Convenient and fast cutting equipment for energy-saving and environment-friendly materials

A cutting equipment, energy-saving and environment-friendly technology, applied in metal processing, etc., can solve the problems of difficult walls and edge parts that are difficult to cut flat, fit, etc., and achieve good cutting results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

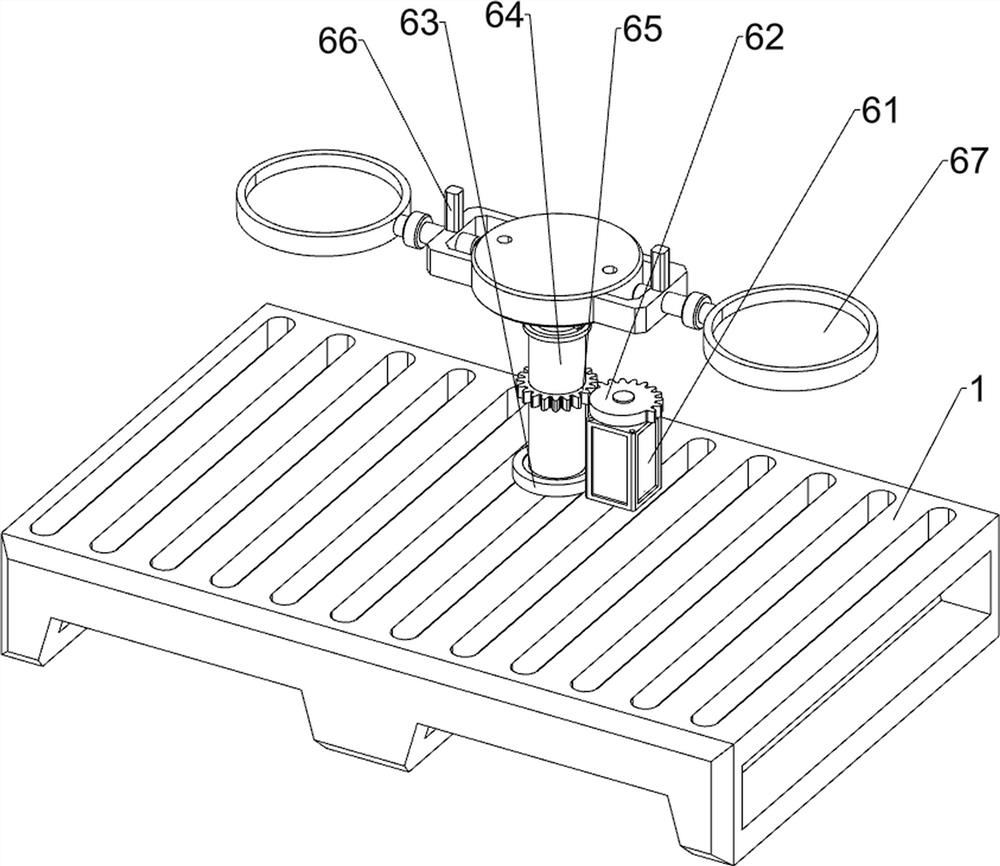

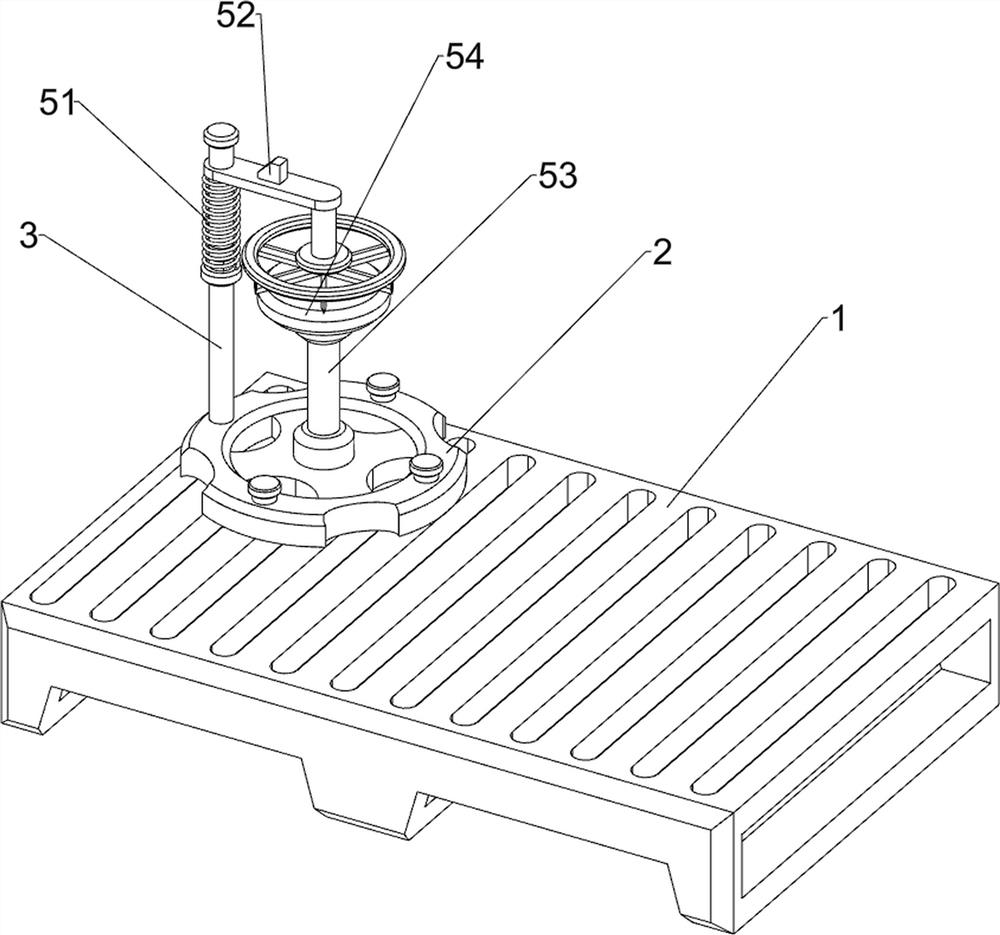

[0024] A convenient cutting equipment for energy-saving and environment-friendly materials, see figure 1 As shown, it includes a base 1, a first mounting seat 2, a guide column 3, a cutting disc 4, a cutting mechanism 5, and a rotating mechanism 6. The left rear side of the top of the base 1 is provided with a first mounting seat 2, and the top of the first mounting seat 2 is There is a guide post 3 on the left side, a cutting disc 4 is slidingly arranged on the guide post 3, a cutting mechanism 5 is connected between the first installation seat 2, the guide post 3 and the cutting disc 4, and a rotating disc is provided in the middle of the top rear side of the base 1. Institution 6.

