Automatic waste pulverizer

A pulverizer and pulverizing mechanism technology, applied in grain processing and other directions, can solve the problems of low pulverization level, low work efficiency, time-consuming and laborious manual feeding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

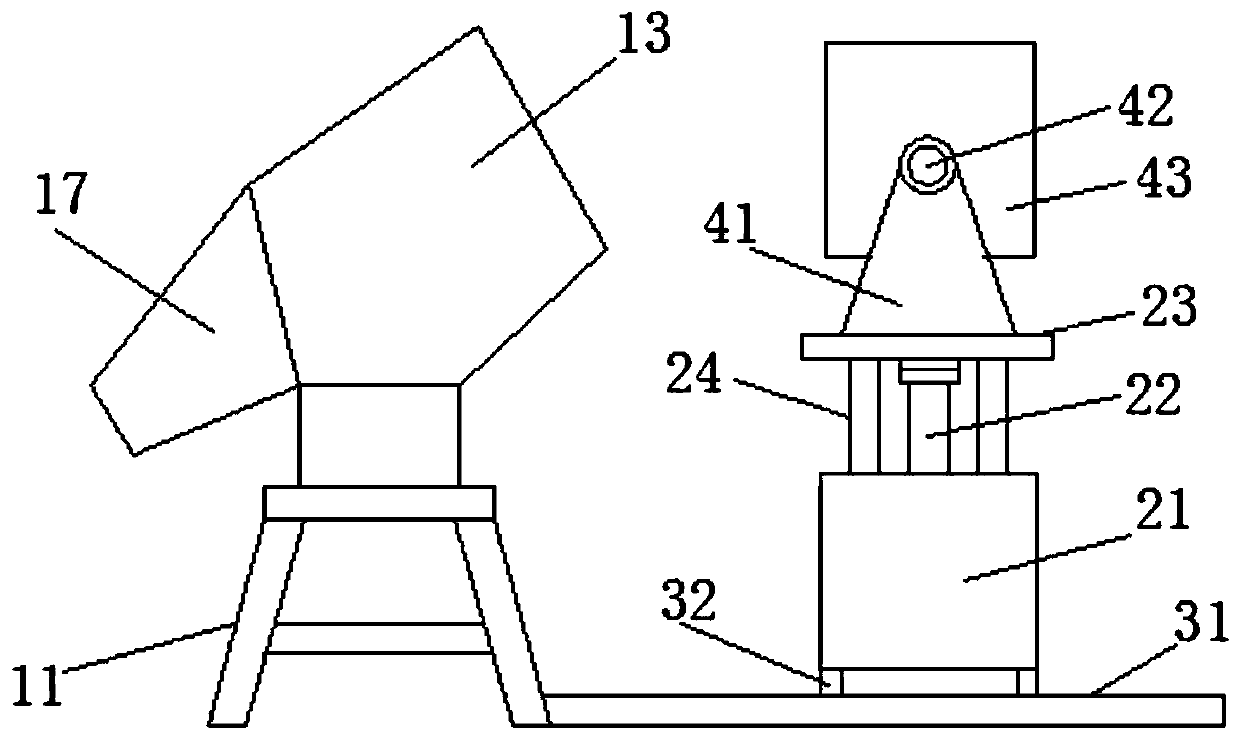

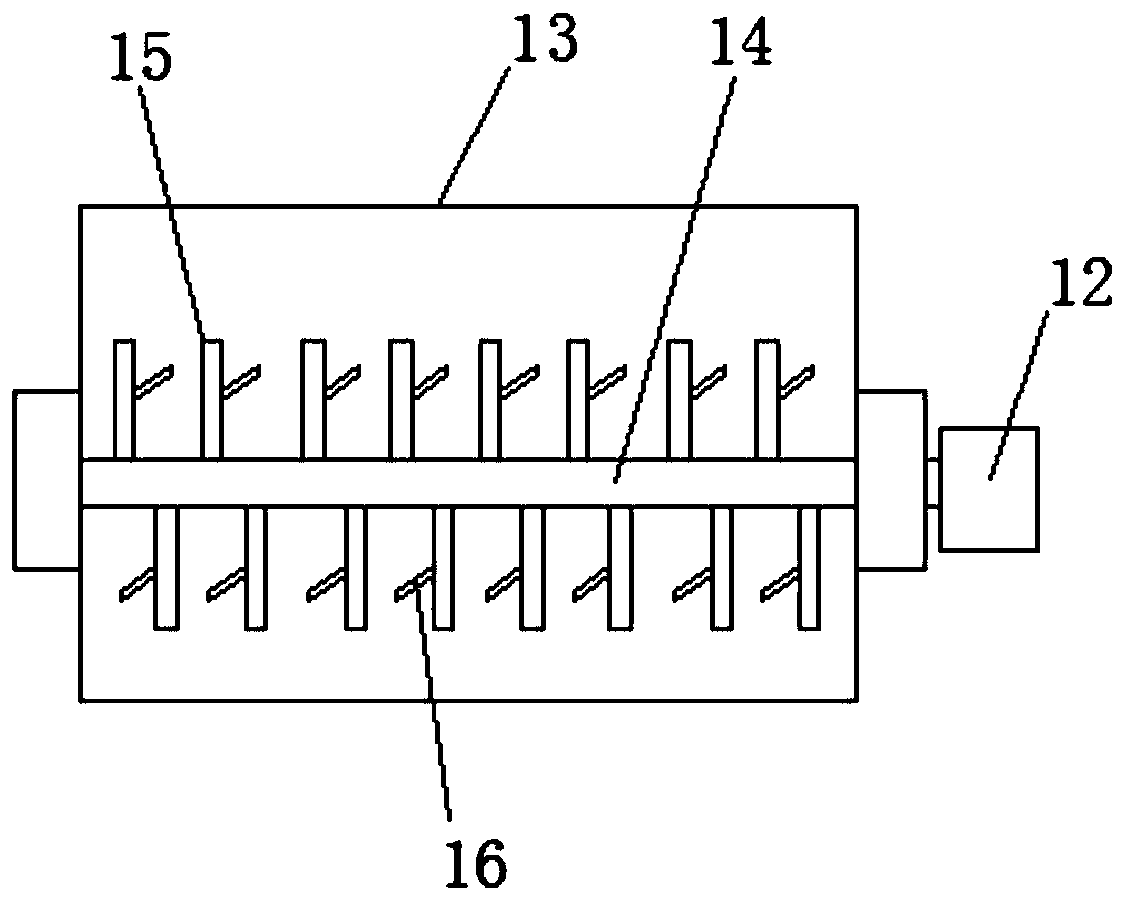

[0019] see Figure 1-2 , the figure shows an automatic waste shredder provided by Embodiment 1 of the present invention, which includes a feeding mechanism and a crushing mechanism. Components, the crushing mechanism includes a frame 11, a crushing motor 12 arranged on the frame 11, a crushing bin 13, a cutter rest 14 arranged in the powder bin 13 and a crushing knife arranged on the cutter rest 14, and the crushing motor 12 drives Connect the knife rest 14, the crushing bin 13 includes a feed port and a discharge port, and the crushing knife includes a main knife 15 arranged vertically with the knife rest 14 and an auxiliary knife 16 arranged obliquely with the knife rest 14, and the auxiliary knife 16 is arranged on the main knife 15 Above, the main knives 15 are evenly distributed along the outer diameter of the knife holder 14 .

[0020] In the waste automatic pulverizer provided in this embodiment, the feeding mechanism can automatically feed the pulverizing mechanism, w...

Embodiment 2

