Efficient supercharged cotton yarn environment-friendly dyeing device

A technology of dyeing device and yarn dyeing machine, which is applied in the direction of cleaning device for processing textile materials, liquid/gas/steam processing transmission device, liquid/gas/steam yarn/filament processing, etc., and can solve the problem of contact between yarn and dyeing agent Insufficient, affecting the dye liquor filtration effect, surface wool clogging and other problems, to achieve the effect of facilitating loading and unloading work, improving loading and unloading speed, and increasing contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

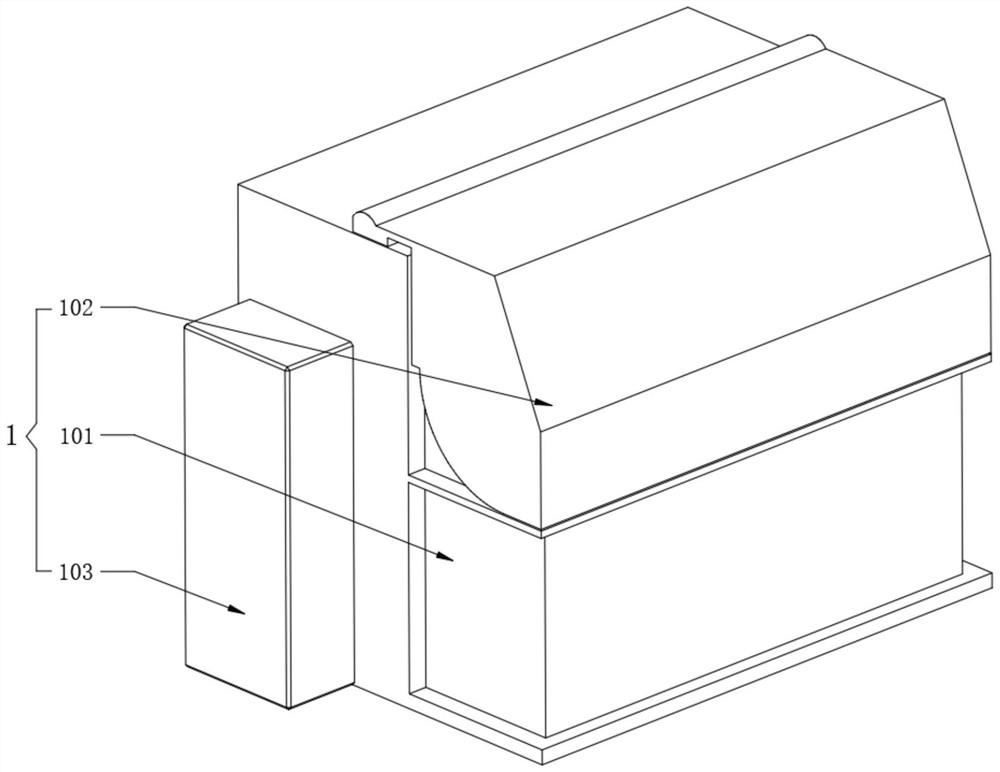

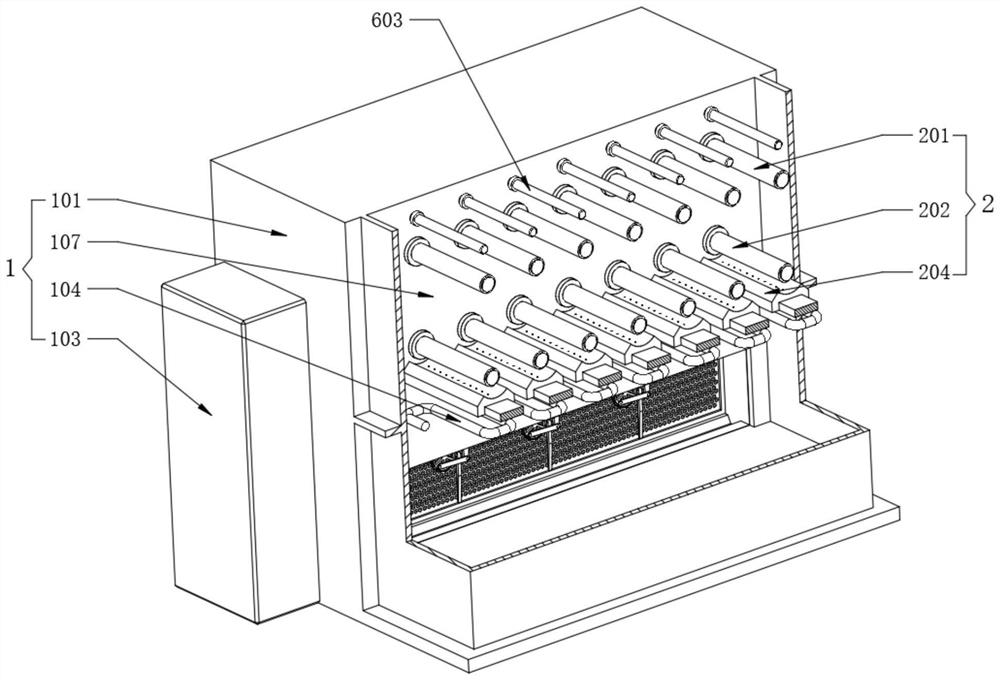

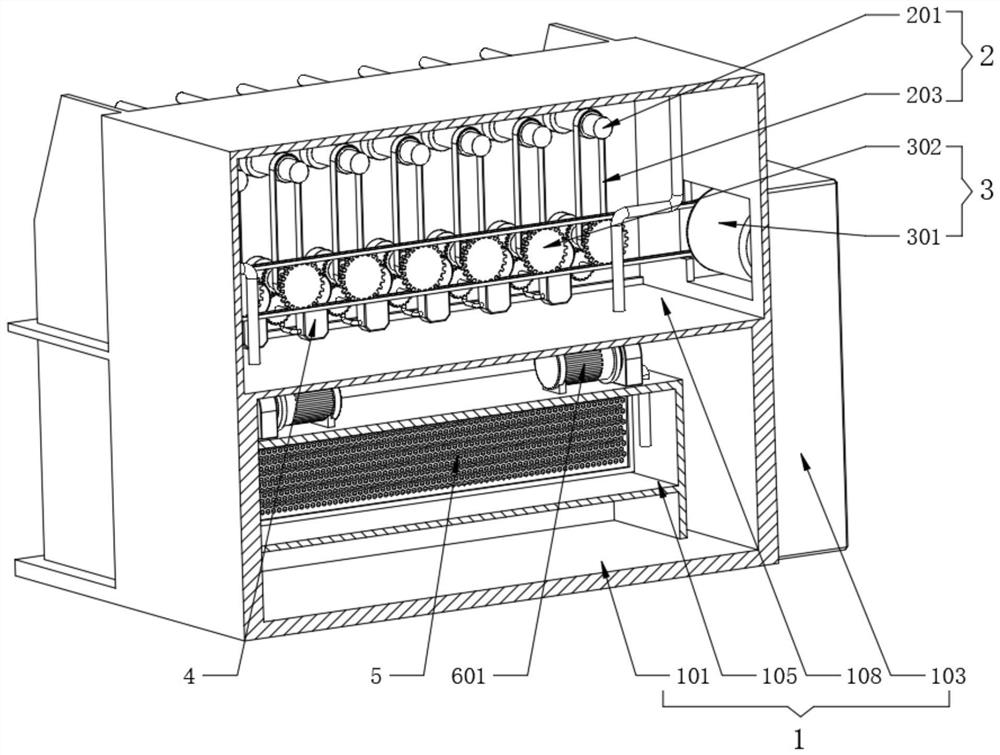

[0043] see Figure 1-5 , a high-efficiency pressurized cotton yarn environmentally friendly dyeing device, including a yarn dyeing machine 1 and a winding and dyeing component 2:

[0044] see figure 1 , figure 2 and image 3, the yarn dyeing machine 1 also includes a body 101, the surface of the body 101 is rotatably installed with an organic cover 102, a dyeing chamber 107 is fixed on one side of the body 101, and the interior of the dyeing chamber 107 provides a place to complete the yarn dyeing, and the other side of the body 101 A transmission chamber 108 is fixedly opened, and a coil heater 104 is fixedly installed under the inside of the body 101. After the coil heater 104 is energized, it can heat the dyeing agent, thereby improving the dyeing effect. The inner bottom end of the body 101 is fixedly provided with a circulating liquid tank 105. A filter screen 5 is fixedly assembled on the inner side of the circulating liquid tank 105, and the dye enters the inside of...

Embodiment 2

[0049] see Figure 5-6 , a high-efficiency pressurized cotton yarn environmentally friendly dyeing device, including a hydraulic pressurizer 4:

