Patents

Literature

33results about How to "Convenient discharge work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

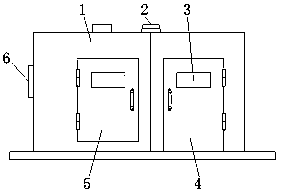

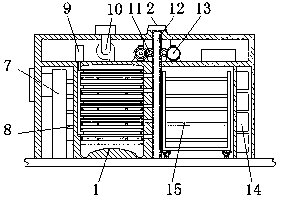

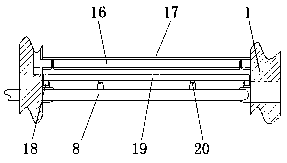

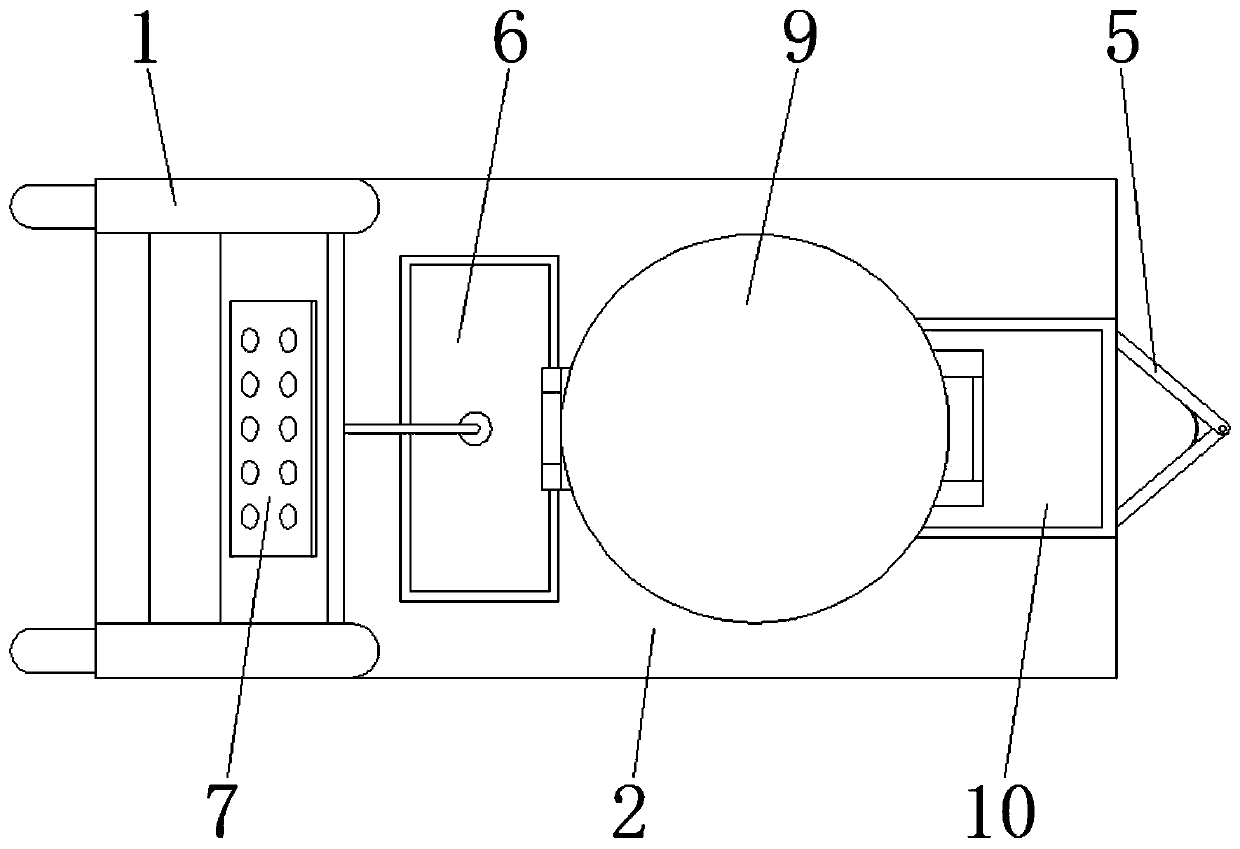

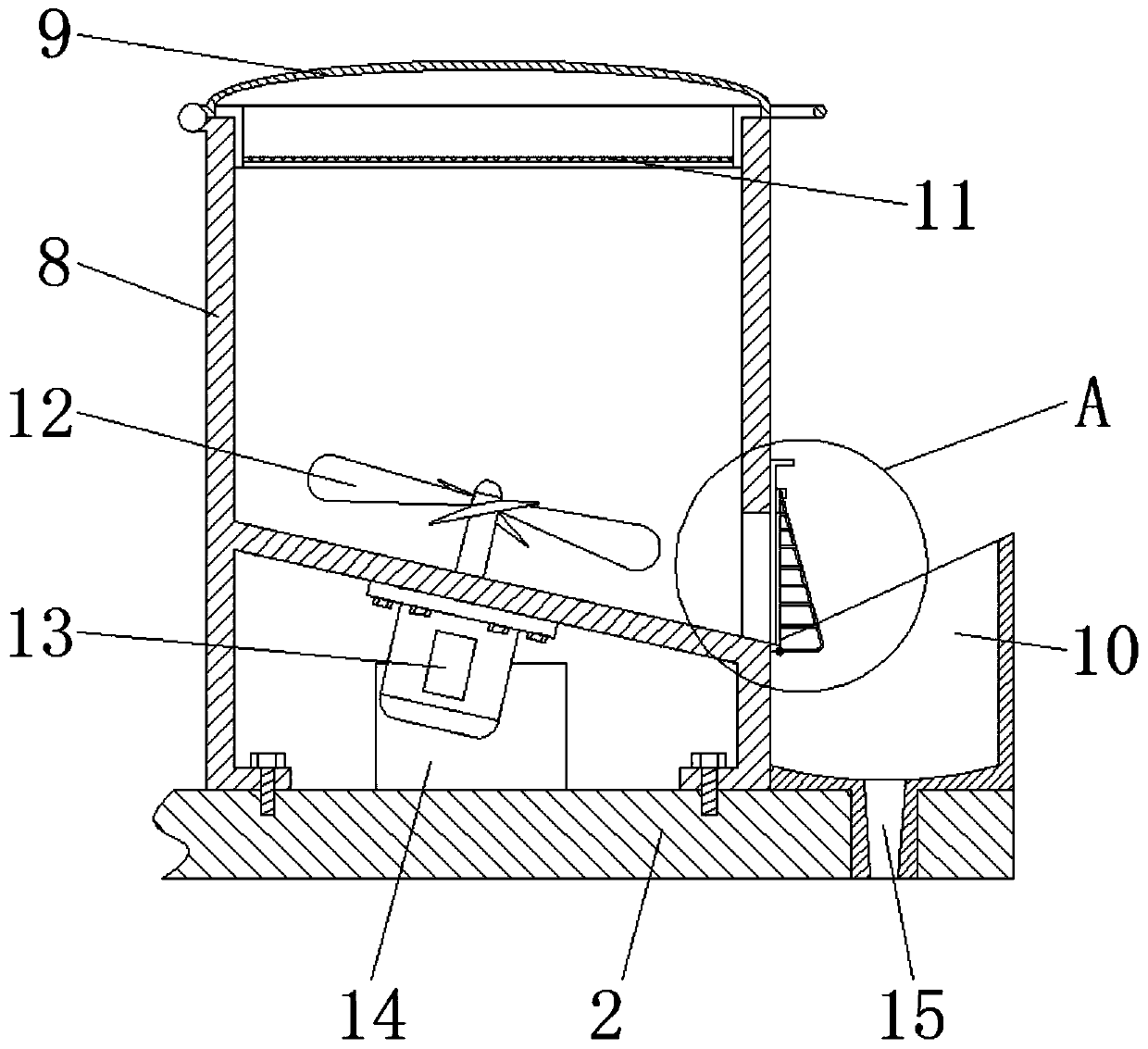

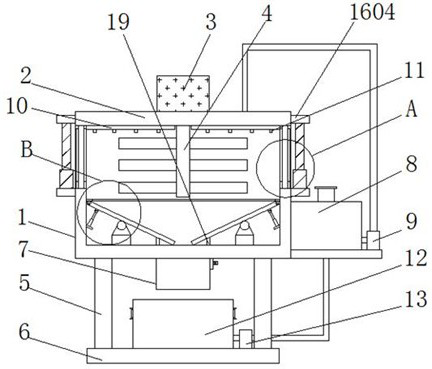

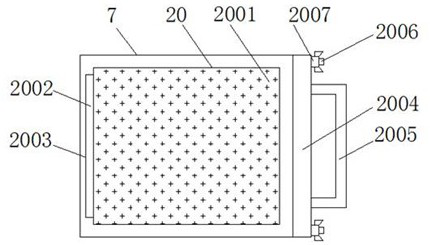

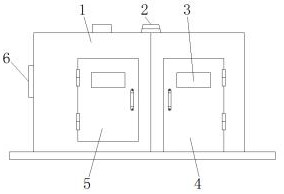

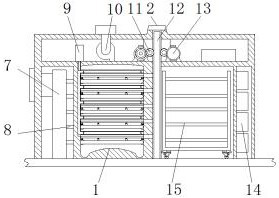

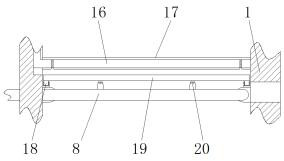

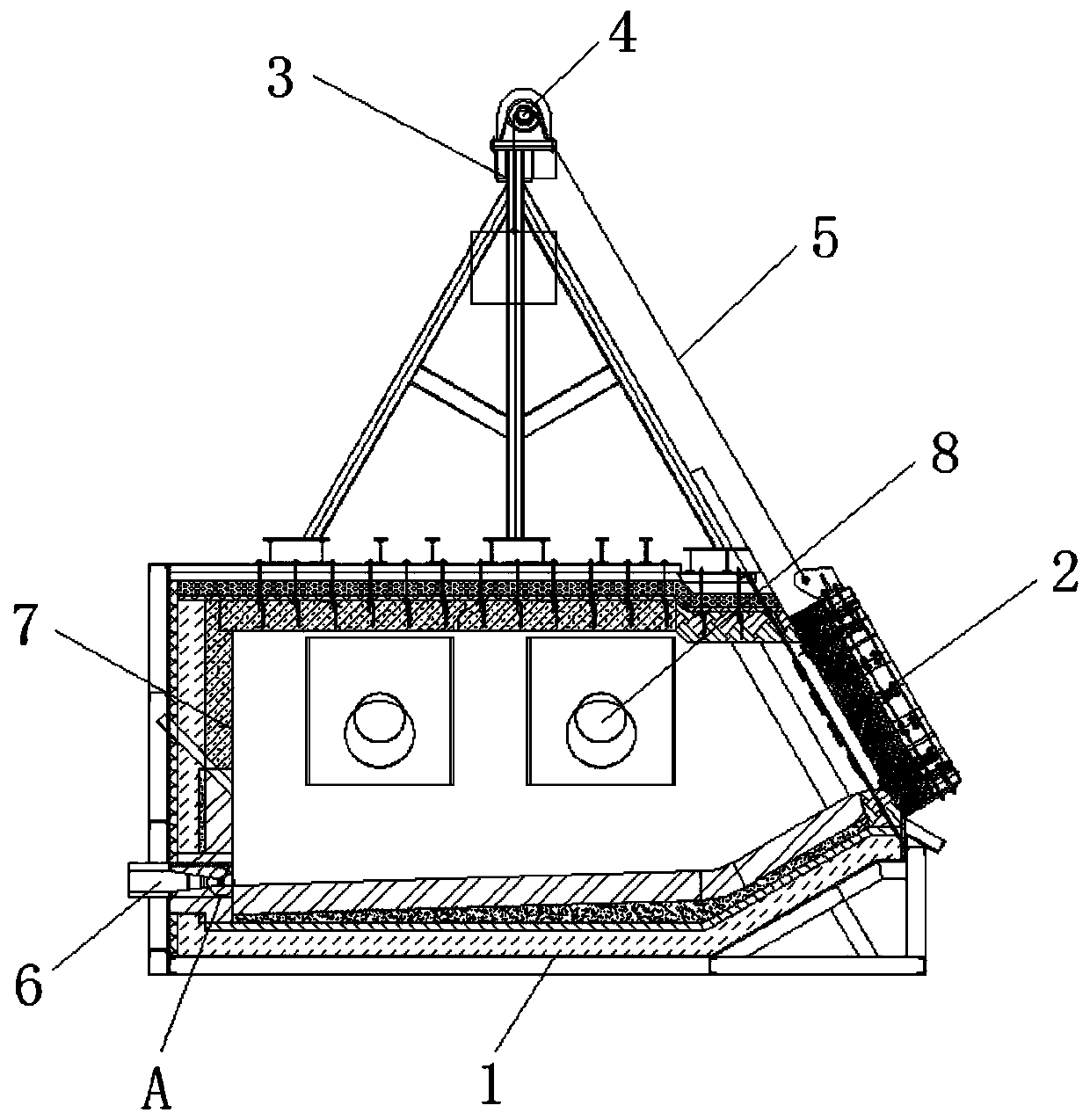

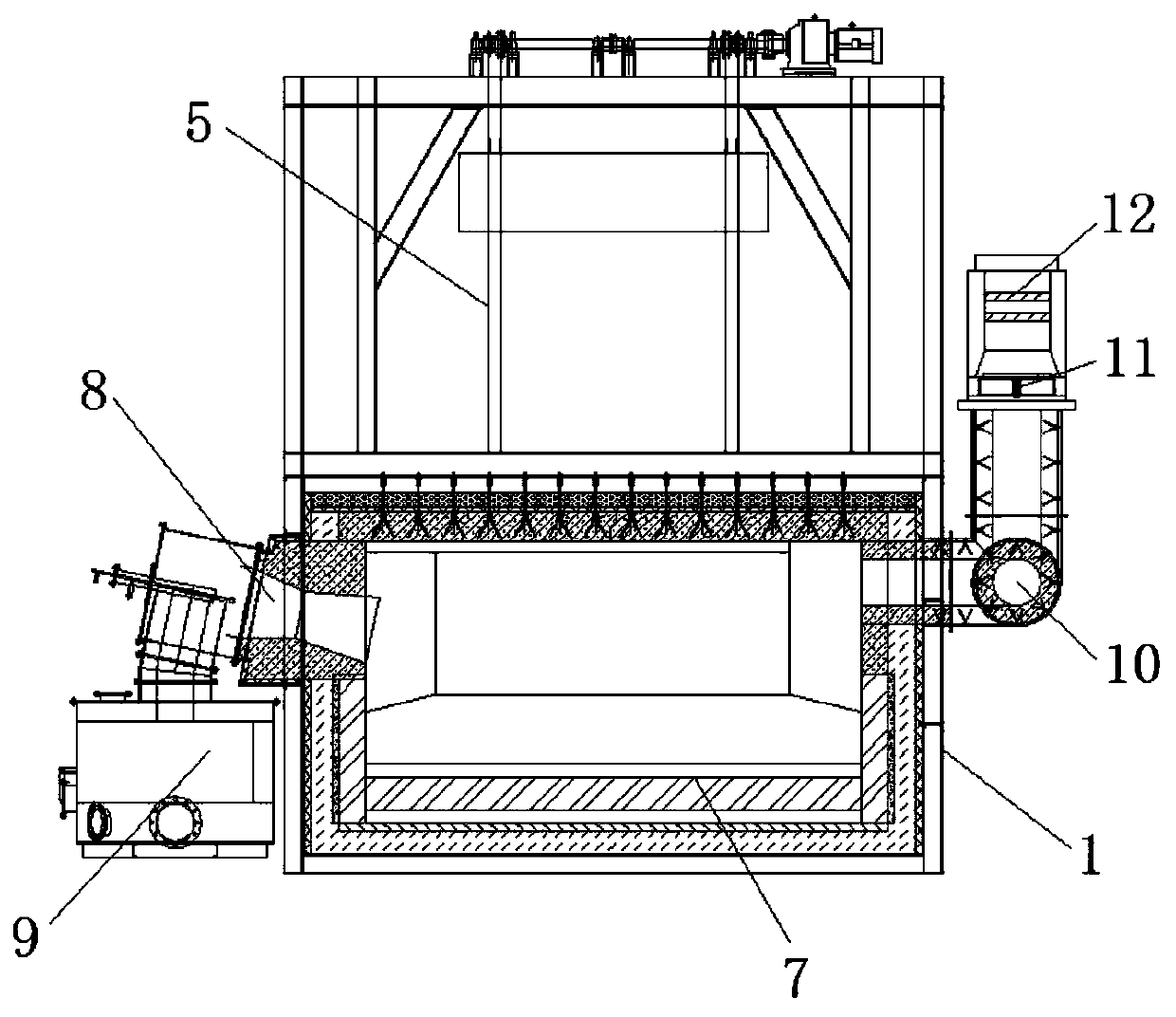

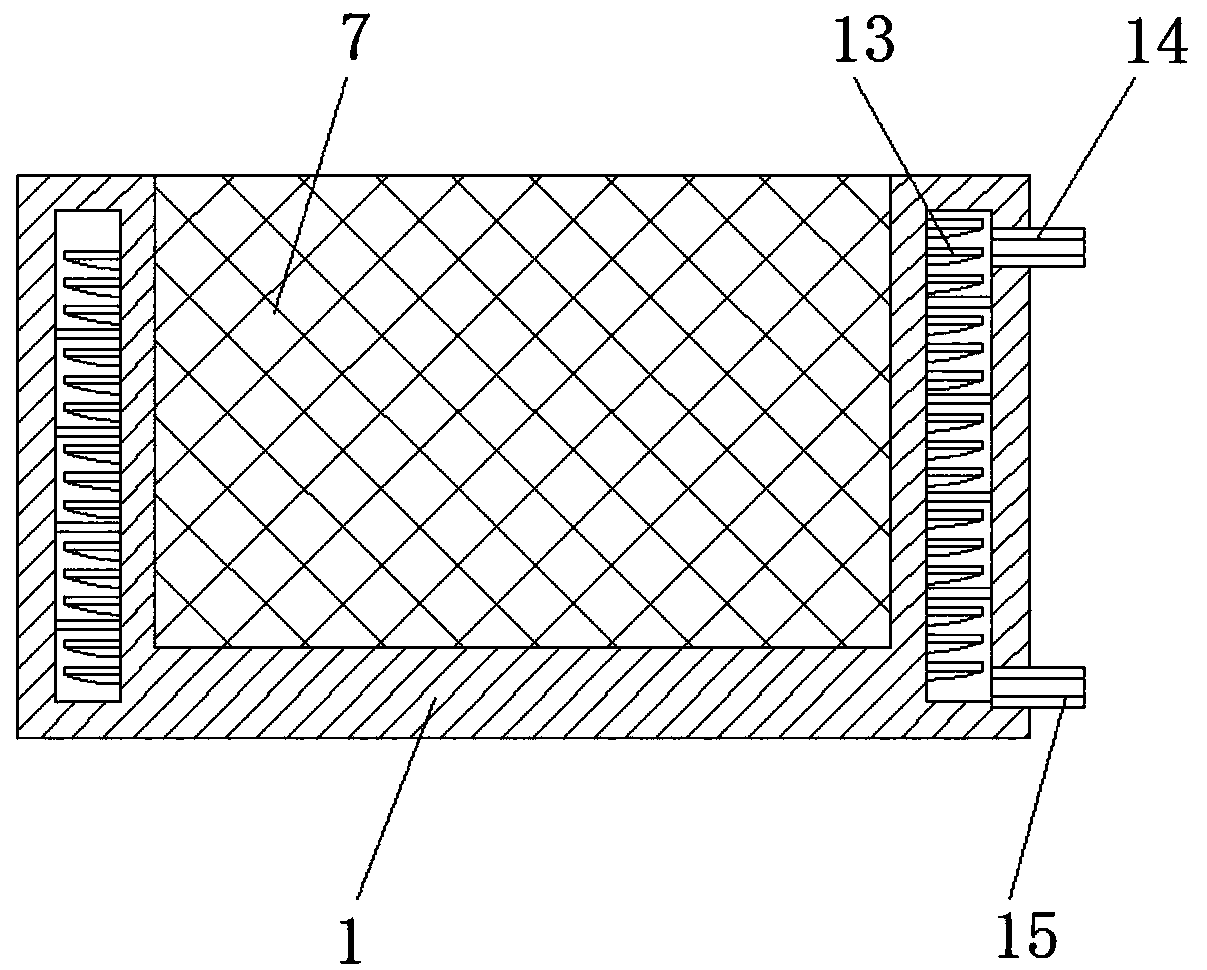

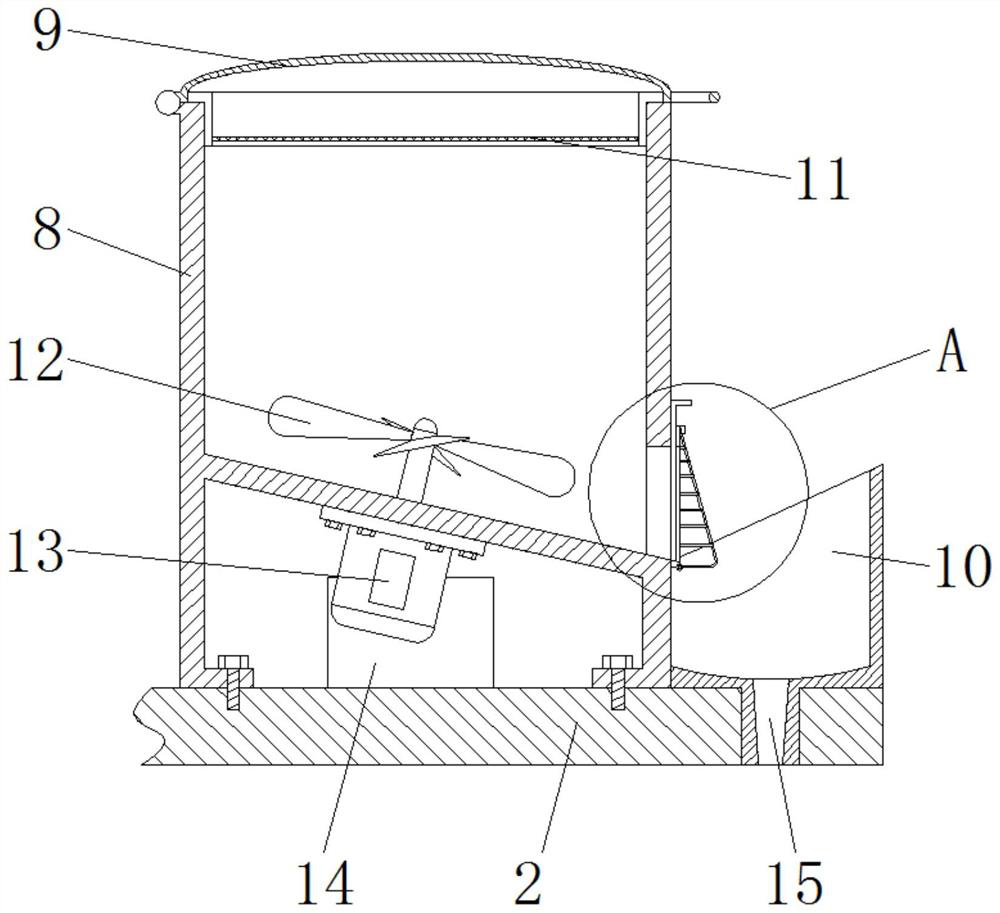

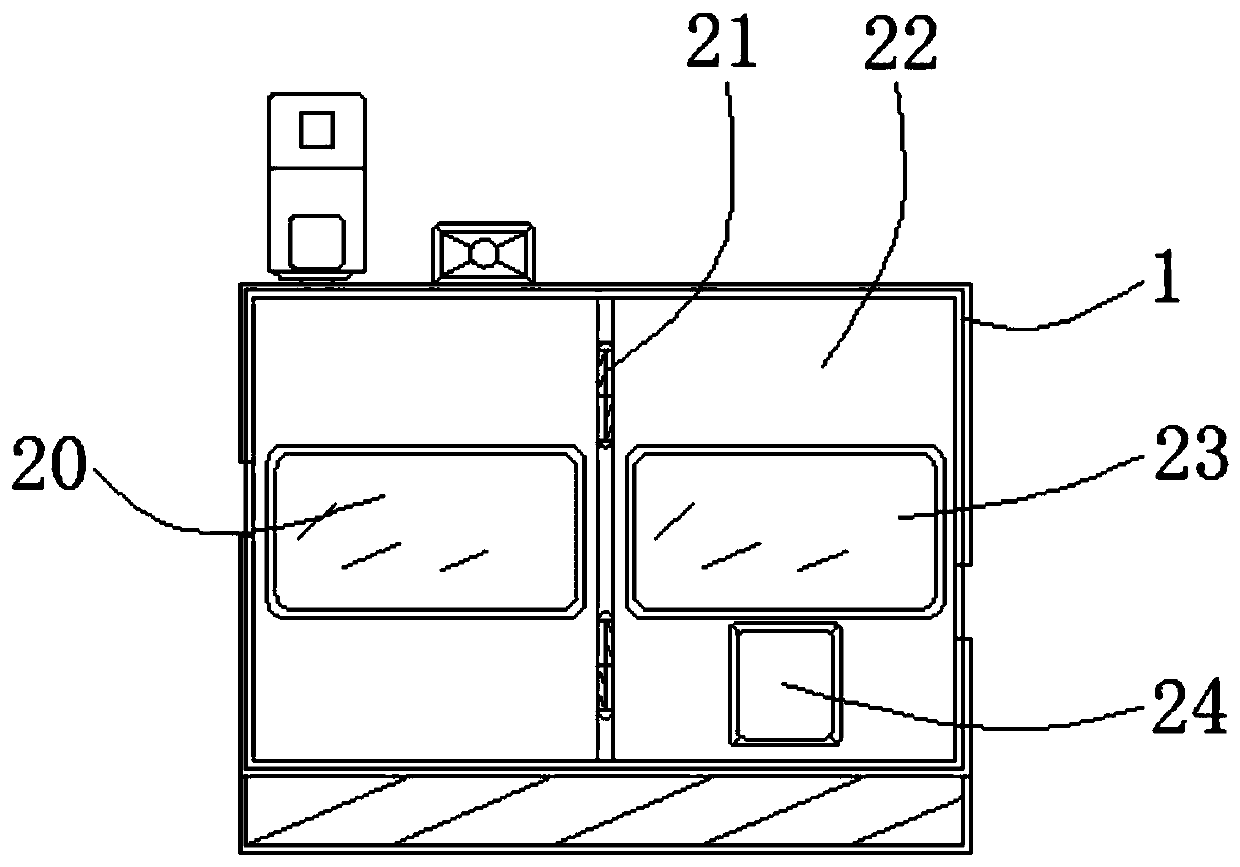

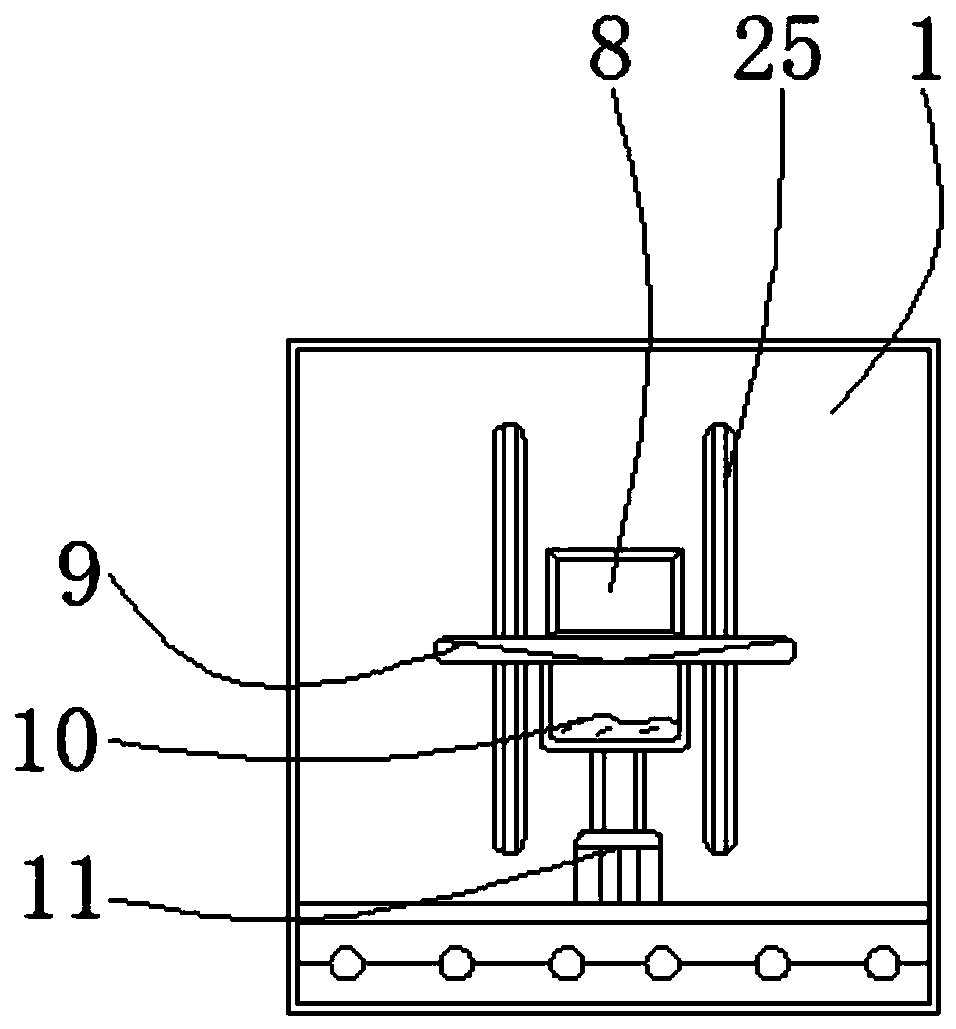

Convenient-to-discharge traditional Chinese medicinal material slice drying integrating equipment