[0022] see figure 2 , the figure shows an automatic waste shredder provided by Embodiment 2 of the present invention. On the basis of the above embodiment, this embodiment further makes the following technical solutions as improvements: the main knife 15 along the knife rest 14 The radial direction is staggered, and along the two radial sides of the tool holder 14, the direction of the tip of the auxiliary knife 16 is opposite.

[0023] Through the above further improvements, compared with the prior art, this embodiment has the following advantages: waste materials can be crushed from various angles and directions, and the crushing level can be further improved.

Embodiment 3

[0025] see figure 1 , the figure shows an automatic waste shredder provided by Embodiment 3 of the present invention. On the basis of the above embodiment, this embodiment further makes the following technical solutions as improvements: the upper and lower lifting components include a base 21, The lifting cylinder arranged in the base 21 , the lifting rod 22 connected to the lifting cylinder and the feeding table 23 connected to the lifting rod 22 ; a guide column 24 is arranged between the feeding table 23 and the base 21 .

[0026] Through the above-mentioned further improvements, this embodiment also has the following advantages compared with the prior art: the lifting cylinder works, drives the lifting rod 22 to move up and down, and then drives the loading table 23 to move up and down; 23 is guided, and deviation phenomenon can not take place, realizes automatic lifting waste material, until the waste material is sent to the feeding port place of crushing bin 13.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com