[0025] refer to figure 2 As shown, the cutting mechanism 5 includes a first spring 51, a first wedge block 52, a support rod 53 and a tray 54, a first spring 51 is connected between the cutting disc 4 and the guide post 3, and a second spring 51 is arranged in the middle of the cutting disc 4 ...

Embodiment 2

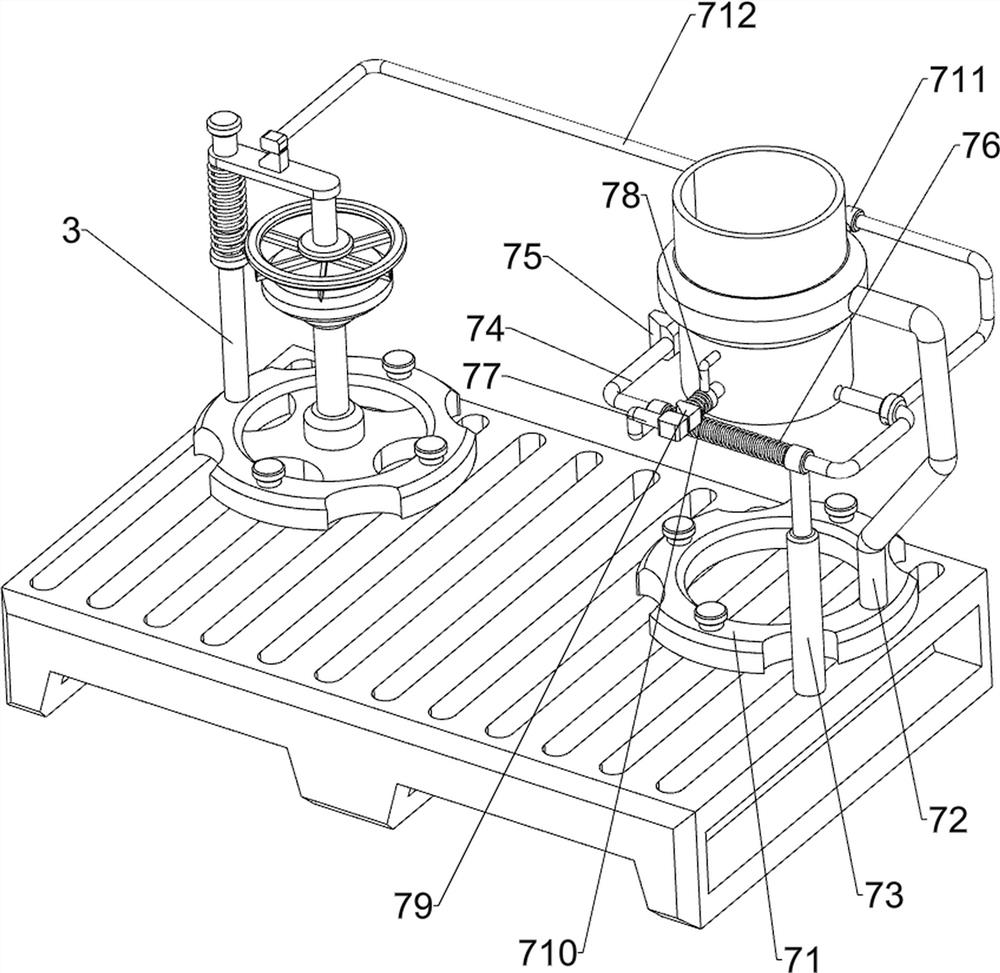

[0029] On the basis of embodiment 1, refer to Figure 4 As shown, a feeding mechanism 7 is also included, and the feeding mechanism 7 includes a second mounting seat 71, a material guide barrel 72, a first sliding sleeve 73, a first extruding rod 74, a second wedge block 75, a second spring 76. Push block 77, second sliding sleeve 78, second extruding rod 79, third spring 710, third sliding sleeve 711 and third extruding rod 712, the second mounting seat 71 is provided on the right rear side of the top of base 1 , the top right side of the second mounting seat 71 is provided with a guide barrel 72, the top right side of the base 1 is provided with a first sliding sleeve 73, and the upper side of the first sliding sleeve 73 is slidingly provided with a first extrusion rod 74, the first extrusion The left side of the compression rod 74 is provided with a second wedge block 75, the second spring 76 is connected between the first extrusion rod 74 and the first sliding sleeve 73, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com