ActiveCN109910071AAvoid pollutionImprove processing efficiencyDrying solid materialsDrying machines with local agitationBiochemical engineeringEngineering

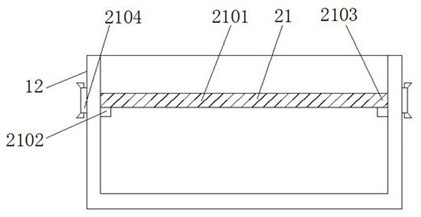

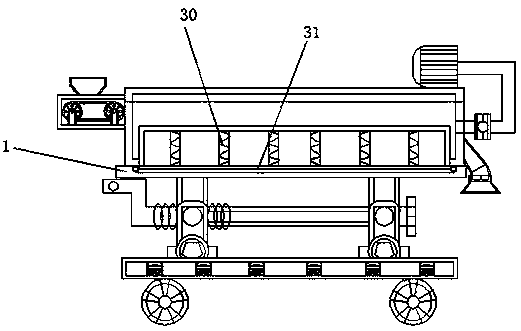

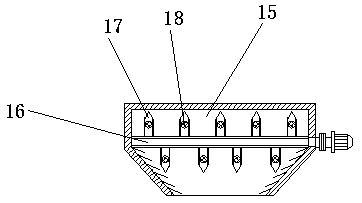

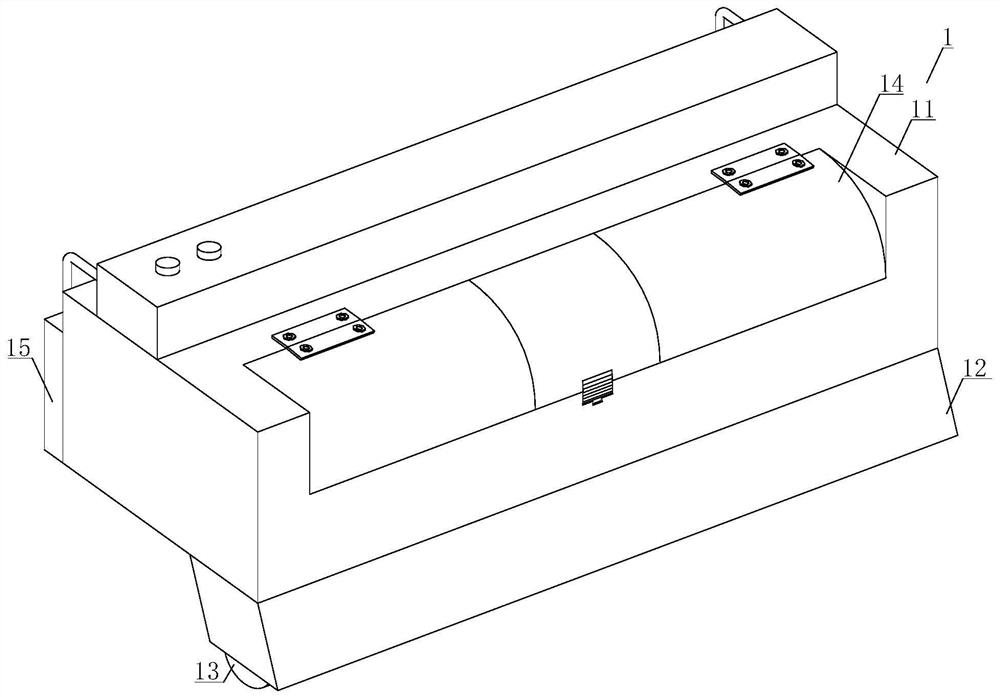

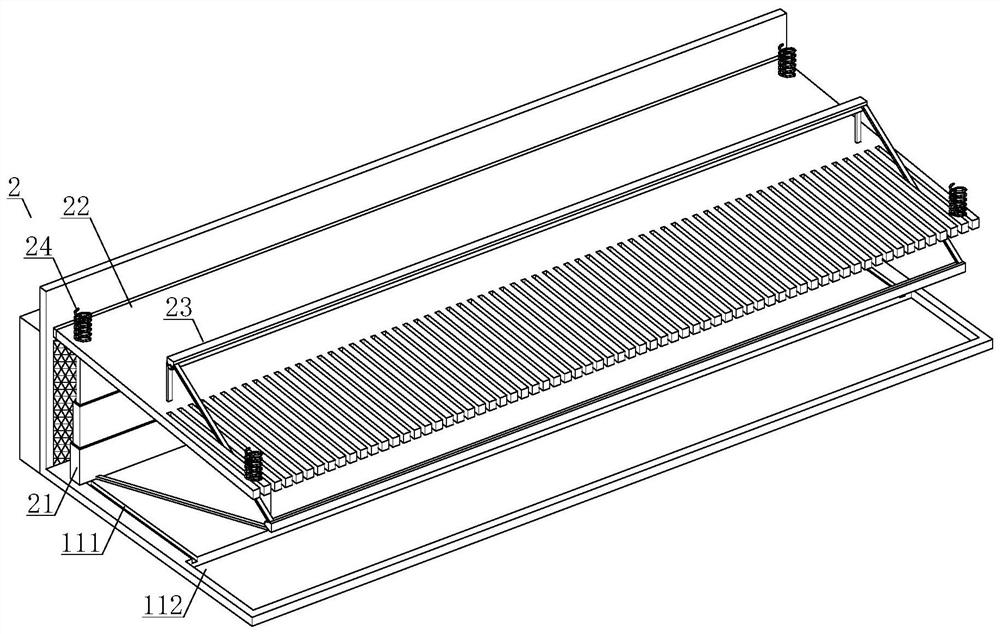

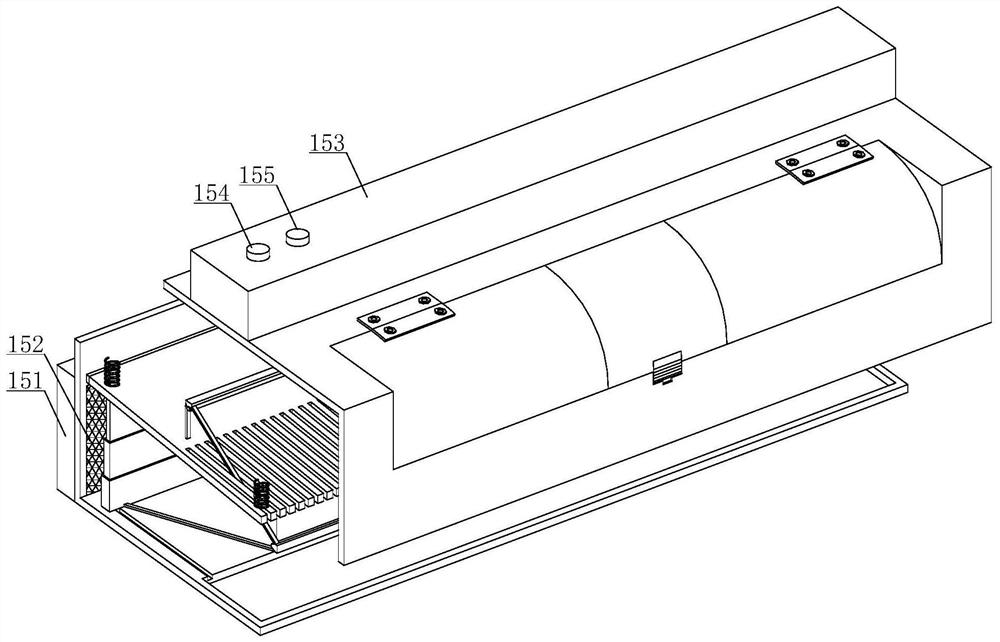

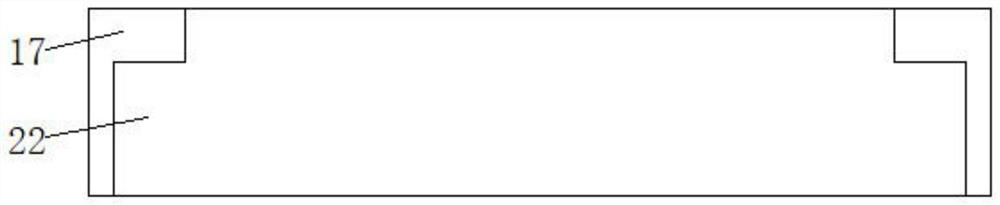

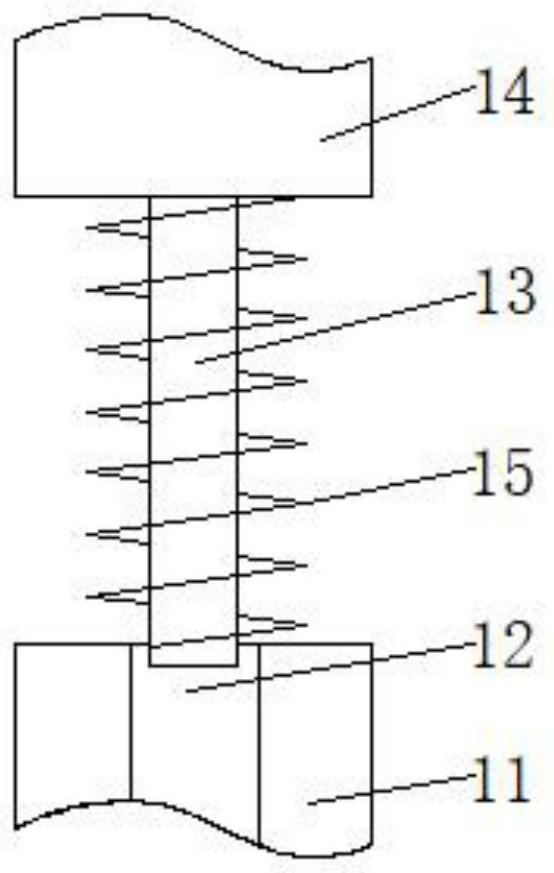

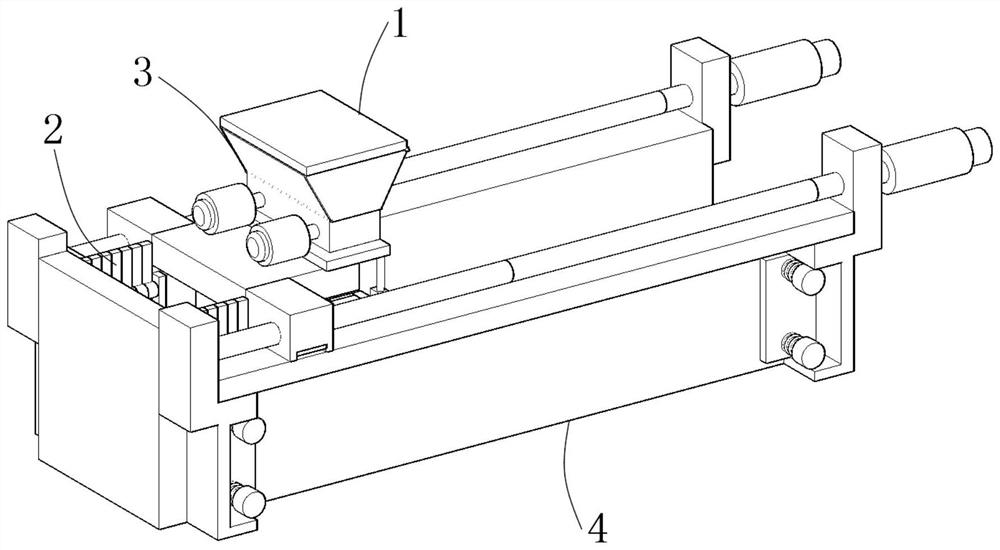

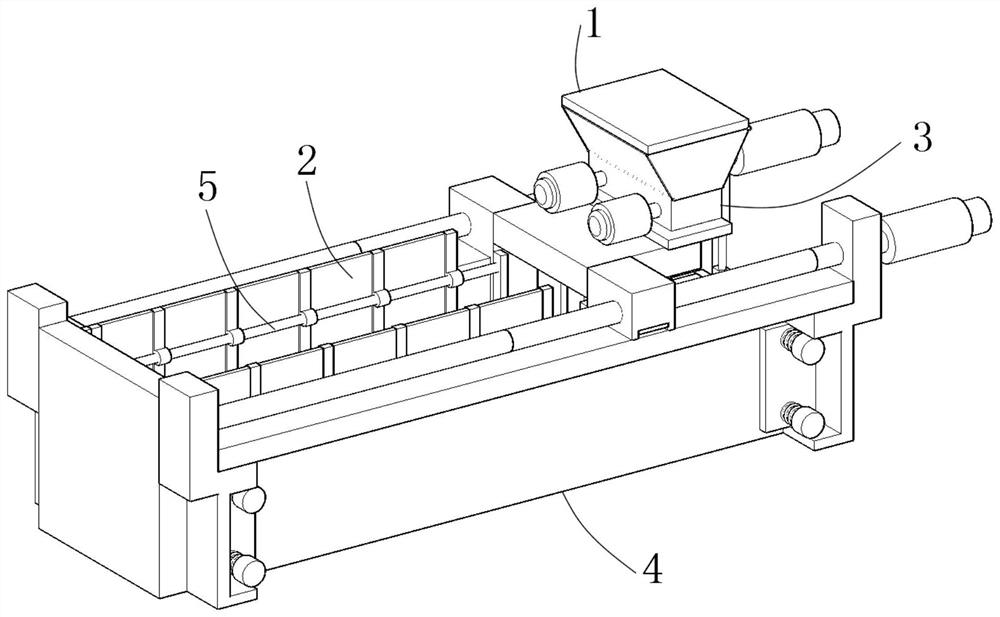

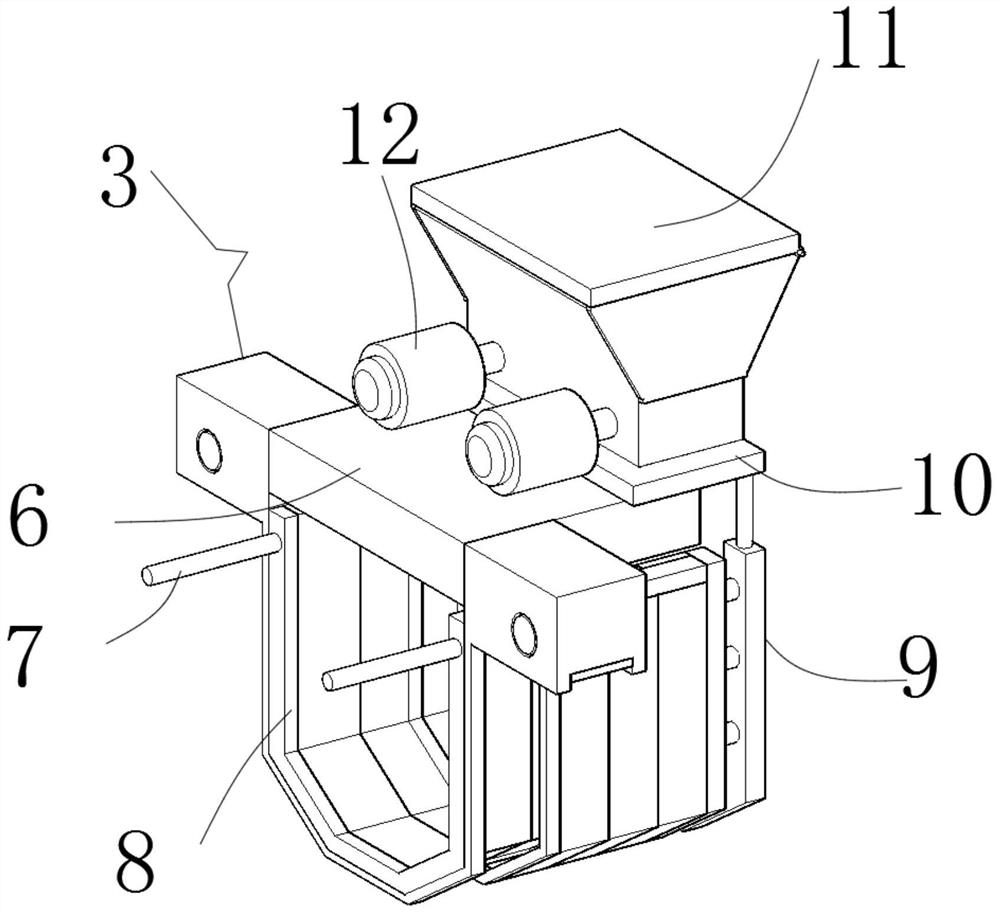

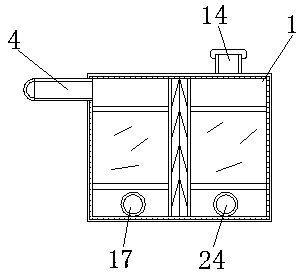

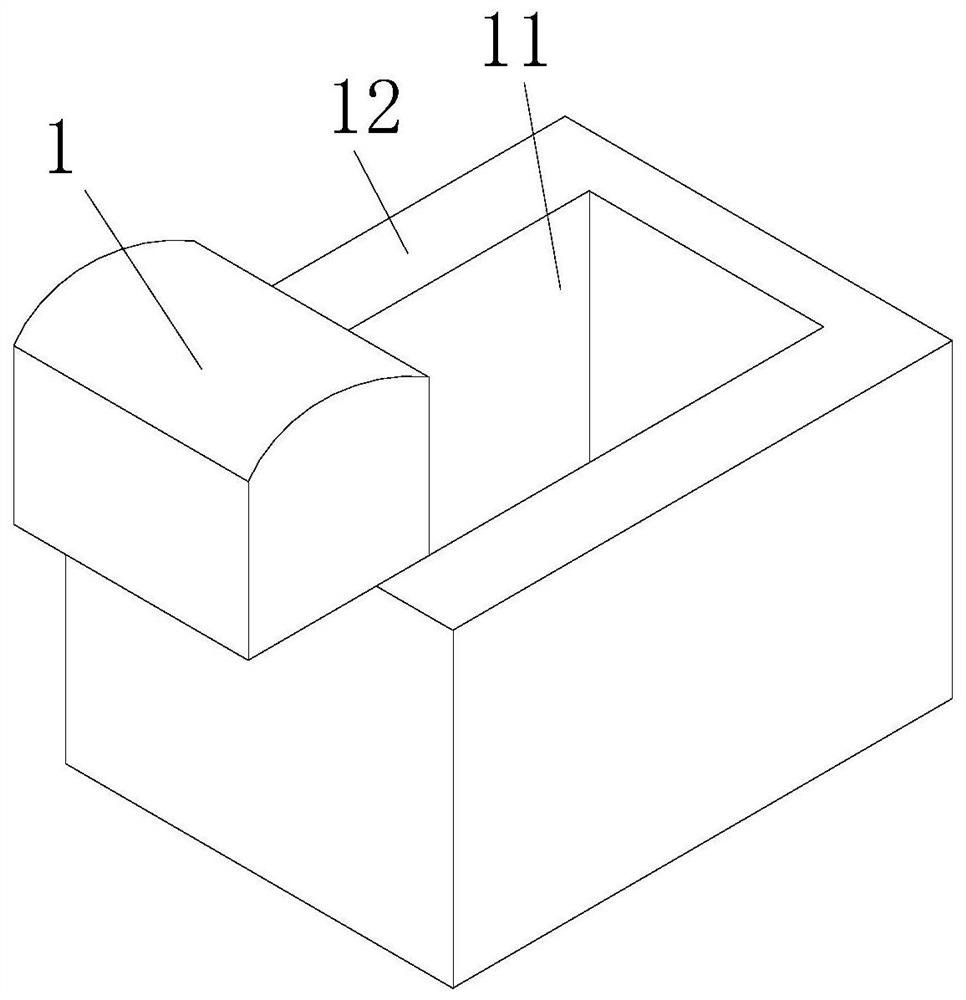

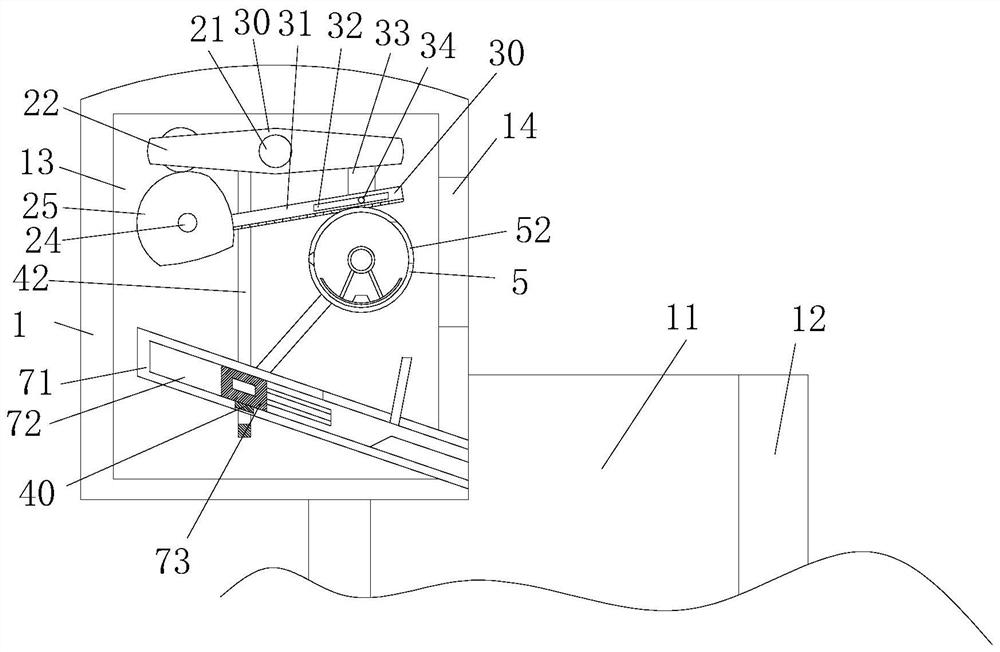

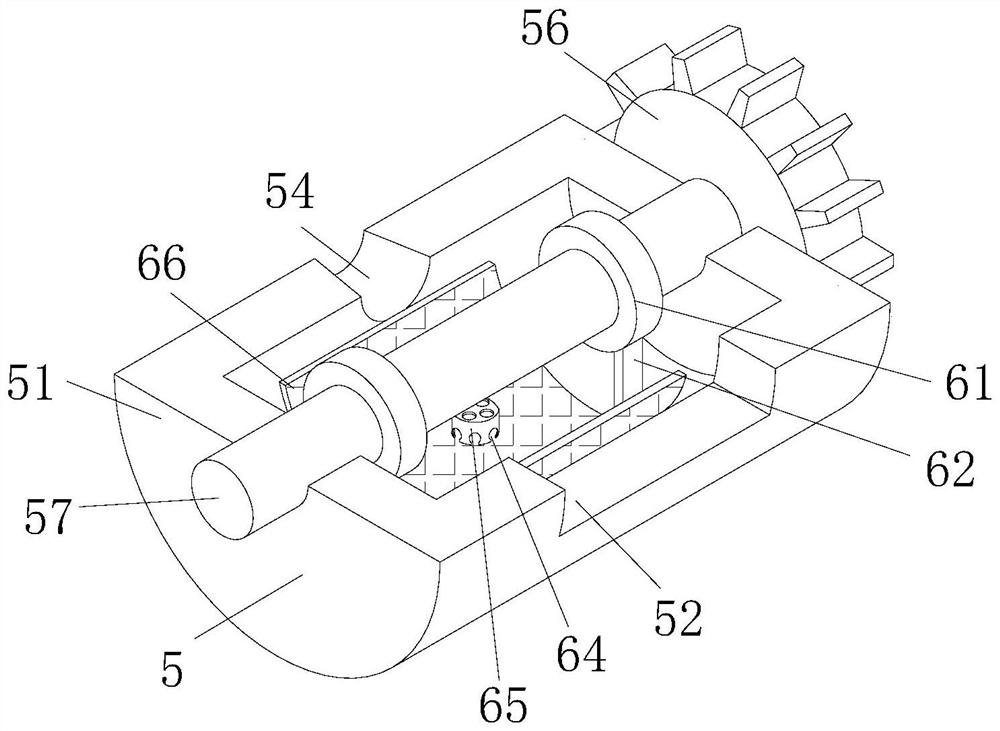

The invention discloses convenient-to-discharge traditional Chinese medicinal material slice drying integrating equipment. The equipment comprises a device body, a control panel, a first electric telescopic rod and a rotary shaft, a discharging door and a feeding door are installed on the outer side of the device body, the discharging door and the feeding door are provided with observation windows, the inner side of the control panel is connected with a heating device, the outer side of the heating device is fixedly provided with a heat guiding pipe, the lower side of the electric telescopic rod is fixedly provided with a device body, a gas discharging pump is installed in the device body, the upper side of the heat guiding pipe is fixedly provided with a feeding rolling shaft and a discharging rolling shaft, the upper sides of the feeding roller shaft and the discharging rolling shaft are connected with material placing plates. The equipment is provided with a slicing cutter and a blade clamping plate so that slicing and drying can be conducted simultaneously, the labor intensity of workers is effectively reduced, the sliced traditional Chinese medicinal materials can be preventedfrom bonding on the slicing cutter, and the normal operation of the drying of the traditional Chinese medicinal materials is ensured.

