Automatic packaging machine for optical filter switcher

A switcher and optical filter technology, applied in packaging and other directions, can solve the problems of reducing work efficiency and achieve the effect of improving work efficiency and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

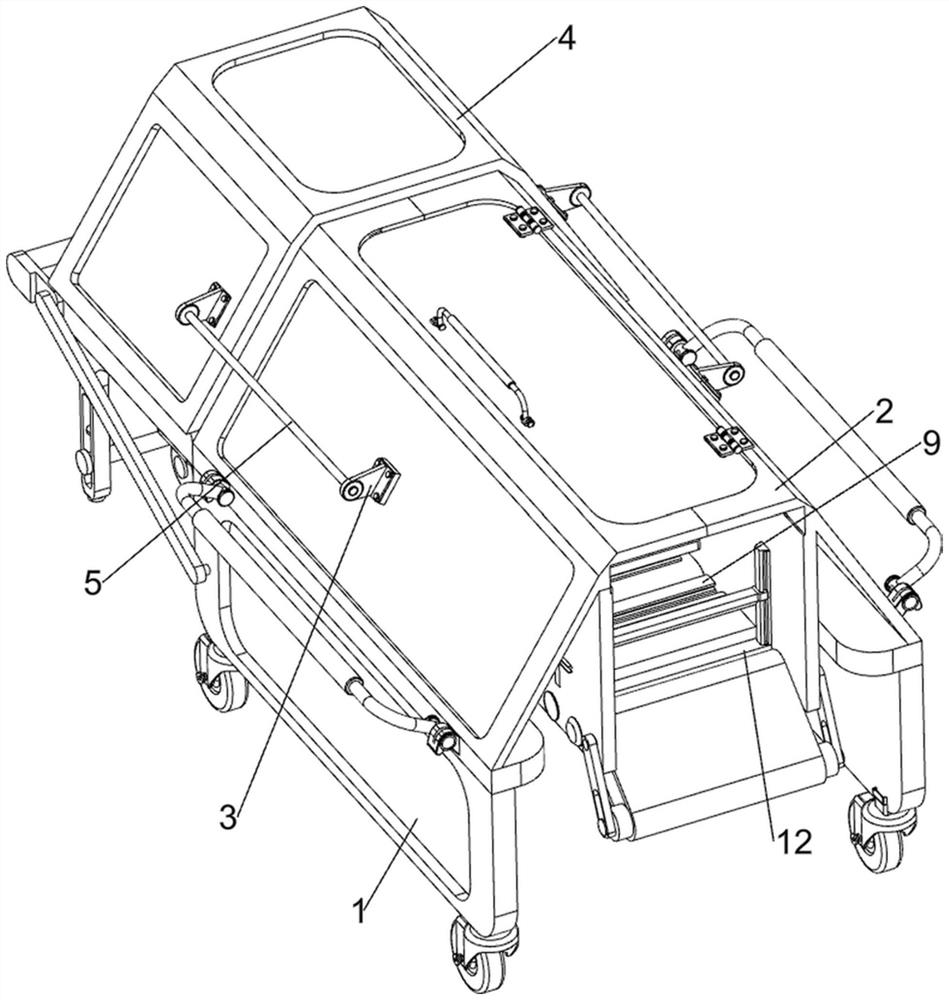

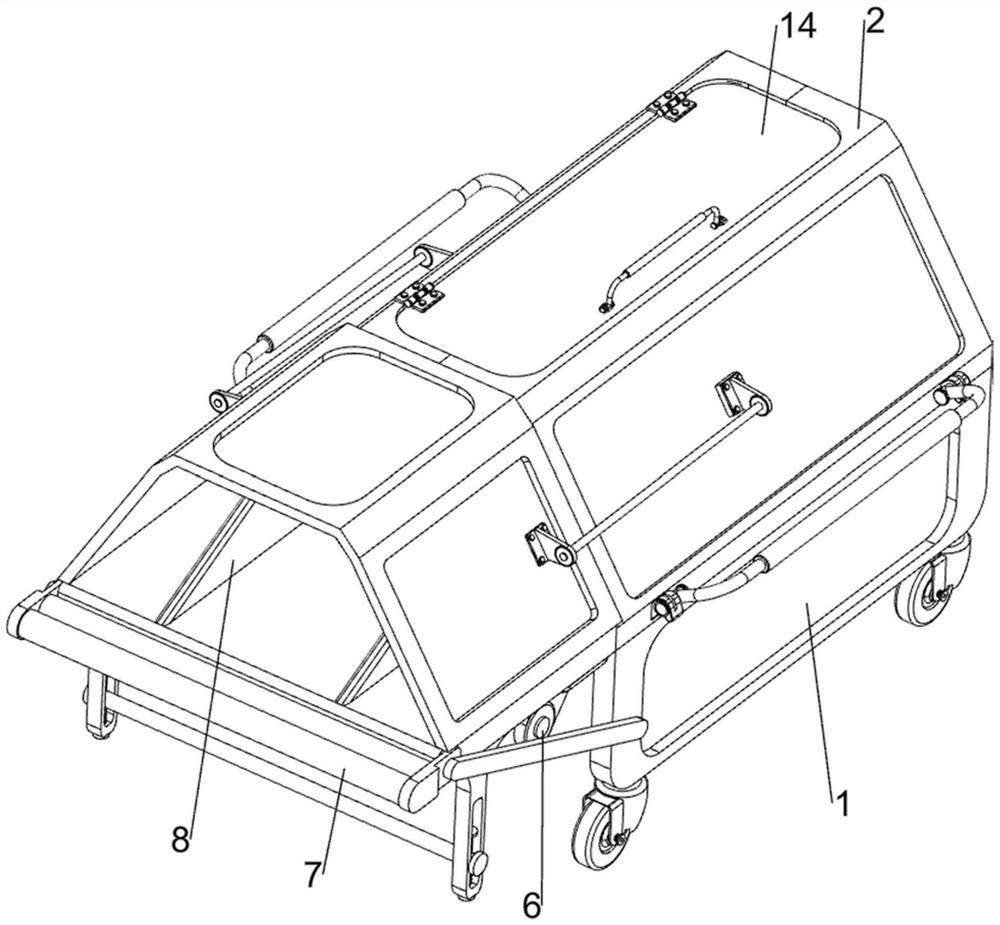

[0084] An automatic packaging machine for filter switchers, now refer to Figure 1-4 , including a support frame 1, a first protective frame 2, a limiter 3, a second protective frame 4, a first limit shaft 5, a coiler 6, a roller frame 7, a molding roller frame 71, and a winding block 8 , the tail packaging mechanism 9 and the welt packaging mechanism 10, the upper front side of the supporting frame 1 is connected with a first protective frame 2, the left and right sides of the first protective frame 2 are fixed with the stopper 3 by bolts, and the front side of the lower part of the supporting frame 1 is connected. The coiler 6 is fastened by bolts, the first limit shaft 5 is slidably connected to the two limiters 3, and the second protective frame 4 is connected between the rear sides of the two first limit shafts 5. The second protective frame 4 is slidably connected with the first protective frame 2 and the supporting frame 1. Two winding blocks 8 are fixedly connected to ...

