Hotpot condiment processing equipment

A processing equipment and technology of hot pot bottom material, which is applied in the field of hot pot bottom material processing equipment, can solve the problems of manual work, single function, and inability to fish out, etc., and achieve the effect of convenient use, high degree of automation, and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

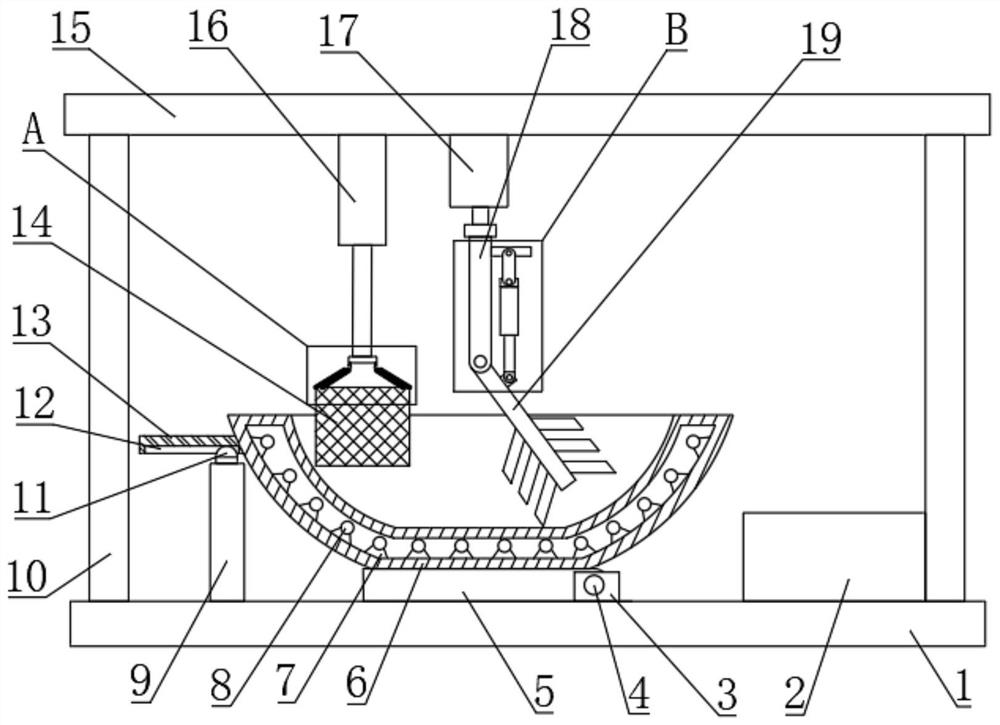

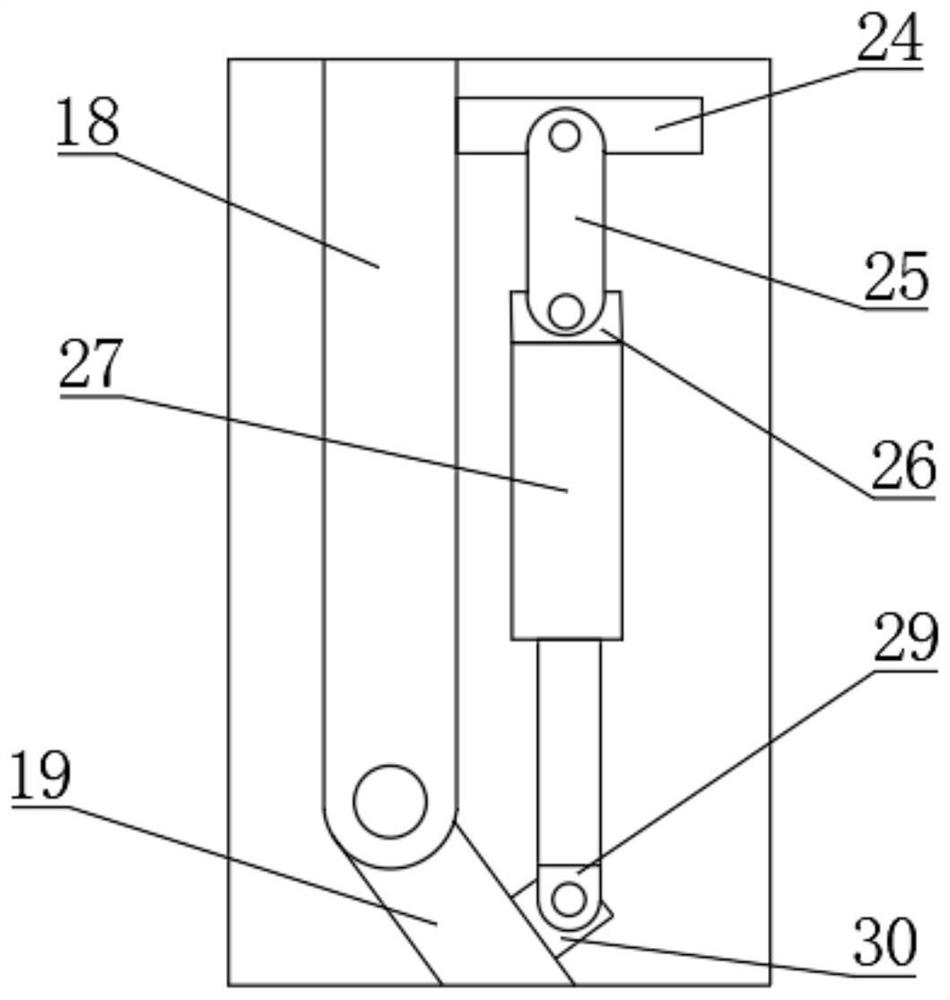

[0025] see figure 1 , figure 2 , image 3 and Figure 4 , a kind of chafing dish bottom material processing equipment, comprises base 1, pot body 6, top plate 15 and the 3rd electric push rod 27, the side wall of described pot body 6 is hollow, is provided with a plurality of in the side wall of pot body 6 An electric heating tube 8, a fixed block 3 and a first electric push rod 9 are fixedly installed on the upper surface of the base 1, a support plate 5 is fixedly connected to the bottom surface of the pot body 6, and one end of the support plate 5 is rotationally connected with the fixed block 3, and the pot body 6 is connected with a fixed plate 13, the upper end of the first electric push rod 9 is connected with a slider 11, the slider 11 is in contact with the lower surface of the fixed plate 13, and the lower surface of the top plate 15 is equipped with a second electric push rod. Rod 16 and motor 17, the lower end of the second electric push rod 16 is fixedly conne...