Owner:LINGNAN NORMAL UNIV

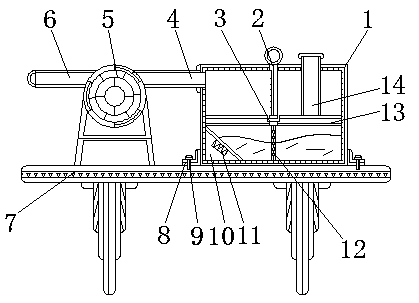

Tea processing machine

InactiveCN105432830AEasy to controlConvenient discharge workPre-extraction tea treatmentDrive wheelSolenoid valve

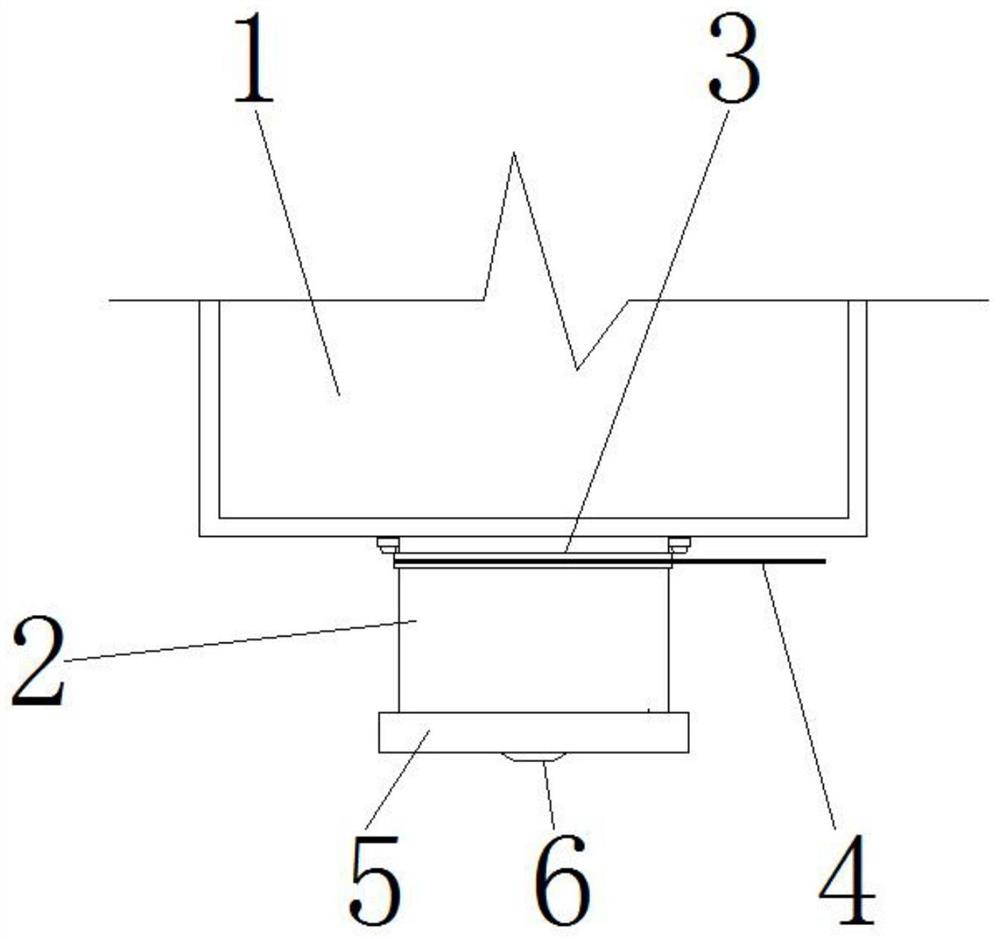

The invention discloses a tea processing machine comprising a shell and a heating wire, wherein a temperature sensor is arranged on the upper end at the right side of the inner cavity of the shell; the lower end of the outer side of the temperature sensor is provided with a humidity sensor; the upper end at the left side of the inner cavity of the shell is provided with the heating wire; the lower end of the inner cavity of the shell is provided with a baffle; the middle end of the inner cavity of the baffle is provided with a first discharging opening; the lower end of the inner cavity of the first discharging opening is provided with a solenoid valve; the right end of the bottom of the inner cavity of the shell is provided with a driven wheel which is in transmission connection with a driving wheel through a conveyor belt. The tea processing machine is provided with the temperature sensor, can display temperature in the shell through a display screen, is convenient for controlling temperature in the shell by people, can automatically switch off the heating wire and stop continuous heating when the temperature reaches the highest preset value, can automatically switch on the heating wire when the temperature reaches the lowest preset value, and thus the self-heating of the heating wire can be realized, the loss of the electric energy can be reduced and the stir-frying quality of the tea leaves can also be ensured.

Owner:HENGYANG ZHIYUAN AGRI TECH

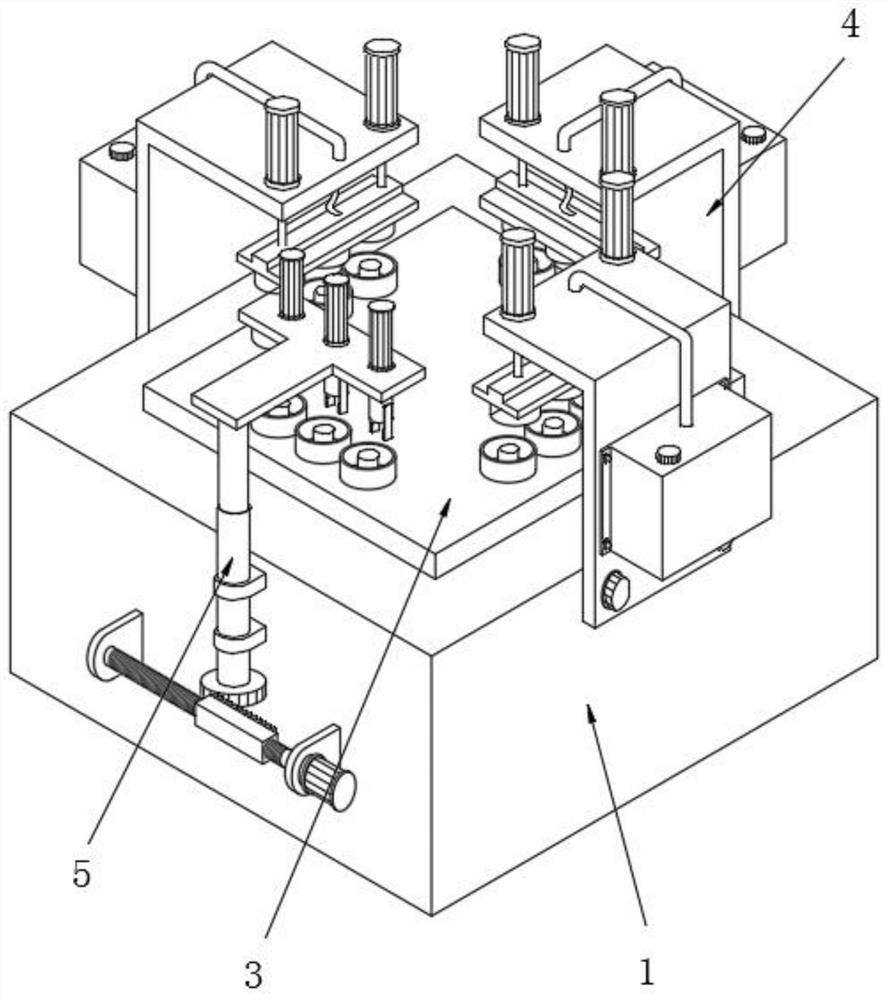

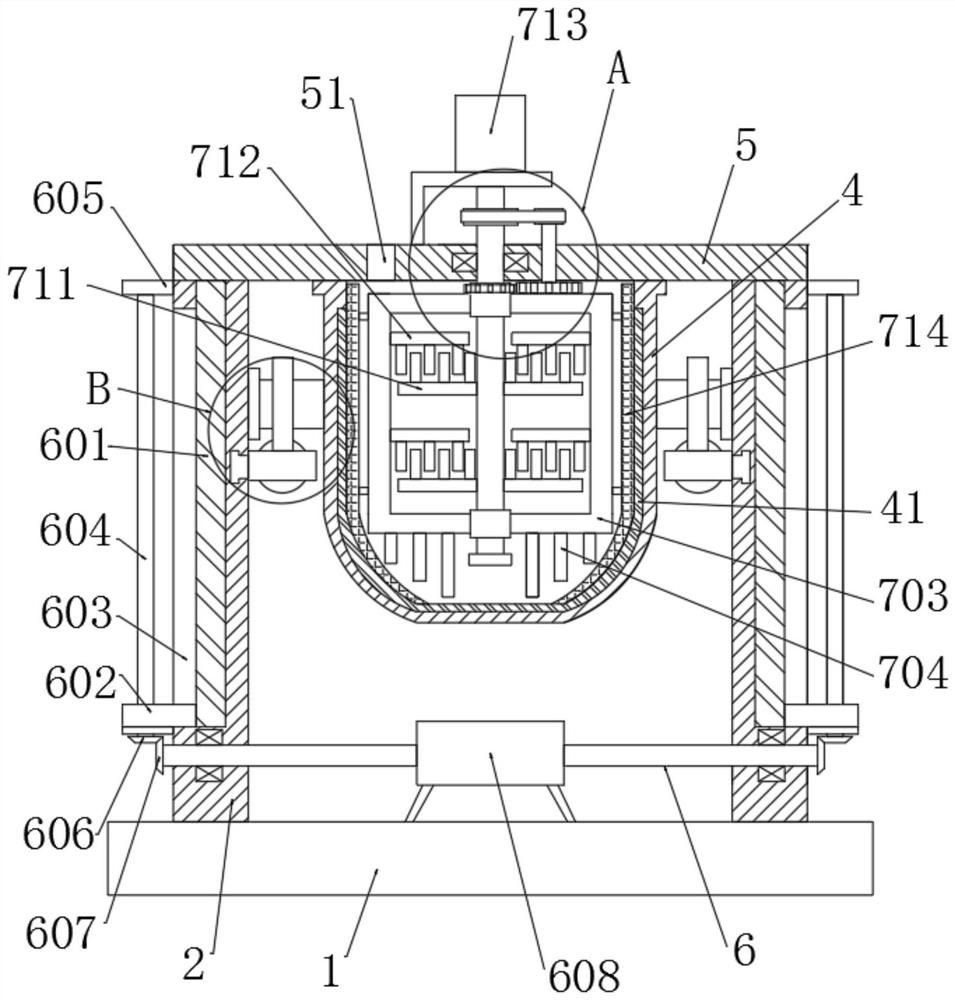

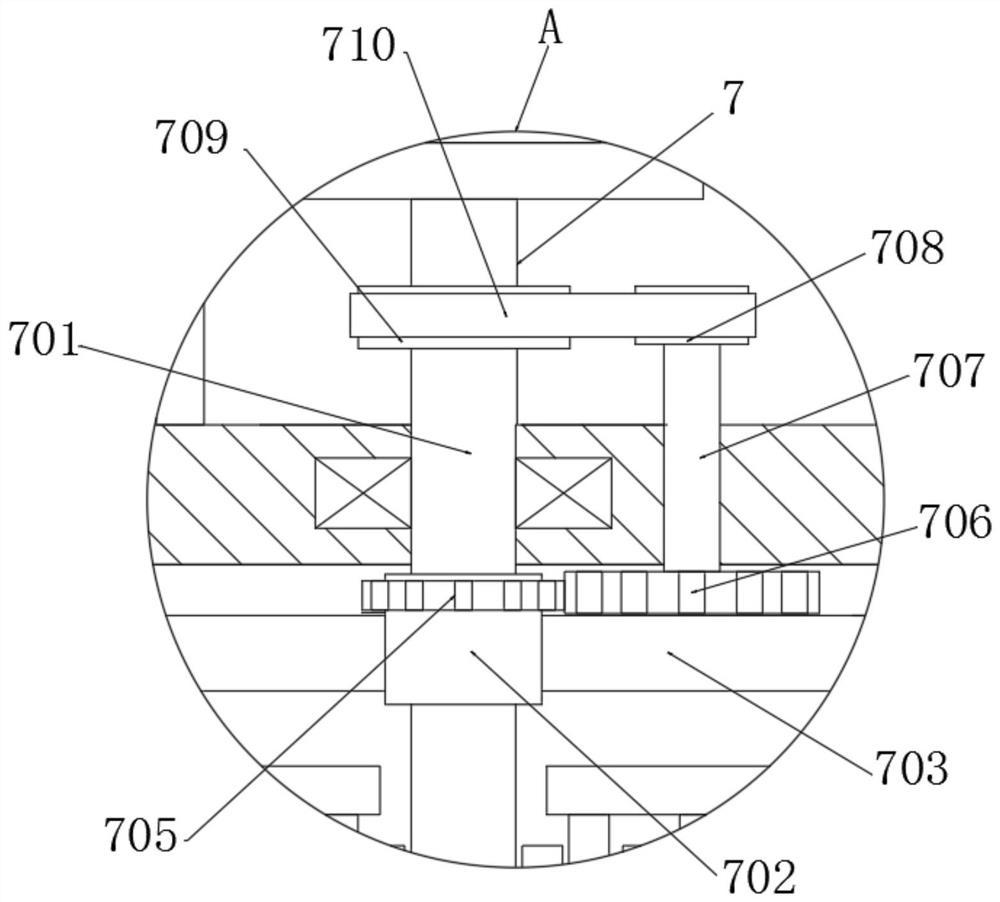

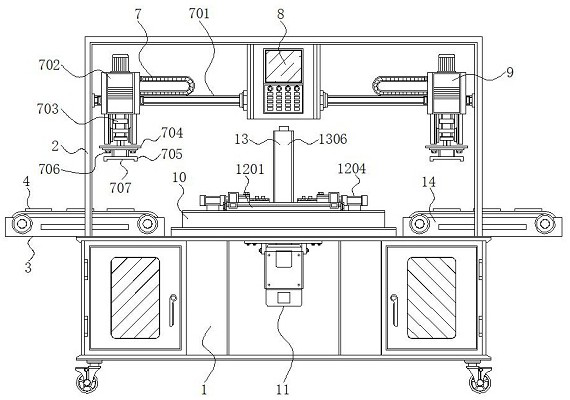

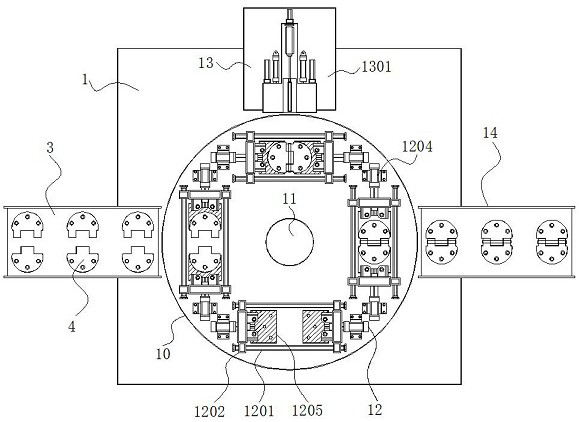

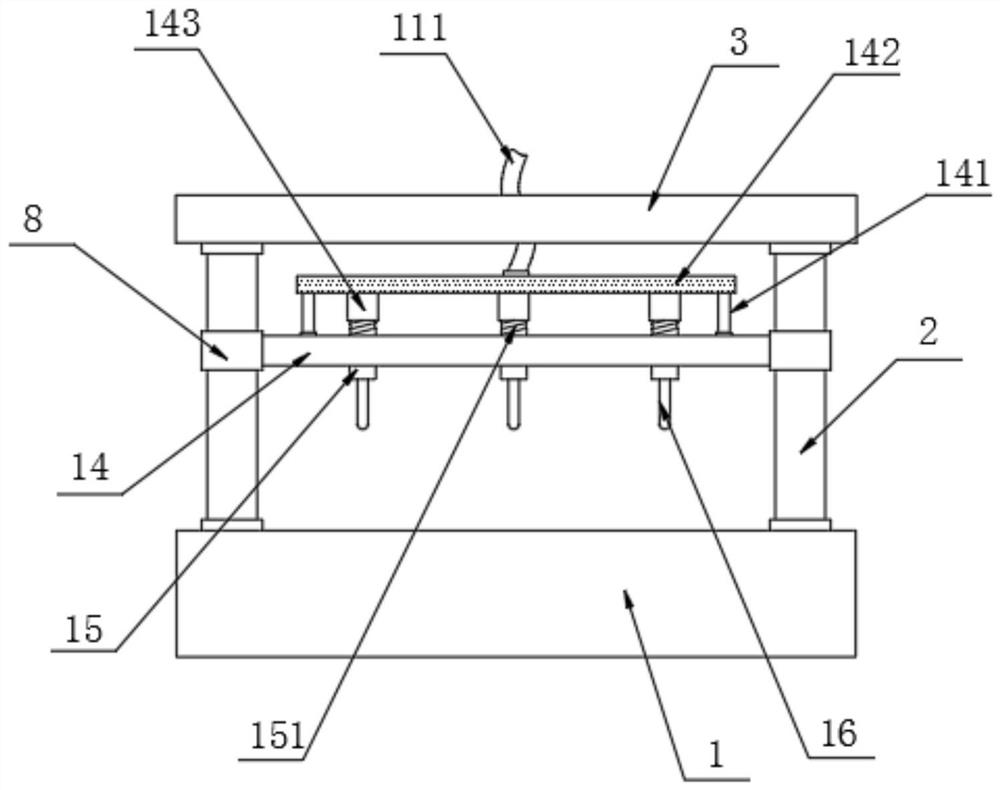

Three-color injection molding rapid forming mold based on vehicle lamp and control forming method of three-color injection molding rapid forming mold

PendingCN112959598AReduce labor intensityIncrease injection speedCoatingsCircular discElectric machine

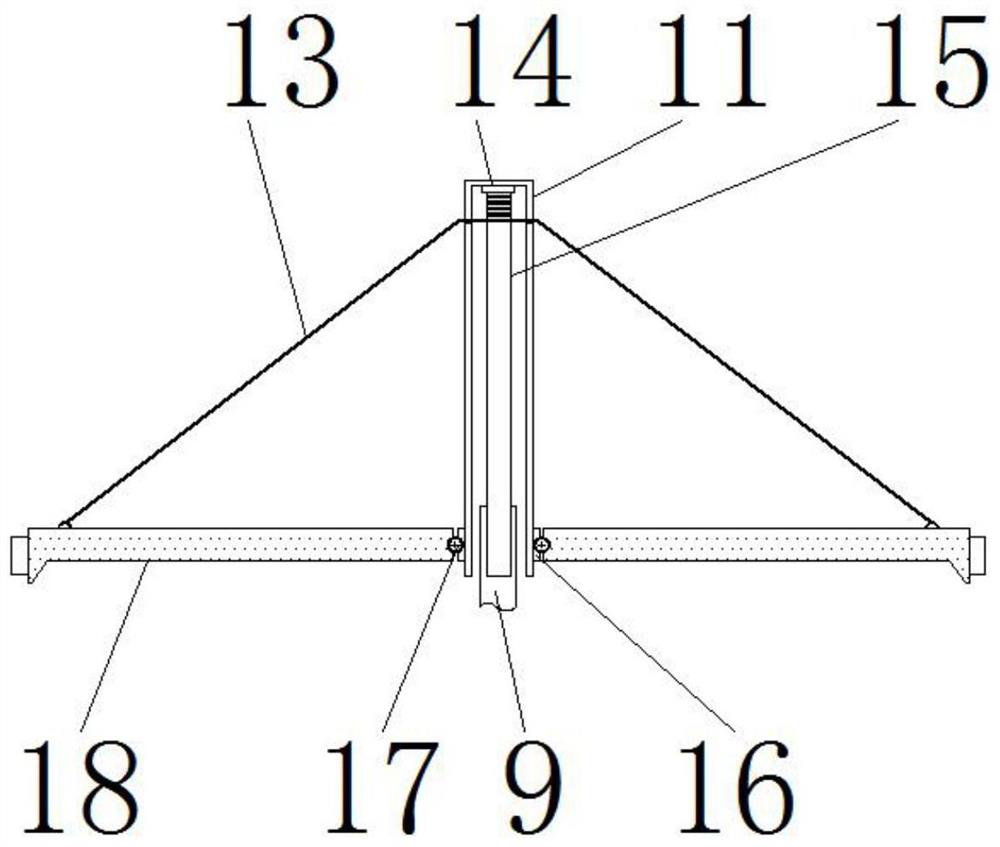

The invention discloses a three-color injection molding rapid forming mold based on a vehicle lamp and a control forming method of the three-color injection molding rapid forming mold. The mold comprises a box body seat, a driving assembly is arranged in the box body seat, a base part is rotationally arranged in the middle of the upper surface of the box body seat, injection molding assemblies are arranged on the two side faces and the rear surface of the box body seat correspondingly, and a discharging mechanism is arranged on the front surface of the box body seat. The invention relates to the technical field of vehicle lamp mold machining. According to the three-color injection molding rapid forming mold based on the vehicle lamp and the control forming method of the three-color injection molding rapid forming mold, a convex shaft is slidably arranged in one sliding groove in a square plate, the upper end of the convex shaft is fixedly connected with the lower surface of one side of a disc, and a rotating motor is fixedly connected to the middle of the lower surface of a round plate; and the vehicle lamp three-color injection molding work can be automatically completed, the injection molding speed and efficiency are high, compared with traditional equipment, the equipment is more automatic, and the injection molding precision is high, so that the labor intensity of workers is reduced.

