Quantitative subpackaging and packaging equipment for flour wholesale

A quantitative packaging and equipment technology, which is applied in the field of quantitative packaging equipment for flour wholesale, can solve the problems of slow packaging speed, difficult flour precise packaging, and difficult flour quantification, etc., to achieve the effect of precise packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A flour wholesale use quantitative dispensing equipment, such as figure 1 As shown, there is a primary frame 1, a lower pressure mechanism 2, and a clamping mechanism 3, and the main frame 1 is provided with a lower pressure mechanism 2, a main frame 1 clamping mechanism 3.

[0029] When the user needs to quantify the flour, the device can be used, first, the package is placed in the clamping mechanism 3, and the flour is subjected to the packaging bag, under the gravity of flour, The components of the lower pressure mechanism 2 move down, the user can move the distance to the lower pressure mechanism 2, and then achieve quantitative dispensing, after the discharge is completed, the user will remove the package in the clamping mechanism 3. .

Embodiment 2

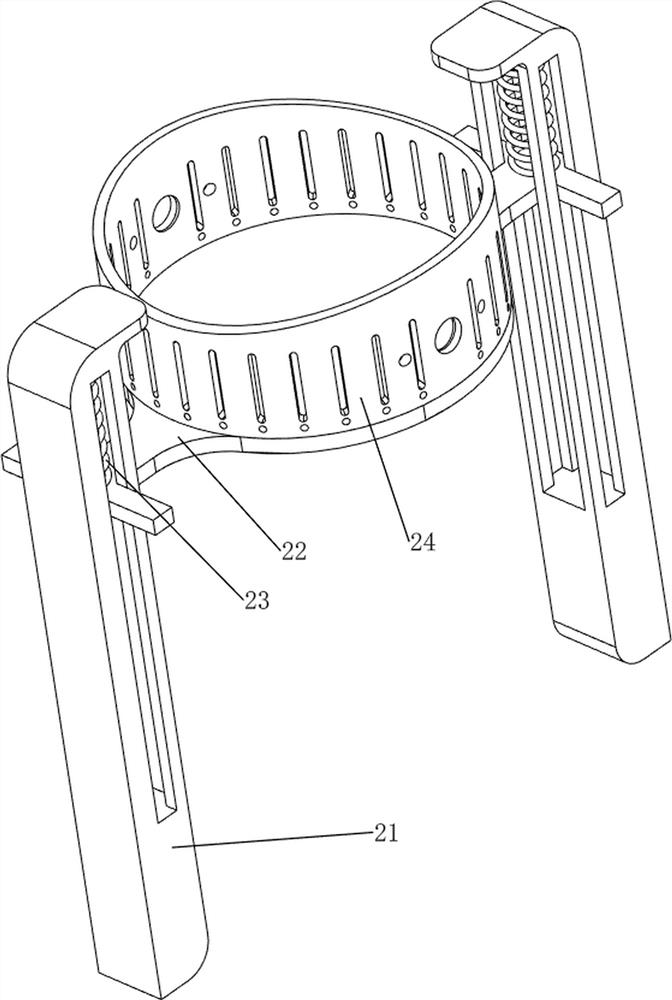

[0031] On the basis of Example 1, such as Figure 2-3 As shown, the lower pressure mechanism 2 includes a slide rail 21, a pallet 22, a linear spring 23, a limit frame 24, and a slide rail 21 on the main frame 1, and the sliding type of the rails 21 on both sides. The plate 22, the pallet 22 is connected to the rails 21, and the upper portion of the pallet 22 is provided with a limit border 24.

[0032] The package is located in the limit box 24, and then the weight of the flour increases, so that the limit frame 24 will move the pallet 22 downwardly down the slide rail 21, at which time the linear spring 23 is stretched, when the user will be uniformly When the flour is removed, the pallet 22 and the limit frame 24 move downward under the reset action of the linear spring 23.