Embodiment 2

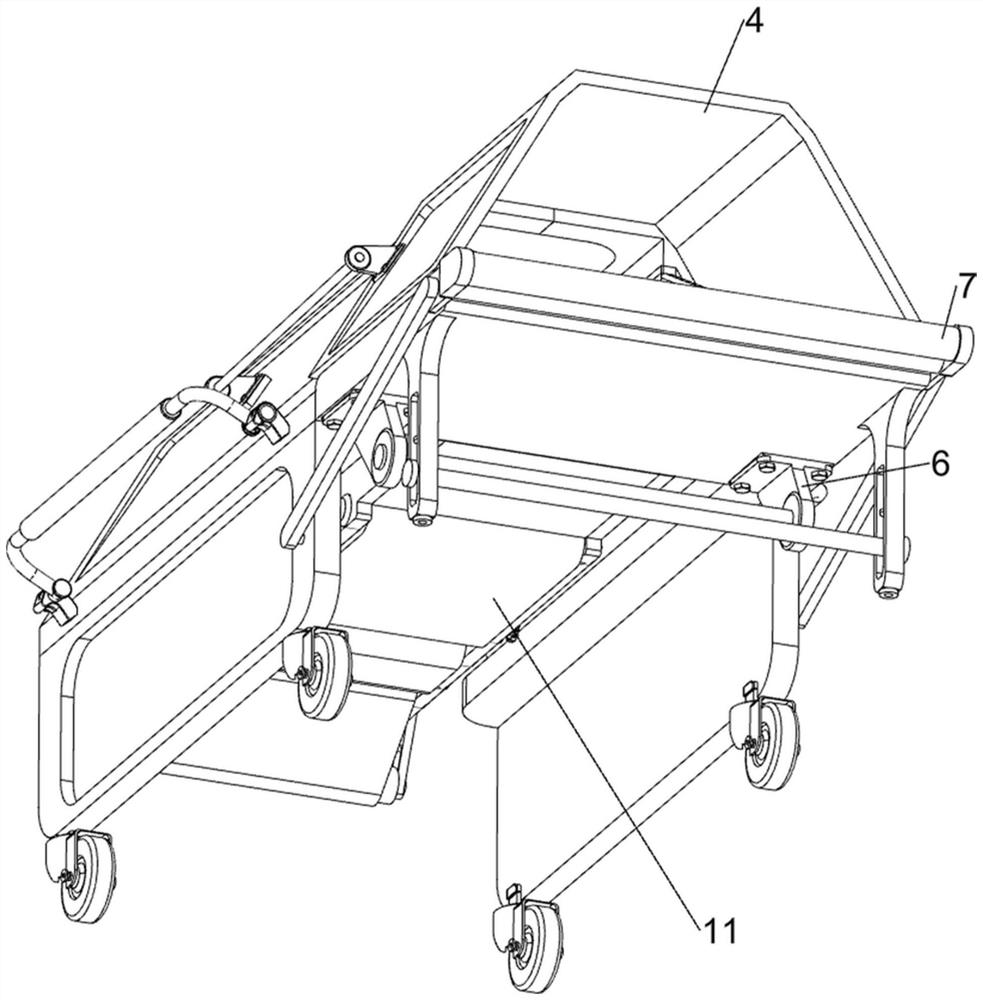

[0089] On the basis of Example 1, now refer to image 3 , Figure 4 , Figure 7 , Figure 8 and Figure 10 , also includes a push mechanism 11, the push mechanism 11 includes a third gear 111, a fourth gear 112, a connecting rod 113, a third shaft 114, a fourth shaft 115, a fifth gear 116, a conveying belt 117 and a transmission belt 118, A third gear 111 is connected to the left side of the first rotating shaft 108 , a fourth gear 112 is rotatably connected to the left front side of the first protective frame 2 , the fourth gear 112 meshes with the third gear 111 , and the fourth gear 112 drives the shaft The left side is rotatably connected with the connecting rod 113, the first protective frame 2 is rotatably connected with three third rotating shafts 114, the first protective frame 2 is rotatably connected with three fourth rotating shafts 115, and the first third rotating shaft 115 on the front side is rotatably connected. A conveying belt 117 is wound around the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com