Owner:杭州索凯实业有限公司

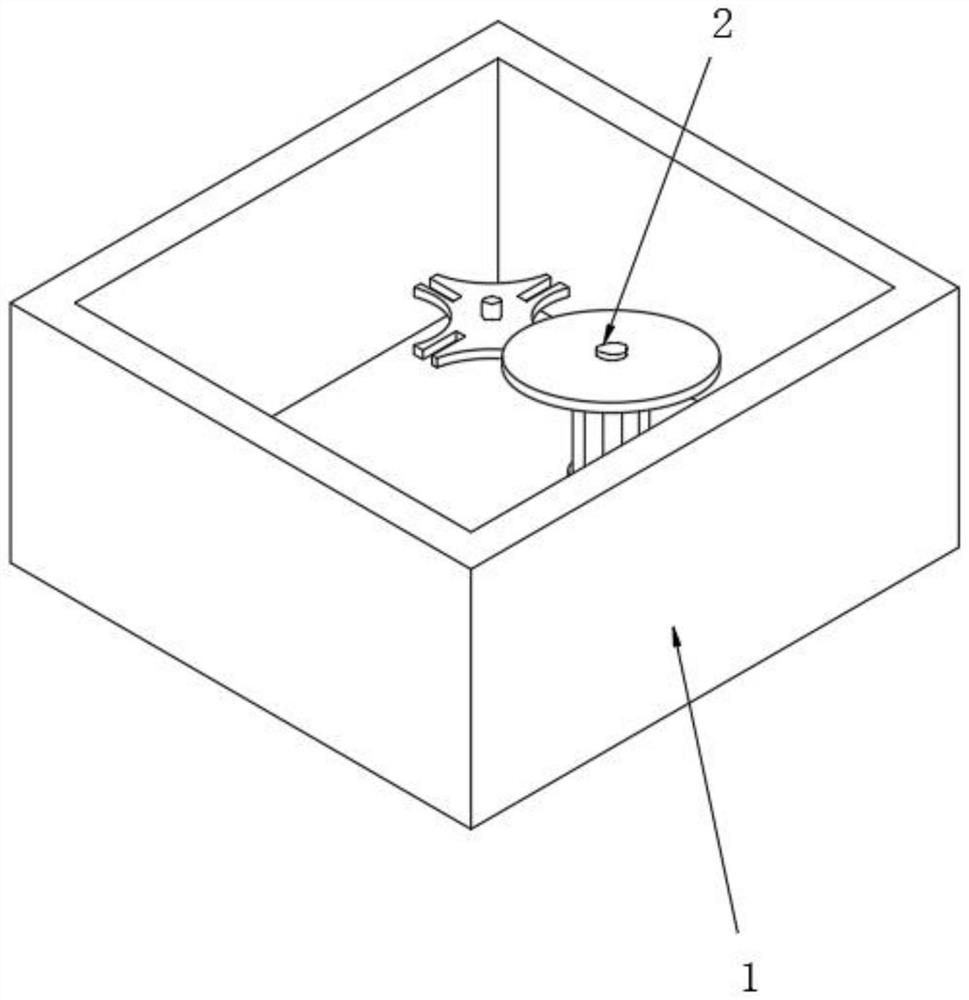

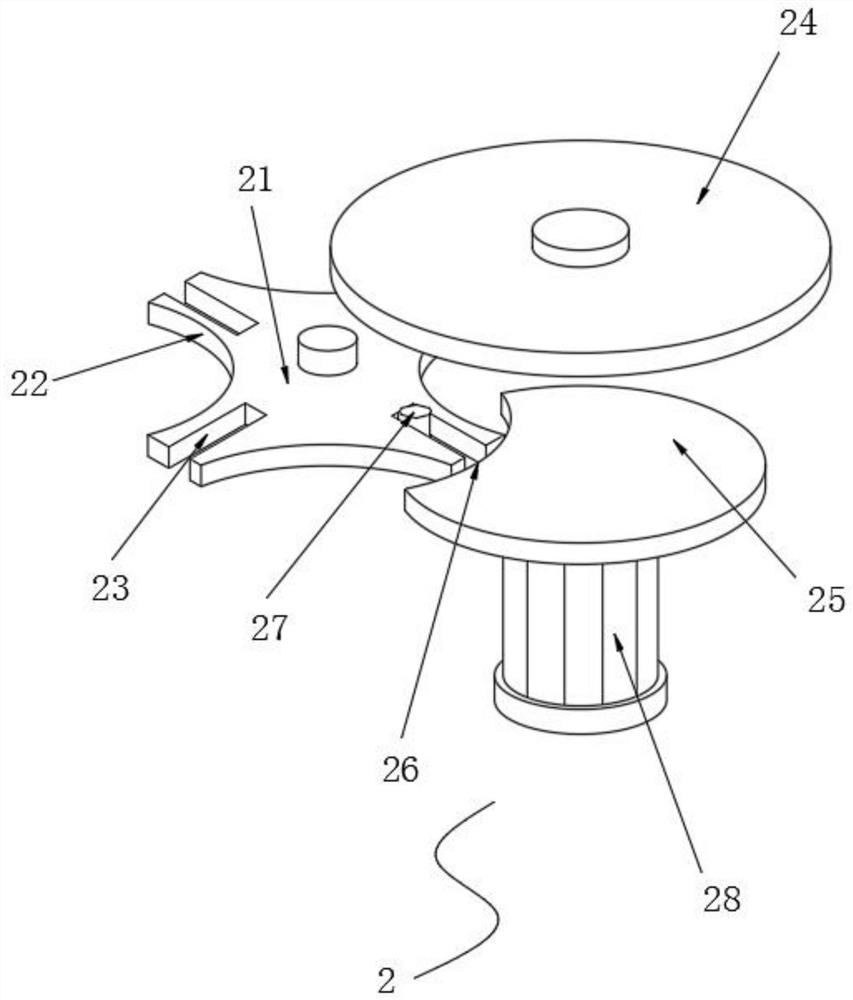

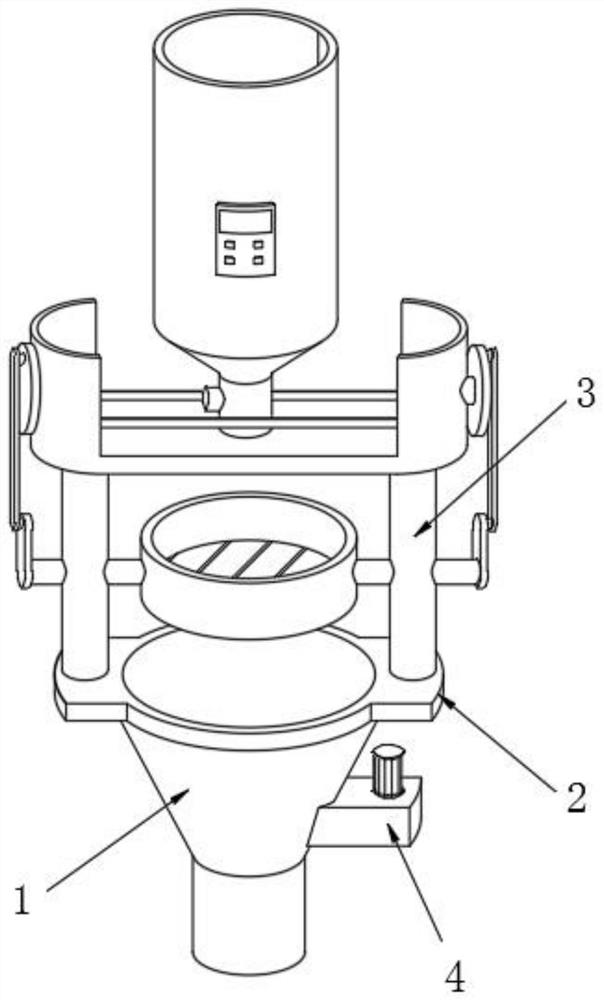

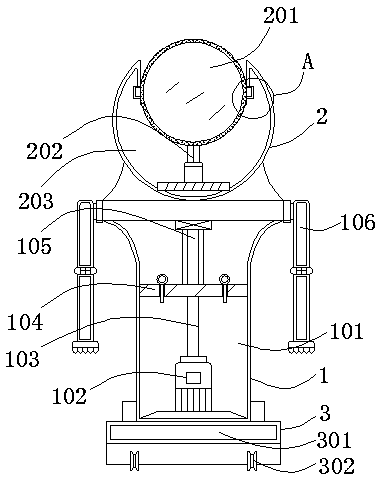

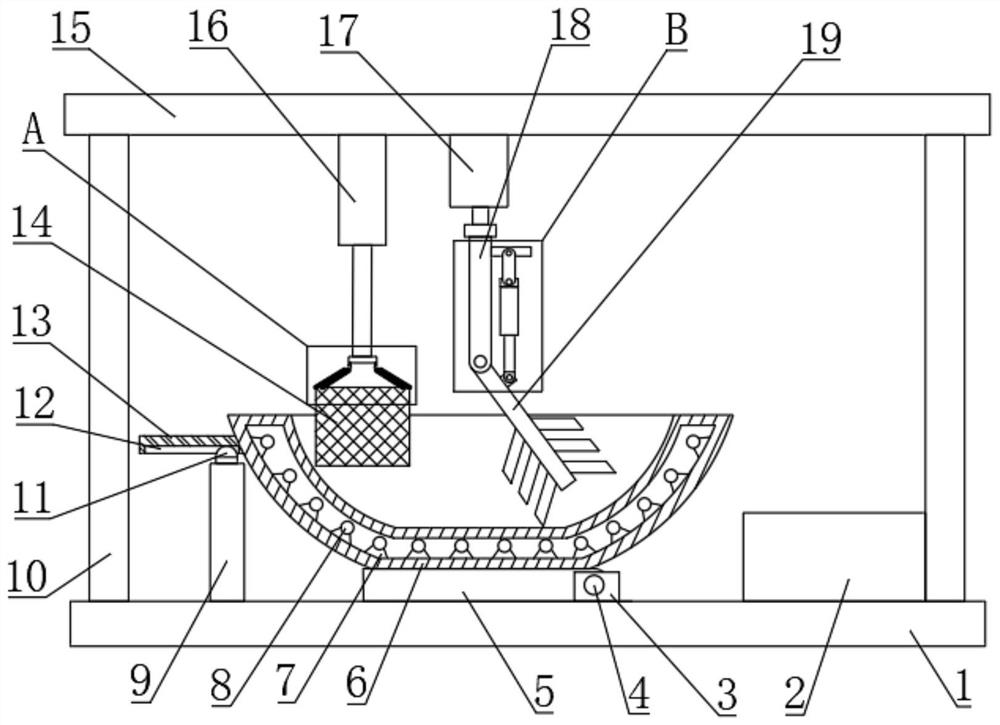

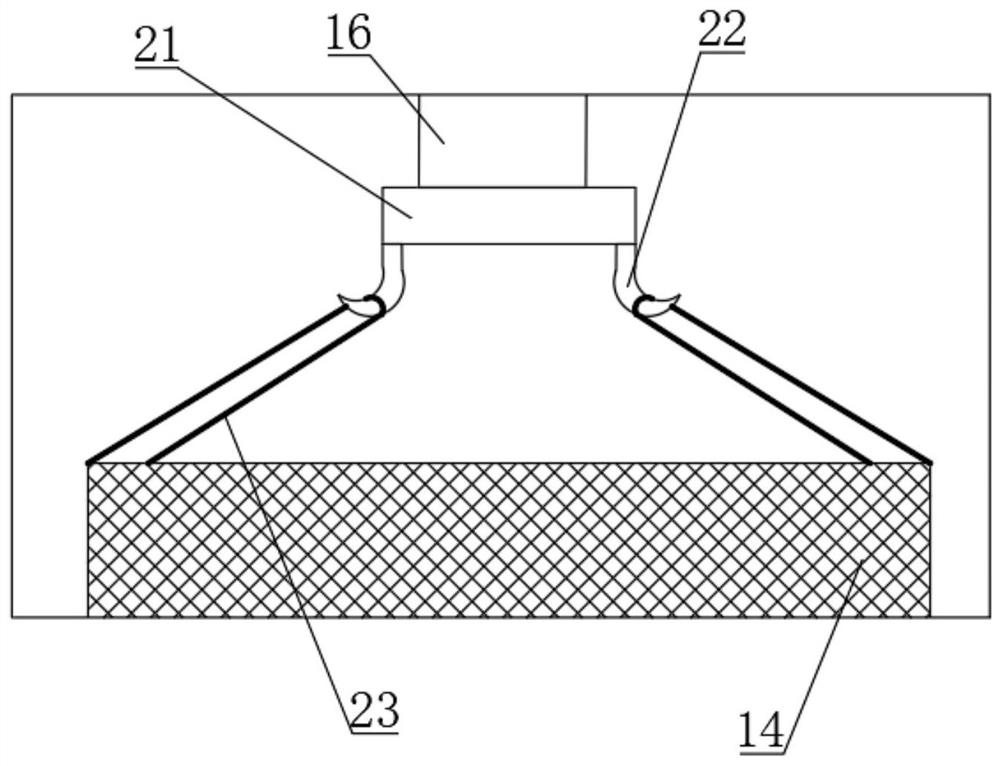

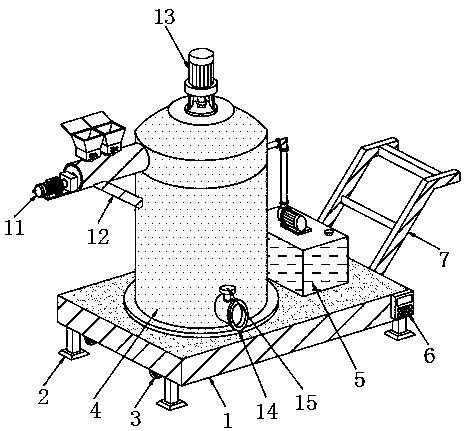

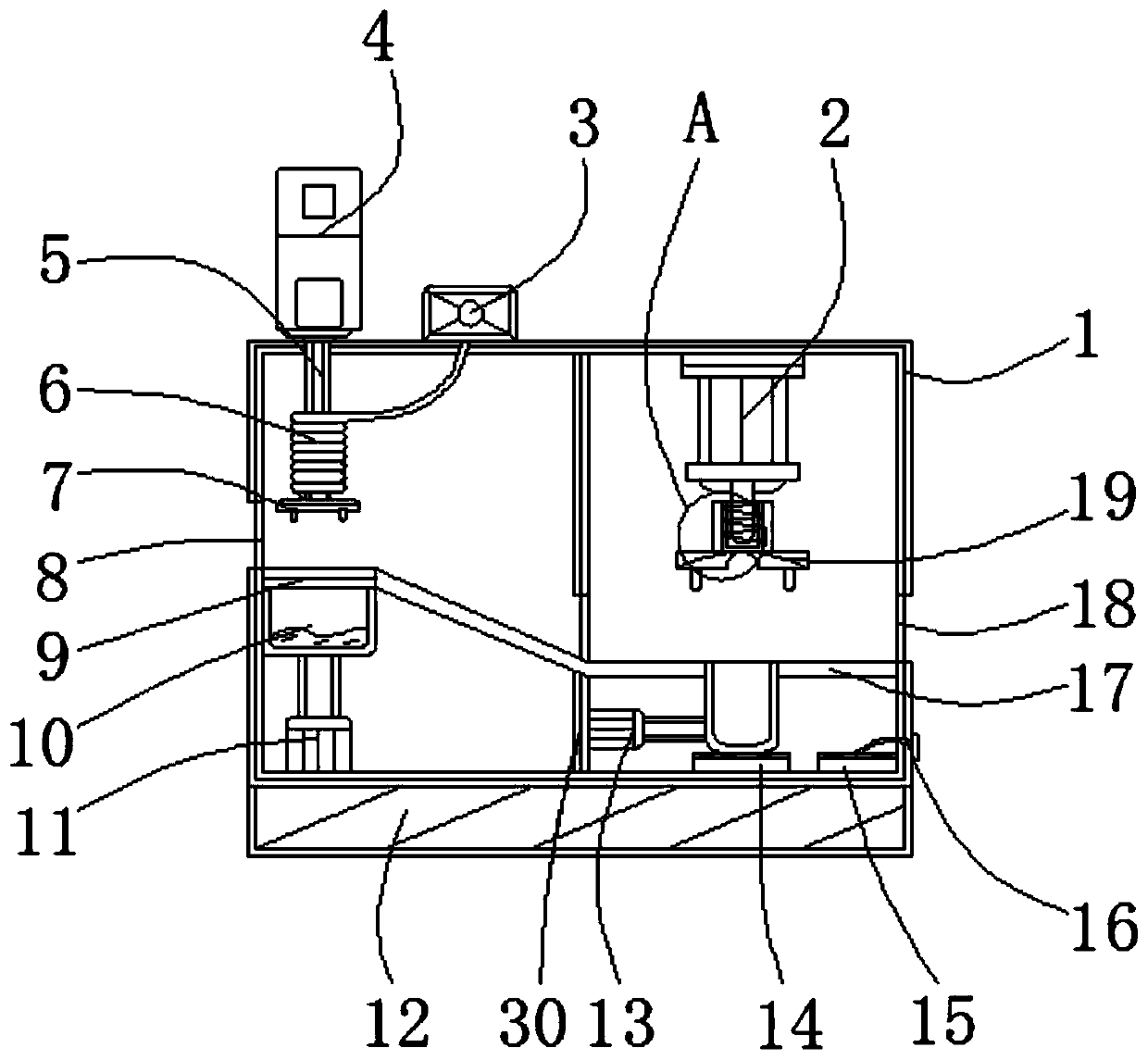

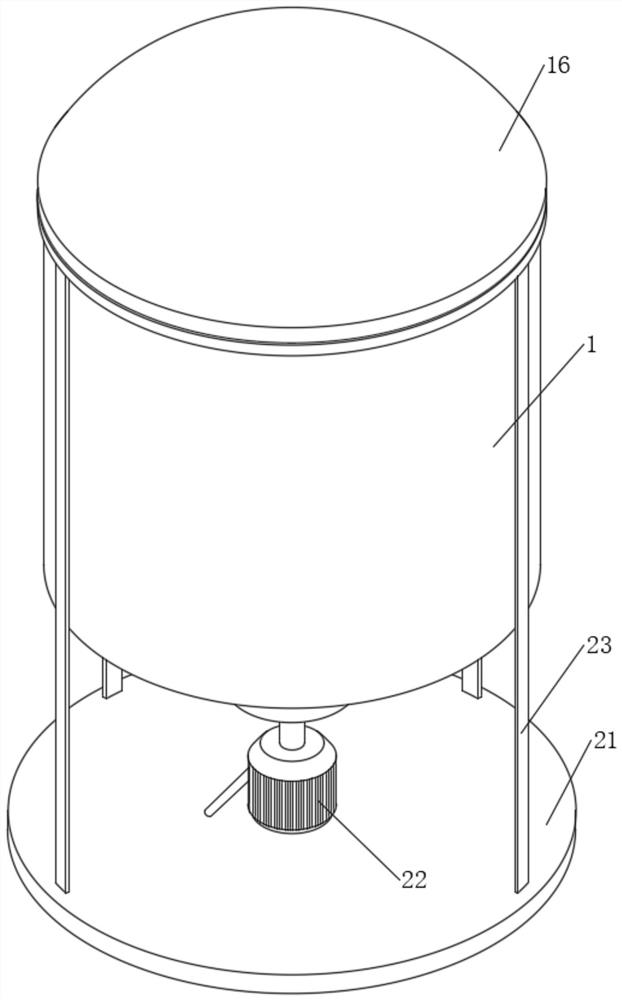

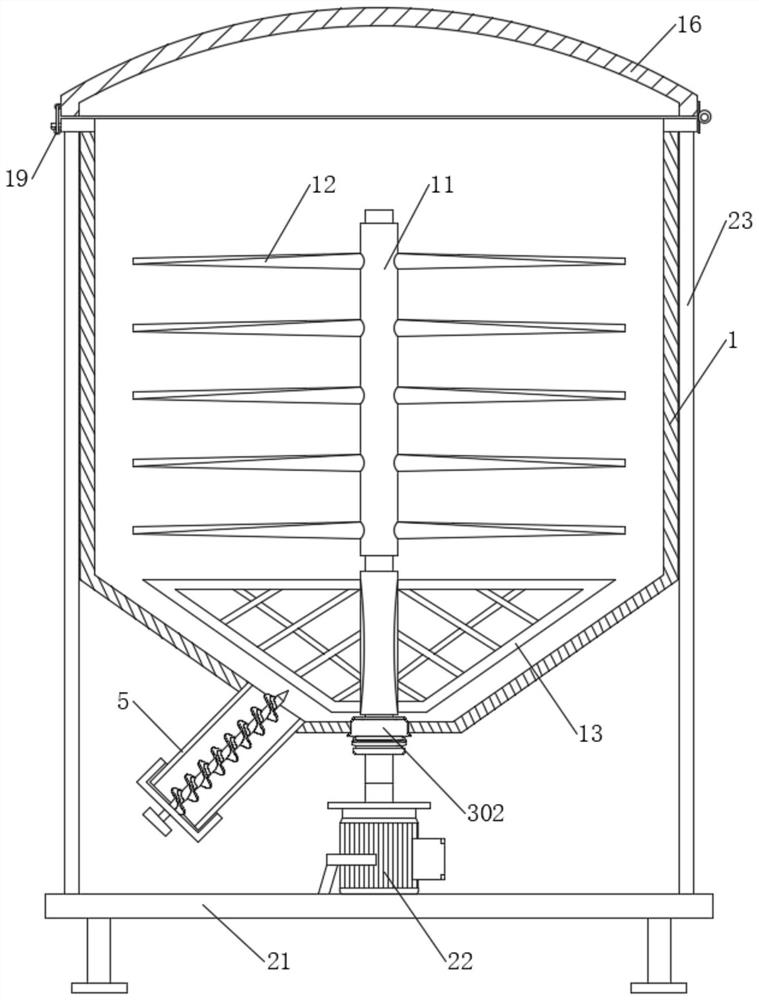

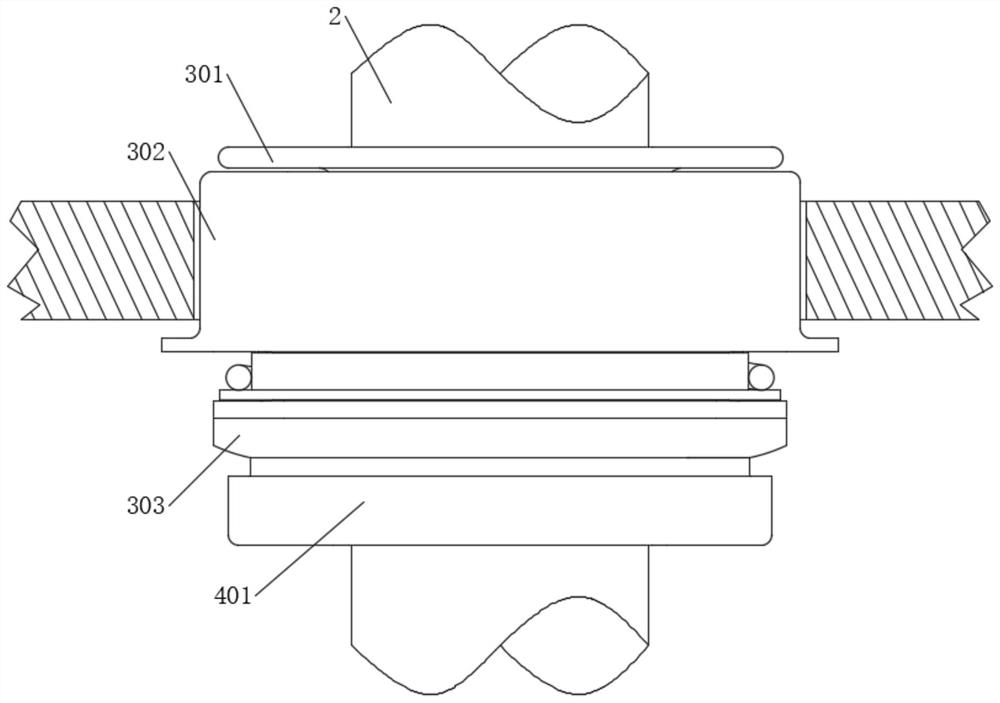

Vacuum emulsifying machine for beauty and skin care products

PendingCN113083069AEasy to pourPrevent burnsTransportation and packagingRotary stirring mixersProcess engineeringSkin Care Product

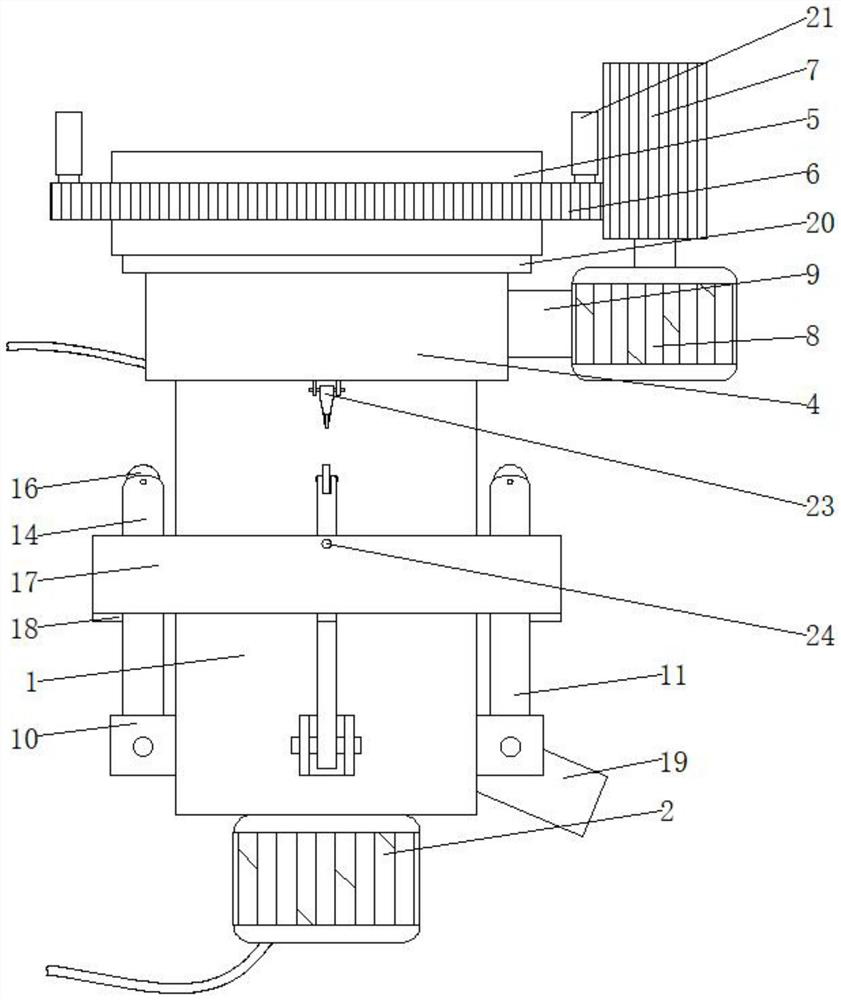

The invention belongs to the technical field of cosmetic processing equipment, particularly relates to a vacuum emulsifying machine for beauty and skin care products, and aims to solve the problems that an existing emulsifying machine is inconvenient for feeding cosmetic raw materials, is poor in stirring effect due to non-uniform heating when the cosmetic raw materials are stirred again, and stirred cosmetic raw materials are inconvenient to discharge. According to the scheme, the vacuum emulsifying machine comprises a supporting base, two symmetrical vertical plates are fixed to the top end of the supporting base, rotating shafts are rotationally connected to the opposite sides of the two vertical plates, and a stirring tank is fixed between the two rotating shafts. The cosmetic raw materials can be uniformly stirred through the stirring mechanism, and the cosmetic raw materials are uniformly heated while the stirring mechanism is matched with a heating plate for electrifying and heating, so that the stirring working efficiency is greatly improved.