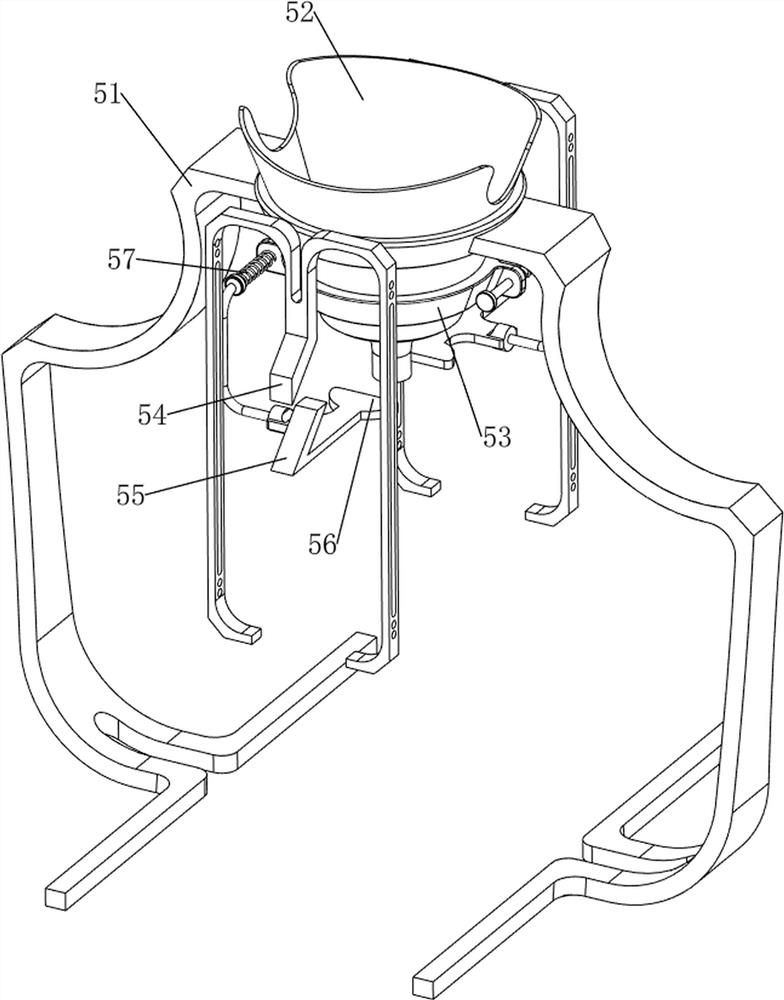

[0033] The clamping mechanism 3 includes a first fixing plate 31, a first fixing post 32, a first pinch plate 33, a second pinch plate 34, and a first spring 35, and the main frame 1 is symmetrically connec...

Embodiment 3

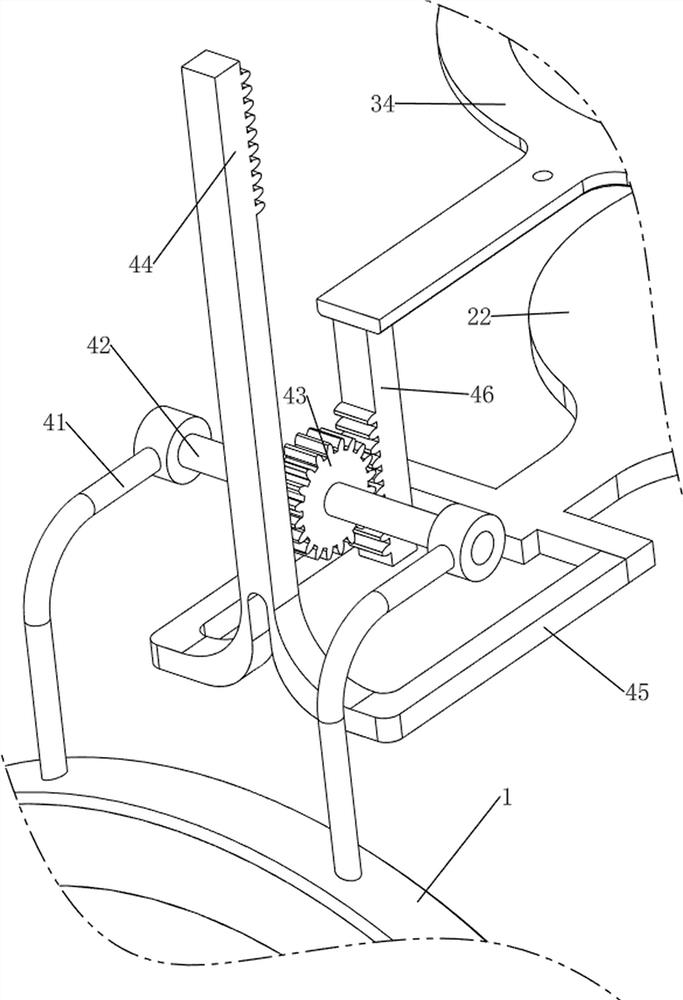

[0036] On the basis of Example 2, such as Figure 4-8 As shown, there is also a detachment mechanism 4, and the disengagement mechanism 4 includes a second fixing post 41, a rotating shaft 42, a straight gear 43, a first rack 44, a link 45, and a second rack 46, and the main frame 1 is provided. Symmetrical equipped with a second fixing post 41, a spinning shaft 42 is provided between the second fixed column 41 on both sides, and a straight gear 43 is provided on the rotating shaft 42, and a connecting rod 45 is connected to the pallet 22, and the link. The first rack 44 is provided on 45, and the first rack 44 is fitted with the straight gear 43, and the second pinch plate 34 is provided with a second rack 46, and the second rack 46 cooperates with the straight gear 43.

[0037] The pallet 22 roses the link 45 and the first rack 44 downward, when the first rack 44 is engaged with the straight gear 43, so that the straight gear 43 is rotated, and the straight gear 43 is engaged wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com