Three-roller grinding machine

A three-roller mill and push mechanism technology, applied in grain processing and other directions, can solve the problem of accumulation in the main funnel, and achieve the effects of facilitating maintenance, improving product quality, and avoiding wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

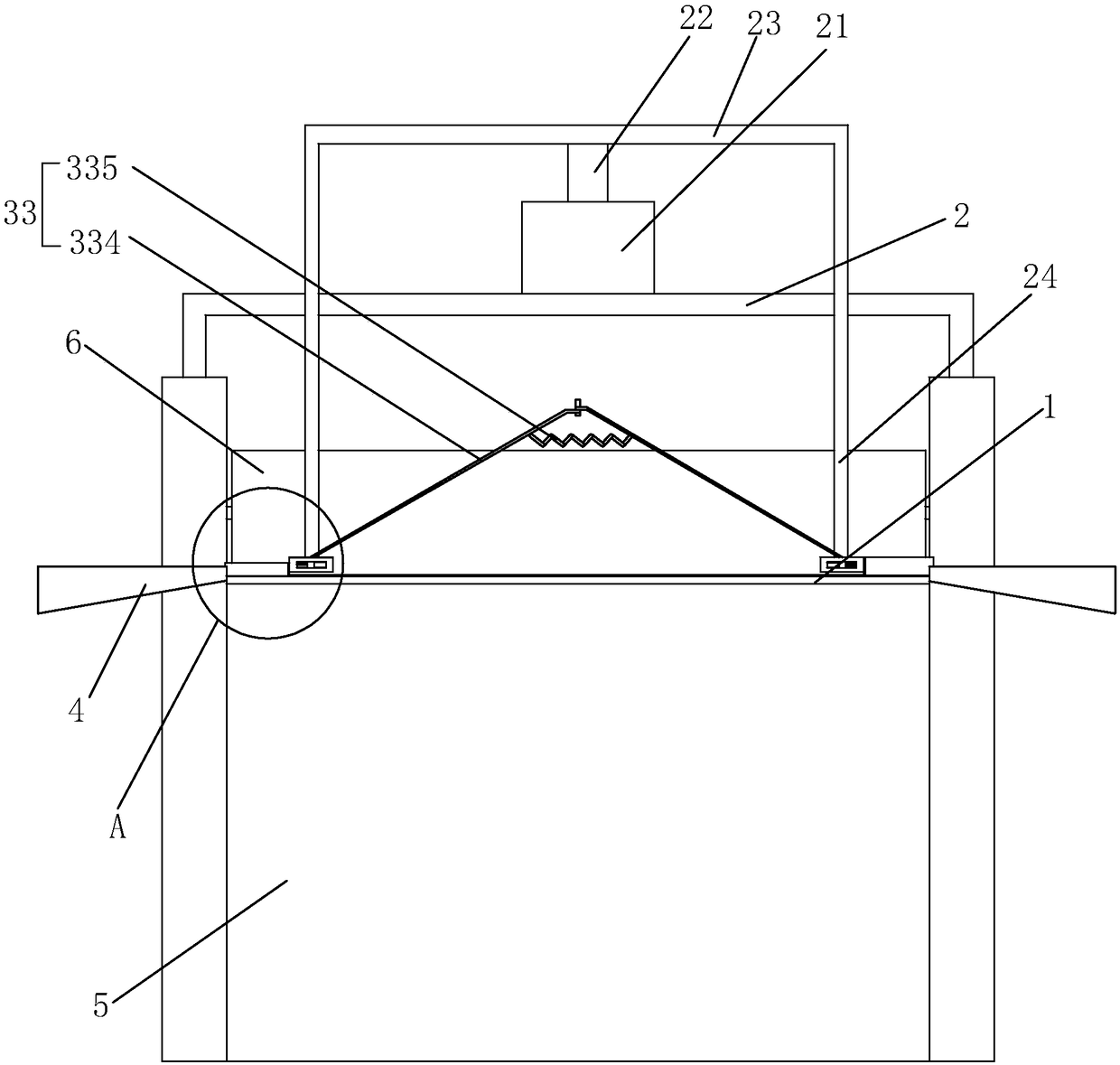

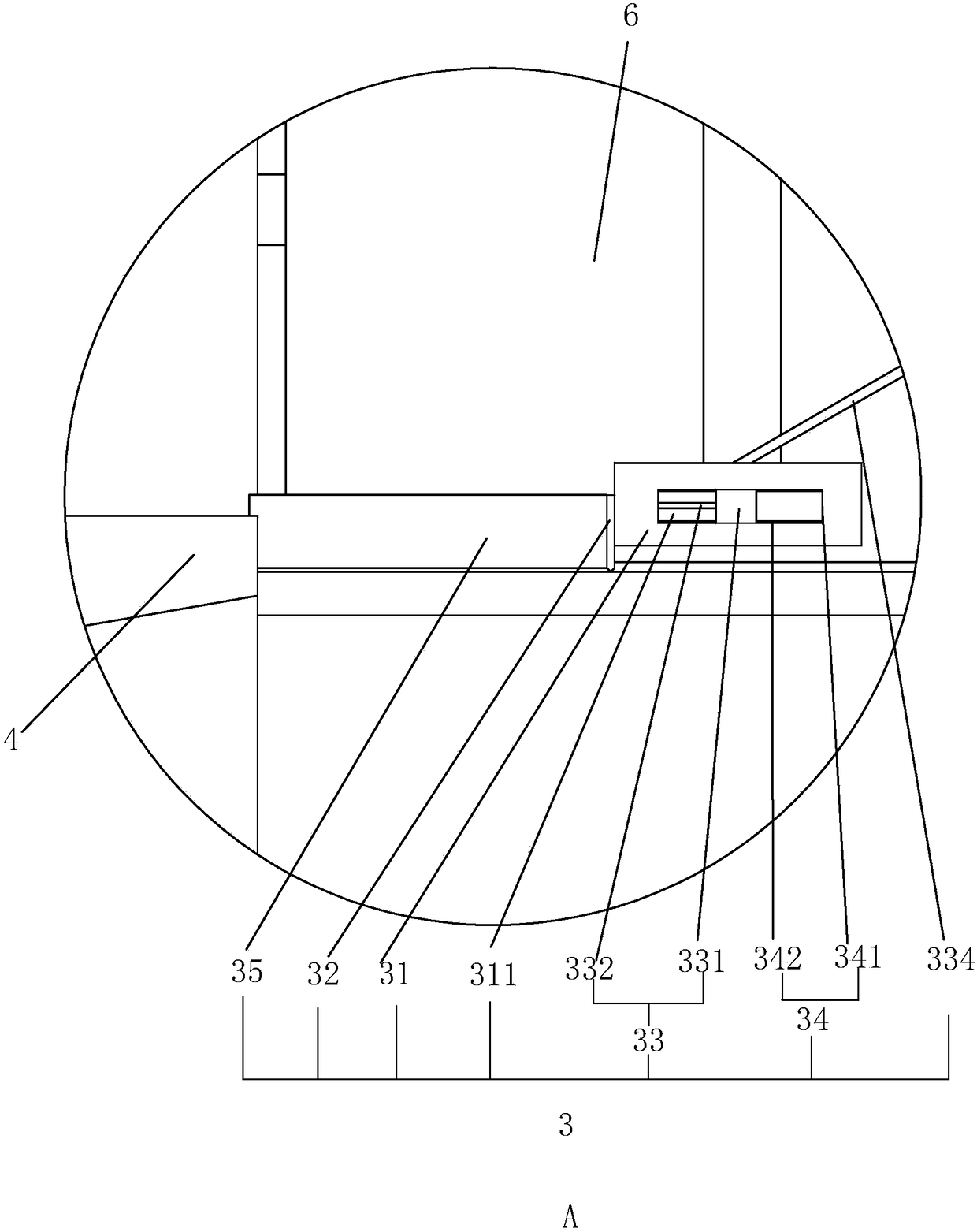

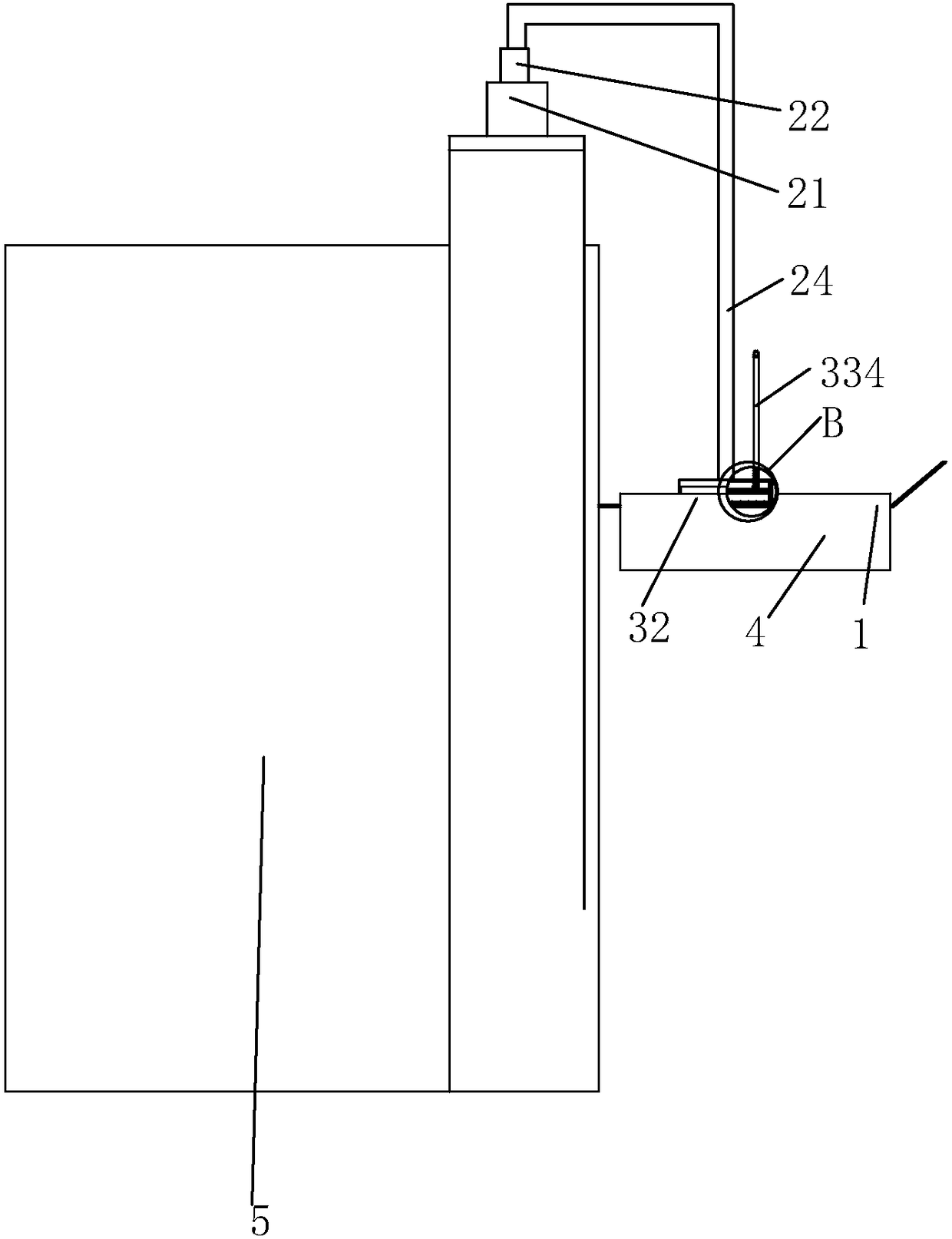

[0038]Embodiment: a kind of three-roll grinder, comprise frame 5, be arranged on the transmission system in frame 5, and be arranged on three roller shafts 6 that are controlled to rotate by transmission system on frame 5, these three roller shafts 6 are respectively The rear roller, the middle roller and the front roller, the rear roller is the feeding end for the material to be