Owner:上海莲煦实业有限公司

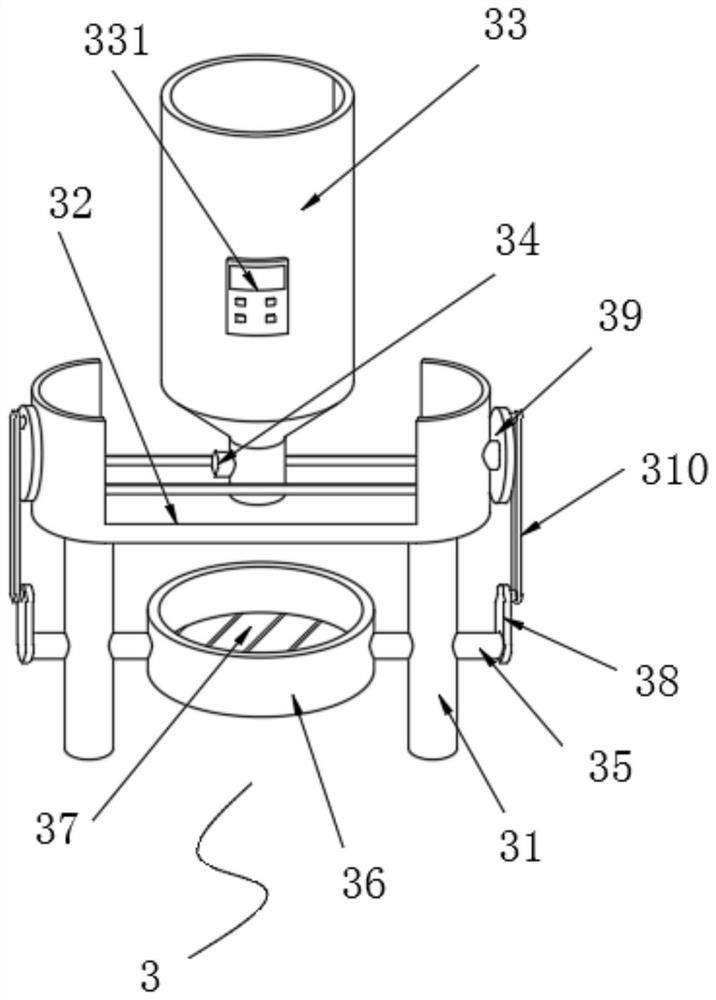

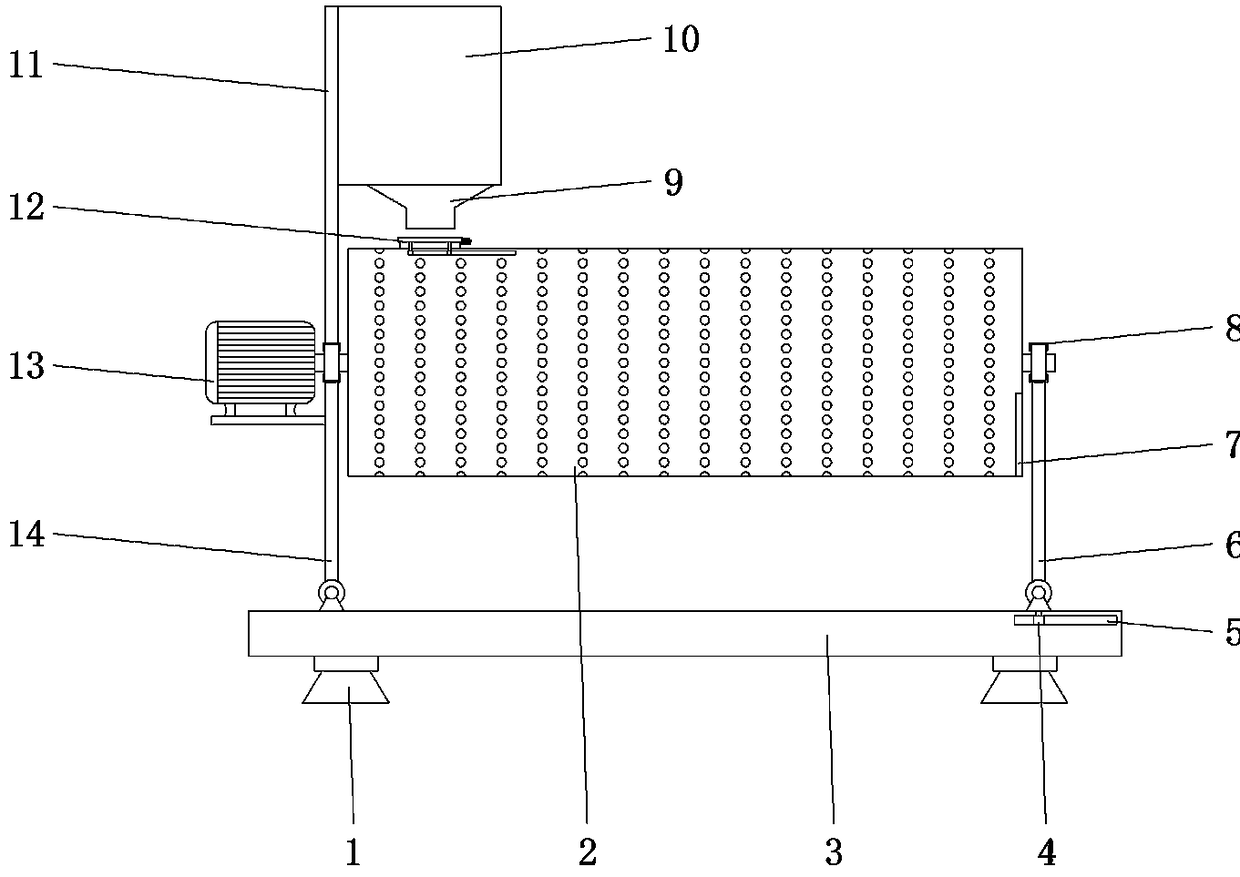

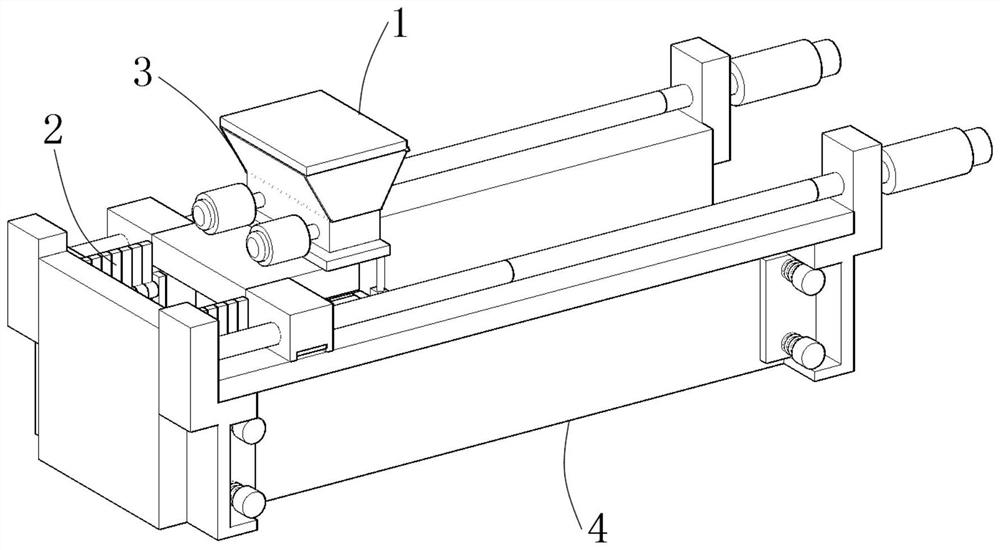

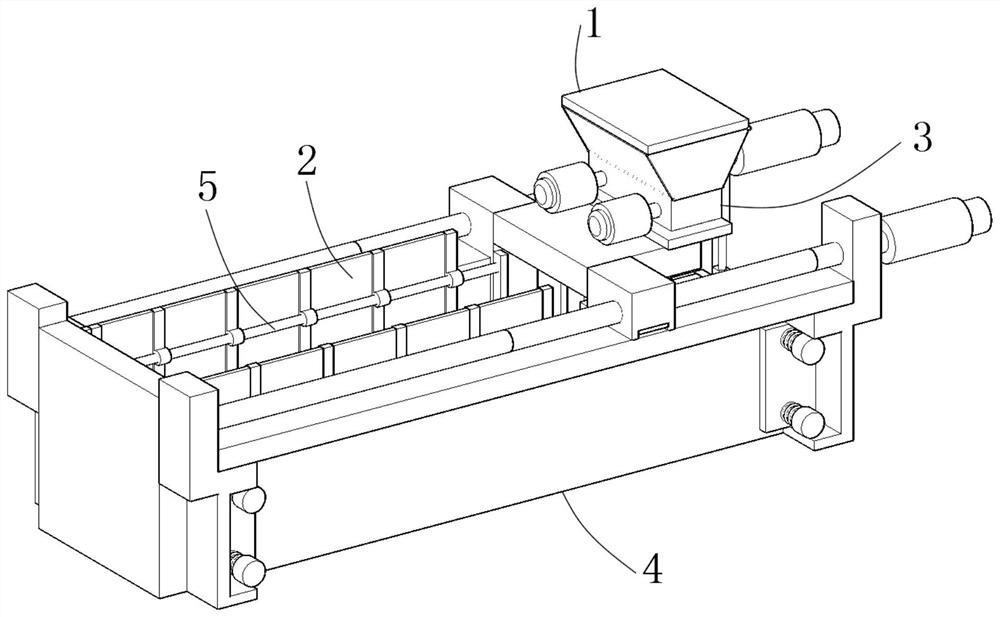

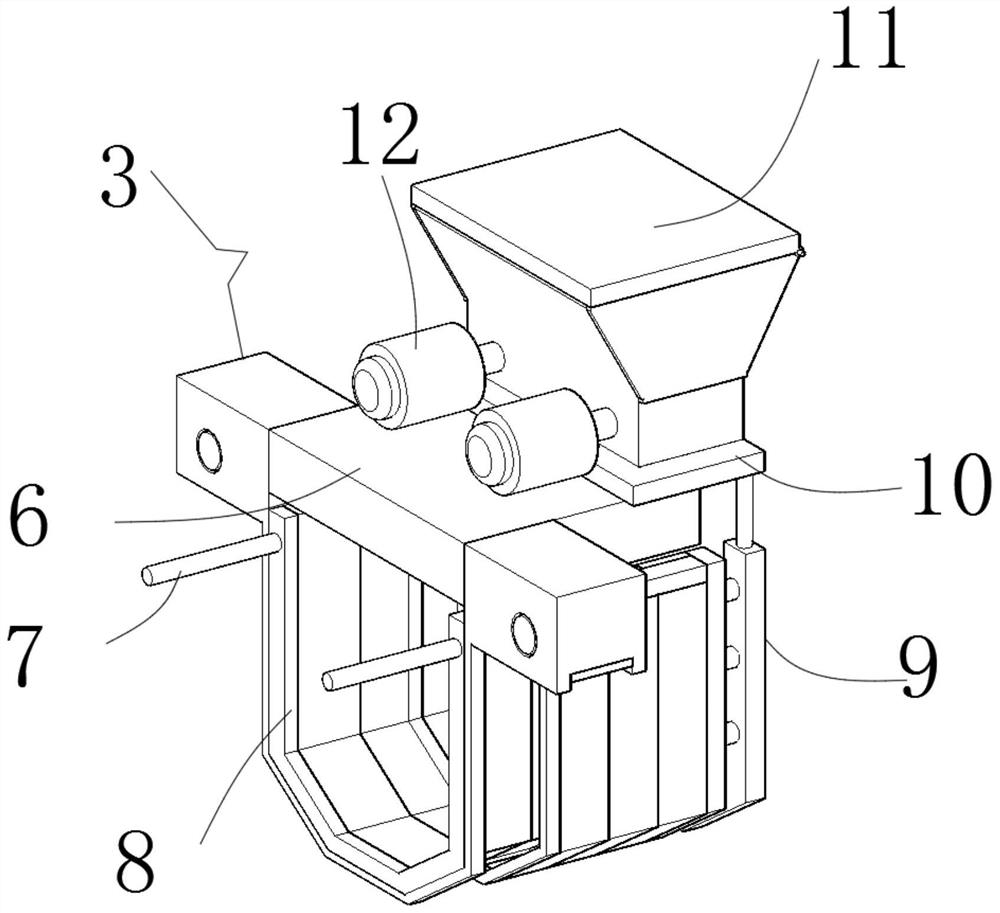

Automatic feeding system of automatic feeding machine for semiconductor device processing

PendingCN113213192AConvenient processing workImprove automationLarge containersControl devices for conveyorsCircular discDevice material

The invention discloses an automatic feeding system of an automatic feeding machine for semiconductor device processing, and relates to the technical field of semiconductor device processing and feeding. The automatic feeding system comprises a feeding hopper, wherein convex plates are arranged on the two sides of the upper portion of the feeding hopper, a feeding assembly is arranged between the upper surfaces of the two convex plates, and an anti-blocking assembly is arranged in the middle of one side face of the feeding hopper. According to the automatic feeding system, driving bevel gears are fixedly connected to the middle positions of the upper surfaces of two transmission discs, driven bevel gears corresponding to the driving bevel gears are fixedly connected to the opposite ends of two discs, the driven bevel gears are engaged with the driving bevel gears, when semiconductor devices are fed, quantitative feeding work can be conducted on the semiconductor devices, the amount of the semiconductor devices entering the feeding hopper is the same each time, manual guarding is not needed in the whole process, the automation degree is high, follow-up relevant processing work on the semiconductor devices is facilitated, and the working efficiency is improved.

Owner:湖北福灿电子科技有限公司

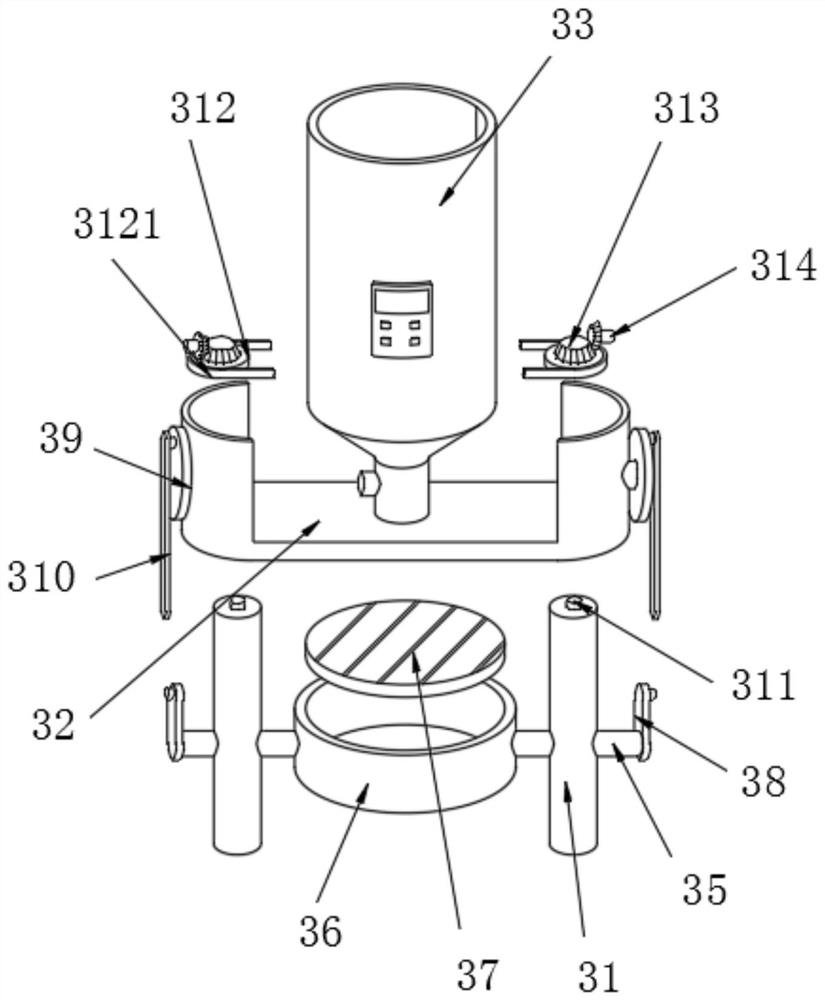

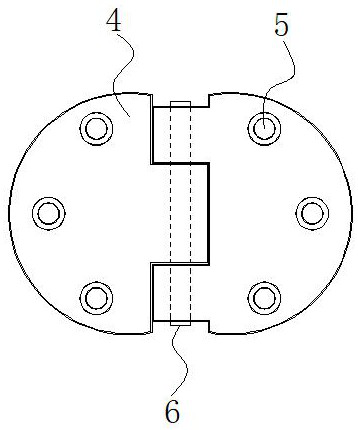

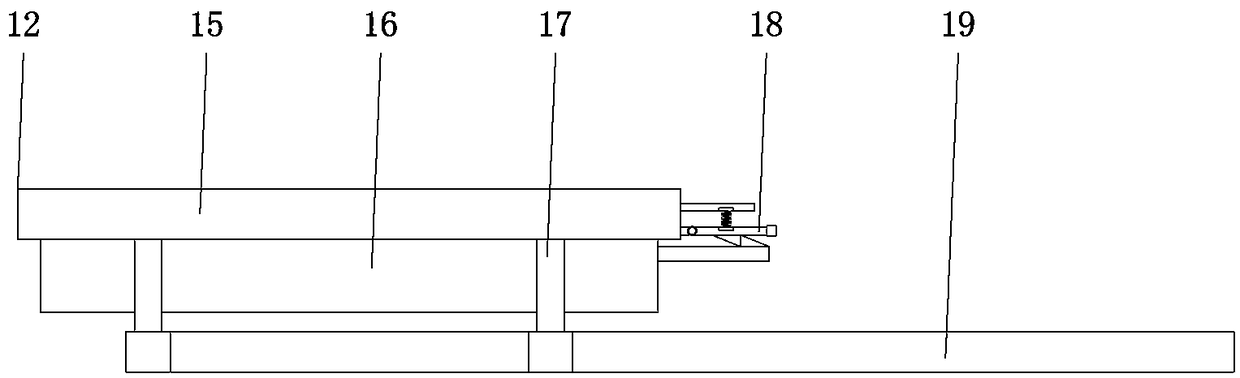

Part splicing equipment with conveying structure for machining

InactiveCN113953789AGuaranteed accuracyGuaranteed continuityMetal working apparatusConveyor partsEngineeringStructural engineering

The invention discloses part splicing equipment with a conveying structure for machining, and relates to the technical field of machining. The part splicing equipment comprises a base, a clamping mechanism and a splicing mechanism, a placement frame is arranged at the position, close to the edge, of the upper end of the base, a feeding conveying belt is arranged on the left side of the upper end of the base, by means of a magnetic suction plate and a connecting block which are distributed in parallel, the position accuracy between the magnetic suction plate and the connecting block can be guaranteed, the magnetic suction plate connected with the connecting block through a fastening bolt is convenient to mount, dismount and replace, a hinge body can be well protected by means of a protection layer arranged on the upper surface of the magnetic suction plate in a matched mode, the situation that scratches appear on the surface of the hinge body in the splicing process is avoided, limiting columns arranged at the upper end of the magnetic suction plate are matched with threaded holes formed in the two sides of the hinge body, the accuracy of the hinge body placed at the upper end of the magnetic suction plate each time can be guaranteed, the hinge body can be subjected to power-on adsorption and power-off loosening through the magnetic suction plate, and the splicing efficiency is effectively improved.

Owner:重庆信易源智能科技有限公司

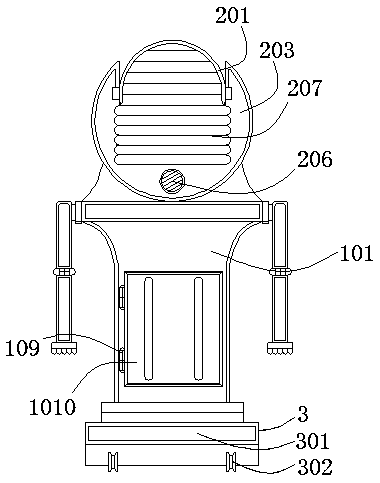

Preparation device of antibacterial coating of implantable medical instrument

The invention discloses a preparation device of an antibacterial coating of an implantable medical instrument. The instrument comprises anti-skid supporting legs, a ball mill, a mounting plate, a movable rotating rod, a temporary storage box and a fixed rotating rod, anti-skid supporting legs are welded on the lower surface of the mounting plate, a slide way is formed in one side of the inner partof the mounting plate, and a slide block is arranged in the slide way in a sliding mode; a movable rotating rod is arranged at the upper end of the sliding block, and a fixed rotating rod is arrangedon one side, deviating from the slide way, of the upper end of the mounting plate; the top of the fixed rotating rod is provided with a supporting plate, spherical bearings are installed at the top ends of the movable rotating rod and the fixed rotating rod, the ball mill is inserted into the spherical bearings, and a feeding device is arranged at the upper end of one side, close to the fixed rotating rod, of the ball mill; and a feeding hole is formed in the middle position of the feeding device, and a sealing plate is arranged at the upper end of the feeding opening in a sliding mode. According to the preparation device, the feeding can be conveniently carried out, and the surface of the raw material can be polished to be smooth through the ball mill, so that the coating effect is better.

Owner:成都信通家医健康科技有限公司

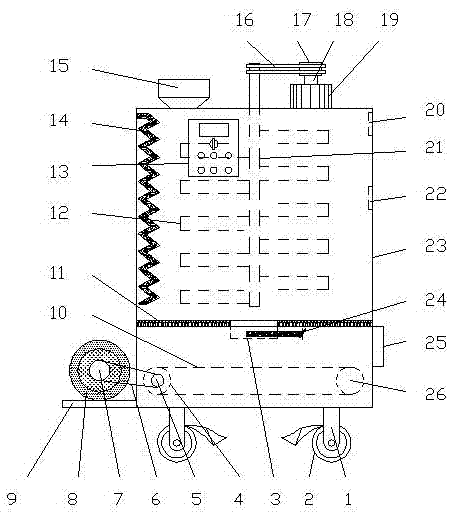

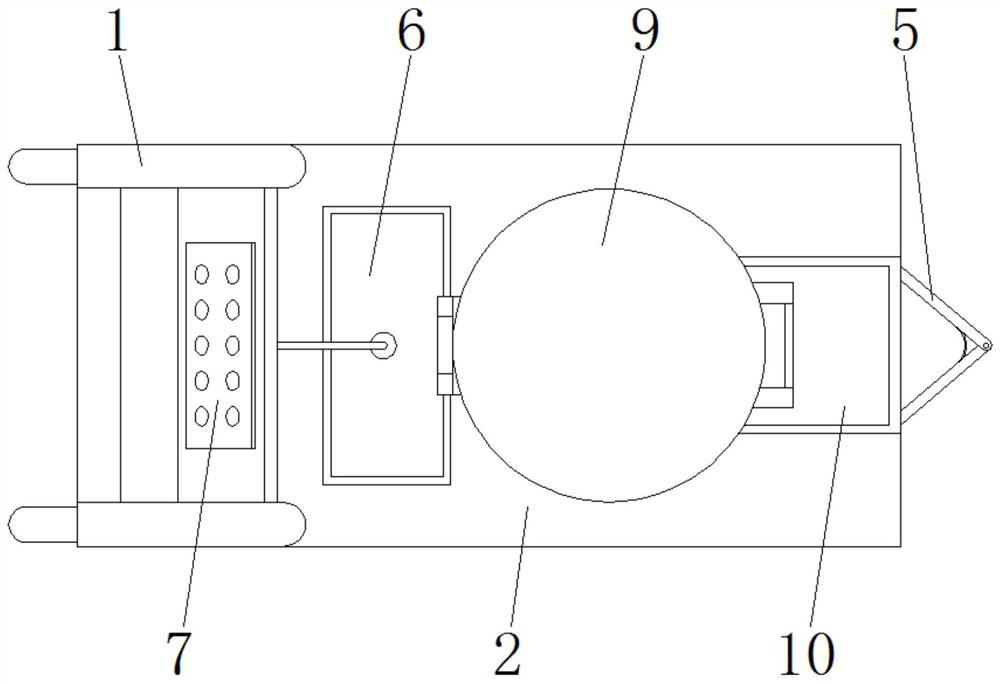

Convenient-jointing size-adjusting road surface crack sealing machine

The invention discloses a convenient-jointing size-adjusting road surface crack sealing machine. The road surface crack sealing machine comprises a pushing handle, a battery box, a control board, a driving motor, an electric hydraulic rod and a protective tarpaulin, wherein the lower end of the pushing handle is fixedly provided with a cart main body, universal wheesl and moving wheels are mountedon the lower side of the cart main body, the battery box is fixedly arranged on the cart main body, the control board is connected to the upper end of the battery box, a feeding bucket is fixedly arranged on the cart main body, a bucket cover is mounted on the upper end of the feeding bucket, the driving motor is mounted inside the lower end of the feeding bucket, and a maintenance port is formedin the lower part of the feeding bucket. According to the convenient-jointing size-adjusting road surface crack sealing machine, through the stretch of the electric hydraulic rod, a joint sealing material plate is of a rhombus structure and the size of the joint sealing material plate is changed, and the lateral dimension of the inside of a frame formed by the joint sealing material plate is changed, so that the size of the frame formed by the joint sealing material plate can conform to cracks with different sizes, and the applicability of the device is increased.

