Powder feeding device of electrical automation equipment

An electrical automation, powder feeding technology, used in packaging, loading/unloading, transportation and packaging, etc., can solve the problem of low accuracy of automation, inability to set feeding time, and inability to realize automatic material conveying, etc. problem, to save manpower, realize automatic conveying function, and avoid powder escape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

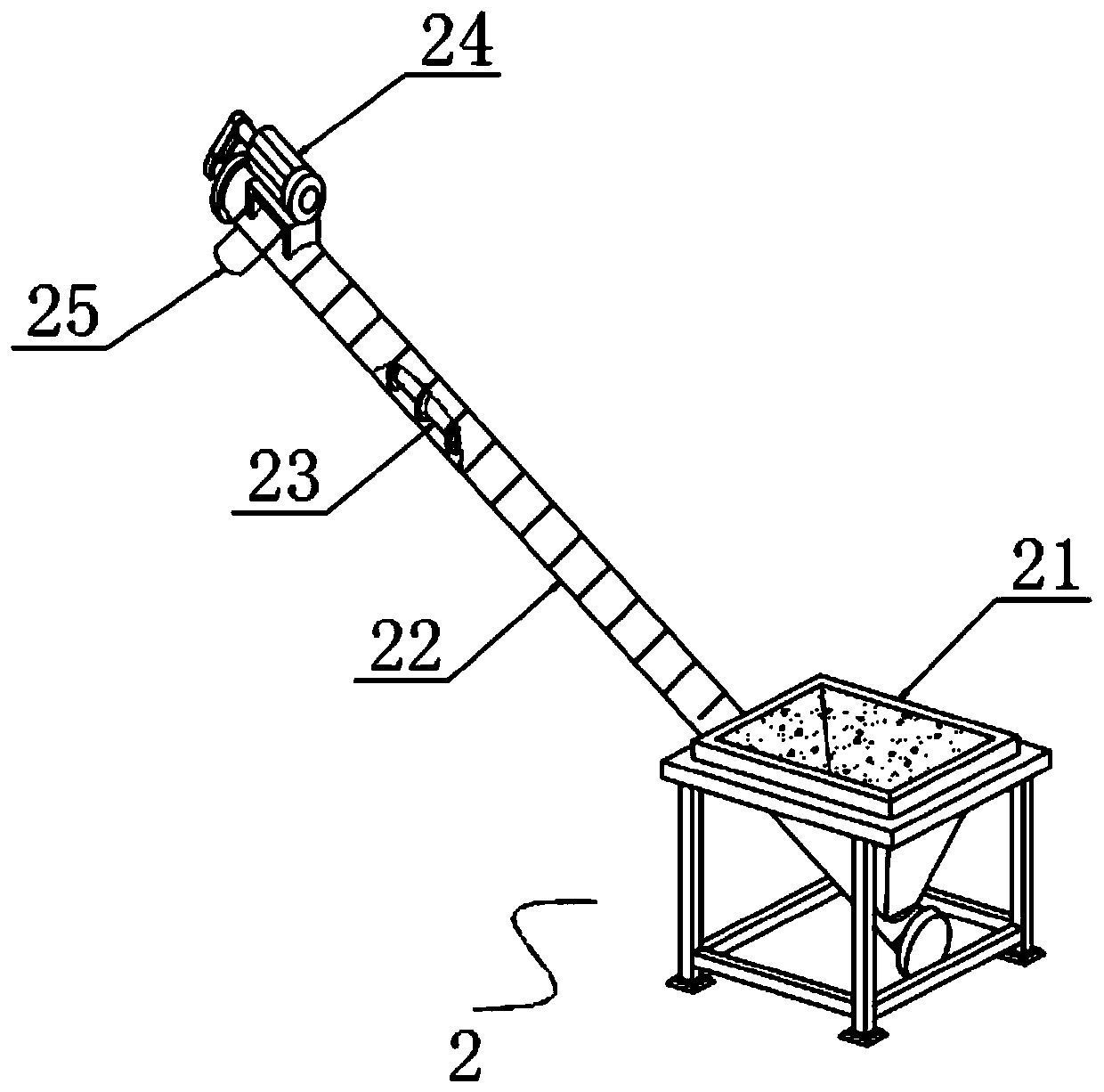

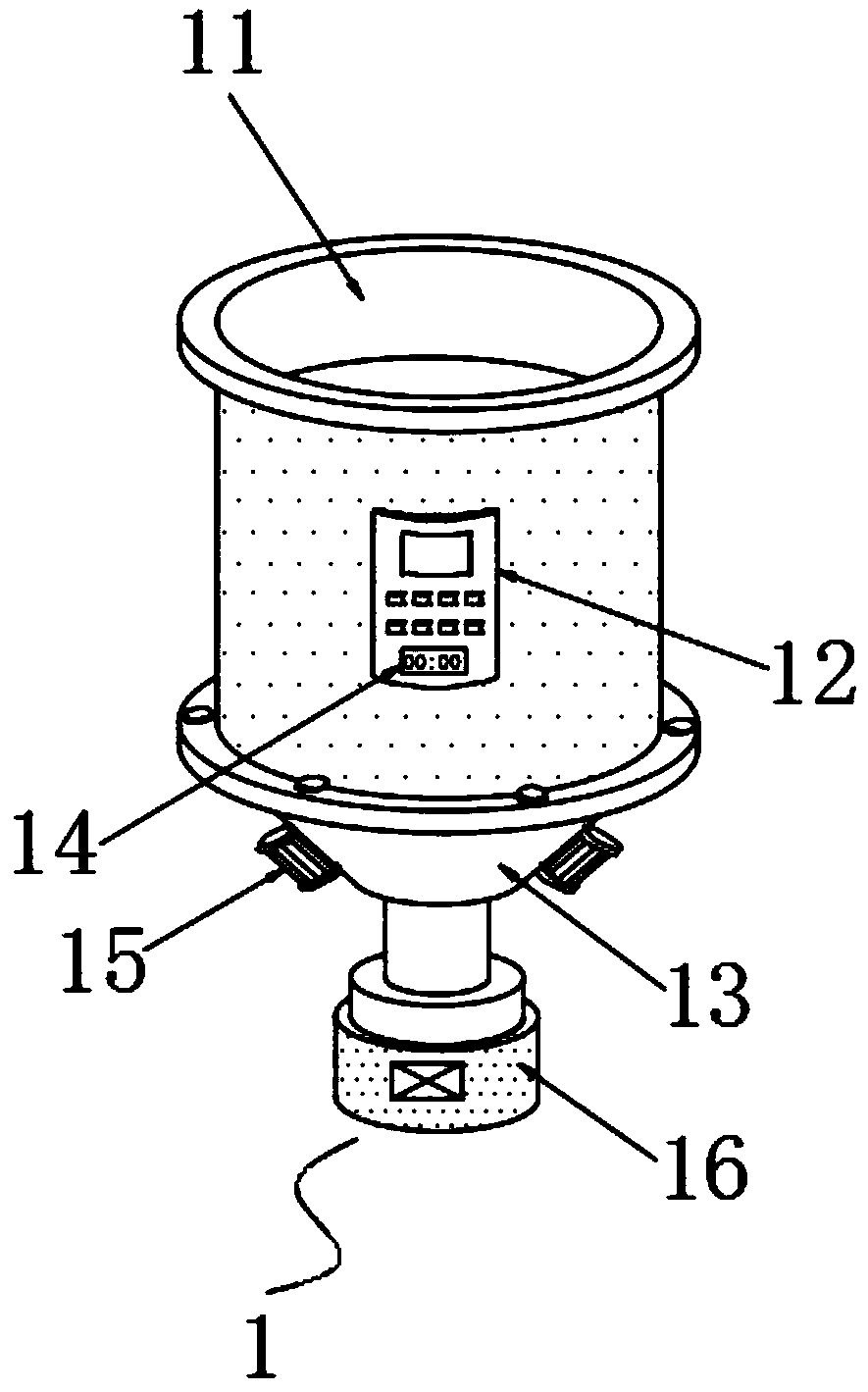

[0021] see Figure 1~4 , in an embodiment of the present invention, a powder feeding device for electrical automation equipment includes a storage tank 1, and one side of the storage tank 1 is provided with a feeding mechanism 2, and the feeding mechanism 2 includes a feeding hopper 21, and the feeding hopper 21 A feeding pipe 22 is fixedly installed on one side of the bottom end of the feeding pipe 22, and a screw rod 23 is installed inside the feeding pipe 22, and a drive motor 24 (type YL80) is fixedly installed on the top of the feeding pipe 22. The position below the end of the feeding pipe 22 There is a discharge port 25 at the center, and a belt is installed at the connection between the screw rod 23 and the drive motor 24, and the screw rod 23 and the drive motor 24 are connected by belt transmission, and the automatic feeding of materials can be realized through the provided feeding mechanism 2. , to overcome the defects of manual feeding of traditional equipment, imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com