Coal crushing device of coal mine

A crushing device and coal technology, which is applied to mixers with rotating stirring devices, transportation, packaging, dissolution, etc., can solve the problems of uneven crushing surface, poor crushing effect, unusable crushing devices, etc., to avoid coal block drop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

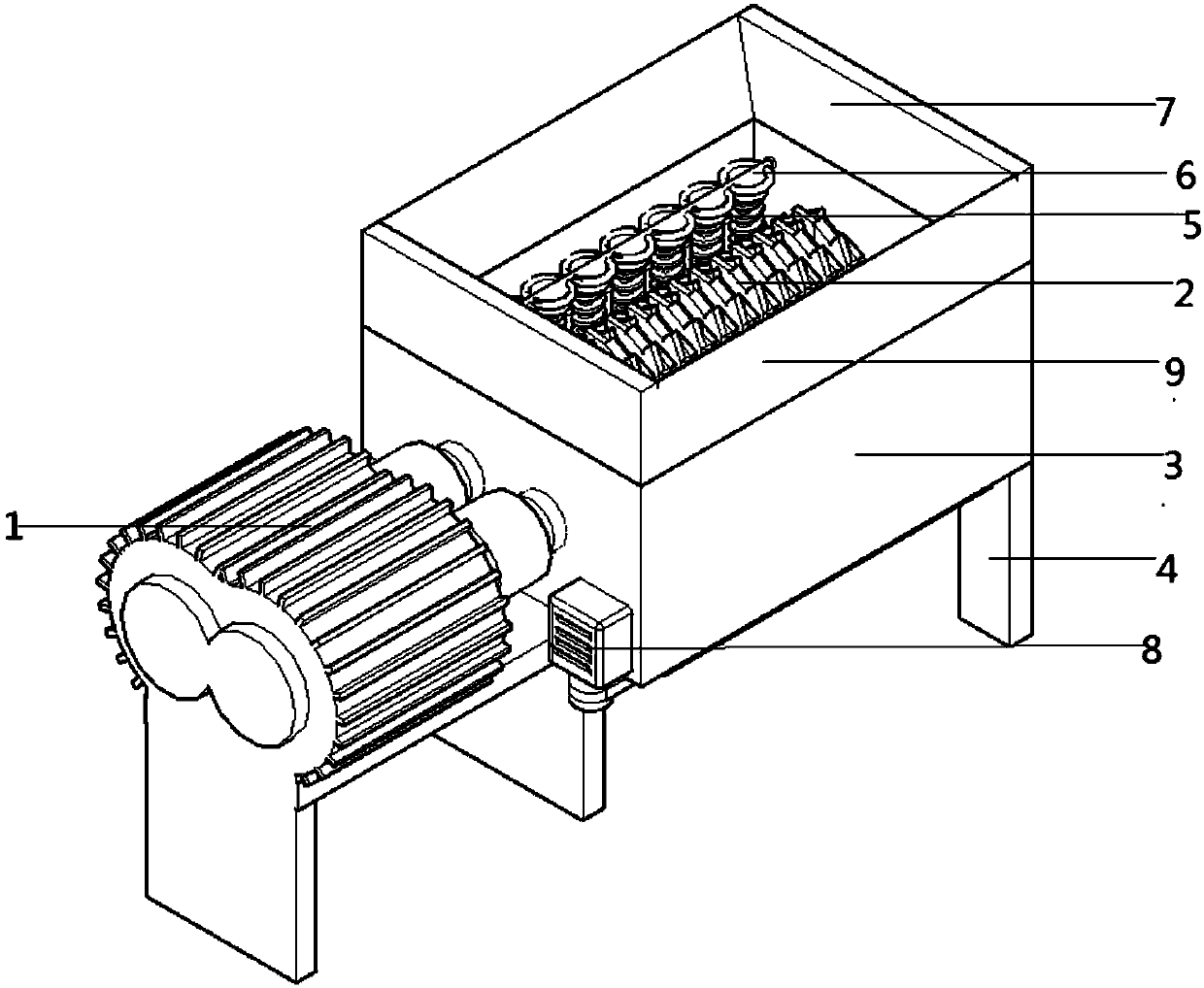

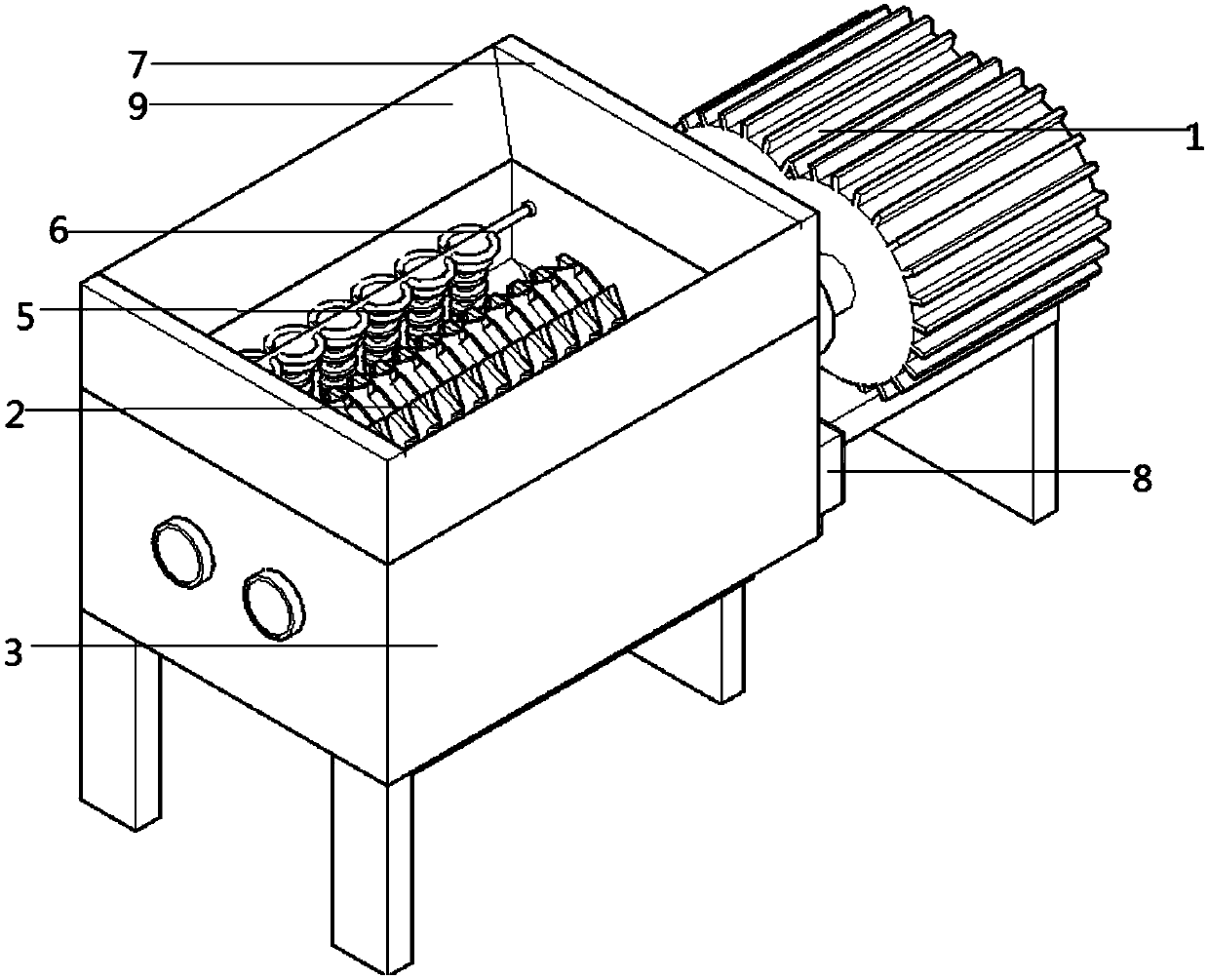

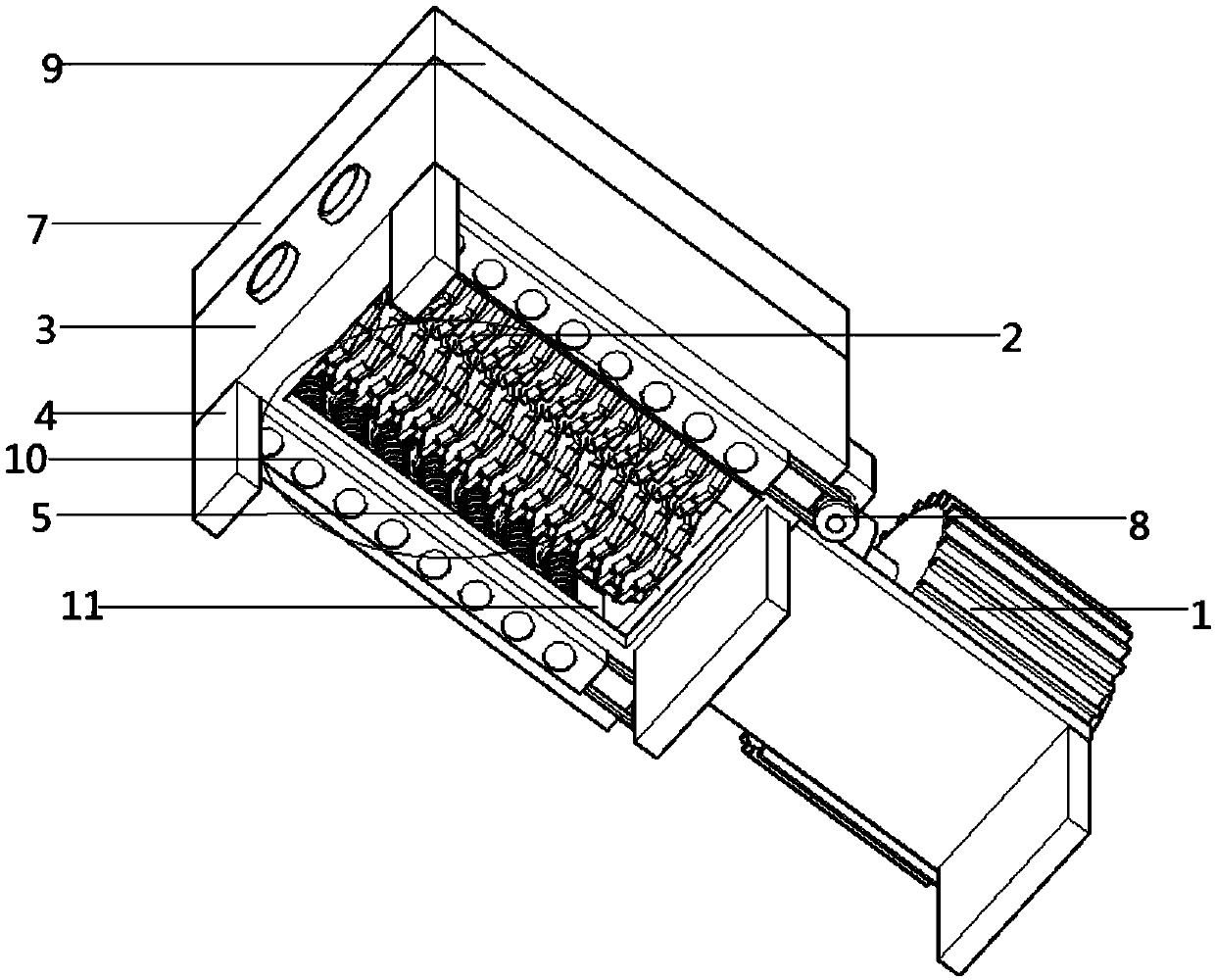

[0027] as attached figure 1 to attach Figure 9 Shown:

[0028] The invention provides a coal crushing device for a coal mine, which includes a main motor 1, a crushing shaft 2, a housing 3, a support leg 4, an auxiliary stirring group 5, a connecting piece 6, a baffle 7, a stirring motor 8, a guide plate 9, and a stirring group drive Body 10, accommodating body 11, grinding body 201, cutting body 202 and accommodating hole 1001, the main motor 1 and the bottom of the housing 1 are fixedly welded with supporting feet 4; the main motor 1 is arranged on the bottom of the housing 3 The left side is external, and the main motor 1 is a double unit, and the right end of the main motor 1 is connected with two parallel crushing shafts 2 built in the inside of the housing 3; A horizontal container body 11, and auxiliary stirring groups 5 are arranged side by side on the container body 11; the top of the auxiliary stirring group 5 is rotatably connected to the connectors 6 fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com