Automatic epoxy powder coating mixing equipment for high-steel-grade pipeline

A technology of epoxy powder and mixing equipment, which is applied in the direction of mixers, feeding devices, chemical/physical/physicochemical processes, etc. It can solve the problem of not being easy to stir, not easy to mix epoxy resin pigments fully and evenly, and easy to adhere to the stirring Axis and other problems, to achieve the effect of improving utilization rate, improving production quality and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

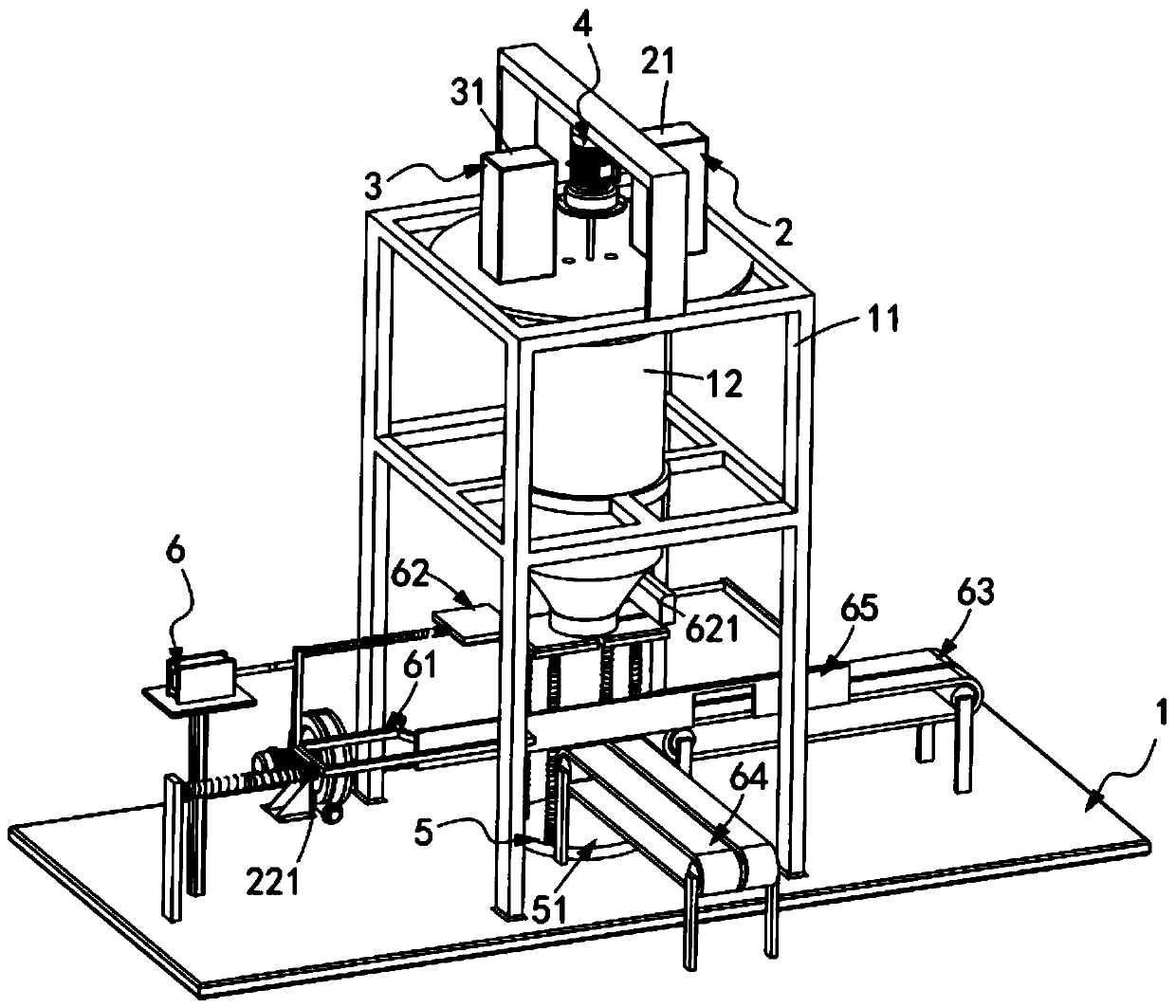

[0069] Such as figure 1 , figure 2 and image 3 As shown, an automatic mixing equipment for epoxy powder coatings for high-grade steel pipelines, including:

[0070] Supporting mechanism 1, described supporting mechanism 1 comprises frame 11 and the reactor 12 that is installed on described frame 11;

[0071] Material A conveying mechanism 2, the material A conveying mechanism 2 includes a first storage bin 21 installed on the frame 11 and a spreading material located in the reaction kettle 12 and communicated with the first storage bin 21 component 22;

[0072] B material conveying mechanism 3, said B material conveying mechanism 3 includes the second storage bin 31 installed on the frame 11 and the thinning assembly 32 built in the spreading assembly 22;

[0073] The driving mechanism 4, the driving mechanism 4 is installed on the frame 11 and is used to drive the spreading component 22 and the flinging component 32 to rotate along the circumference and be arranged in t...

Embodiment 2

[0117] Such as Figure 14 to Figure 17 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0118] further, such as Figure 14 to Figure 17 As shown, the upper end of the output end of the guide tube 324 is set obliquely downward;

[0119] Both the first discharge plate 224 and the second discharge plate 323 are arranged obliquely downward, the slope ratio of the first discharge plate 224 is k1, and the slope ratio of the second discharge plate 323 is k2, k1 >k2;

[0120] The first discharge pipe 222 and the second discharge pipe 321 are integrally formed and installed on the reactor 12 by rotating the swivel 13 .

[0121] In this embodiment, by setting k1>k2, the conveying speed of materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com