Owner:吉林省榆长建筑工程有限公司

Paved sand treatment device and method for peacock breeding

InactiveCN111602599AEasy inputEasy accessRotary stirring mixersTransportation and packagingElectric machineFishery

Owner:袁裕忠

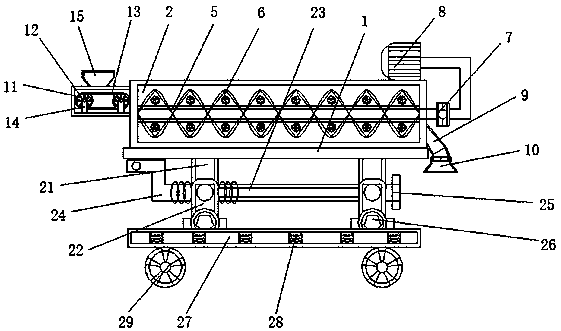

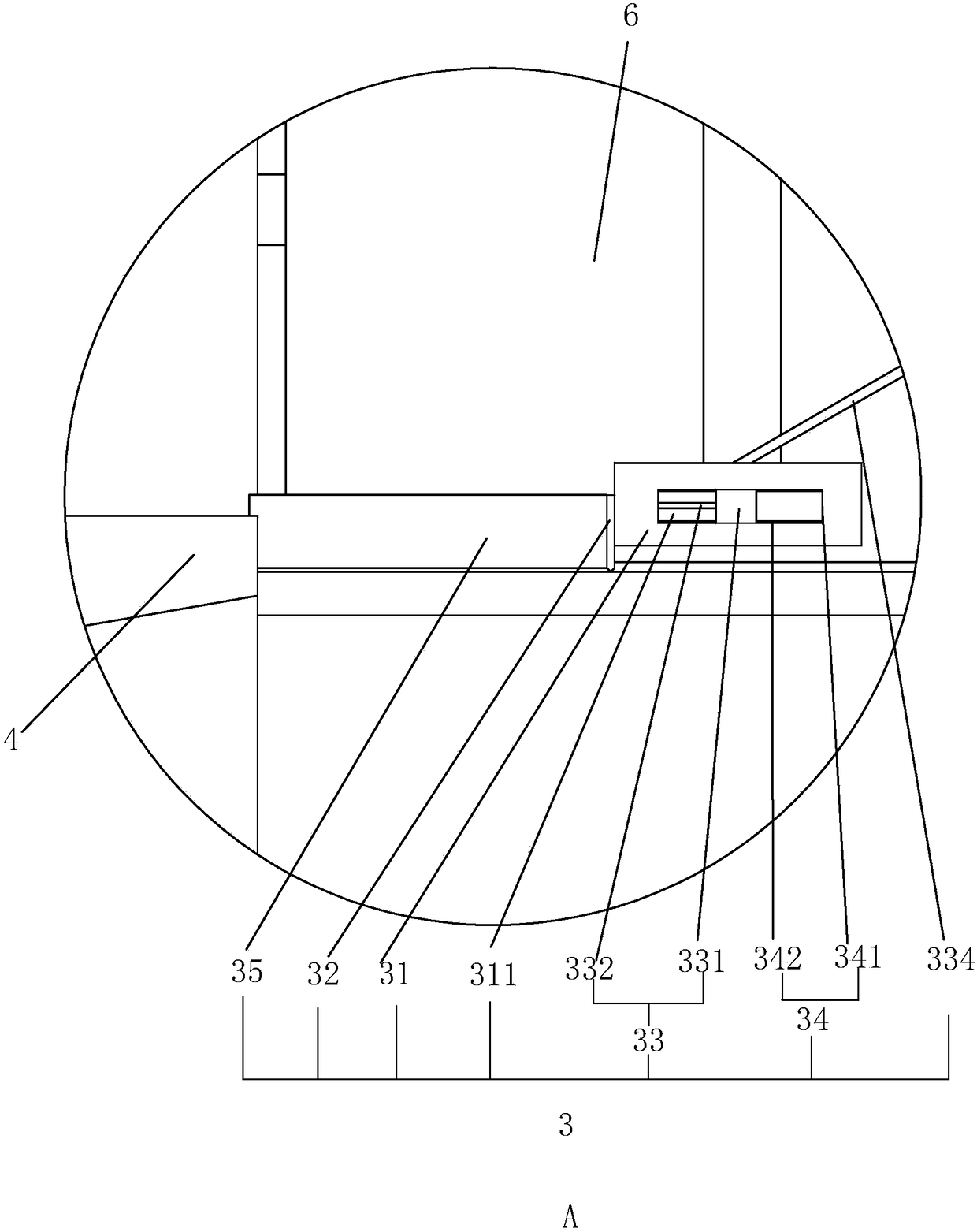

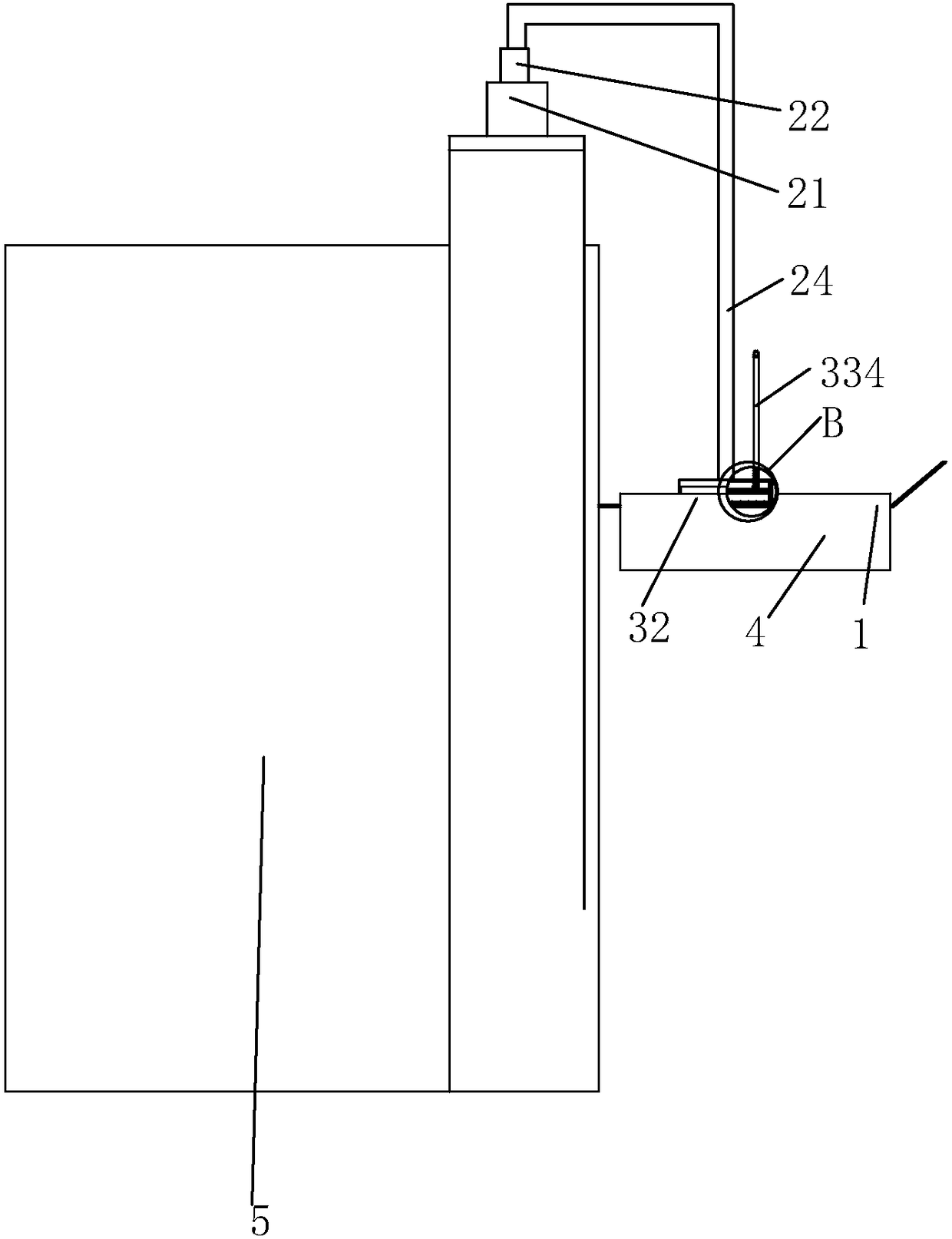

Channel one-time forming machine for water conservancy engineering

ActiveCN111660406ATo achieve the purpose of maintenanceAchieve levelingFeeding arrangmentsAuxillary shaping apparatusMolding machineStructural engineering

The invention discloses a channel one-time forming machine for water conservancy engineering. The channel one-time forming machine for the water conservancy engineering comprises a channel forming machine body. Connecting bases are arranged at the bottom of the inner end of the channel forming machine body, a material laying frame is connected to the upper ends of the connecting bases in a slidingmode, lifting pull rods are connected with the rear end of the material laying frame in a stretchable mode, and curing covering membranes are connected with the side ends of the lifting pull rods ina sleeving mode. The material laying frame comprises a supporting plate, sleeve rod frames, a scraping plate, a material conveying base frame, a communicating pipe base, a hopper frame and pressure pumps. The material conveying base frame is arranged at the bottom end of the material laying frame, the upper end of the material conveying base frame and the communicating pipe base are arranged in acommunicating mode, the center of the communicating pipe base and the bottom end of the hopper frame are arranged in a communicating mode, the pressure pumps are installed on the upper portion of theside end of the hopper frame, and the bottom ends of the communicating pipe base and the hopper frame are fixedly connected with the supporting plate. According to the channel one-time forming machinefor the water conservancy engineering, due to the arrangement of the material laying frame, the purpose that materials are laid by the inner end is achieved.

Owner:宁夏凯拓建设工程有限公司

Robot capable of inducing children to talk

The invention discloses a robot capable of inducing children to talk, and relates to the technical field of robots. The robot comprises a body mechanism and a head mechanism, wherein the bottom end ofthe body mechanism is equipped with a travelling mechanism; the inner side of the travelling mechanism comprises a movable base; the head mechanism is arranged at the bottom end of the body mechanism; the inner side of the head mechanism comprises a second housing; and a display screen is arranged above the inner side of the second housing. The robot capable of inducing children to talk has the beneficial effects that: a movable door, a first housing, a display screen, a movable block, a movable slot and the second housing are arranged, and the movable door is magnetically connected to the first housing, so that a first electric pushing rod moves when children learn through videos and voices played by the display screen and corresponding correct replay of the children is obtained, and therefore, the movable door performs rotary operation through a movable shaft, discharge operation of objects is favourably induced, and working efficiency of inducing the children to talk by the deviceis effectively improved.

Owner:DONGGUAN UNIV OF TECH

Dust conveying device for metallurgical machinery

InactiveCN108792531AWith lifting functionConvenient feeding workLarge containersSupporting framesIndustrial engineering

Owner:YUNHEMAN WALKER TOYS CO LTD

Display type carbon powder storage device with dust suppression structure

InactiveCN112731779AAvoid flying dustWith dust suppression effectElectrographic process apparatusComposite materialMagnetic powder

The invention discloses a display type carbon powder storage device with a dust suppression structure. The display type carbon powder storage device with the dust suppression structure comprises an outer shell and an inner cavity, wherein a magnetic plate is an inclined component, carbon powder slides down along a clamping groove, the carbon powder can be discharged through a discharging opening, when more carbon powder exists at the upper end of the magnetic plate, the carbon powder automatically presses the magnetic plate downwards to enable a spring to extend and enable the magnetic plate to move downwards, a magnetic plate is arranged in the inner cavity to serve as an interlayer, carbon powder is prevented from flying in the inner cavity, a certain dust suppression effect is achieved, the magnetic plate sinks to enable a contact head to be electrically connected with a first touch plate, current enables a first display lamp to be lightened through the first touch plate and a lead wire, an electromagnetic block is arranged at the lower end of a mounting block and electrically connected with the first touch plate through the lead wire, meanwhile, the electromagnetic block generates magnetism, the magnetic plate can move downwards again due to the fact that like poles of the electromagnetic block and the magnetic plate repel each other, all the carbon powder slides down through the clamping groove in the moving process, the magnetic powder at the lower end of the magnetic plate can be conveniently arranged, the surface of the magnetic powder is smooth, and the effect of suppressing magnetic powder flying is further achieved.

Owner:温州乔断机械科技有限公司

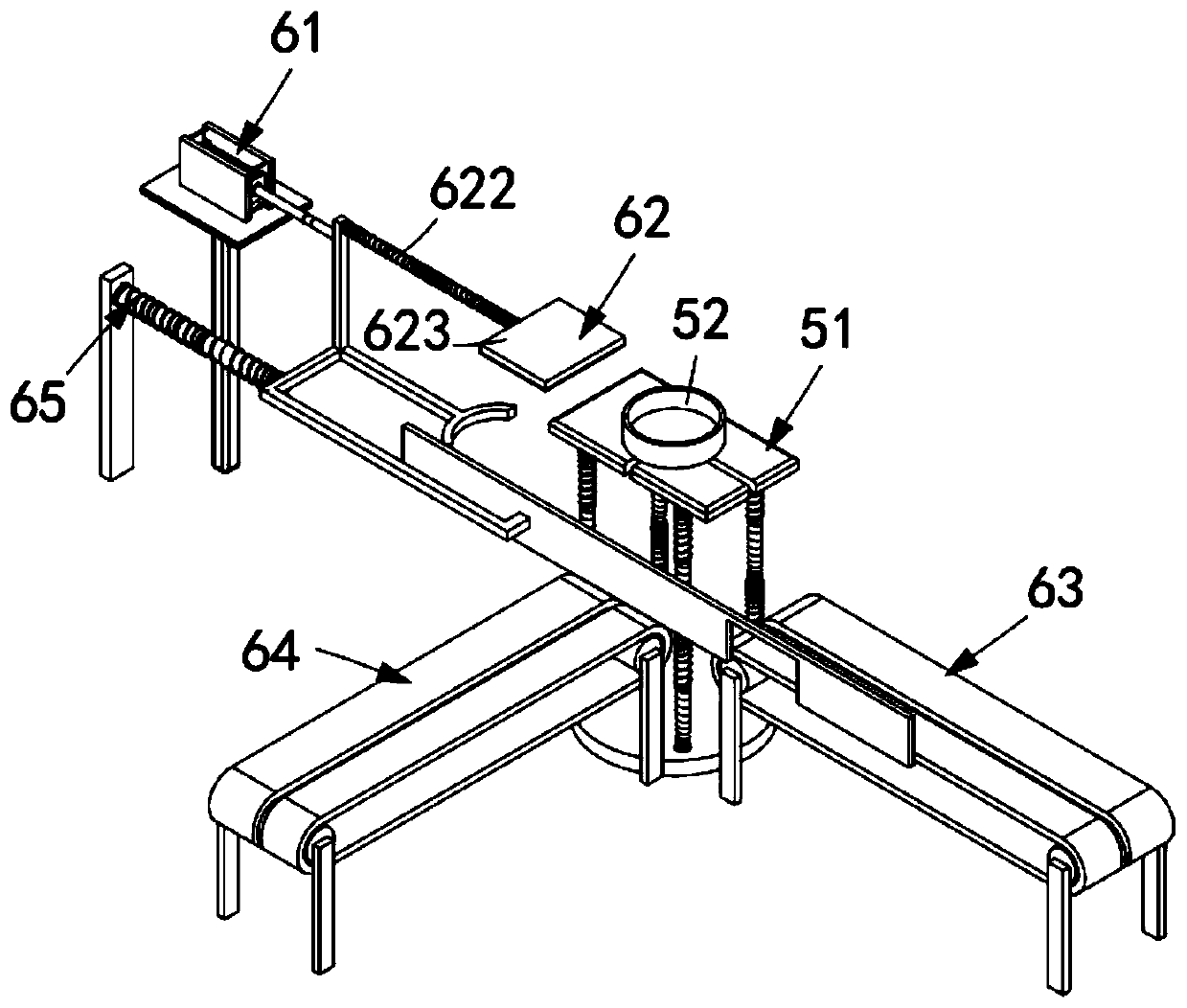

Discharging device for nylon heat insulation strip master batch production and discharging method thereof

The invention discloses a discharging device for nylon heat insulation strip master batch production. The discharging device comprises a connecting device, a discharging main body and a conveying belt, the discharging main body is mounted at the bottom of the connecting device through bolts, a rotating disc is arranged in the middle of the discharging main body, the conveying belt is wound aroundthe outer portion of the rotating disc, the outer portion of a middle cylinder is connected with the inner wall of the discharging main body through a second fixing rod, a winding rod is arranged on the outer portion of the top end of a rotating rod and arranged on the inner side of a lead screw, the outer portion of the lead screw is in threaded connection with the inner side of a connecting cylinder, and a scraper is connected to the lower portion of the outer wall of the lead screw. When the discharging device for nylon heat insulation strip master batch production is used for discharging,the whole discharging device can conveniently and rapidly discharge, it is guaranteed that the discharging efficiency of the whole device is very high, and the discharging speed can be increased whenthe whole device is in the tail period of discharging.

Owner:安徽中鑫宏伟科技有限公司

Uniform variable-speed blanking device for producing silicone sealant

PendingCN114162624AGuaranteed stabilityConvenience guaranteedLoading/unloadingSilicone sealantElectromagnetic valve

The uniform variable-speed discharging device comprises a discharging barrel, the bottom of the discharging barrel is fixedly connected with a first motor, an output shaft of the first motor penetrates into an inner cavity of the discharging barrel and is fixedly connected with a discharging roller, the top of the discharging barrel is fixedly connected with an electromagnetic valve, and the electromagnetic valve is fixedly connected with the discharging roller. The top of the electromagnetic valve is sleeved with a threaded sleeve, the surface of the threaded sleeve is fixedly connected with a driven gear, the right side of the driven gear is meshed with a driving gear, and the bottom of the driving gear is fixedly connected with a second motor. Through cooperative use of the discharging barrel, the first motor, the discharging roller, the electromagnetic valve, the threaded sleeve, a driven gear, a driving gear, a second motor, a mounting base, a U-shaped frame, a connecting column, a buffer groove, a buffer rod, a connecting rod, a spring, a rolling wheel and a limiting sleeve, the device can be conveniently replaced, time and labor are saved, and great convenience is brought to discharging work.

Owner:广东力伊祥新材料有限公司

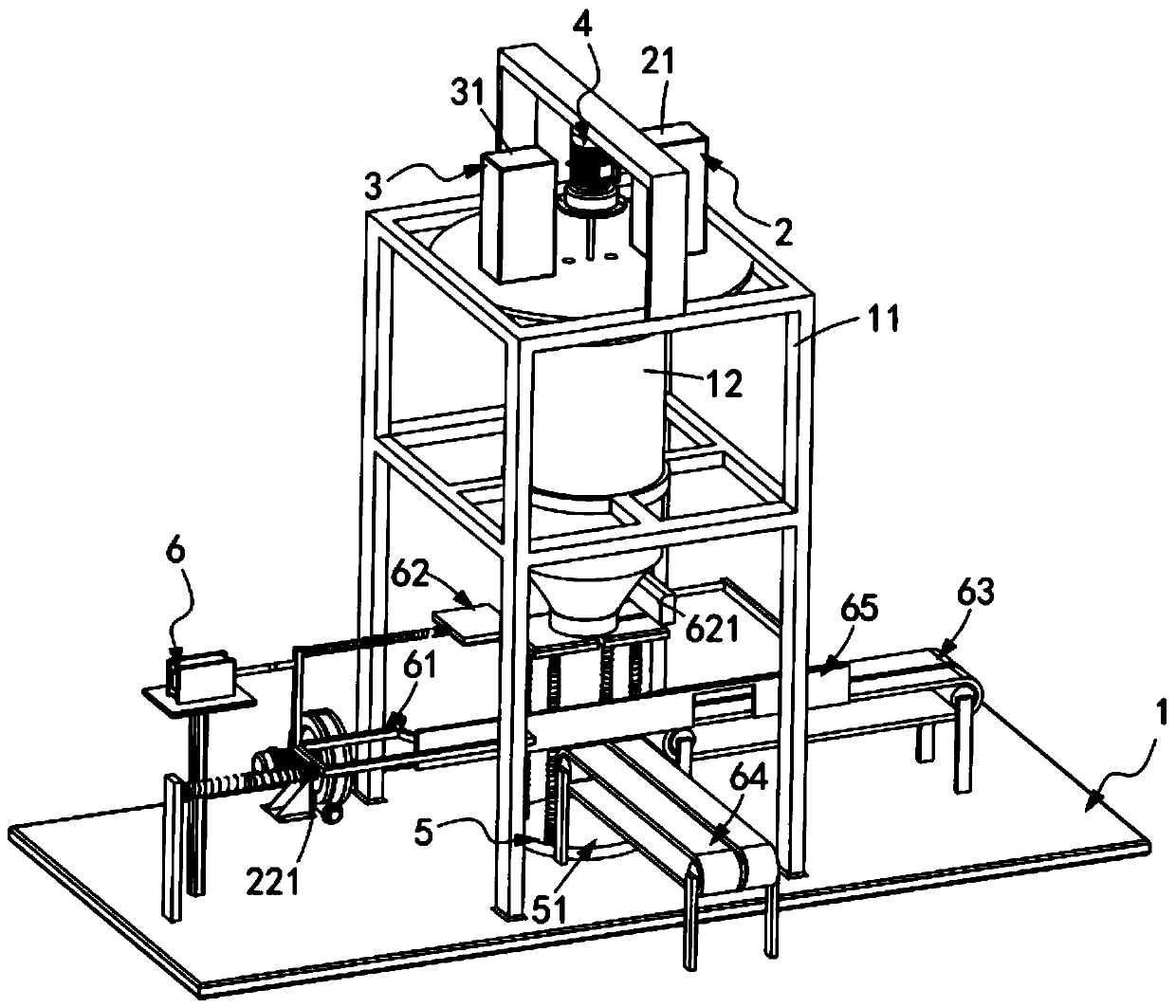

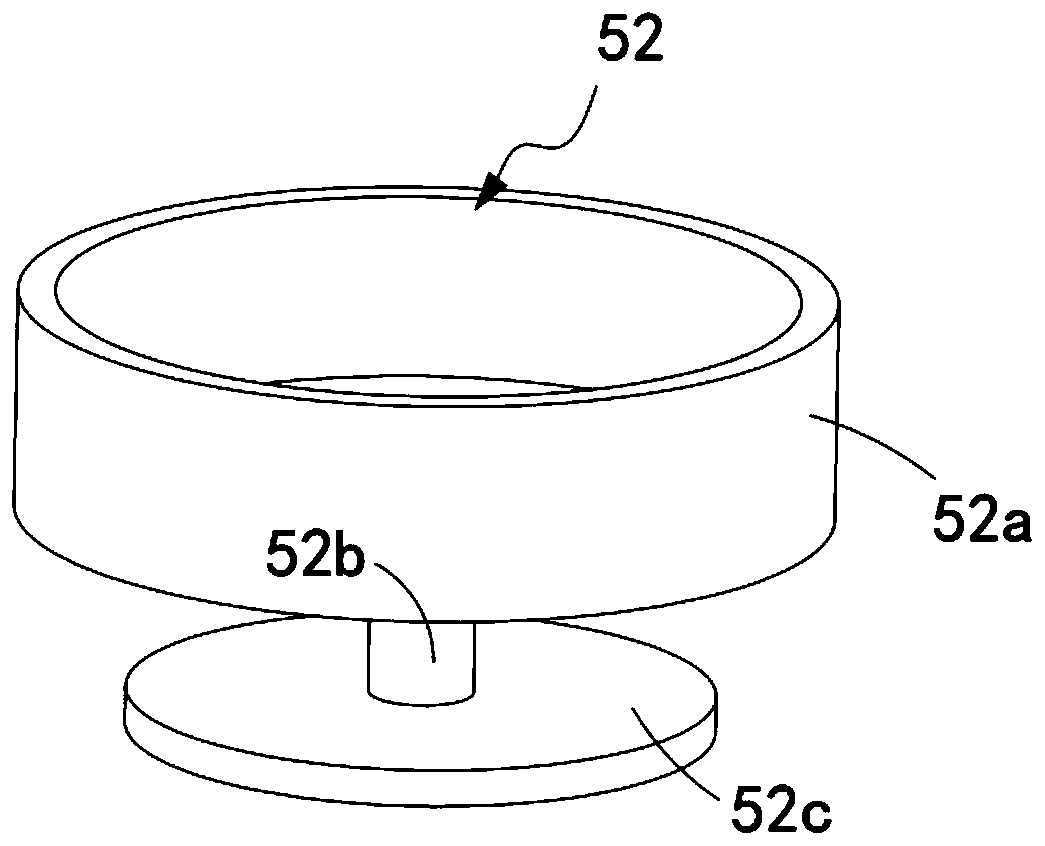

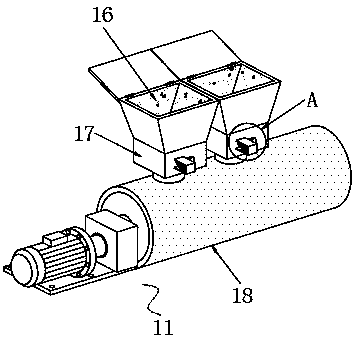

Automatic epoxy powder coating mixing equipment for high-steel-grade pipeline

InactiveCN111569752AIncrease profitImprove product qualityTransportation and packagingMixer accessoriesEpoxyEngineering

The invention relates to automatic epoxy powder coating mixing equipment for a high-steel-grade pipeline, which comprises: a supporting mechanism that includes a rack and a reaction kettle; a materialA conveying mechanism that comprises a first storage bin and a material scattering assembly; the B material conveying mechanism that comprises a second storage bin and a thinning assembly; the driving mechanism that is mounted on the rack and is used for driving the material scattering assembly and the thinning assembly to be rotationally arranged in the reaction kettle along the circumference; the dish feeding mechanism that comprises a lifting assembly, a material containing dish and a distance sensor, and the material containing dish is of an H-shaped structure and is sequentially composedof a dish device, a connecting column and a round base in the vertical direction; the discharging mechanism that comprises a horizontal pushing assembly, a material blocking assembly, an output assembly, an input assembly and a control assembly; according to the invention, the technical problems that epoxy resin is a thick fluid, is not easy to stir and is easily adhered to the stirring shaft during mixing, so that the epoxy resin is not easy to be fully and uniformly mixed with fillers and pigments, and the utilization rate of raw materials is low are solved.

Owner:浙江众鑫新材料科技有限公司

An integrated device for sliced and dried Chinese herbal medicines that is convenient for feeding

ActiveCN109910071BAvoid pollutionImprove processing efficiencyDrying solid materialsDrying machines with local agitationAir pumpStructural engineering

The invention discloses convenient-to-discharge traditional Chinese medicinal material slice drying integrating equipment. The equipment comprises a device body, a control panel, a first electric telescopic rod and a rotary shaft, a discharging door and a feeding door are installed on the outer side of the device body, the discharging door and the feeding door are provided with observation windows, the inner side of the control panel is connected with a heating device, the outer side of the heating device is fixedly provided with a heat guiding pipe, the lower side of the electric telescopic rod is fixedly provided with a device body, a gas discharging pump is installed in the device body, the upper side of the heat guiding pipe is fixedly provided with a feeding rolling shaft and a discharging rolling shaft, the upper sides of the feeding roller shaft and the discharging rolling shaft are connected with material placing plates. The equipment is provided with a slicing cutter and a blade clamping plate so that slicing and drying can be conducted simultaneously, the labor intensity of workers is effectively reduced, the sliced traditional Chinese medicinal materials can be preventedfrom bonding on the slicing cutter, and the normal operation of the drying of the traditional Chinese medicinal materials is ensured.