[0050] see Image 6 , the water pressure press 4 also includes a water pressure shell 401. The pressure water shell 401 is installed in the transmission chamber 108 at equal distances. One end of the lower winding roller 202 is fixedly sleeved with a driving gear 206, and the transmission chamber 108 rotates inside. A driven gear 207 is installed, and the driving gear 206 is meshed with the driven gear 207. When the lower winding roller 202 rotates, the driving gear 206 will drive the driven gear 207 to rotate together, and a crankshaft 404 is installed on the inner top of the pressurized water shell 401. One end of the crankshaft 404 and one end of the driven gear 207 are fixedly sleeved with a secondary belt 208. After the transmission of the secondary belt 208, the crankshaft 404 can be rotated inside the pressurized water shell ...

Embodiment 3

[0053] see Figure 7 , a high-efficiency pressurized cotton yarn environmentally friendly dyeing device, including winding and dyeing components 2:

[0054] see Figure 7 , the side walls of the upper winding roller 201 and the lower winding roller 202 are fixedly welded with an inner rod 209, and the outer surface of the inner rod 209 is movably sleeved with an outer tube 210. The tube 210 is pulled out. After the yarns are wound on the surfaces of the two outer tubes 210, the outer tube 210 is reassembled. The inner wall of the outer tube 210 is fixedly provided with a convex strip 211, and the surface of the inner rod 209 is fixed with a groove 212, and the convex strip 211 is movable. embedded in the groove 212 .

[0055] In use: in the process of yarn feeding, first pull out the outer tube 210 at one end of the upper winding roller 201 and the lower winding roller 202, wrap the yarn on the surfaces of the two outer tubes 210, and reassemble the outer tube 210. During t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com