Embodiment 2

[0030] see Figure 1 to Figure 5 , this embodiment is a further description of a kind of hot pot bottom material processing equipment described in specific embodiment 1. In this embodiment, the upper surface of the base 1 is fixedly equipped with a collection container 2, and the collection container 2 is located in the pot. The lower right side of the body 6, the fixed plate 13 is fixedly connected to the left side of the pot body 6, and the inner wall of the pot body 6 is provided with a diversion groove 61, and the diversion groove 61 is located at the right end of the pot body 6 , the side wall of the pot body 6 and the interior of the bottom plate are fixedly connected with several mounting seats 7, the electric heating tube 8 is mounted on the mounting seats 7, and the top plate 15 is fixedly connected with the base 1 through several support columns 10.

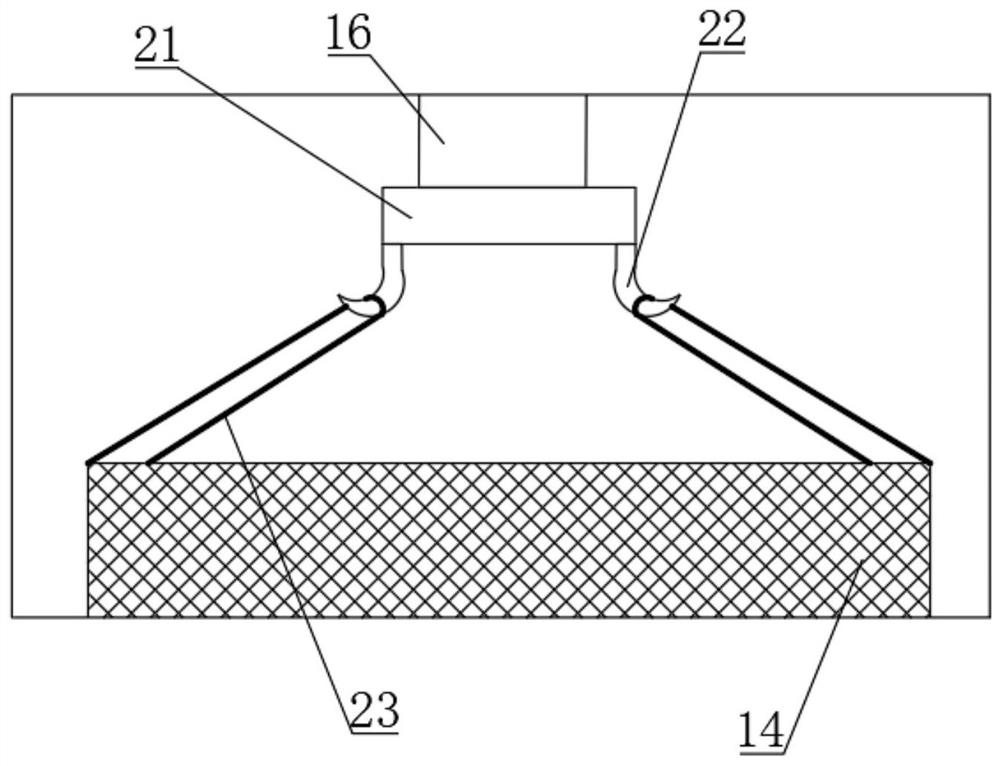

[0031] Described net basket 14 is made up of side and bottom surface, and the side surface and bottom surface of net ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com