Owner:GUANGZHOU WANGLAOJI PHARM CO LTD +1

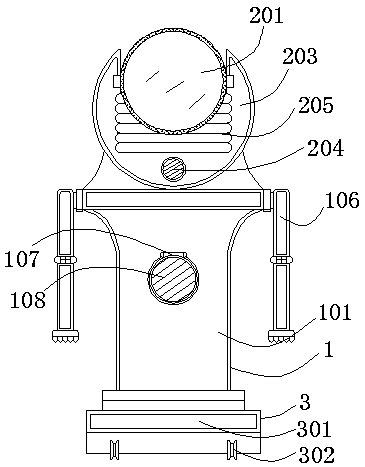

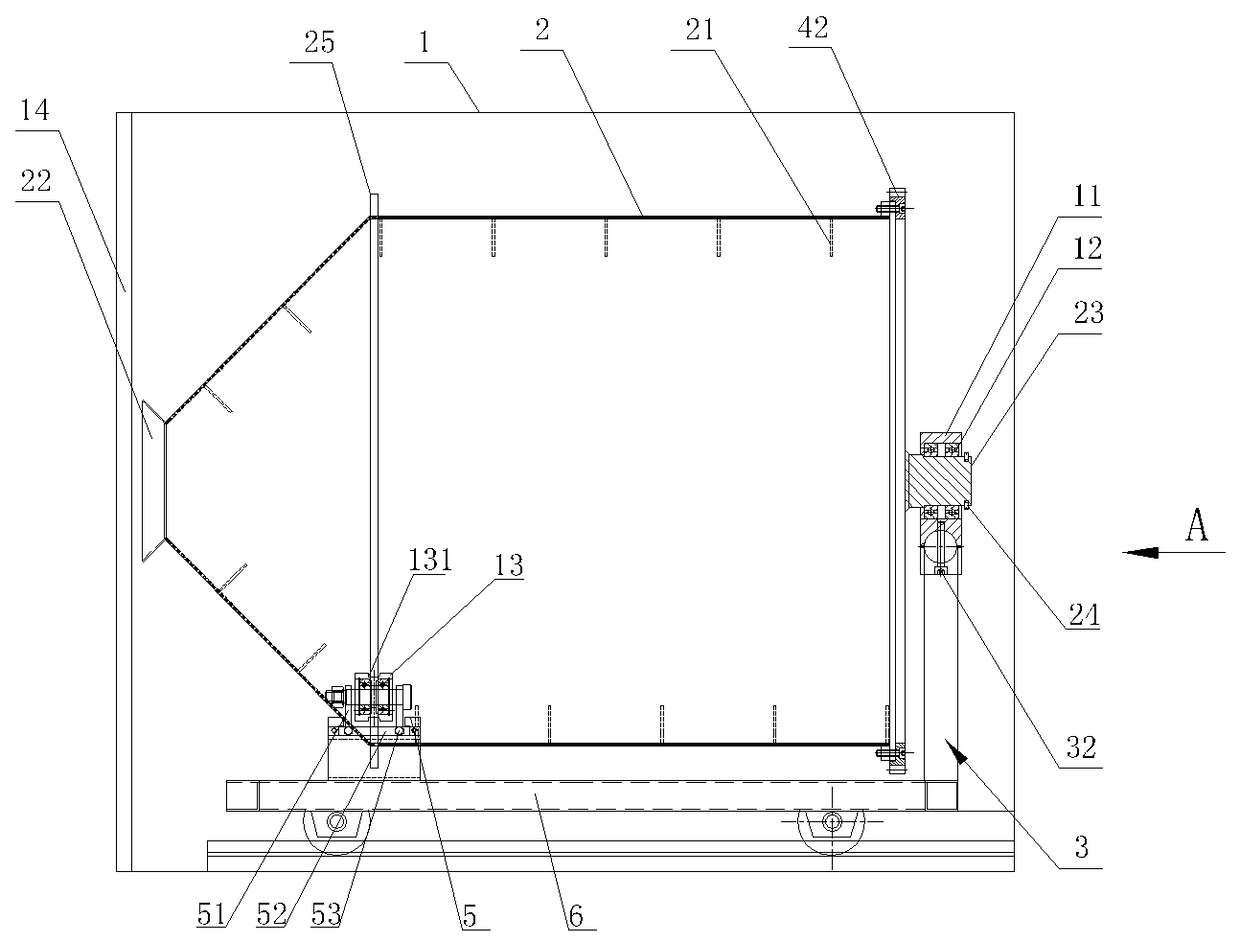

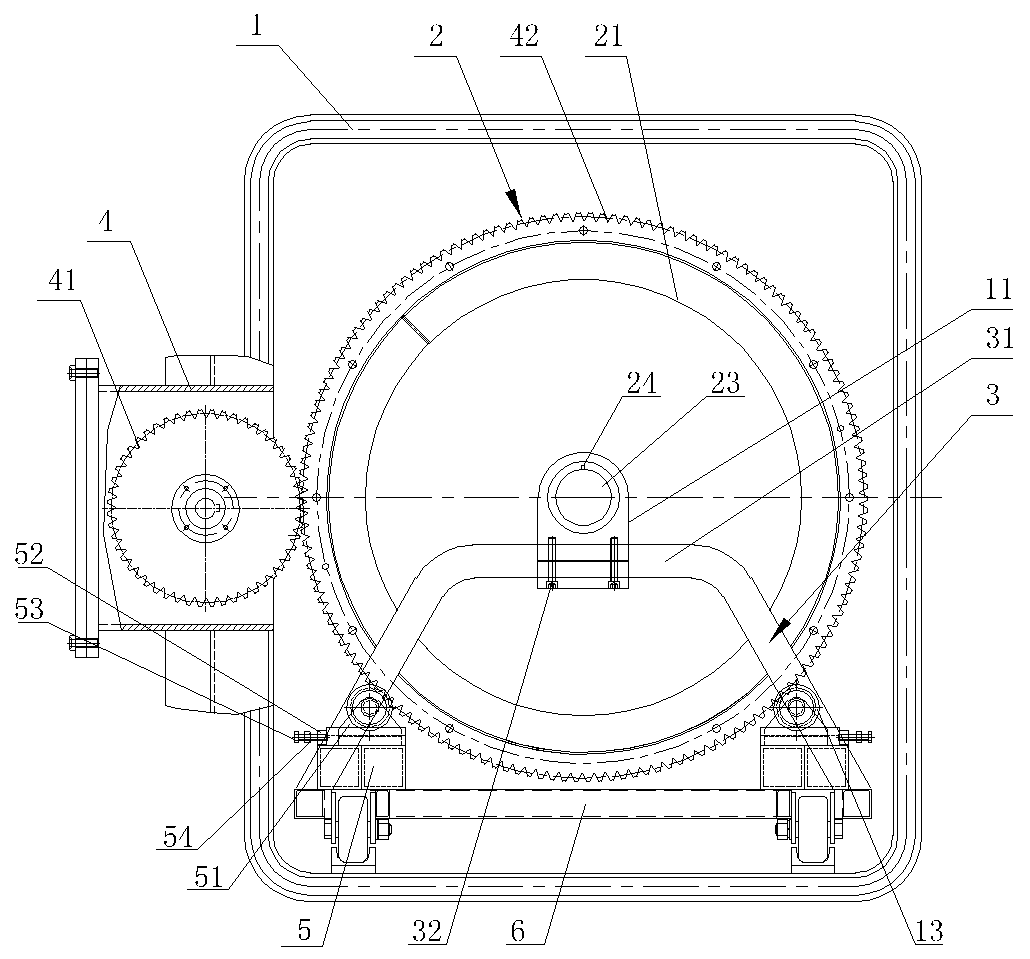

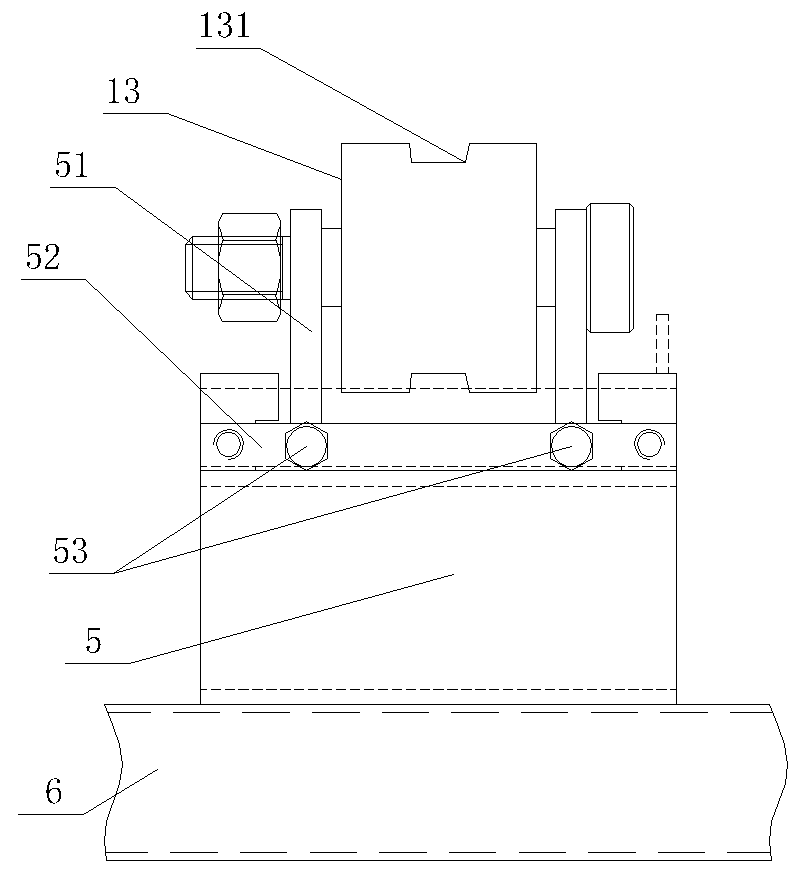

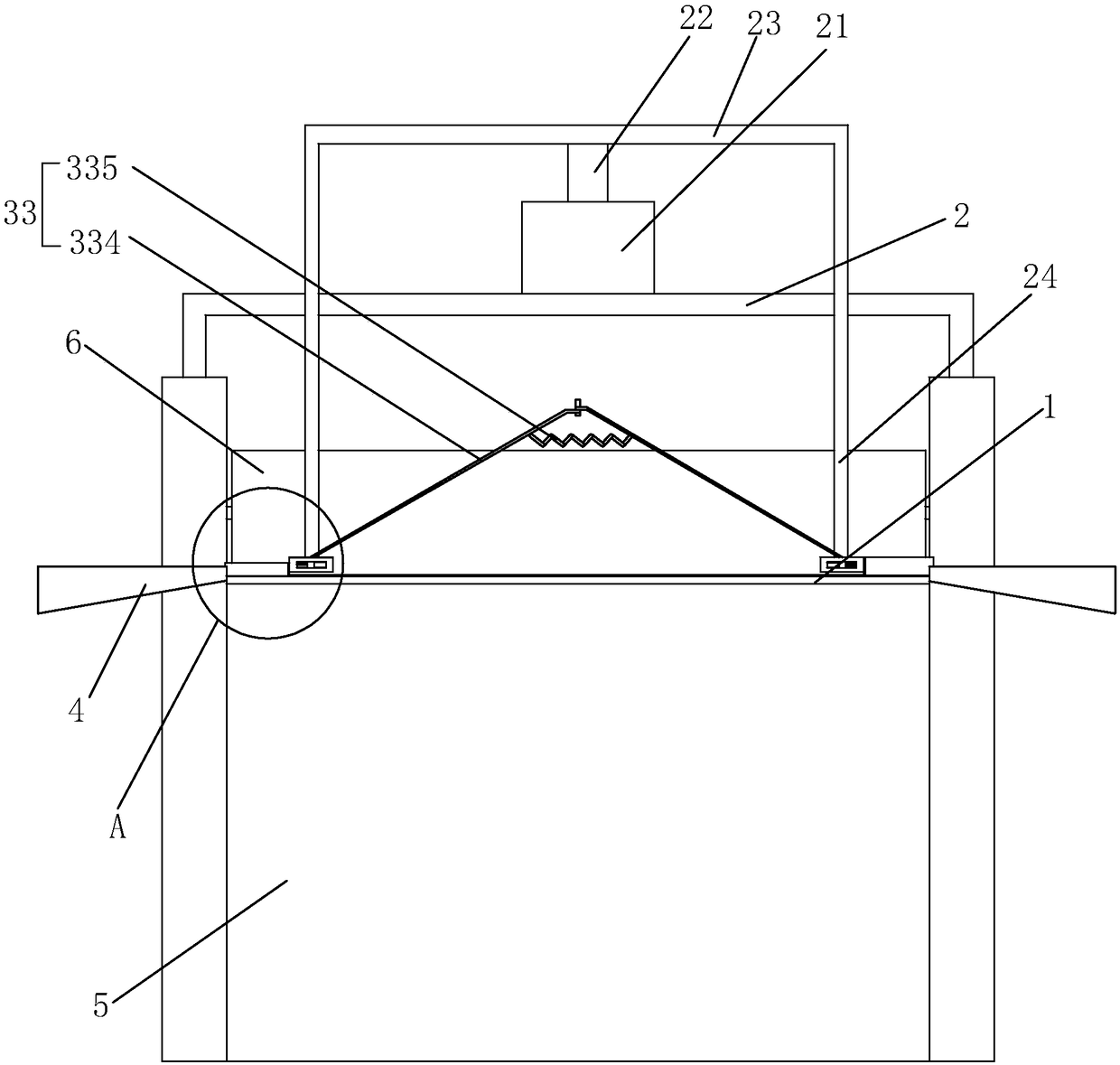

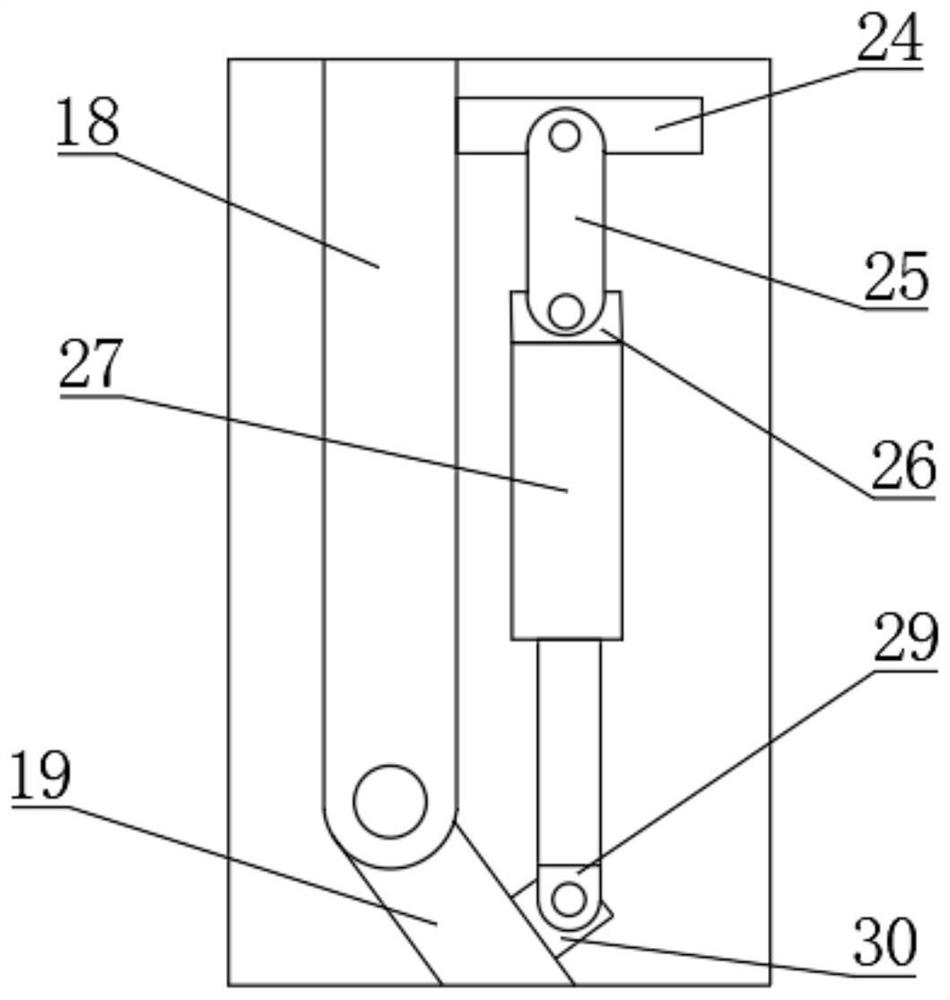

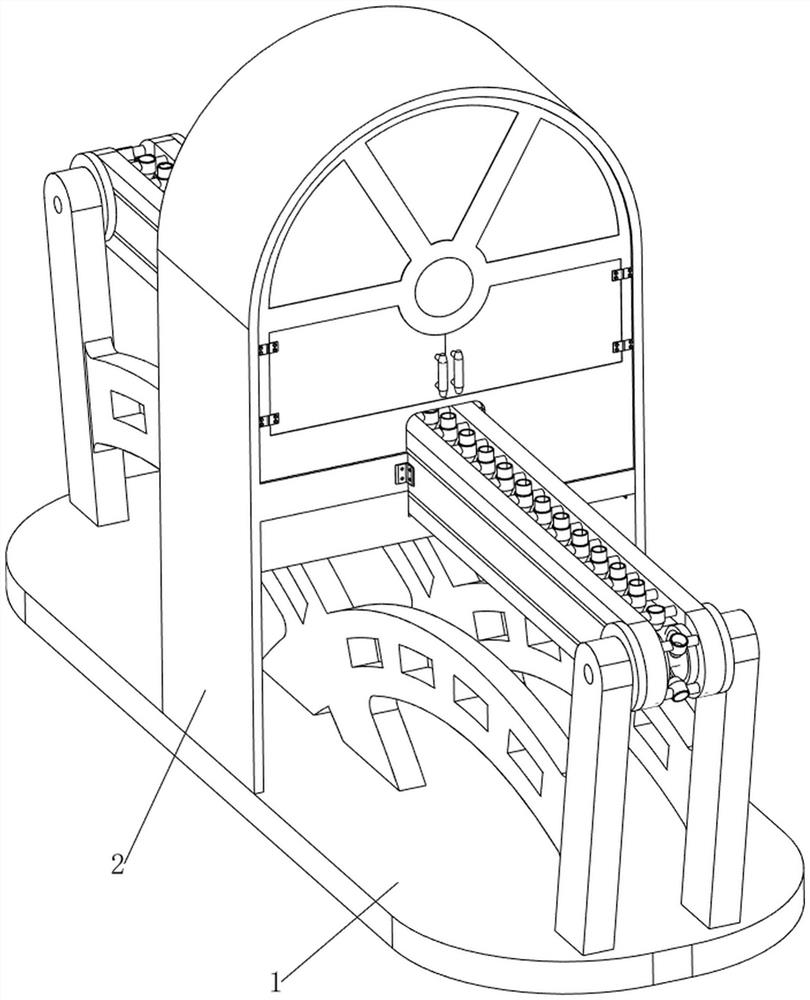

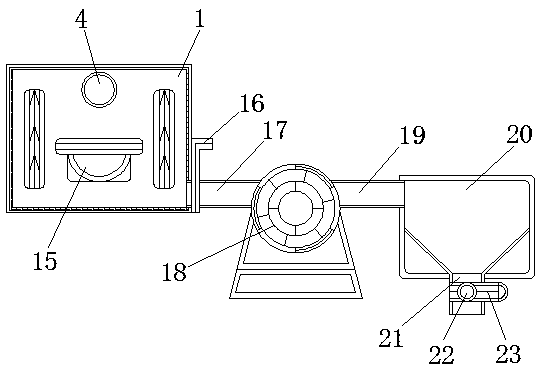

Automatic guiding device for rotating rubber plug sterilization cabinet

PendingCN108888794AConvenient discharge workImprove discharge efficiencyLavatory sanitoryDisinfectionDischarge efficiencyCentrifugal force

The invention discloses an automatic feeding device for a rotating rubber plug sterilization cabinet, which comprises a shell, a mounting rack and a sterilizing cylinder, a spiral guide groove is arranged on the inner wall of the sterilizing cylinder, and a port and a rotating shaft are arranged on the sterilizing cylinder; a supporting base and two supporting wheels are arranged on the mounting rack; the sterilizing cylinder is arranged on the two supporting wheels, the rotating shaft on the sterilizing cylinder is cooperatively connected with the supporting base, a drive assembly capable ofdriving the sterilizing cylinder to rotate is arranged between the shell and the sterilizing cylinder, and the drive assembly comprises a servomotor, a driving gear and a gear ring. The servomotor isfixedly arranged in the shell, the driving gear is fixedly connected to an output shaft of the servomotor, the gear ring fixedly sleeves the sterilizing barrel, and the driving gear is engaged with the gear ring. The rubber plug can move to the port along the spiral guide groove, which improves the discharge efficiency, and water on the rubber plug can be thrown off under the centrifugal force, which is beneficial to the drying process of a rear track.

Owner:JIANGSU SHENNONG AUTOCLAVE

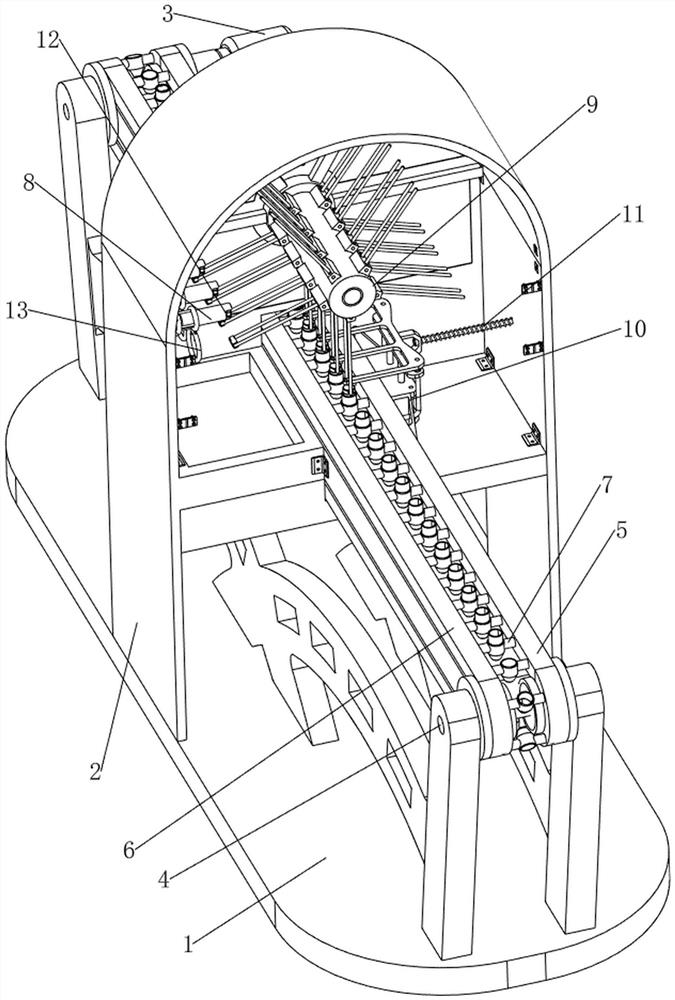

Three-roller grinding machine

ActiveCN108787017AAchieve separationImprove product qualityGrain treatmentsPulp and paper industrySlurry

The invention discloses a three-roller grinding machine. The three-roller grinding machine comprises a main hopper matched with a discharge outlet of the three-roller grinding machine; a support plateparallel to the main hopper is arranged above the main hopper; a drive cylinder is arranged at the upper end of the support plate; a connection rod is fixed to and perpendicularly connected with a piston rod of the drive cylinder; working rods are fixed to the two ends of the connection rod and penetrate through the sliding support plate; a cut-off device for slurry separation is fixedly arrangedat the lower end of each working rod; storage tanks for storing separated slurry are arranged on the two sides of the main hopper; and each cut-off device is provided with a push mechanism for controlling the separated slurry to fall into the storage tanks. By means of the three-roller grinding machine, the large-grain-size slurry on the two sides can be separated and can further be collected smoothly, and no slurry is accumulated on the surface of the main hopper.

Owner:YANCHENG SHENYUAN PLASTIC

Hotpot condiment processing equipment

InactiveCN112189780AEasy to cleanConvenient discharge workFood thermal treatmentLipidic food ingredientsElectric machineryEngineering

The invention discloses hotpot condiment processing equipment. The hotpot condiment processing equipment comprises a base, a pot body, a top plate and a third electric push rod, wherein the side wallof the pot body is hollow, a plurality of electric heating pipes are arranged in the side wall of the pot body, a fixing block and a first electric push rod are fixedly installed on the upper surfaceof the base, a supporting plate is fixedly connected to the bottom surface of the pot body, a fixing plate is connected to the side face of the pot body, a sliding block is connected to the upper endof the first electric push rod and makes contact with the lower surface of the fixing plate, a second electric push rod and a motor are installed on the lower surface of the top plate, a lifting plateis fixedly connected to the lower end of the second electric push rod, a net basket is arranged below the lifting plate, a rotating shaft is connected to an output shaft of the motor, and the lower end of the rotating shaft is rotationally connected with the upper end of a stirring shaft. According to the hotpot condiment processing equipment, by arranging the second electric push rod and the netbasket, garlic sprouts, scallions and dry red peppers fried in beef tallow can be automatically fished out, and the fragrance of the garlic sprouts, the scallions and the dry red peppers is reservedin the hotpot condiment.

Owner:胡水萍

Aluminum material melting furnace

InactiveCN111457725AIncrease the heat-resistant screenConvenient discharge workFurnace safety devicesCrucible furnacesFlueElectric machinery

The invention discloses an aluminum material melting furnace which comprises a machining furnace body. A heat insulation furnace door is movably mounted at one end of the machining furnace body. A mounting support is fixedly mounted at the upper end of the machining furnace body. A lifting motor is movably mounted at the upper end of the mounting support. Connecting lifting ropes are movably mounted between the lifting motor and the heat insulation furnace door. A discharging opening is fixedly mounted at the other end of the machining furnace body. A heating hearth is fixedly mounted on the inner side of the machining furnace body. Connecting pipes are movably mounted at one end of the heating hearth. Combustion furnaces are fixedly mounted on the outer sides of the connecting pipes. A connecting flue is fixedly mounted at the other end of the heating hearth. An exhaust fan is movably mounted at the upper end of the connecting flue. Filter screens are fixedly mounted at the upper endof the exhaust fan. The aluminum material melting furnace can do the work of machining and production better, the work speed and efficiency can be improved, harmful gas discharged outside can be reduced, inner pressure can be controlled better, and machining and production can be achieved better.

