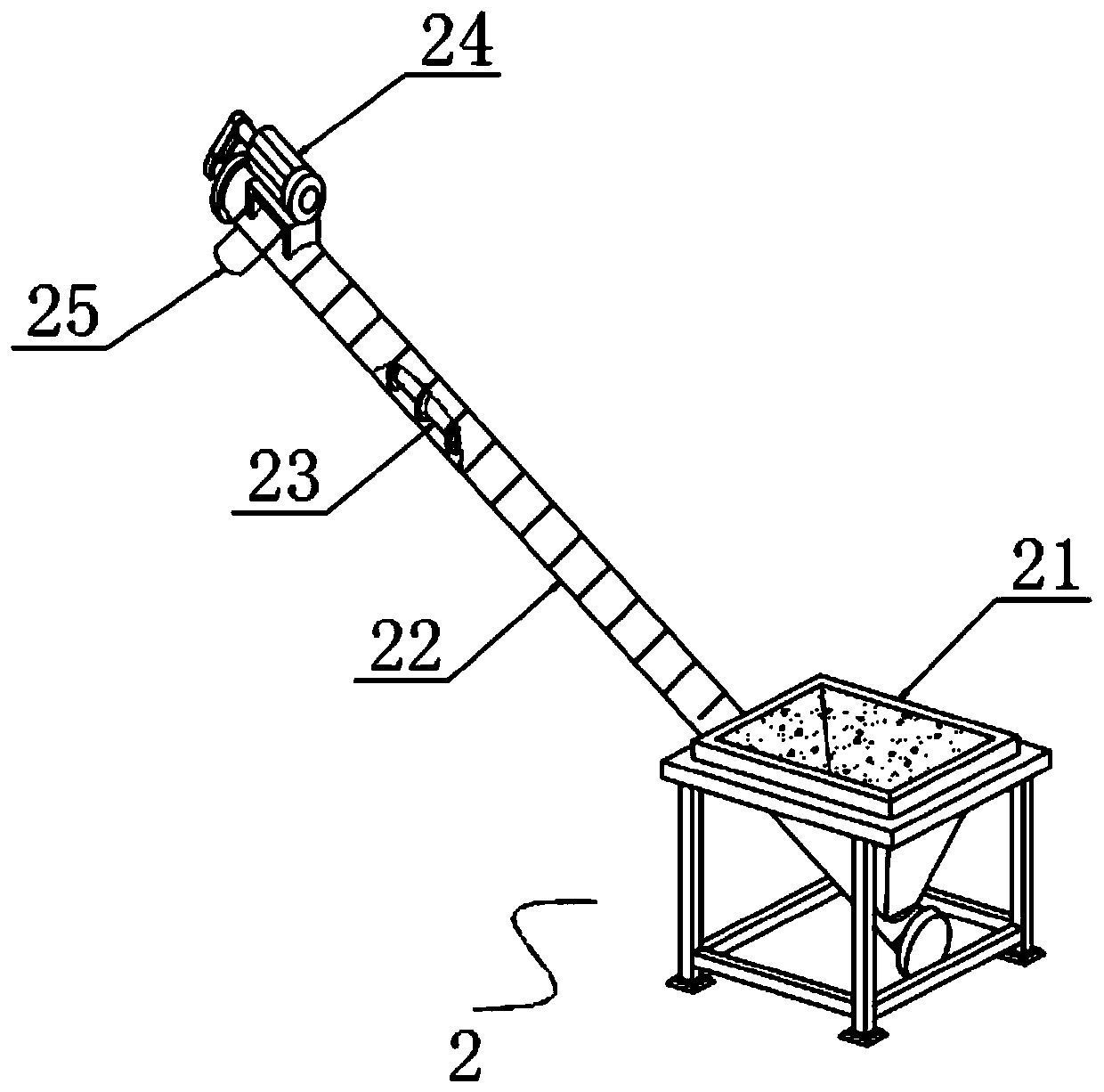

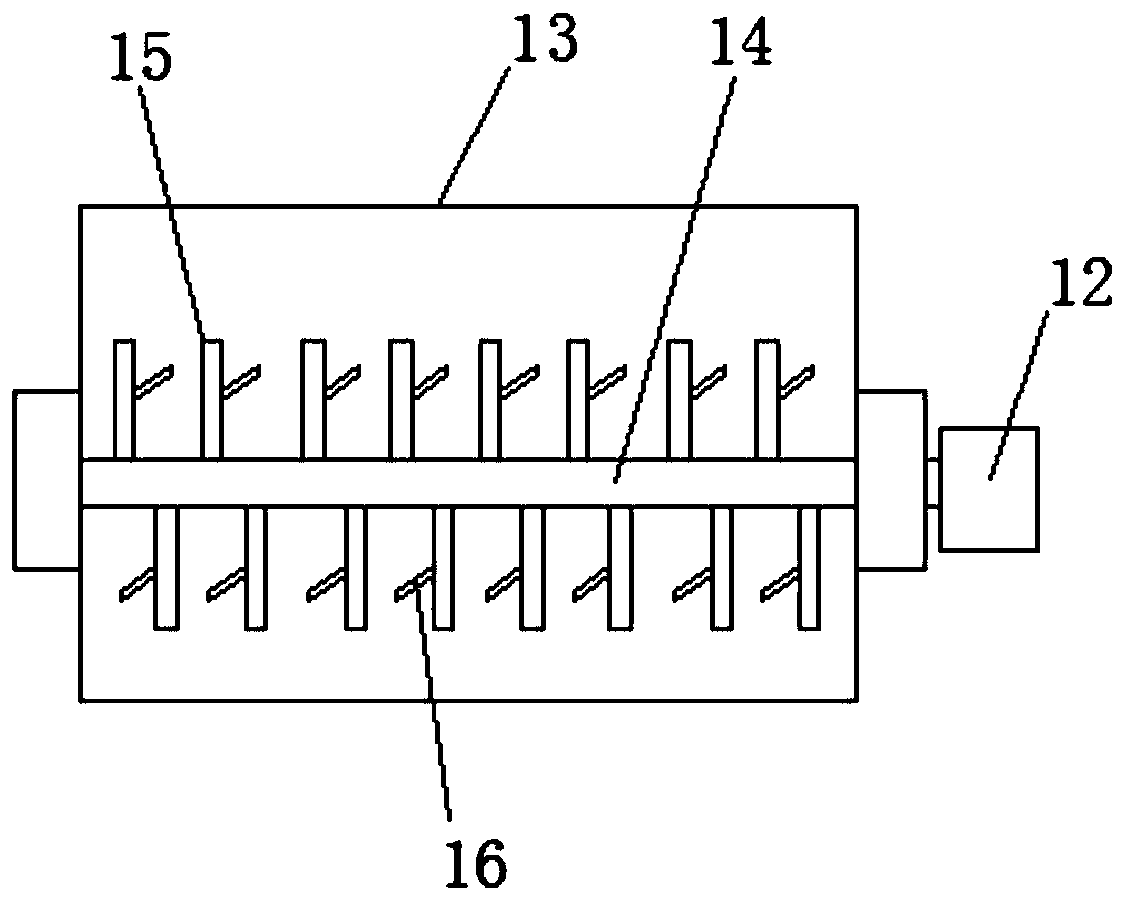

Automatic waste pulverizer

The invention provides an automatic waste pulverizer. The automatic waste pulverizer comprises a feeding mechanism and a pulverizing mechanism, wherein the feeding mechanism comprises a translating assembly, a vertical lifting assembly, and a shuffling assembly; the translating assembly is connected with the vertical lifting assembly; the shuffling assembly is arranged on the vertical lifting assembly; the pulverizing mechanism includes a rack, a pulverizing motor arranged on the rack, a pulverizing chamber, a tool holder arranged in the pulverizing chamber, and pulverizing cutters arranged onthe tool holder; the pulverizing motor and the tool holder are in transmission connection; the pulverizing chamber includes a feeding port and a discharging port; the pulverizing cutters include maincutters arranged perpendicular to the tool holder and auxiliary cutters arranged obliquely to the tool holder; the auxiliary cutters are arranged on the main cutters; and the main cutters are evenlyarranged along the outer diameter of the rack. By means of the automatic waste pulverizer, the automatic feeding of waste is achieved, the grade of scrap pulverization is higher, the smashing effect is better, and thus the smashed waste is transported and recycled conveniently.

Owner:苏州冬宝光电科技有限公司

Chinese yam slice processing equipment

InactiveCN113021461AEasy for slicing workPrevent movementMetal working apparatusBiotechnologyMechanical engineering

The invention discloses Chinese yam slice processing equipment, and particularly relates to the field of Chinese yam processing equipment. The Chinese yam slice processing equipment comprises a processing frame and a feeding plate, wherein the feeding plate is located on one side of the processing frame, limiting sliding plates are fixedly connected to the upper portion and the lower portion of the inner wall of the processing frame, a processing frame is slidably connected to the interior of the processing frame through the limiting sliding plates, a fan-shaped groove is formed in the processing frame, a fixing column is fixedly connected to one side of the interior of the fan-shaped groove, a plurality of push-pull holes are formed in the side, close to the feeding plate, of the processing frame, and material moving mechanisms are arranged in the plurality of push-pull holes respectively. By arranging the processing frame, the material moving mechanism and the Chinese yam processing mechanism, automatic slicing work of Chinese yams is achieved, automatic feeding work in the Chinese yam processing process is also achieved, manual feeding is not needed, the Chinese yam processing efficiency is greatly improved, the manual feeding burden is relieved, and automatic production of Chinese yam cutting processing is achieved.

Owner:林志超

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com