put in, the front roller is the output end of the material, and the outlet of the front roller is provided with a main funnel 1 matching the outlet. The material to be ground is placed at the feed end of the rear roller, and the transmission of the material is realized through the transmission between the roller shafts 6. During the transmission process, the mutual extrusion between the roller shafts 6 and the friction at different speeds are achieved. Grinding effect, there is also a scraper at the outlet of the front roller to scrape off the material that has been ground into slurry, so that the slur...

specific Embodiment approach

[0044] Specific embodiments: when the material is being ground between the three roller shafts 6, first control the drive cylinder 21 so that the piston rod 22 is fully extended, that is, the cutting device 3 is located above the main funnel 1, and is connected with the main funnel 1 There is no contact at all, so that the slurry can be output smoothly; the material that has completed the grinding work is formed into a slurry, which is rotated by the front roller and sent to the discharge port, and is scraped off and formed into a block under the action of the scraper. Main funnel 1 direction transmission, when the slurry is transmitted to the main funnel 1, control the driving cylinder 21 to work, the piston rod 22 descends, and drives the working rod 24 to descend, at this time the first scraper 32 cuts the slurry into sections as a whole, and the Simultaneously, the cutting device 3 at both ends is in contact with the slurry, that is, the first scraper 32 directly cuts off b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com