A redwood gasification pressurized softening process

A technique of mahogany and craftsmanship, applied in wood processing appliances, wood treatment, pressure impregnation, etc., it can solve the problems of difficult cutting and equipment wear, and achieve the effects of good softening effect, convenient cutting and ingenious design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The type of mahogany tested is rosewood which is not hard and dense in texture.

[0033] a, selected wood, select 3 rosewoods according to the manufacturing needs;

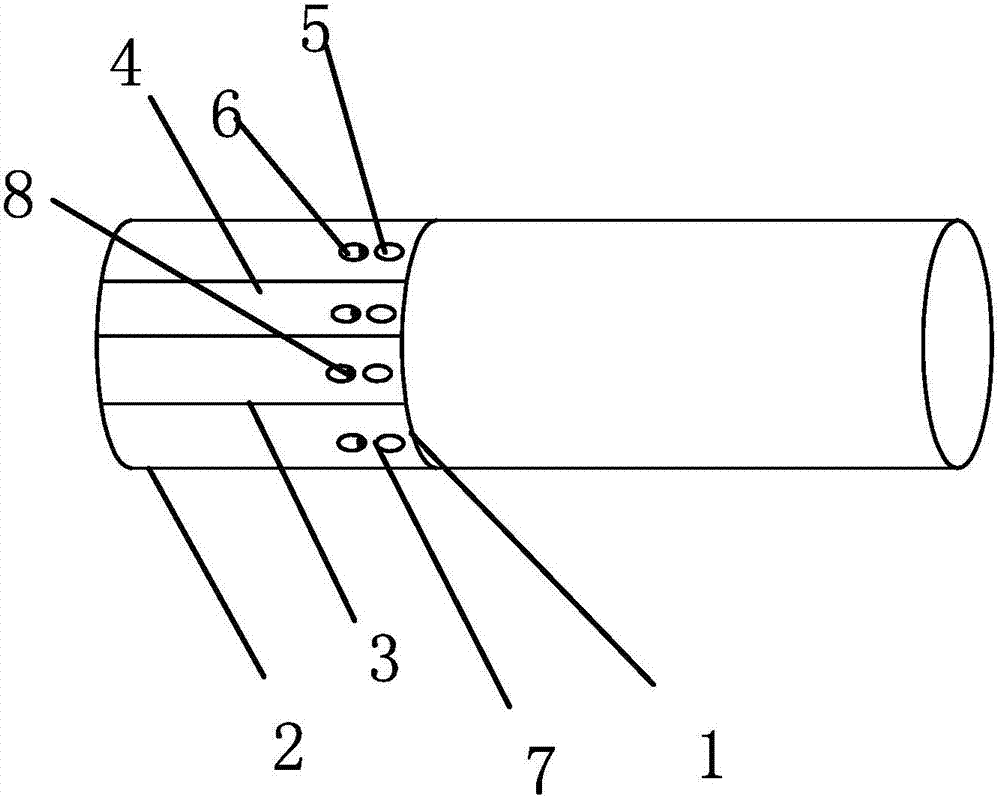

[0034] b. Cutting logo, after selecting the wood, draw a line at one end of the rosewood with a marker according to the size required for cutting. Between the parts is the softening part 2, on the softening part 2, a marking pen is used to draw a horizontal line, which is the marking line 23, and the marking line 23 is distributed at intervals in the transverse direction, and the perforated softening part is formed between the adjacent marking lines 23 4;

[0035] c. Drilling and softening, processing and drilling on the end of the drilling softening part 4 close to the marking line 1, the holes are blind holes, and each drilling softening part 4 is drilled with several pairs of blind holes 5 and blind holes Two 6, the diameter of blind hole one 5 and blind hole two 6 is 1.5cm, blind hole one 5 is closer ...

Embodiment 2

[0042] The type of mahogany in the test is rosewood with hard and dense texture.

[0043] a. Select the wood, choose 3 pieces of rosewood according to the manufacturing requirements;

[0044] b. Cutting logo, after selecting the wood, according to the size required for cutting, draw a line at one end of the red sandalwood with a marker pen. Between the parts is the softening part 2, on the softening part 2, a marking pen is used to draw a horizontal line, which is the marking line 23, and the marking line 23 is distributed at intervals in the transverse direction, and the perforated softening part is formed between the adjacent marking lines 23 4;

[0045] c. Drilling and softening, processing and drilling on the end of the punching softening part 4 close to the marking line 1, the hole is a blind hole, and each drilling softening part 4 is drilled with a blind hole 1 5 and a blind hole 2 6 , the hole diameter of blind hole 1 5 and blind hole 2 6 is 1 cm, blind hole 1 5 is clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com