Owner:佛山市航星机械制造有限公司

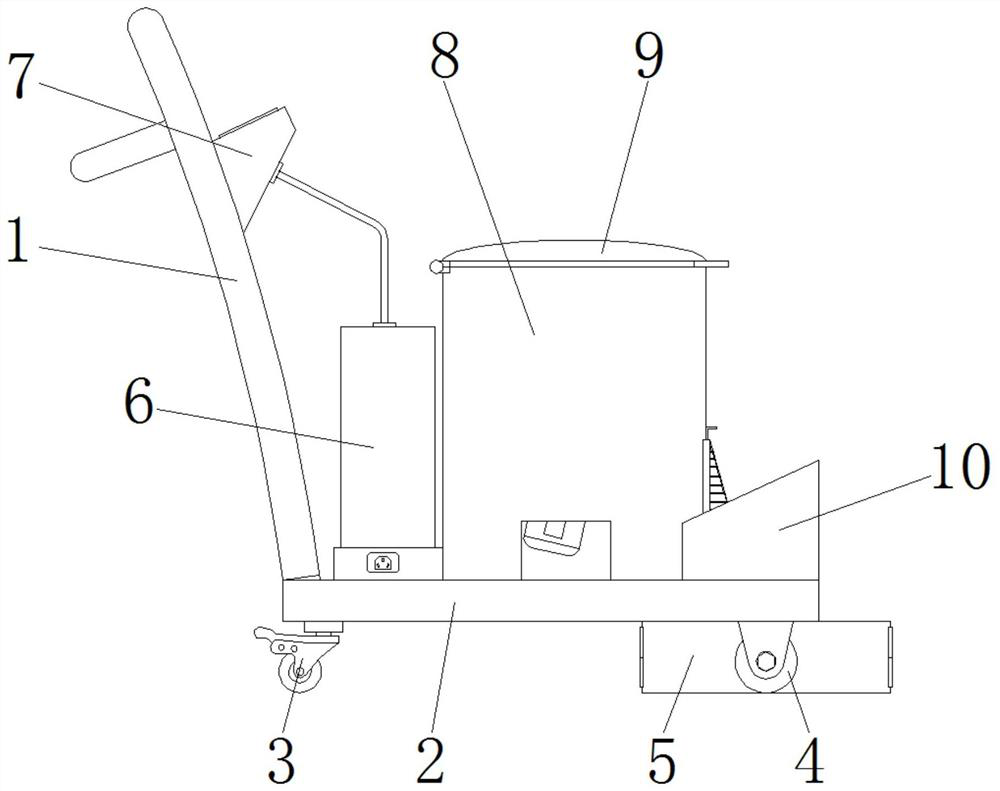

Slurry mixing device for nanosheet preparation and using method

InactiveCN111214994ATo achieve the purpose of height adjustmentImprove practicalityTransportation and packagingMixer accessoriesBLENDER/MIXERPhysical chemistry

The invention discloses a slurry mixing device for nanosheet preparation and a using method, and relates to the technical field of nanosheet preparation. The device comprises a base. Supporting legs are fixedly mounted on the lower surface of the base, telescopic wheels are fixedly mounted at the positions, located on the inner sides of the supporting legs, of the lower surface of the base, a slurry mixing tank is arranged on the upper surface of the base, and a water adding mechanism is mounted at the position, located on one side of the slurry mixing tank, of the upper surface of the base. The device is reasonable in structure and simple in operation; through a sliding mechanism, the height of a handle can be adjusted, and practicality is increased; through a crushing chamber, the raw materials can be directly crushed, so that the processing procedures are reduced, and the production cost is reduced; through a mixer, primary mixing treatment of different raw materials can be realized, and the subsequent slurry mixing uniformity is ensured; and through a stirring mechanism, the mixing and stirring work of the raw materials can be realized and the slurry mixing uniformity is improved.

Owner:南京纳希纳米科技有限公司

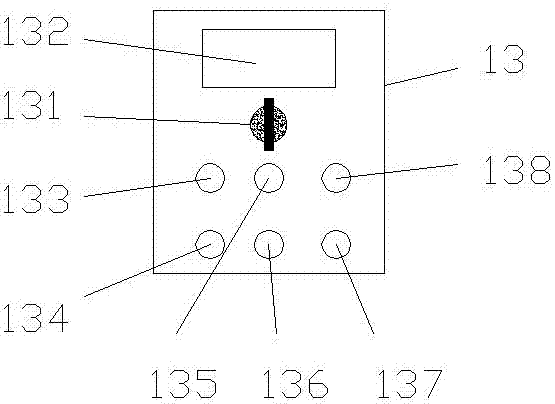

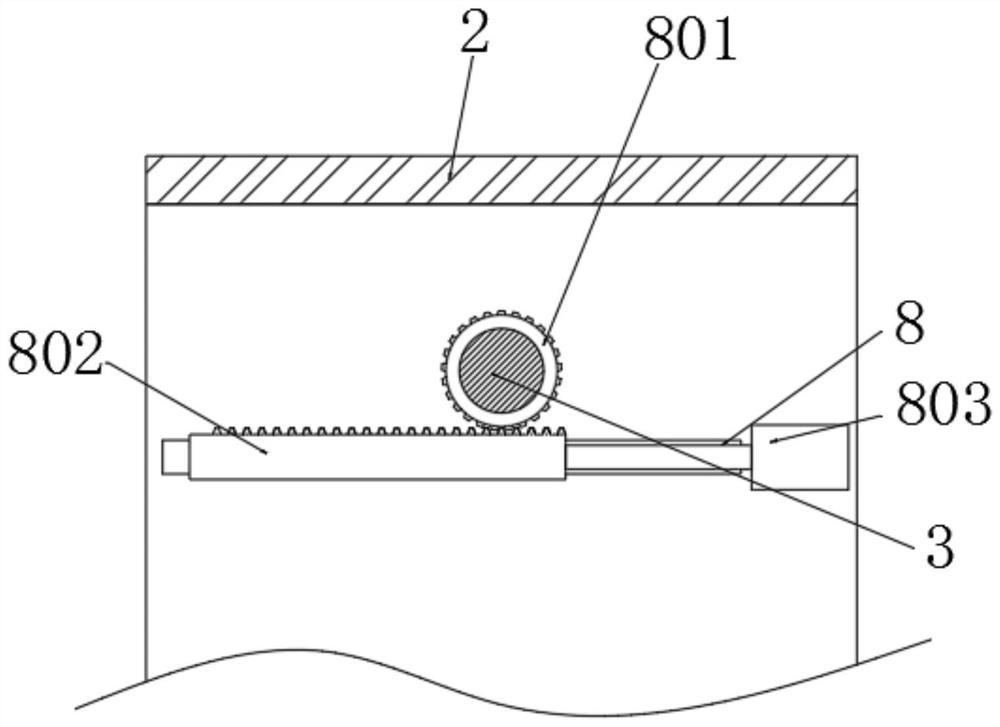

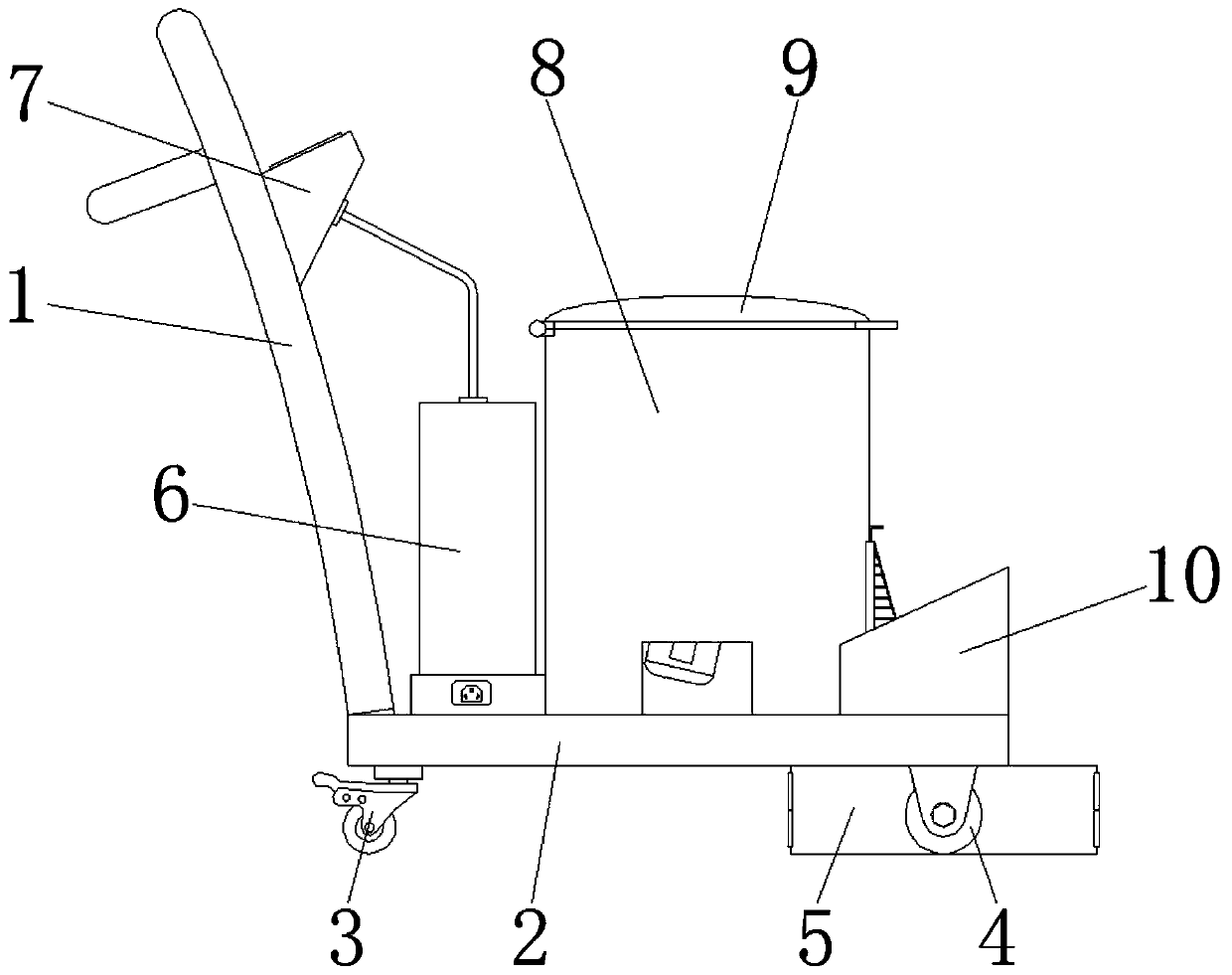

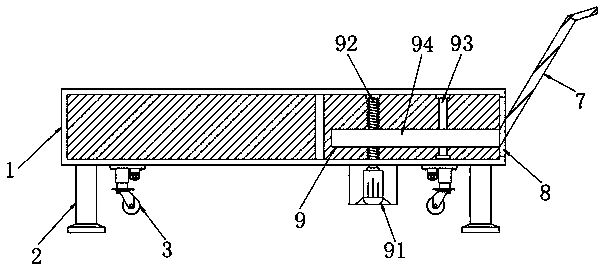

A pavement seam filling machine for conveniently adjusting the size of the seam filling

ActiveCN109914212BEasy to adjust caulk sizeEasy to useRoads maintainenceElectric machineElectro hydraulic

The invention discloses a pavement seam filling machine for conveniently adjusting the size of the seam filling, which comprises a push handle, a battery box, a control panel, a drive motor, an electro-hydraulic rod and a protective tarpaulin. The lower end of the push handle is fixed with a cart main body, and Universal wheels and moving wheels are installed on the lower side of the main body of the cart, a battery box is fixed above the main body of the cart, and a control panel is connected to the upper end of the battery box, and a discharge bucket is fixed above the main body of the cart. And the upper end of the discharging barrel is provided with a bung, the drive motor is installed inside the lower end of the discharging barrel, and the bottom of the discharging barrel is provided with a maintenance port. The pavement caulking machine that is convenient to adjust the size of the caulking can change the size of the caulking material plate in a rhombic structure through the expansion and contraction of the electro-hydraulic rod, so that the internal transverse dimension of the frame composed of the caulking material plate can be changed, so that the caulking material can be filled. The size of the frame composed of the seamed boards can meet the cracks of different sizes, which increases the applicability of the device.

Owner:吉林省榆长建筑工程有限公司

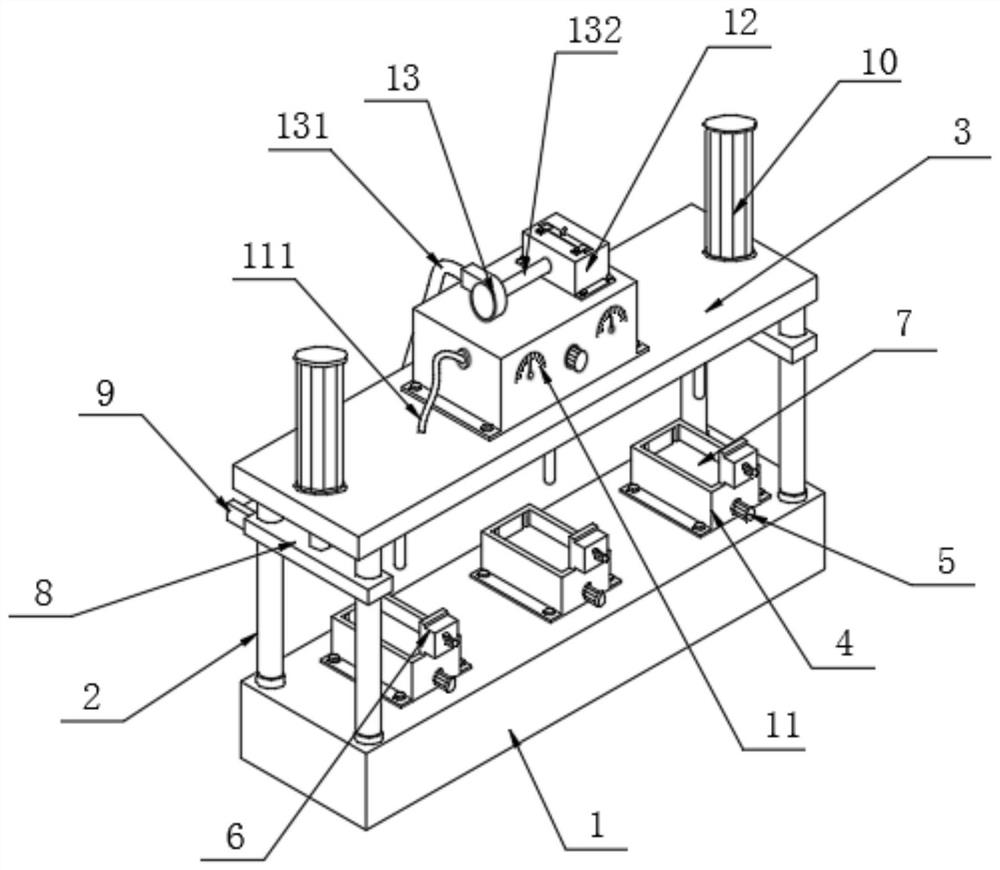

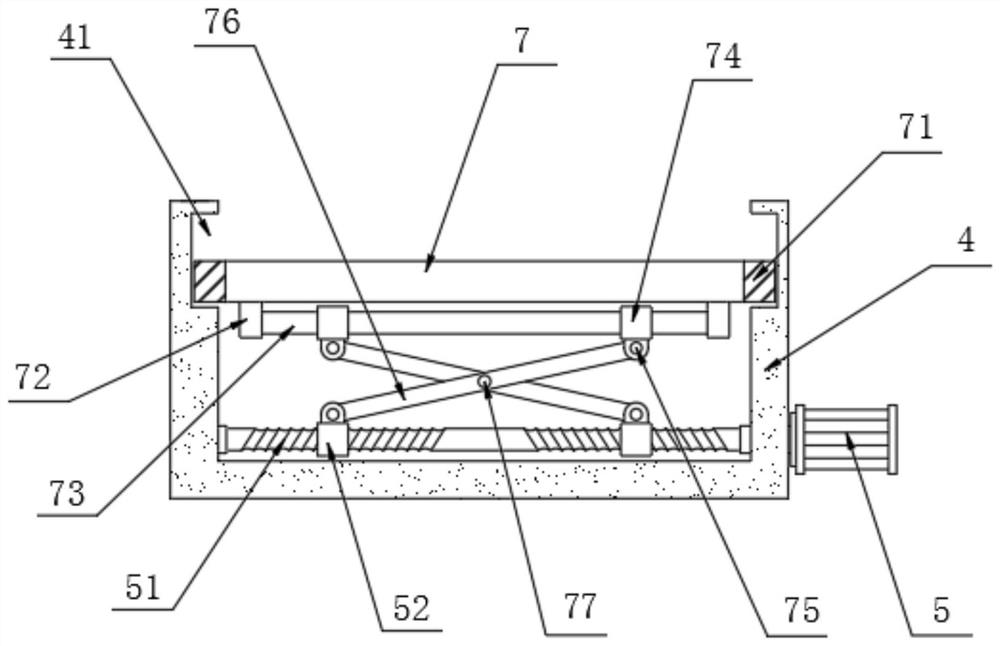

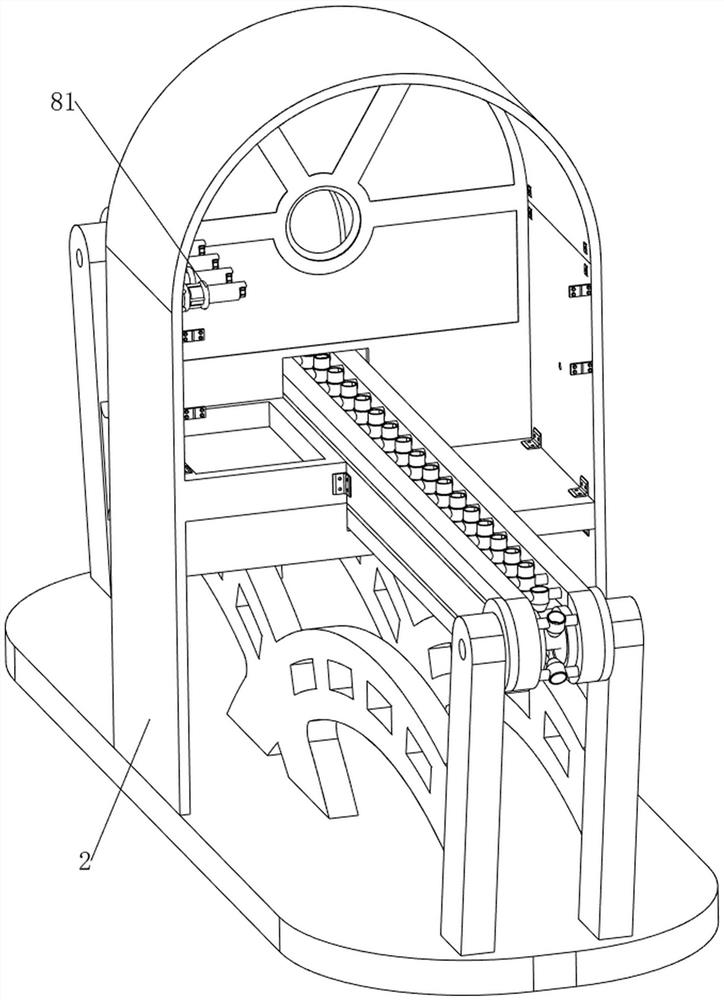

A lithium battery plate welding mold

ActiveCN111230362BFully automatedReduce labor intensityDispersed particle filtrationCell electrodesHydraulic cylinderMechanical engineering

The invention discloses a lithium battery pole plate welding mold, comprising a workbench, four corners of the upper surface of the workbench are vertically arranged with uprights, and a top plate is horizontally connected between the upper ends of the four uprights. The middle position of the upper surface of the worktable is equidistantly and fixedly installed with mold cavities, and a servo motor is embedded in the middle position on the lower side of each mold cavity, and each mold cavity is provided with a heat dissipation cavity on one upper surface. The invention relates to the technical field of lithium battery pole plate welding. In the lithium battery pole plate welding die, a fixing block is arranged on one side of two sliding plates, and hydraulic cylinders are embedded and installed at the middle positions of the front and rear upper surfaces of the top plate. Driven by the cylinder, the welding of lithium battery plates can be automatically completed, automation is realized, labor intensity is reduced, and multiple lithium battery plates can be welded at one time, thereby improving welding efficiency.

Owner:盐城聚安新能源科技有限公司

Mounting equipment for magnets in electronic cigarette atomizer

InactiveCN113184445AConvenient discharge workClamp firmlyConveyorsTobaccoElectric machineryElectronic cigarette

The invention relates to mounting equipment, in particular to mounting equipment for magnets in an electronic cigarette atomizer. The invention provides the mounting equipment for the magnets in the electronic cigarette atomizer. The mounting equipment automatically discharge, is quick to mount and facilitates feeding. The mounting equipment for the magnets in the electronic cigarette atomizer comprises a base, a main frame and a first motor, wherein the main frame is arranged at the middle side of the upper portion of the base; and the first motor is installed at the upper portion of the base. According to the mounting equipment, a discharging mechanism is arranged, the discharging mechanism is matched with a rotary emptying mechanism, the discharging mechanism in a compressed state resets to push other magnets to move rightwards, and the other magnets move rightwards so that the other magnets can be clamped by the rotary emptying mechanism next time; and the rotary emptying mechanism continues to rotate to drive the magnets to rotate to the position over a shell of the electronic cigarette atomizer, then a user pushes the magnets downwards, and the magnets can fall into the shell of the electronic cigarette atomizer, so that the work of installing the magnets in the electronic cigarette atomizer is achieved.

Owner:SHENZHEN AIRUISI ELECTRONICS CO LTD

One-time channel forming machine for water conservancy projects

ActiveCN111660406BTo achieve the purpose of maintenanceAchieve levelingFeeding arrangmentsAuxillary shaping apparatusMolding machineStructural engineering

The invention discloses a channel one-time forming machine for water conservancy engineering. The channel one-time forming machine for the water conservancy engineering comprises a channel forming machine body. Connecting bases are arranged at the bottom of the inner end of the channel forming machine body, a material laying frame is connected to the upper ends of the connecting bases in a slidingmode, lifting pull rods are connected with the rear end of the material laying frame in a stretchable mode, and curing covering membranes are connected with the side ends of the lifting pull rods ina sleeving mode. The material laying frame comprises a supporting plate, sleeve rod frames, a scraping plate, a material conveying base frame, a communicating pipe base, a hopper frame and pressure pumps. The material conveying base frame is arranged at the bottom end of the material laying frame, the upper end of the material conveying base frame and the communicating pipe base are arranged in acommunicating mode, the center of the communicating pipe base and the bottom end of the hopper frame are arranged in a communicating mode, the pressure pumps are installed on the upper portion of theside end of the hopper frame, and the bottom ends of the communicating pipe base and the hopper frame are fixedly connected with the supporting plate. According to the channel one-time forming machinefor the water conservancy engineering, due to the arrangement of the material laying frame, the purpose that materials are laid by the inner end is achieved.

Owner:宁夏凯拓建设工程有限公司

Gland leakage detection device for automatic production of batteries

InactiveCN109827712AIncrease flexibilityEven by forceDetection of fluid at leakage pointElectrical batteryAir pump

The invention relates to a gland leakage detection device for automatic production of batteries. The device comprises a main body, a blowing port and a conduction piece. A hydraulic rod is arranged atthe right side of the inner wall of the top end of the main body, and a pressing plate is connected to the bottom of the hydraulic rod. An air pump is arranged at the left side of the top end of themain body, and a rotating shaft passes through the left side of the inner wall of the top of the main body. The beneficial effects of the invention are as follows: the hydraulic rod, the pressing plate, the rotating shaft, the movable box and the main body are arranged, and the hydraulic rod is in threaded connection with the pressing plate; the hydraulic rod is connected with the pressing plate,so that a worker can replace the pressing plates of different specifications, and improves the working flexibility of the device for the battery pressing cover; the battery top cover can be pressed inall directions under the action of the convex blocks at the bottoms of the pressing plates, and the top cover is stressed uniformly, so the battery liquid leakage phenomenon is avoided.

Owner:胡旭燕

Collecting device for metal powder processing

InactiveCN108816956AFirmly connectedAvoid flying aroundDispersed particle filtrationCleaning using gasesEngineeringAir blower

The invention relates to a collecting device for metal powder processing. The collecting device comprises a main body, a first air blower, a fixing plate and an exhaust pipe, wherein a sucking plate penetrates through the top of the main body, and a first connecting pipe is disposed on the outer side of the main body; the first air blower is installed at the left end of the first connecting pipe,and a feeding pipe is connected to the left side of the first air blower; a supporting body is arranged at the bottom of the first air blower, and a fixing block is arranged on the outer wall of the main body; a bolt penetrates through the top of the fixing block, a cavity is formed in the inner side of the main body, and an electric heating block is mounted on the inner wall of the cavity; and the fixing plate is fixed to the inner side of the main body. The collecting device has the beneficial effects that by the arrangement of the sucking plate, the main body, a groove, the fixing plate anda sealing pad, and the central axis of the sucking plate coincides with the central axis of the main body, and the sucking plate is of a magnetic structure, under the magnetic action of the sucking plate, the sucking plate can perform adsorption work, and the offset phenomenon is not prone to occuring.

Owner:LISHUI FEITIANREN MACHINERY DESIGN CO LTD

A plastic mechanically dyed structure

ActiveCN111515090BPrevent leakageStain clean cleanLiquid surface applicatorsCoatingsStructural engineeringMechanical engineering

The invention discloses a plastic mechanical dyeing structure, which comprises a vertical mixer housing, in which a main shaft is arranged, the bottom of the outer wall of the main shaft is fixedly sleeved with a first shaft sleeve, and the outer sleeve of the first shaft sleeve A fixed sleeve is provided, and the fixed sleeve is fixedly sleeved on the bottom of the vertical mixer shell. The bottom of the fixed sleeve is sleeved with a second bushing, and the outer fixed sleeve of the second bushing is connected with a first connecting ring. The first spring A spring is arranged between the seat and the second spring seat, the middle part of the connecting cylinder cover is rotated and connected with a rotating rod, and an auger is arranged on the outside of the rotating rod. The present invention utilizes the cooperating arrangement of the first shaft sleeve and the fixed sleeve to keep the first shaft sleeve and the fixed sleeve in close contact with each other so as to prevent leakage of the dyeing agent, thereby making the dyeing of plastic particles cleaner and cleaner. The dragon will take out the plastic particles, so that the blocked inner cavity of the discharge pipe can be dredged, so as to continue the discharge work of the discharge pipe.

Owner:山东诺森塑胶有限公司

Swimming training and feeding device for gold arowana

InactiveCN112314502AImprove liquidityExercise wildClimate change adaptationPisciculture and aquariaEngineeringMechanical engineering

The invention relates to the technical field of gold arowana feeding, and discloses a swimming training and feeding device for a gold arowana. The swimming training and feeding device for the gold arowana comprises an outer shell body and a fish tank body, a feeding trough is formed in the upper surface of the fish tank body, an inner trough is formed in the feeding trough, the inner trough is internally and rotatably connected with a kinetic energy mechanism, the kinetic energy mechanism is in transmission connection with a feed storage mechanism through a circulation control mechanism, and afish feed ejection mechanism used for quickly ejecting fish feed is arranged below the feed storage mechanism. The kinetic energy mechanism and the feed storage mechanism are arranged to be matched with the fish feed ejection mechanism and a launching switch mechanism, the feed storage mechanism is driven by the kinetic energy mechanism to do reciprocating quantitative feeding work in the inner trough, then the fish feed is ejected to the water surface in the fish trough through an impacting column, and meanwhile, the fish feed can continuously move in the water under the action of the impactbuffering force, so that the gold arowana can quickly swim when swallowing the fish feed, the wild nature of swim of the gold arowana is exercised while the gold arowana is fed, and meanwhile, the ornamental value when the gold arowana swallows the fish feed is improved.

Owner:余积芳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com